Steel casting capable of forming full cast steel structure

A steel casting and steel casting technology, applied in the field of building structure engineering, can solve the problems that the building effect cannot meet the requirements, reduce the structural bearing capacity, and the number of welding and bolting is large, so as to shorten the installation period, reduce the construction difficulty, improve the The effect of overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

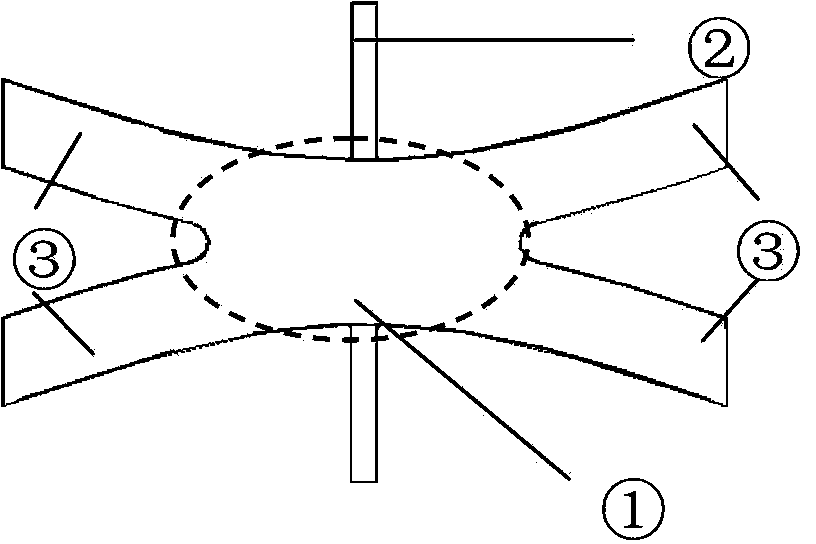

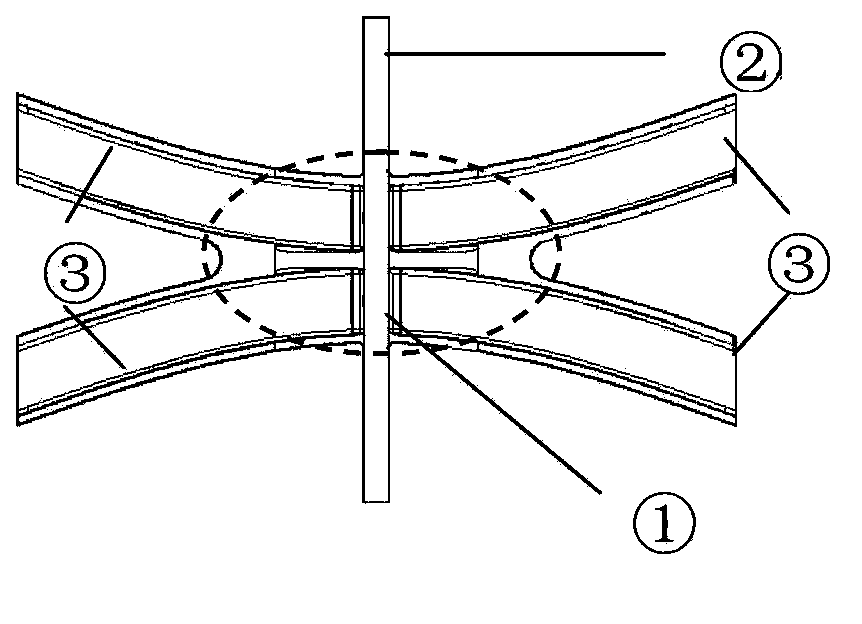

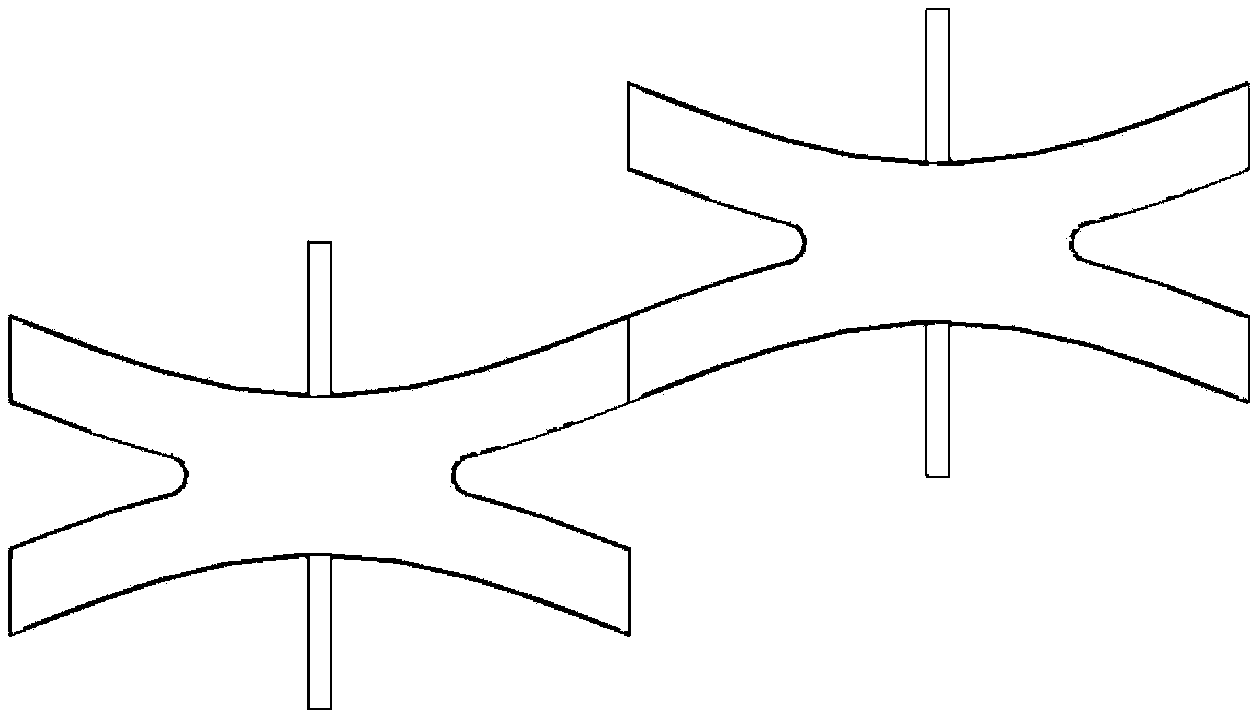

[0034] Please refer to the accompanying drawings, a steel casting that can form an all-cast steel structure, including a node core area part 1, a longitudinal member 2 and a transverse curved member 3 that are fixedly connected as one.

[0035] The connection between the node core area part 1, the longitudinal member 2 and the transverse curved member 3 may be welded or bolted or other forms of connection. In this embodiment, the node core area part 1, the longitudinal member 2 and the transverse curved member 3 are integrally cast. It can also be divided into several smaller steel castings and cast to form standard steel castings through connection. It is also possible to separate the core part 1 of the node, the longitudinal member 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com