Fireproof and explosion-proof combined fireworks

A technology that combines fireworks and fire-resistant materials, applied in the directions of fireworks, offensive equipment, weapon types, etc., can solve the problems of large amount of propellant, major accidents, and fireworks as a whole, so as to ensure the launch effect, improve production efficiency, good launch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

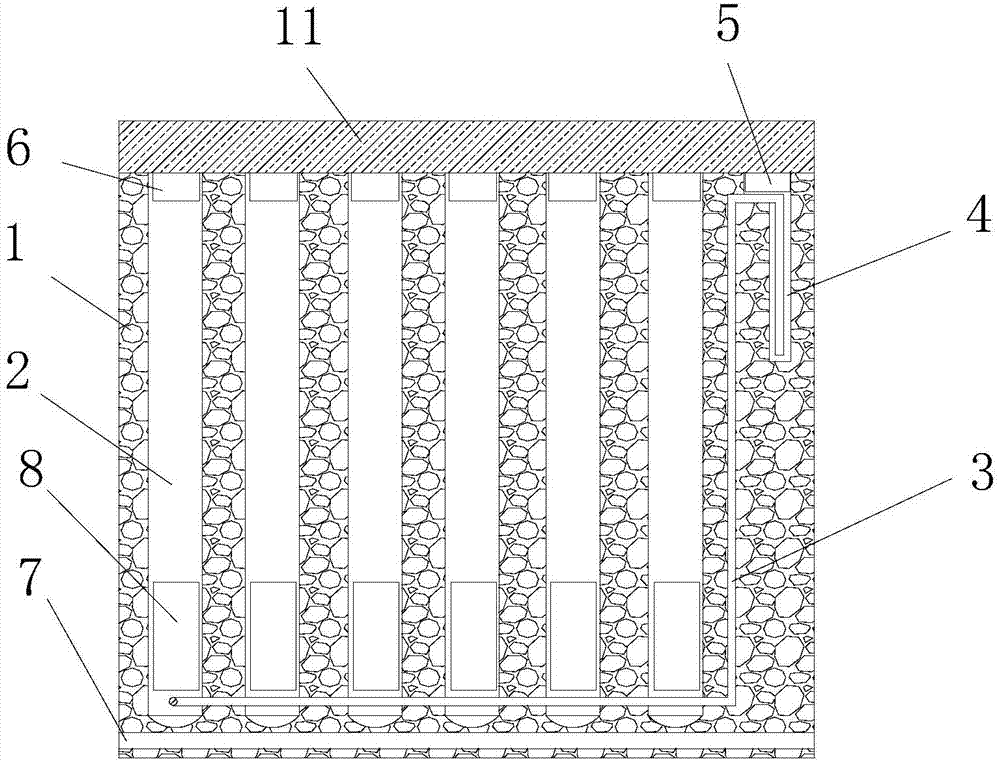

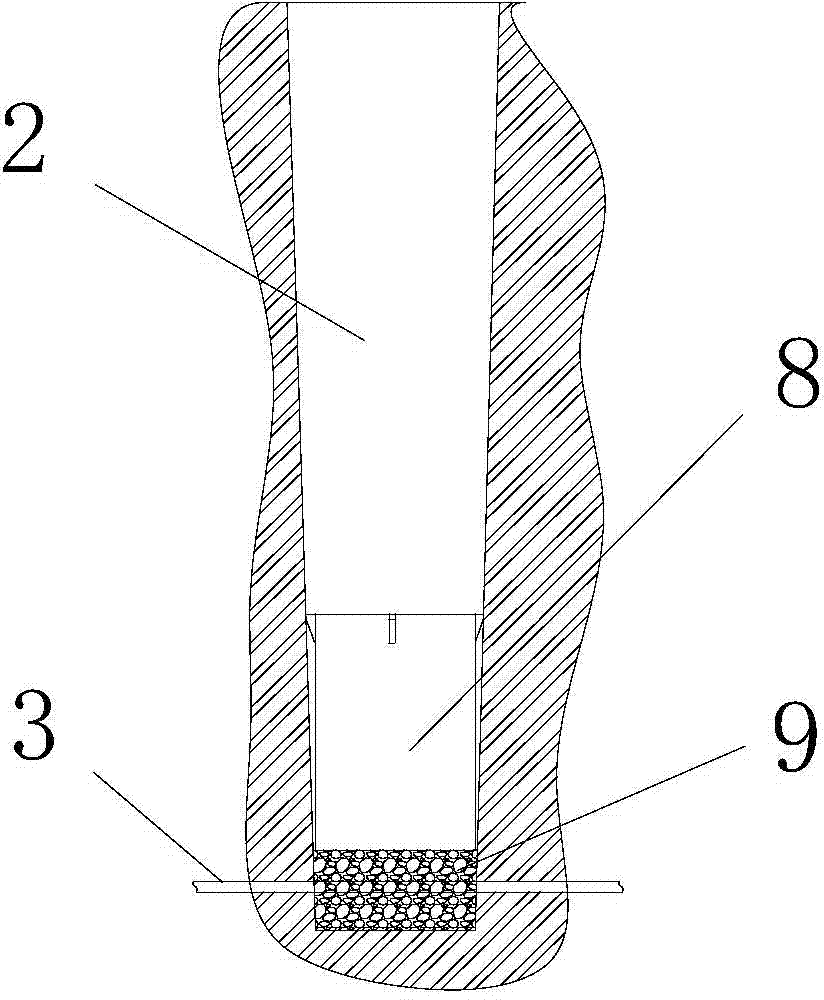

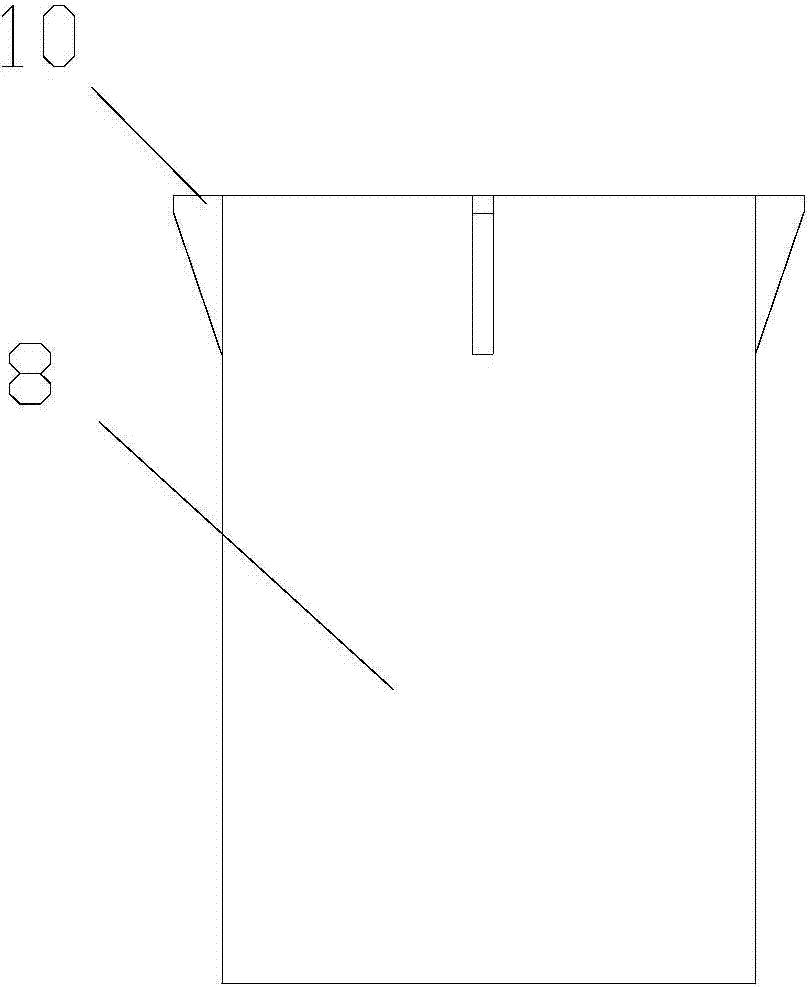

[0034] see figure 1 and figure 2 , the launching base body 1 made of light fireproof material is provided with a launching hole 2, and a lead wire 3 is pre-embedded in the launching base body 1, and the bottom of the launching hole 2 is connected through the lead wire 3, and the lead wire 3 in the launching base body 1 is according to The different laws of firework launch adopt different connection methods. The launch hole 2 is provided with an inner cylinder 8, and the launch seat body 1 is provided with a hidden lead hole 4. The ignition part of the lead wire 3 is hidden in the hidden lead hole 4, and also includes a The fireproof cover 11 made of light fireproof material, the fireproof cover 11 is provided with the fireproof plug 6 of the firing hole and the fireproof plug 5 of the hidden lead hole, the fireproof cover 11 is cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com