Tool for grouting in loose coal seam section during drilling

A loose-while-drilling technology, used in earth-moving drilling, wellbore/well components, sealing/packaging, etc., can solve problems such as abnormality and low normal rate of hole formation, and achieve correct opening, convenient operation and safety. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

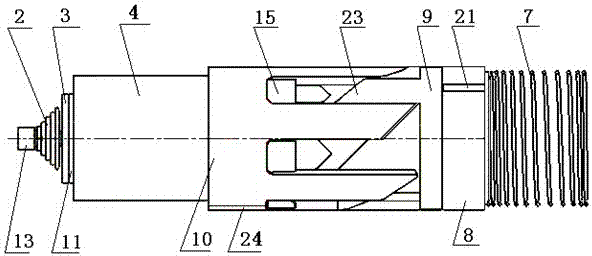

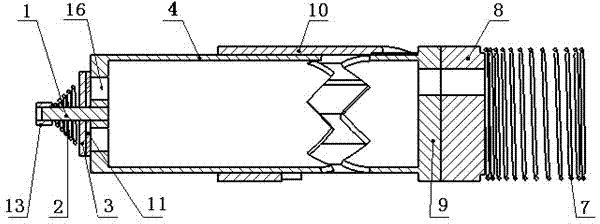

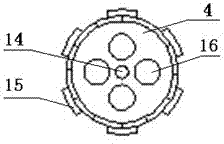

[0033] Embodiment 1: a kind of coal seam loose section while drilling grouting tool of the present invention, its structure is as follows figure 1 , 2 , 3 shown. It includes a one-way valve, valve seat 4, ratchet control mechanism, housing and nozzle 5. The one-way valve is composed of a pallet shaft 1, a valve spring 2, a pallet 3, a rubber pad 11, and a valve nut 13. The valve Seat 4 is a cylinder, one end of the cylinder has a straight groove with beveled sides for guiding and limiting, the other end has a round end face, and the center of the round end face has a pallet shaft hole 14, and the pallet shaft 1 is installed on the pallet shaft In the hole 14, the valve spring 2, the tray 3, and the rubber pad 11 are limited on the tray shaft 1 by the valve nut 13;

[0034] Ratchet control mechanism among the present invention, see figure 2 , 3 , consisting of a ratchet spring 7, a sliding plate 8, a turntable 9, and a fixed groove 10, the end face of the slide plate 8 is ...

Embodiment 2

[0041] Embodiment 2: A grouting tool for drilling loose sections of coal seams according to the present invention is used for drilling loose sections of underground coalbed methane extraction and other underbalanced drilling projects. When in use, it is transmitted through reverse circulation: "normal drilling" and "grouting drilling" commands, the control signal transmission method is the same, the circulating medium is atomized wind, the pressure is 0.5-0.7MPa, "normal drilling" fog The wind flow is positive, such as Figure 12 shown.

[0042] When the signal of "normal drilling" or "grouting drilling" is transmitted, the atomization air flow is reversed, that is, it flows in from the annular gap between the drill pipe and the drill hole, enters the drill pipe through the drill bit, and is driven by the pallet shaft 1, valve spring 2, The one-way valve composed of tray 3, rubber pad 11 and valve nut 13 is closed. Under the action of wind force, the valve seat 4 moves to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com