Emulsion explosive and preparation method thereof

A technology of emulsified explosives and emulsifiers, which is applied to explosives processing equipment, explosives, non-explosives/non-thermic components, etc., can solve problems such as long transportation time of emulsified explosives, decline in the performance of emulsified explosives, and affect the economic benefits of enterprises, and achieve improvement. On-site operating environment, ideal explosion effect, and the effect of improving the intrinsic safety of the industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

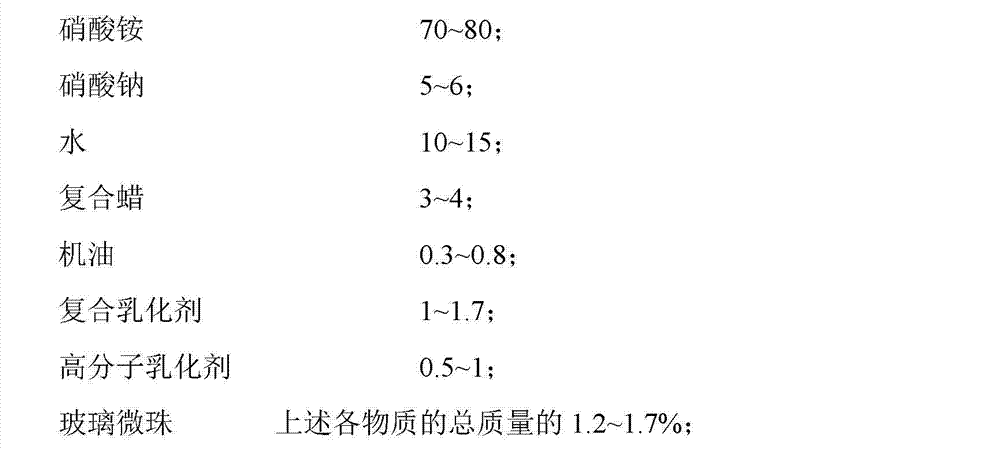

[0041] A kind of emulsion explosive, its composition and parts by weight are as follows:

[0042] ⑴Water phase formula:

[0043] Raw material name

Ammonium nitrate (%)

Sodium nitrate (%)

water(%)

Proportion

73

5

15

[0044] ⑵Oil phase formula:

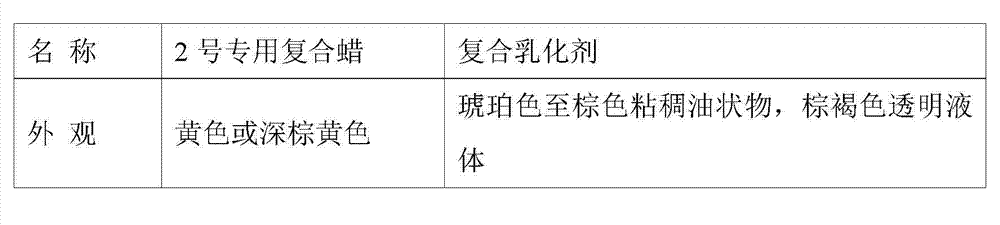

[0045]

[0046] Among them, the composite emulsifier is a mixture of Span 80 and T152 emulsifiers, and the mass ratio of Span 80:T152 is 6:4.

[0047] (3) Glass beads: The amount of glass beads added is 1.2%-1.7% of the total mass of the water phase formula and the oil phase formula.

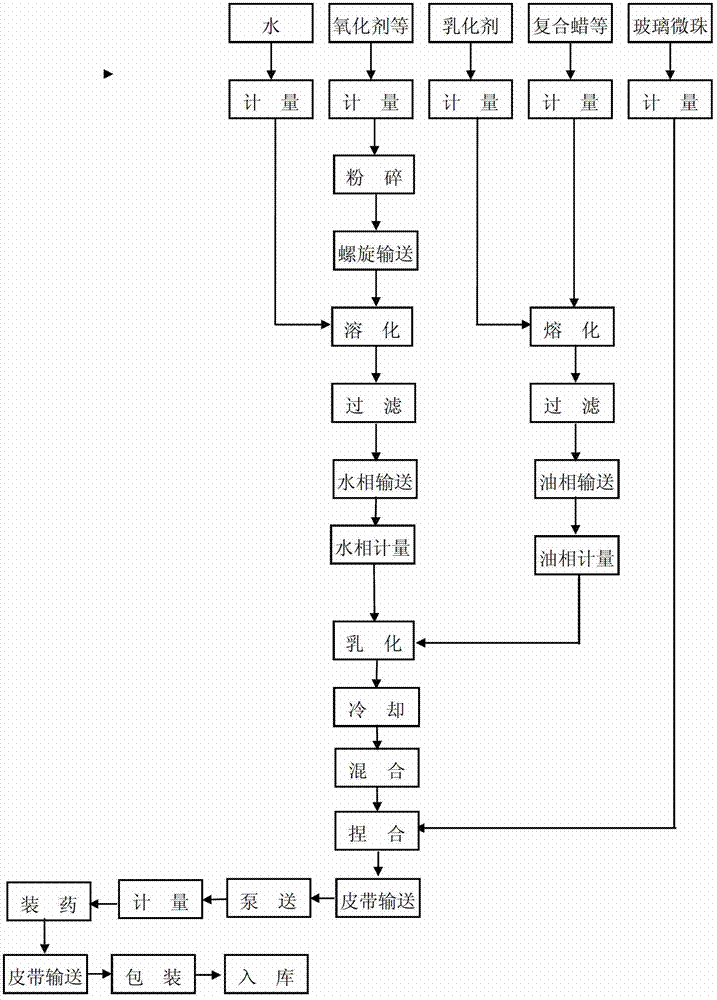

[0048] The steps of the preparation method of the above-mentioned emulsion explosive are as follows:

[0049] 1. Water phase preparation:

[0050] Take the ammonium nitrate whose appearance is white powdery or granular crystal and whose water content is less than 1.0%, crush it until the block size is no more than 35 mm, add water above 60 ℃, take the sodium nitrate whose appearance is white or light...

Embodiment 2

[0060] A kind of emulsion explosive, its composition and parts by weight are as follows:

[0061] ⑴Water phase formula:

[0062] Raw material name

Ammonium nitrate (%)

Sodium nitrate (%)

water(%)

Proportion

77

5.8

11

[0063] ⑵Oil phase formula:

[0064]

[0065] (3) Glass beads: The amount of glass beads added is 1.2%-1.7% of the total mass of the water phase formula and the oil phase formula.

[0066] The steps of the preparation method of the above-mentioned emulsion explosive are the same as in Example 1.

Embodiment 3

[0068] A kind of emulsion explosive, its composition and parts by weight are as follows:

[0069] ⑴Water phase formula:

[0070] Raw material name

Ammonium nitrate (%)

Sodium nitrate (%)

water(%)

Proportion

78

6

10

[0071] ⑵Oil phase formula:

[0072]

[0073] (3) Glass beads: The amount of glass beads added is 1.2%-1.7% of the total mass of the water phase formula and the oil phase formula.

[0074] The steps of the preparation method of the above-mentioned emulsion explosive are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com