Method and device for improving blasting propagation reliability of plastic film-packaged emulsified explosive

An emulsion explosive and reliability technology, applied in blasting and other directions, can solve problems such as product rejection, safety hazards, and impact on product explosion reliability, and achieve the effects of light and easy to carry, improve safety, and improve explosion reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method and device for improving the reliability of detonation transmission of plastic-film-packed emulsion explosives, characterized in that: when blasting and charging on-site, the plastic-film-packed emulsion explosives are taken out, and one end of the plastic-film-packed explosive roll is inserted into the device, and the explosives When the medicine roll is inserted into the position of the bottom blade, rotate the medicine roll one circle, the buckle of the medicine roll and the remaining plastic film are cut off by the blade and fall from the bottom hole;

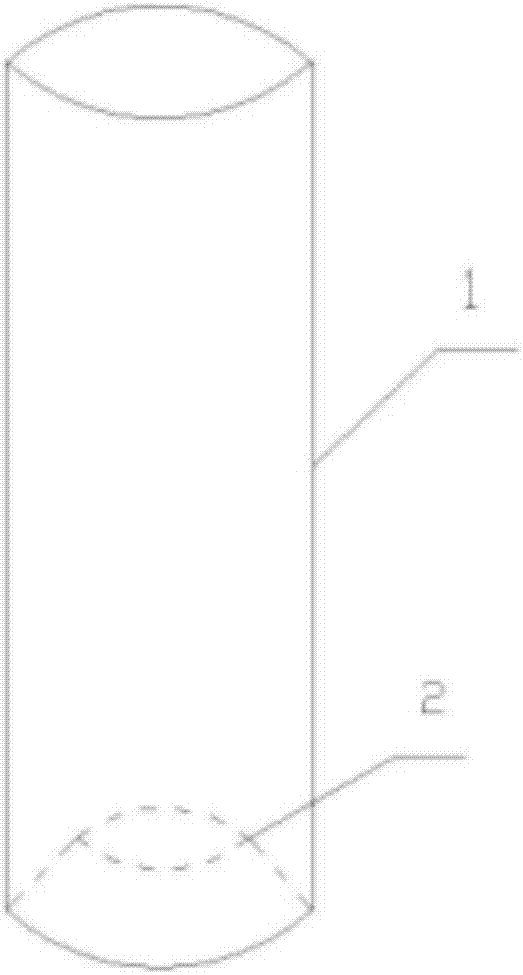

[0018] The device includes: a pipe body (1), a circular blade (2), and is characterized in that: the circular blade (2) is recessed and mounted on the inner wall of the pipe body (1), tapered and located on the pipe body (1) ), the diameter of the circular blade (2) is smaller than that of the tube body (1), and the diameter of the emulsion explosive packaged in plastic film is 32 mm, which is inserted into t...

Embodiment 2

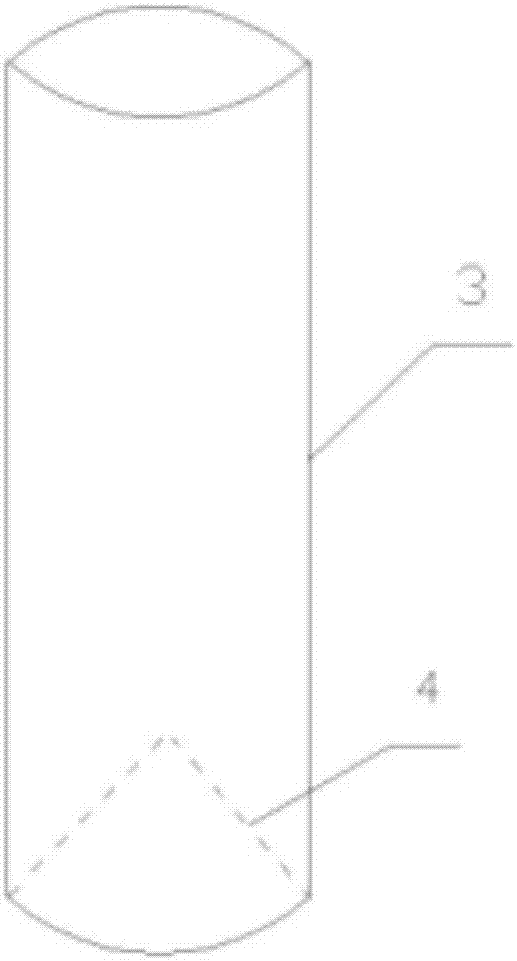

[0020] The device in embodiment 2 realizes that the buckle is squeezed into the drug roll, ensuring that the drug-loading buckles at both ends of the medicine roll do not protrude. Simultaneously all avoids the generation of the gap between the charge rolls, improves the reliability of blast transmission, avoids the incomplete blasting of blasting, improves the safety in the blasting engineering, the device of embodiment 2 comprises: pipe body (3), cone (4 ), which is characterized in that: the plastic film-packed emulsion explosive has a diameter of 32 mm, and is inserted into the pipe body (3) with a diameter of 34 mm, and the length of the pipe body (3) is shorter than that of the drug roll, so that it is convenient to take out the drug roll. After inserting the drug roll to the bottom, the plastic film-packed drug roll touches the bottom cone (4), and the drug roll is squeezed on the cone (4), and the drug roll enters the plastic film-packed drug roll through extrusion, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com