Automatic control system for producing emulsion ammonium nitrate-fuel oil explosive

An automatic control system, ammonium explosive technology, applied in explosives, explosives processing equipment, offensive equipment and other directions, can solve the problems of low safety, high labor intensity, many online personnel, etc., to improve safety, ensure safety, Effects that reduce the likelihood of explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

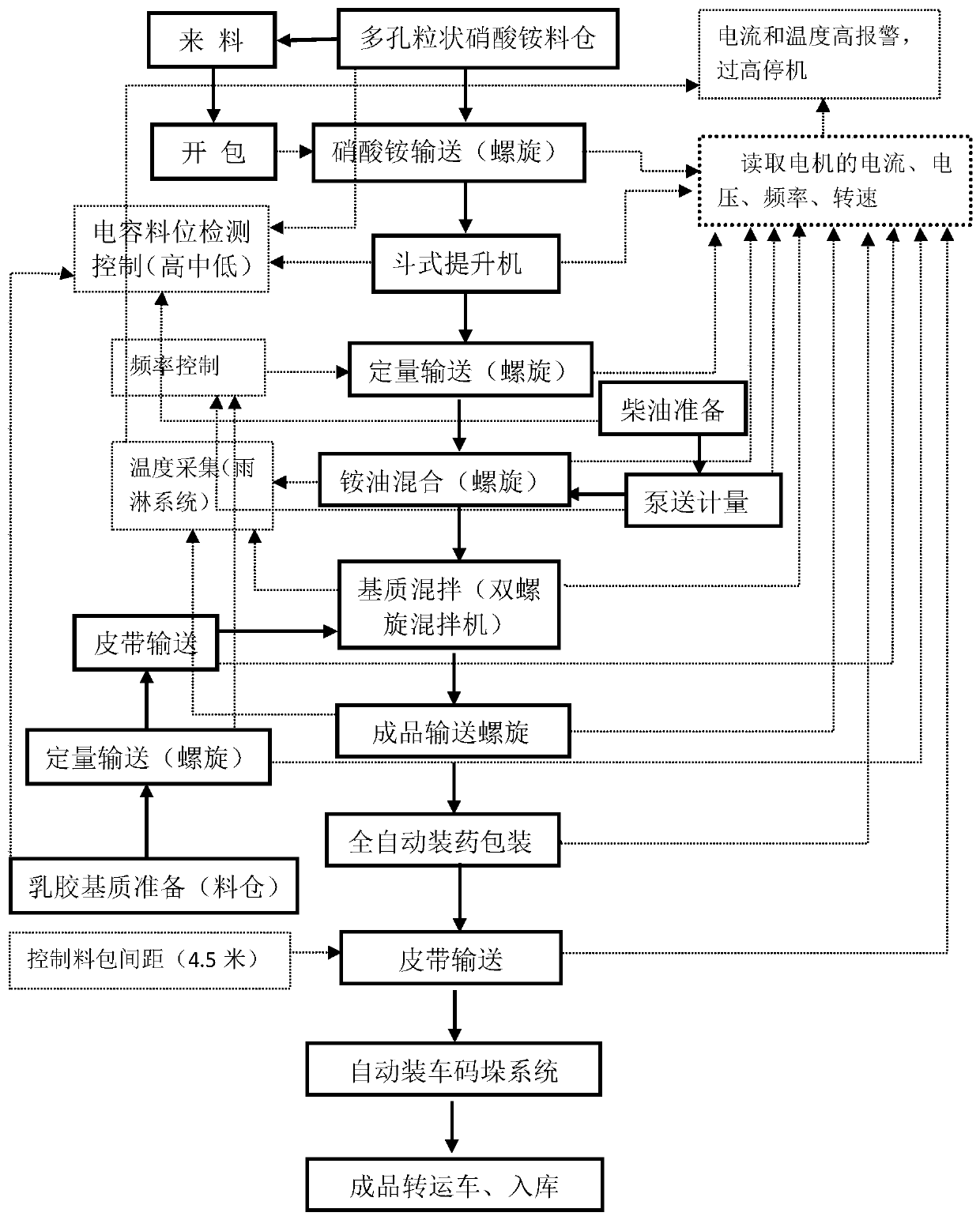

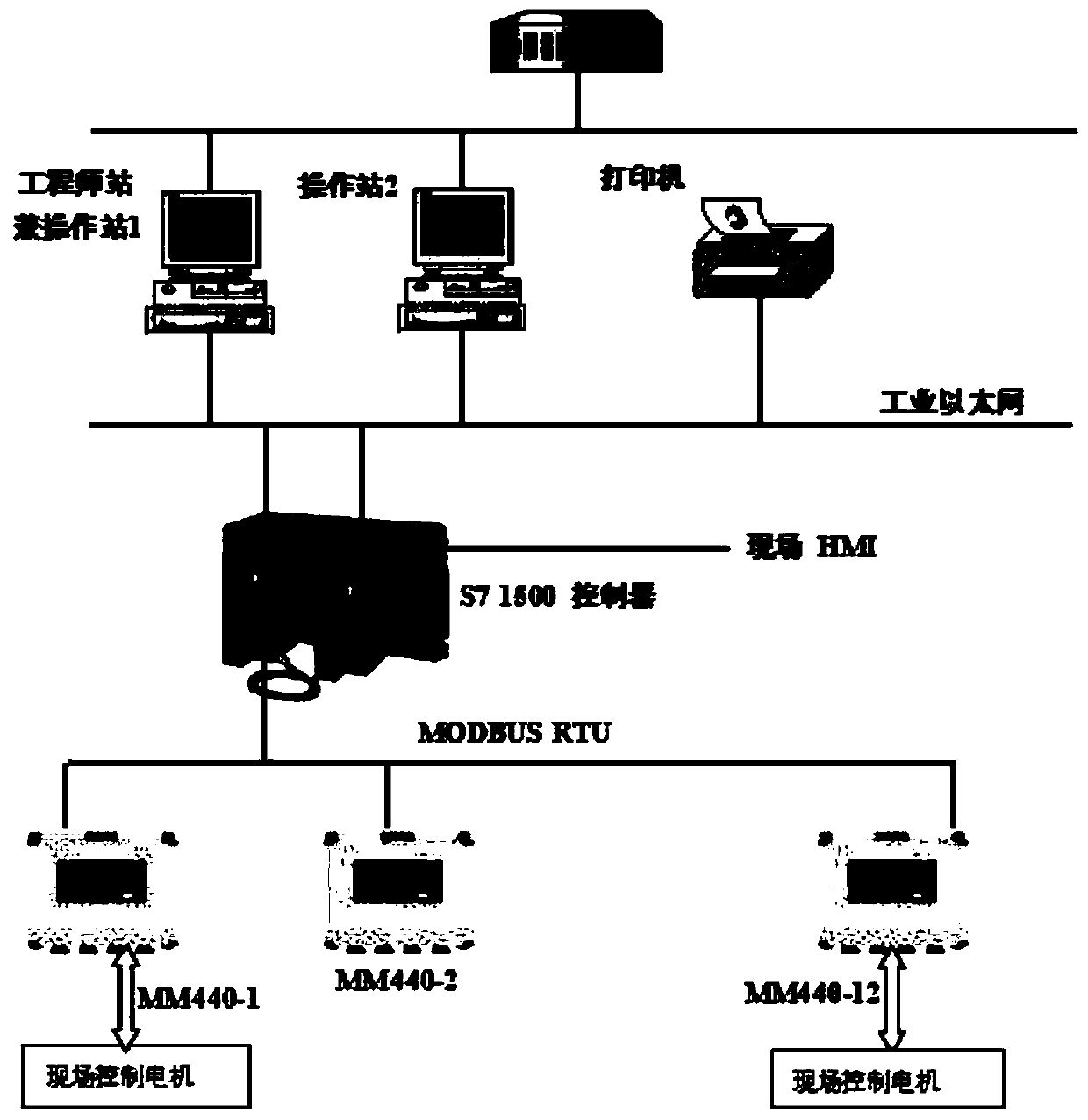

[0031] Such as figure 1 As shown, an automatic control system for the production of emulsified ammonium oil explosives is used for the automatic control of the automatic production line of emulsified ammonium oil explosives. Packaging components, palletizing components, loading components (including figure 1 The equipment for the warehousing process of the finished product transfer vehicle), figure 1 The automatic loading and palletizing system includes palletizing components and loading components. The automatic control system includes: porous granular ammonium nitrate unpacking control module, material level detection control module, motor control module, material bag spacing control module, On-line drug quantity control module,

[0032] Described porous granular ammonium nitrate unpacking control module is used for completing the one-time unpacking action that porous granular ammonium nitrate material bag needs after coming out from silo; figure 1 It says "incoming mater...

Embodiment 2

[0052] Compared with Embodiment 1, this embodiment is different in that it also includes an on-site emergency control module, and a start-stop button is set on the production site for emergency control.

[0053] All the other contents are the same as in Embodiment 1.

Embodiment 3

[0055] Compared with Embodiment 2, this embodiment is different in that it also includes a control matching module to realize automatic matching between the palletizing loading speed and the packaging speed of the large charter machine, and sends an alarm to the packaging equipment when the palletizing equipment is abnormal; the packaging equipment Send an alert to the pharmaceutical process when there is an abnormality.

[0056] All the other contents are the same as the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com