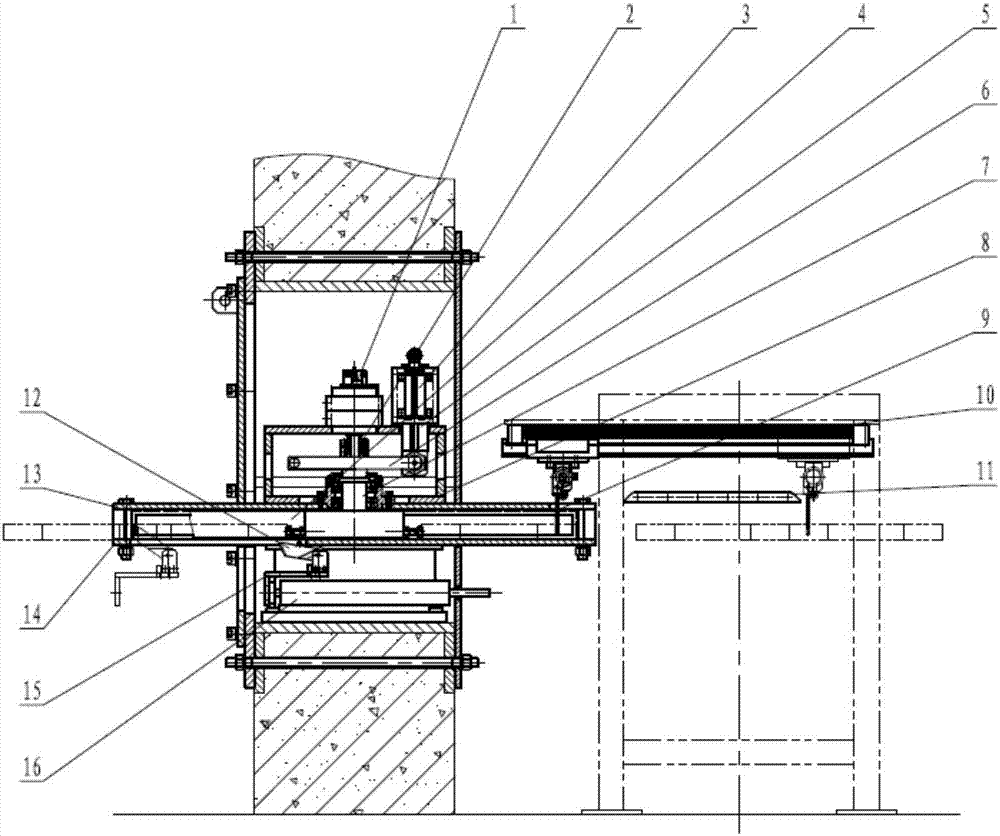

Rotary-type antiknock conveying device

A conveying device and rotary technology, applied in the directions of fireworks, offensive equipment, weapon types, etc., can solve the problems of hidden dangers in the opening of anti-explosion walls, and achieve the effect of compact structure, protection of personnel safety, and small footprint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

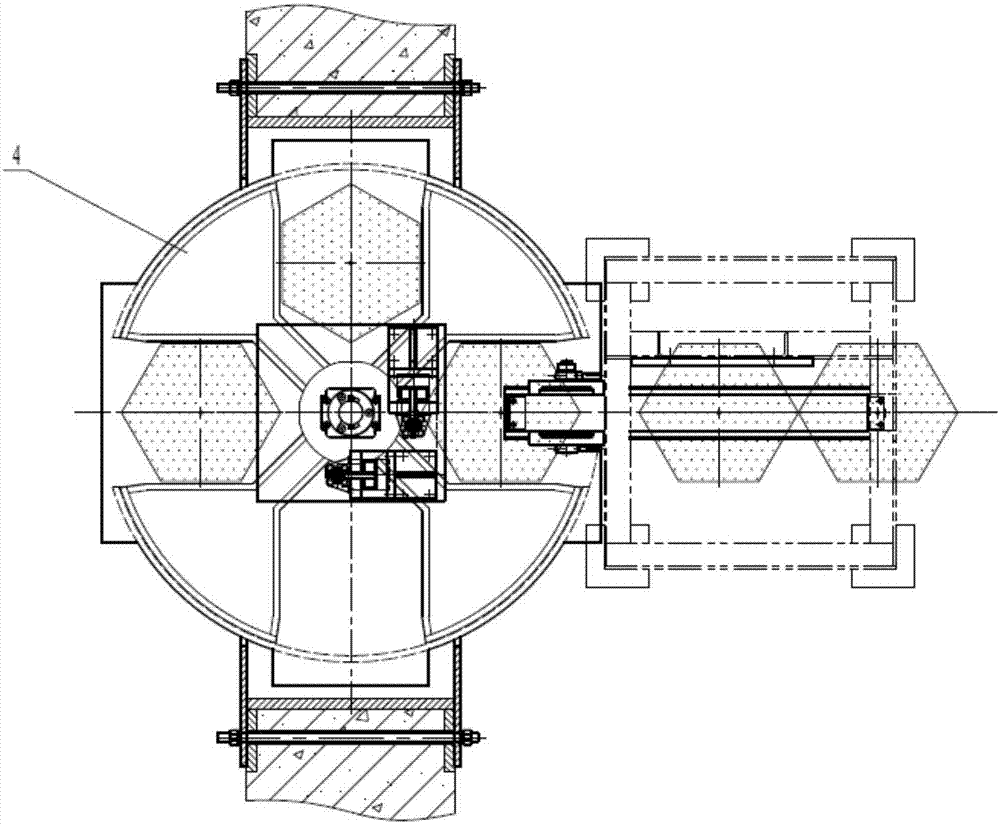

[0026] A rotary explosion-resistant conveying device for fireworks and firecrackers production, comprising: a push-in assembly, a middle part, and a push-out assembly;

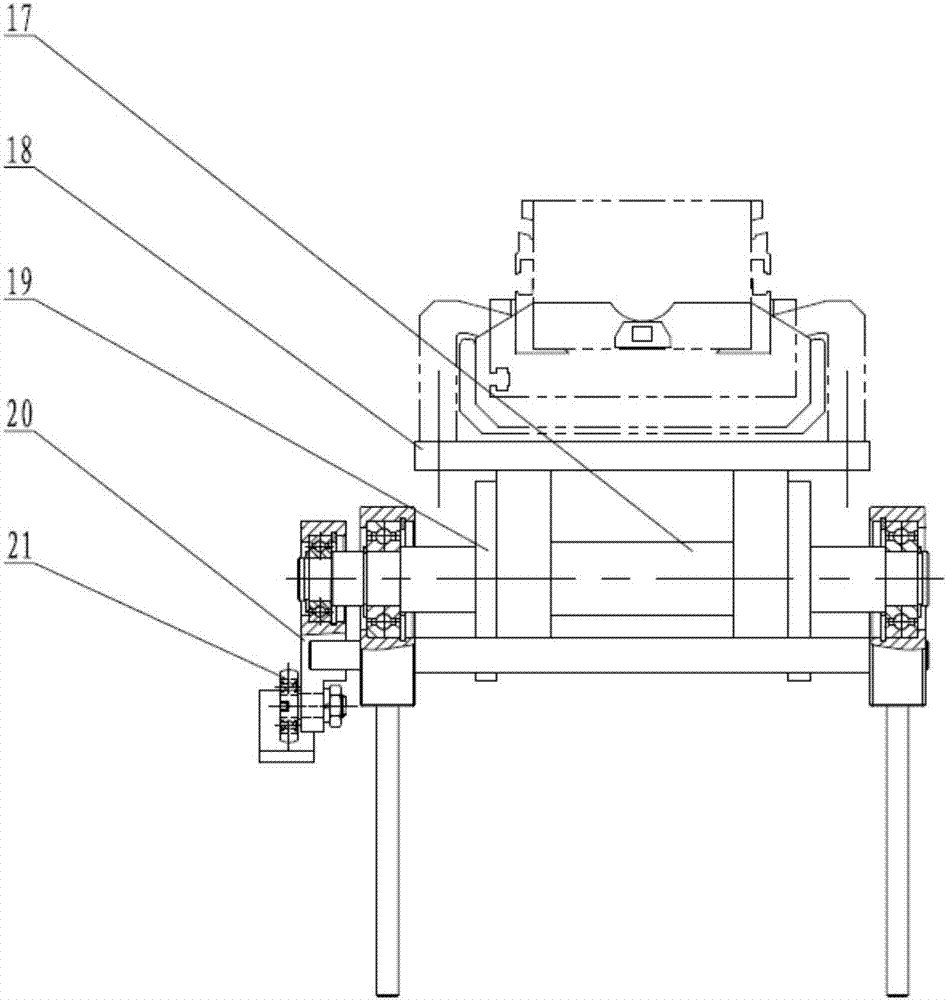

[0027] The push-in assembly includes: push rod 9, push-in cylinder 10, guide rail 11, shaft 17, push-in side connector 18, limit block 19, driving rod 20, roller 21; the push-in side connector 18 is a A flat plate with two lugs; the slide block pushed into the cylinder 10 is fixedly connected with the flat plate; two limit blocks 19 are fixedly connected with the lugs to limit the moving direction of the push rod 9; the two push rods 9 are in the same direction It is fixed on the connecting rod; the shaft 17 passes through two lugs and two limit blocks 19 and is flexibly connected with the push rod 9 through the bearing; one end of the driving rod 20 is flexibly connected to one end of the shaft 17 through the bearing; the roller 21 is fixedly installed At the other end of the driving rod 20; the connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com