Non-glazed art pottery brick shuttle kiln multi-layer branch firing kiln loading process

A shuttle kiln and ceramic brick technology, which is applied in furnaces, lighting and heating equipment, furnace components, etc., can solve the problems of insufficient artistic effect, single color of ceramic bricks, low kiln loading efficiency, etc., and achieves improved kiln firing. Efficiency, ensure artistic effect, save kiln fuel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

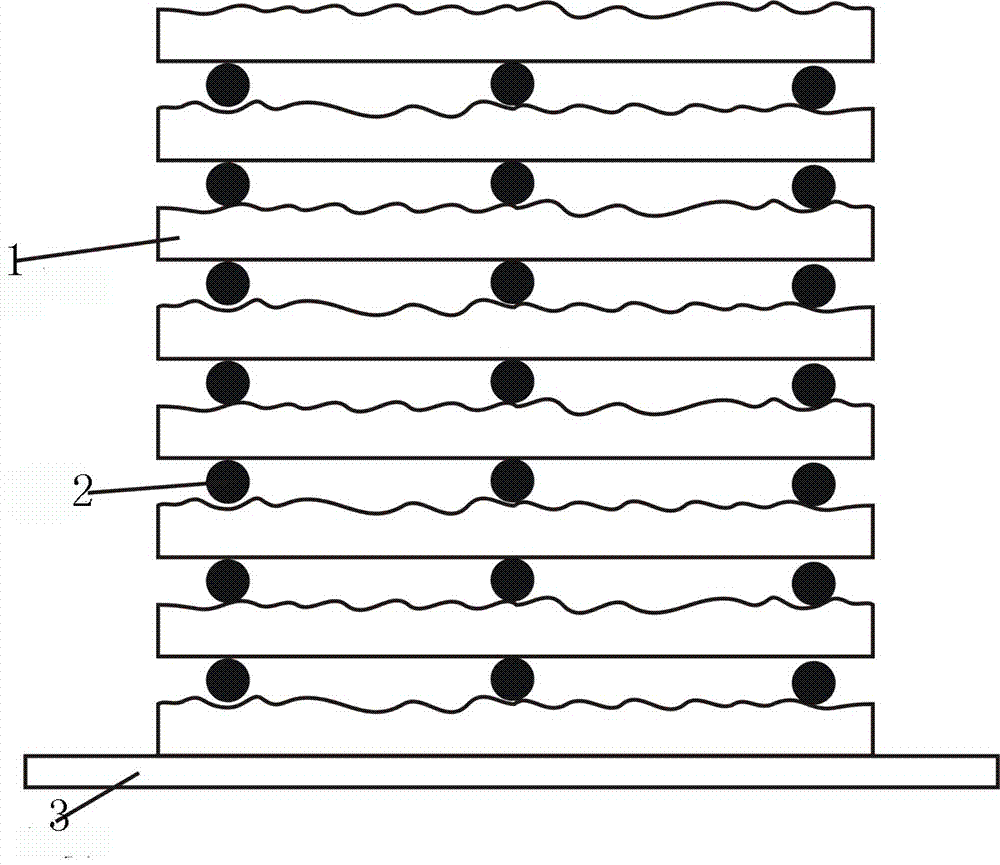

[0020] as attached figure 1 , 2 Shown the non-glazed artistic pottery brick shuttle kiln multi-layer kiln loading process of the present invention, the steps of its method are:

[0021] 1. Arrange the first layer of boron plates 3 reasonably according to the size of the shuttle kiln (the high-temperature-resistant plates used to build interlayers in the kiln).

[0022] 2. Place the first ceramic brick 1 on the boron board first (the size of the ceramic brick is calculated as 20cm×20cm).

[0023] 3. Prepare a certain amount of wet mud ball 2 with a diameter of 6mm.

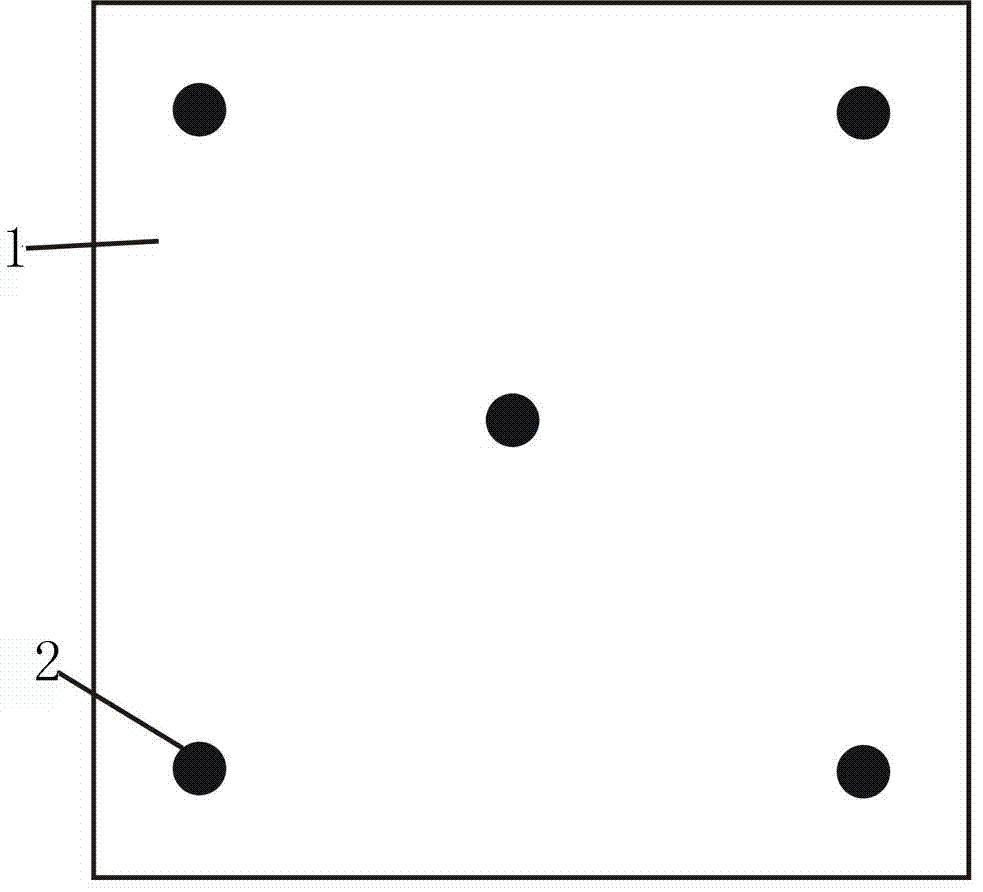

[0024] 4. Place at least 3 uniformly arranged mud balls that can support a plane on the first ceramic brick (the number and position of mud balls placed on a single layer of ceramic brick can be determined according to the size of the ceramic brick, or according to different shapes or the ceramic brick characteristics of the material to determine, this embodiment adopts such as figure 2 Place 5 mud balls as sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com