Lead-embedded firework launching base

A launcher and lead wire technology, applied in pyrotechnics, weapon accessories, blasting tubes, etc., can solve the problems of long manufacturing time, large amount of propellant, and easy deformation of paper tubes, so as to shorten the manufacturing time, ensure the launching effect and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

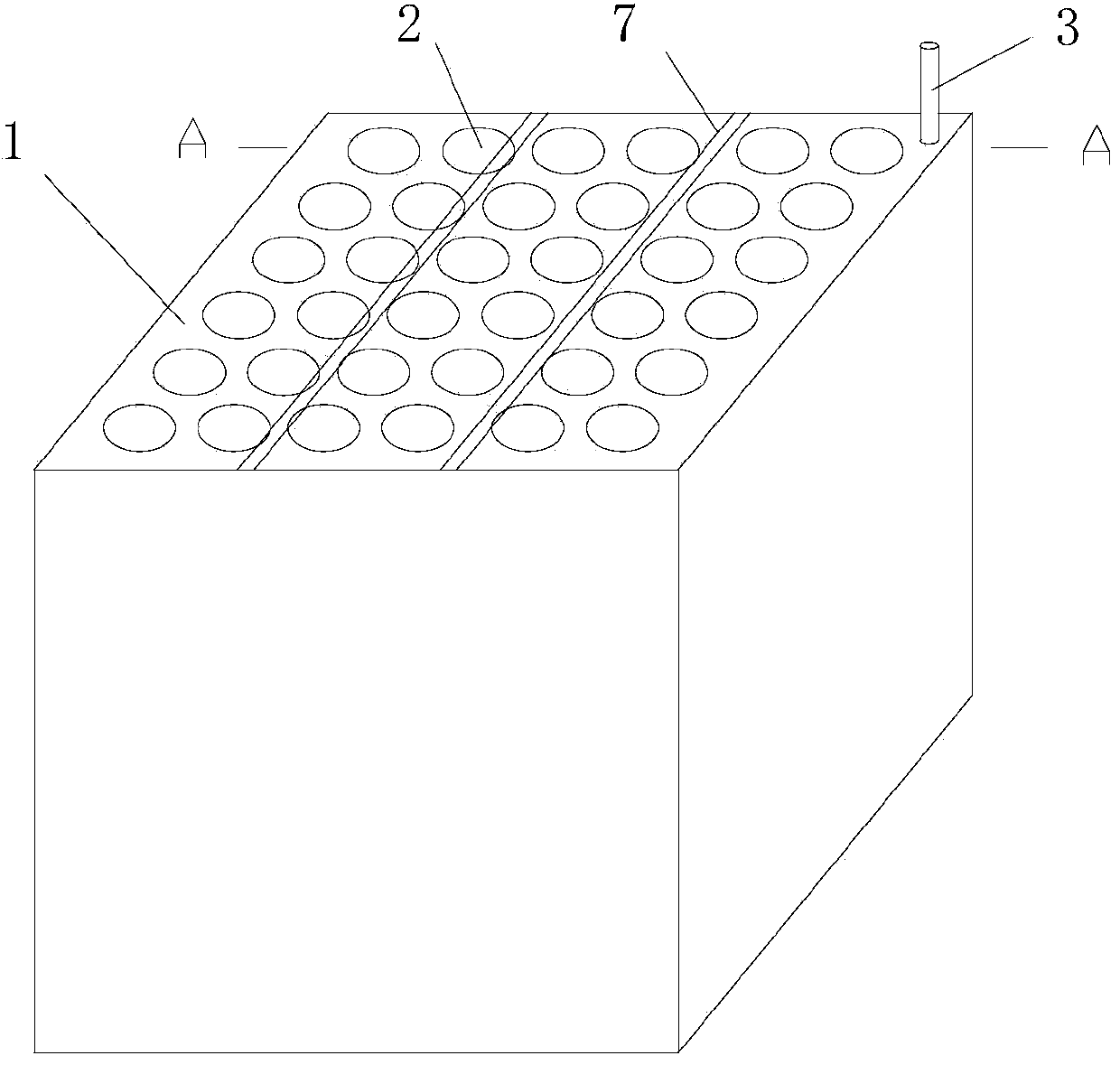

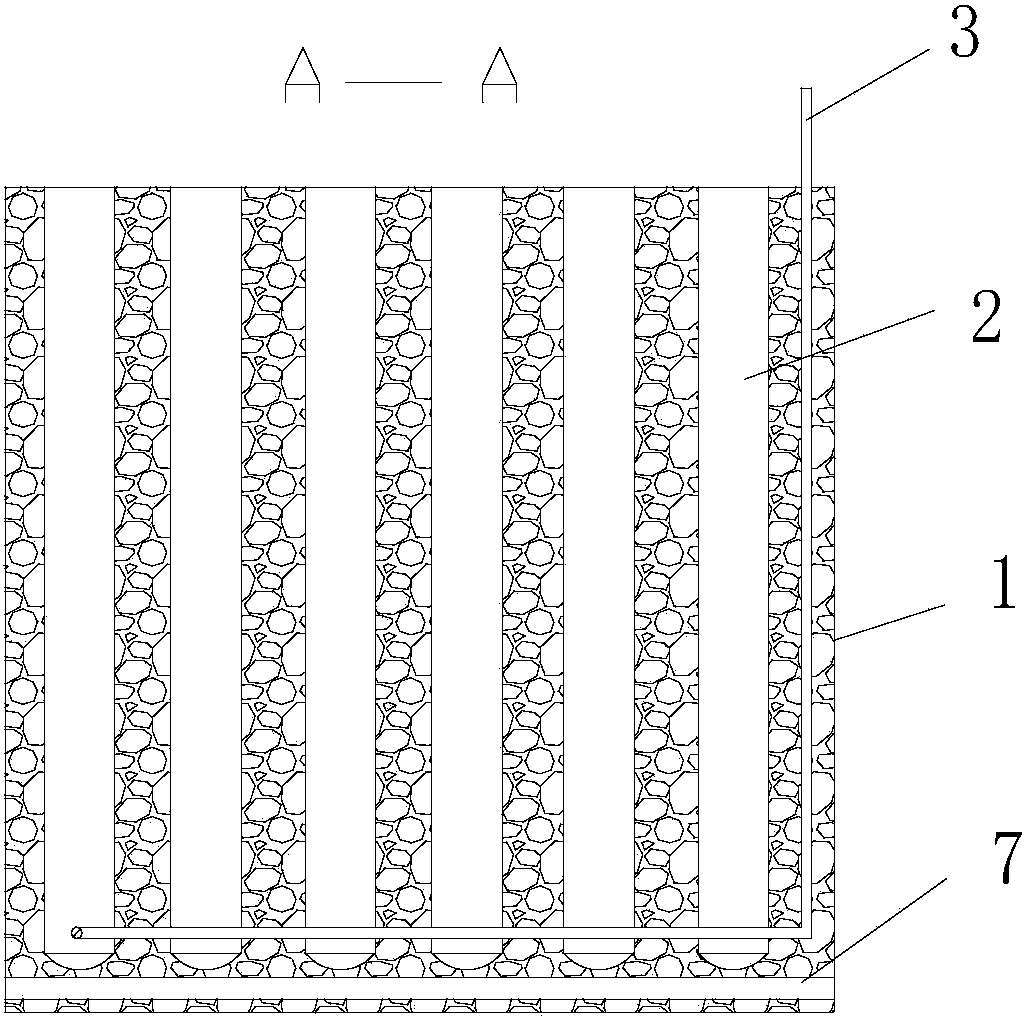

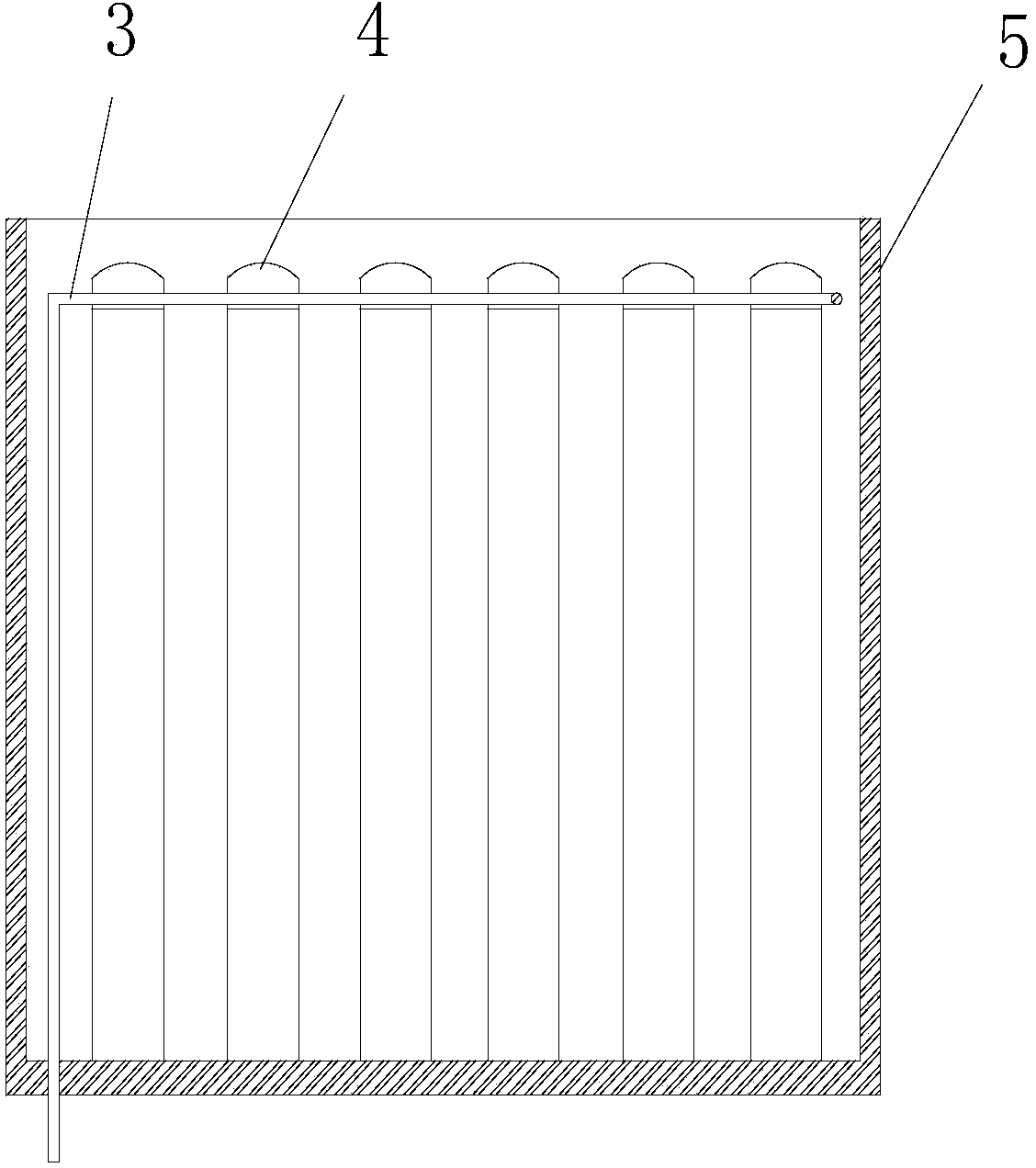

[0035] see figure 1 , figure 2 , Figure 4 , Figure 5 and Figure 6 Lead wires 3 are pre-embedded in the launcher body 1, the launcher body 1 is square, and 36 launcher holes 2 are arranged on the launcher body 1, and the inner space of the launcher holes 2 is an inverted cone shape with a small bottom and a big top, The bottoms of all launch holes 2 are communicated with lead wires 3. The launch base body 1 is prefabricated by light materials such as gypsum powder and perlite powder mixed with water, or mixed with perlite powder and water. The lead wires in the launch base body 1 3 Different connection methods are adopted according to the different laws of fireworks launching. The connection method of the lead wire 3 is that the bottoms of the several emission holes 2 in front are connected in series with the lead wire 3, and then connected by multiple groups. A parallel group composed of the launch hole groups, after the parallel group, there are launch holes connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com