Insensitive munitions barrier

a technology of insensitive munitions and barriers, applied in the field of insensitive munitions, packaging of artillery ammunition, can solve the problems of inability to prevent sd in packaged high explosive ammunition, the propagation of detonation reaction, and the loss of life and critical military equipmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

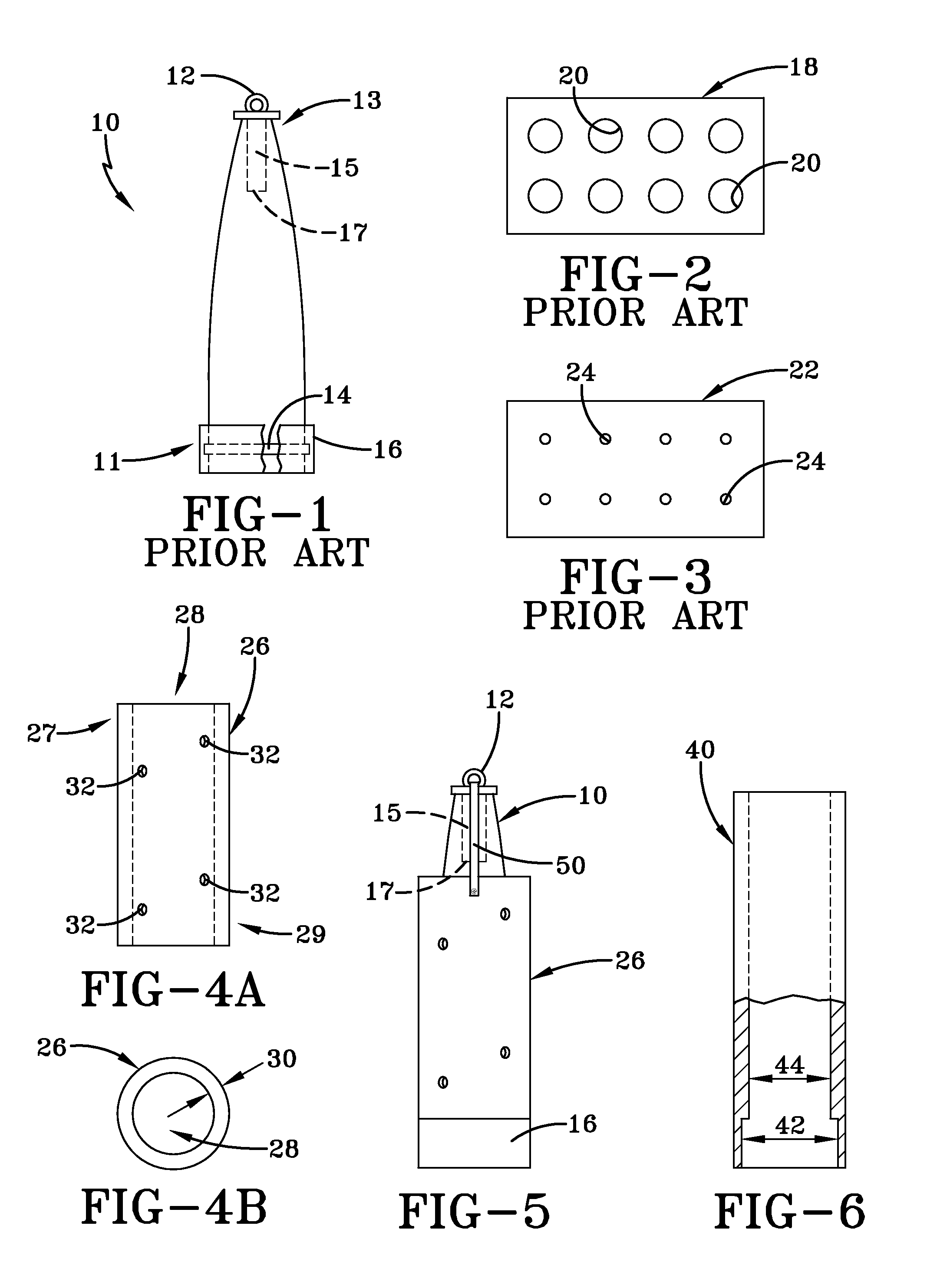

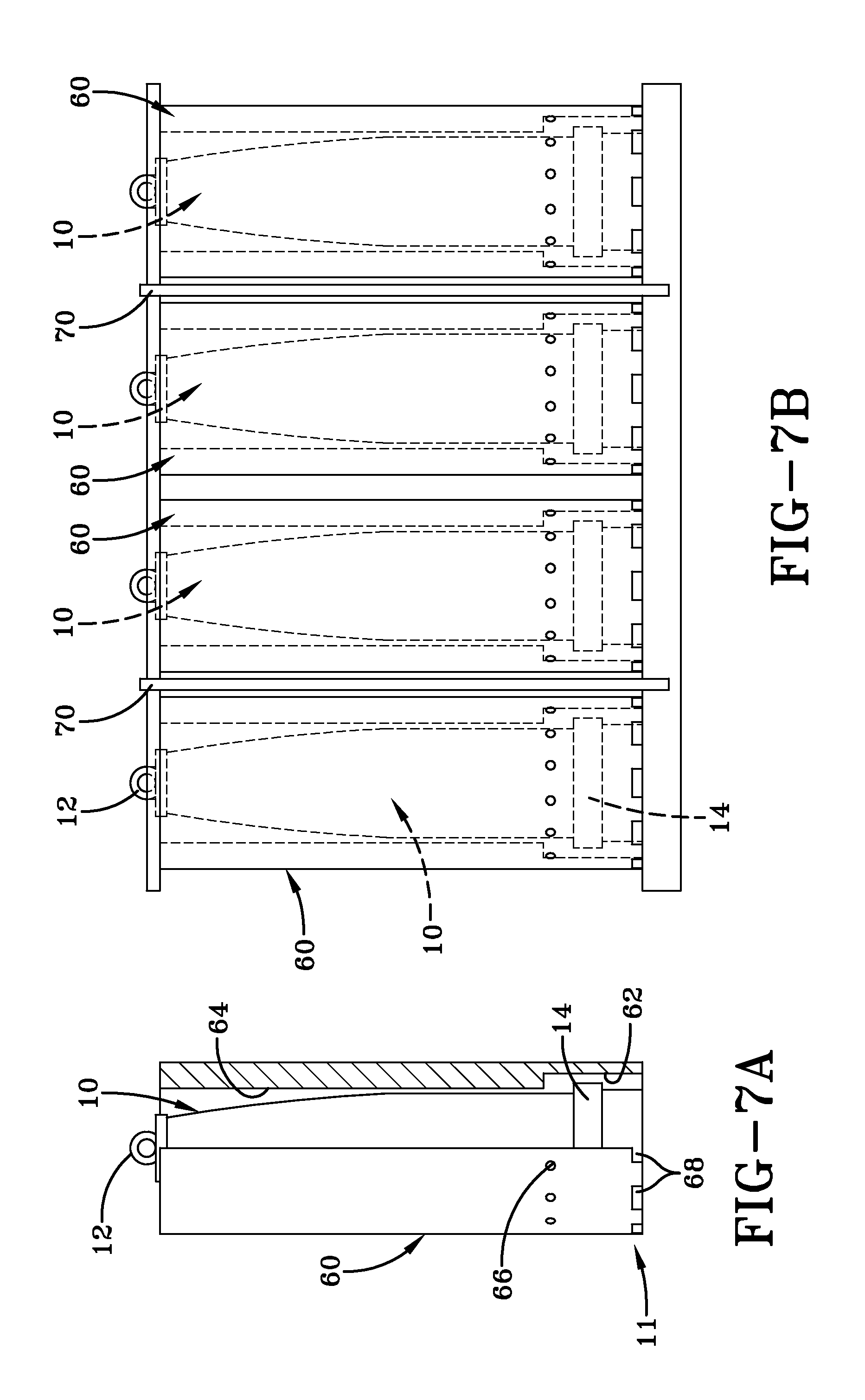

[0023]The invention mitigates or eliminates the problem of sympathetic detonation (SD) in large caliber high explosive packaged artillery ammunition. The invention may be applied to other types of ammunition as well (such as missiles, mines, mortars, grenades, etc). The invention includes a generally cylindrical sleeve that is placed over high-energy munitions. The sleeve is preferably made of high-density polyethylene (HDPE). The sleeve is of a thickness sufficient to prevent neighboring high-energy munitions from SD. Thus, a high order explosive event in one ammunition round will not propagate to neighboring ammunition rounds. The invention will also mitigate and / or prevent the loss of life and subsequent collateral damage.

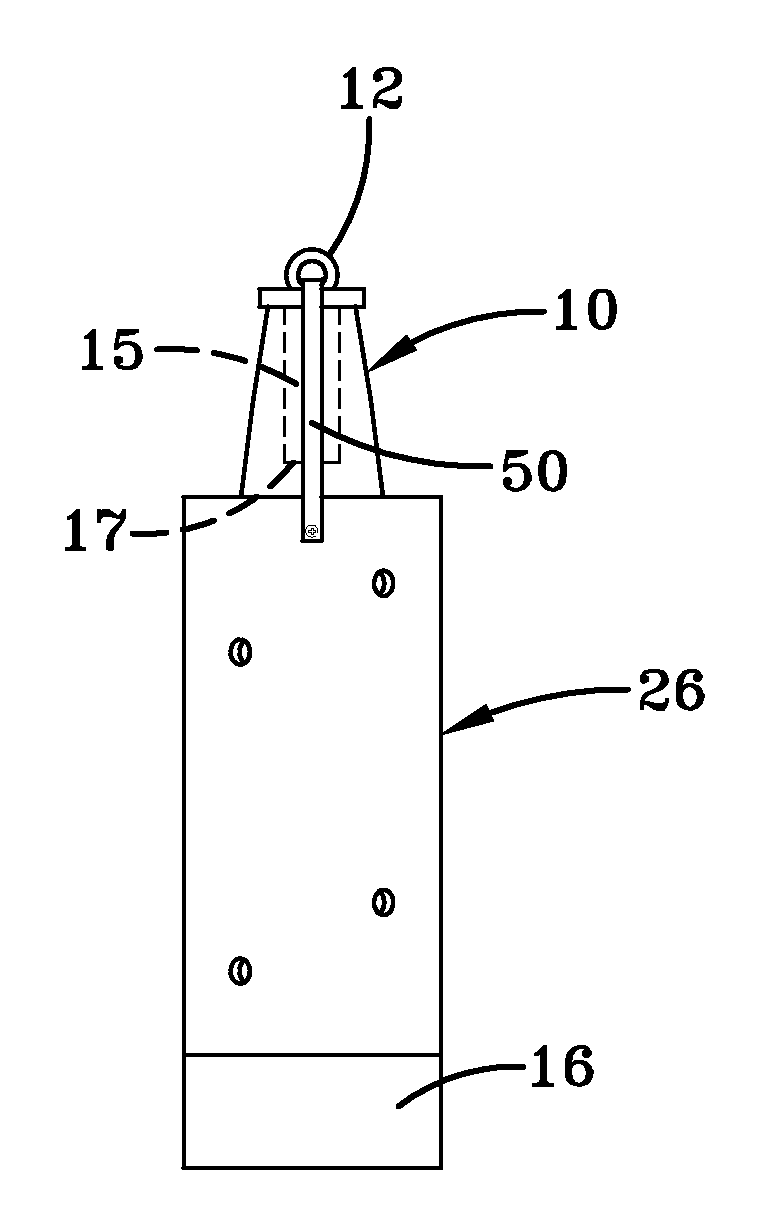

[0024]FIG. 1 is a side view of a munition 10. The munition 10 shown is an artillery projectile, but the invention is applicable to other types of munitions, also. Munition 10 includes a rear end 11, a front end 13, a lifting plug 12 at the front end 13, a fuze w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com