Patents

Literature

47 results about "Explosives engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Explosives engineering is the field of science and engineering which is related to examining the behavior and usage of explosive materials.

Heavy ammonium nitrate-fuel oil explosive with detonator sensitivity produced by using chemical sensitization

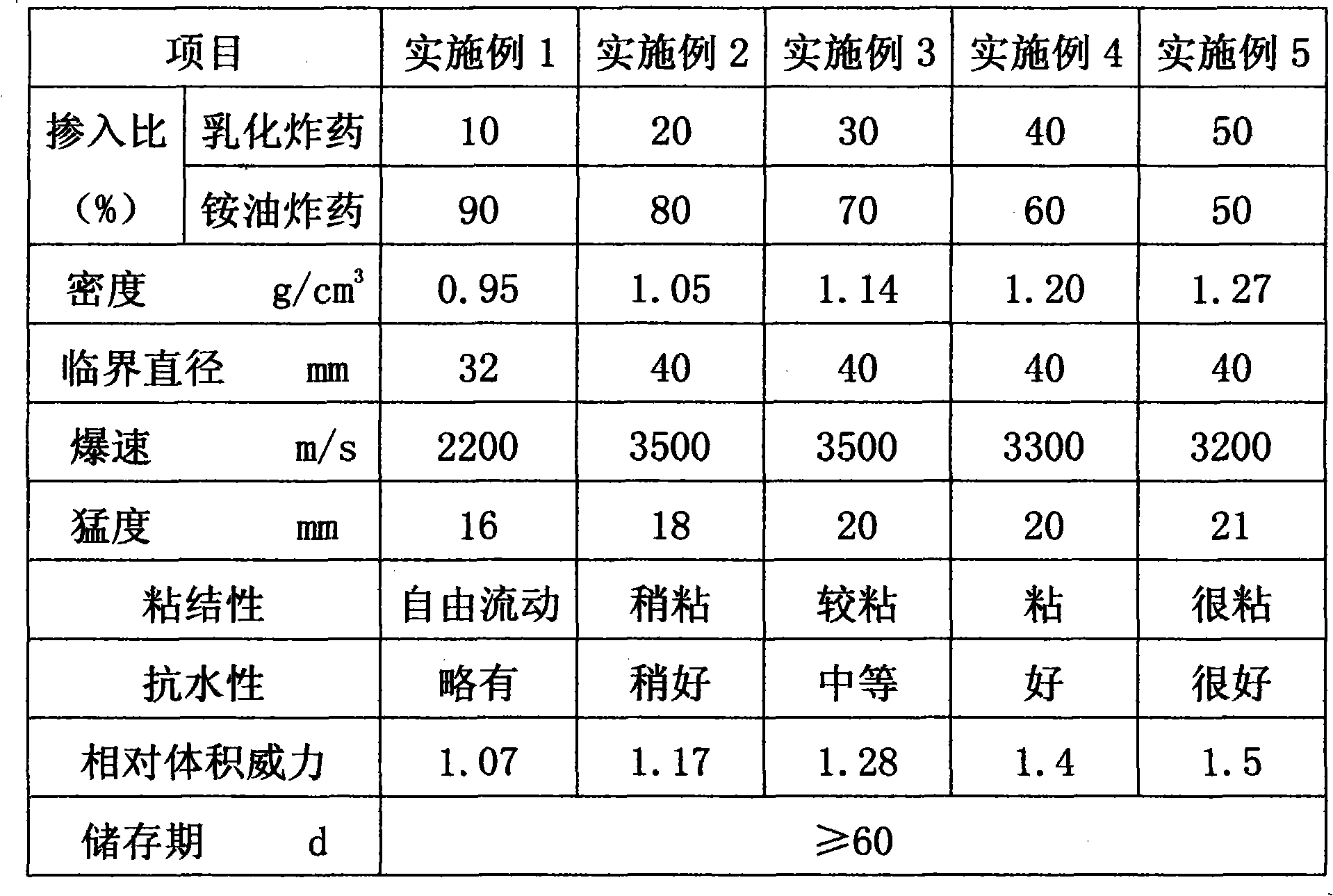

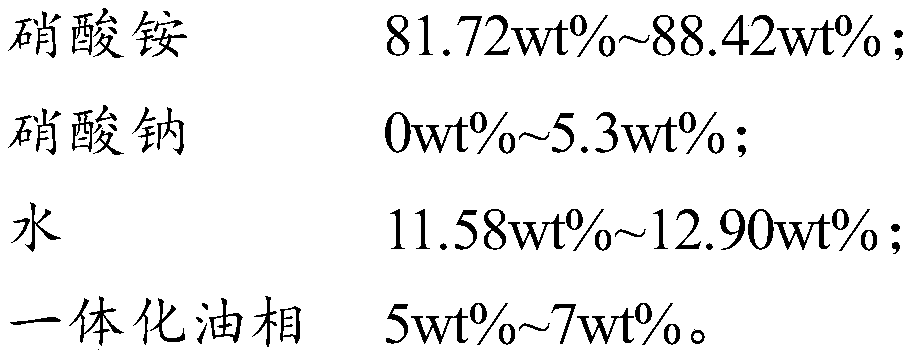

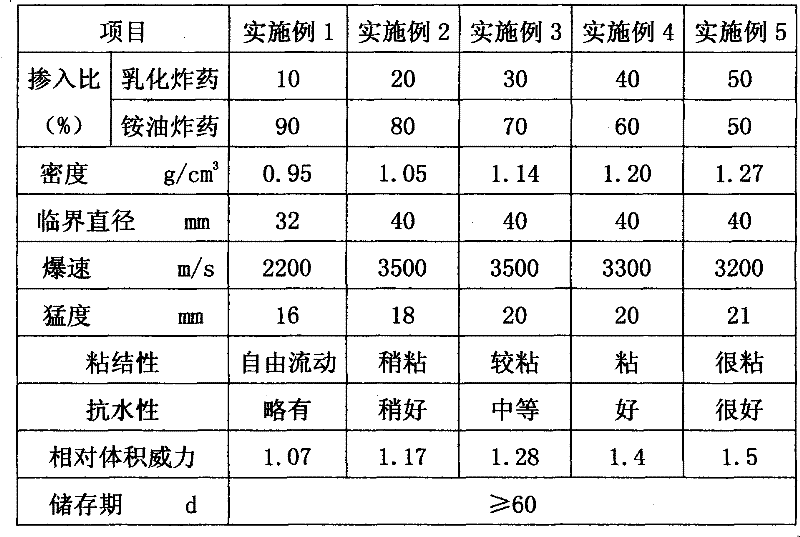

The invention relates to a heavy ammonium nitrate-fuel oil explosive with detonator sensitivity produced by using chemical sensitization and a preparation method thereof. The heavy ammonium nitrate-fuel oil explosive comprises the following components in percentage by mass: 5-55 percent of emulsion explosive and 45-95 percent of porous granular ammonium nitrate-fuel oil explosive. The preparation method comprises the following steps of: preparing the porous granular ammonium nitrate-fuel oil explosive; preparing a latex matrix; sensitizing the latex matrix; and mixing the emulsion explosive with the porous granular ammonium nitrate-fuel oil explosive. The heavy ammonium nitrate-fuel oil explosive with detonator sensitivity has small critical diameter, favorable detonator sensitivity and large capacity power without igniting an igniting primer, and can be used for various blasting engineering, such as medium-small blast hole, big hole diameter and upward fan-shaped medium-length hole, and the like. In the invention, the chemical sensitization is carried out by utilizing a brand new and quick chemical foaming agent at the same time. The novel quick chemical foaming agent has the characteristics of high foaming speed, thoroughly eliminated after-effect and fine and stable bubbles, and is a novel safe and effective chemical sensitization technique.

Owner:谢斌

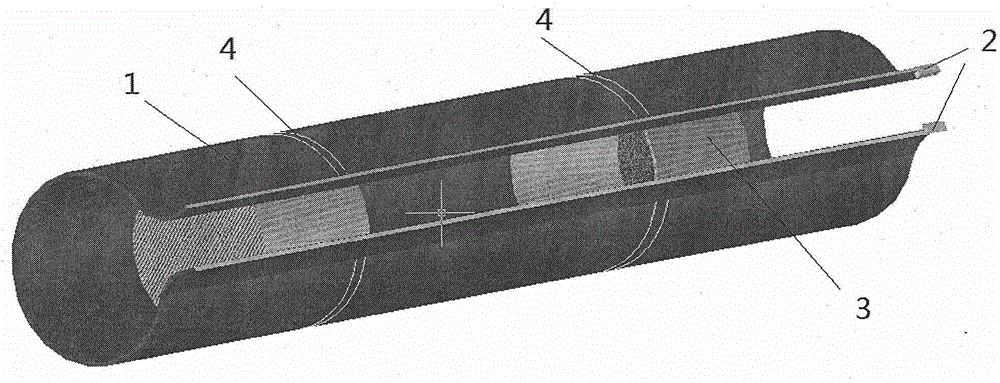

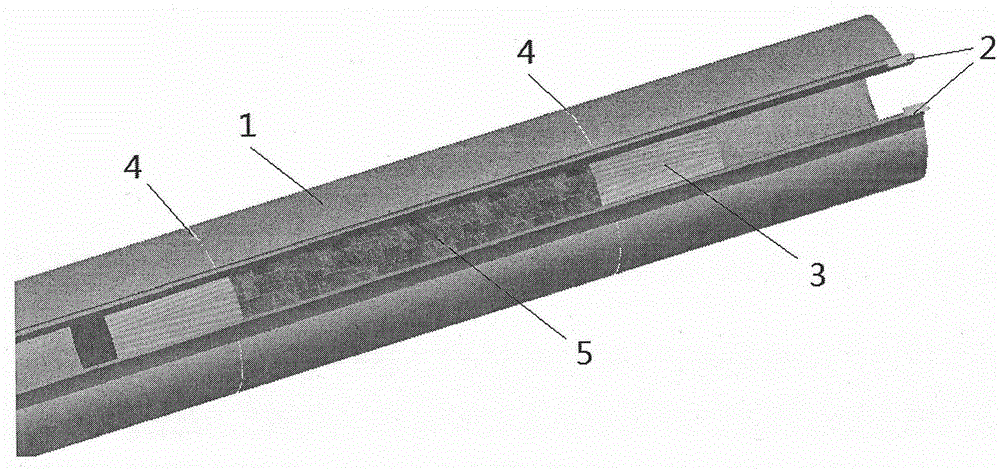

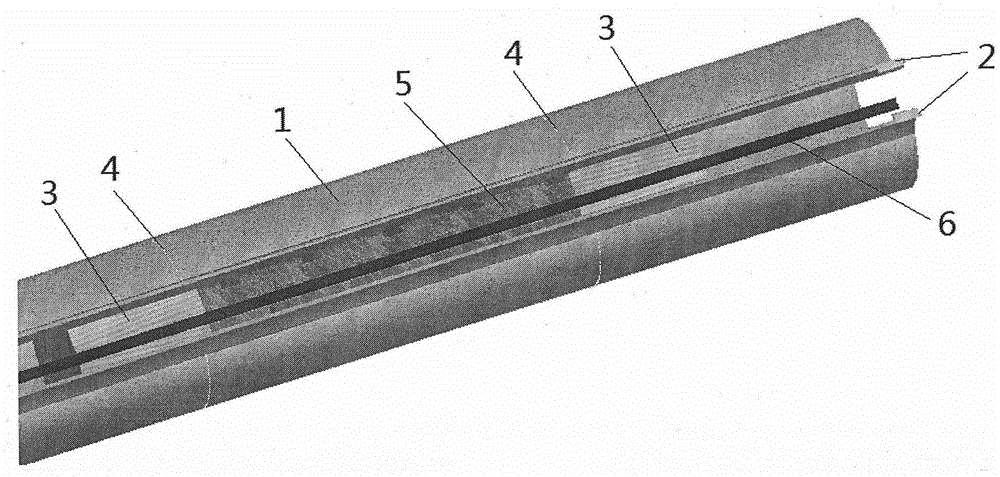

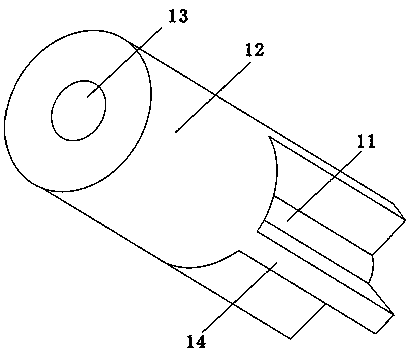

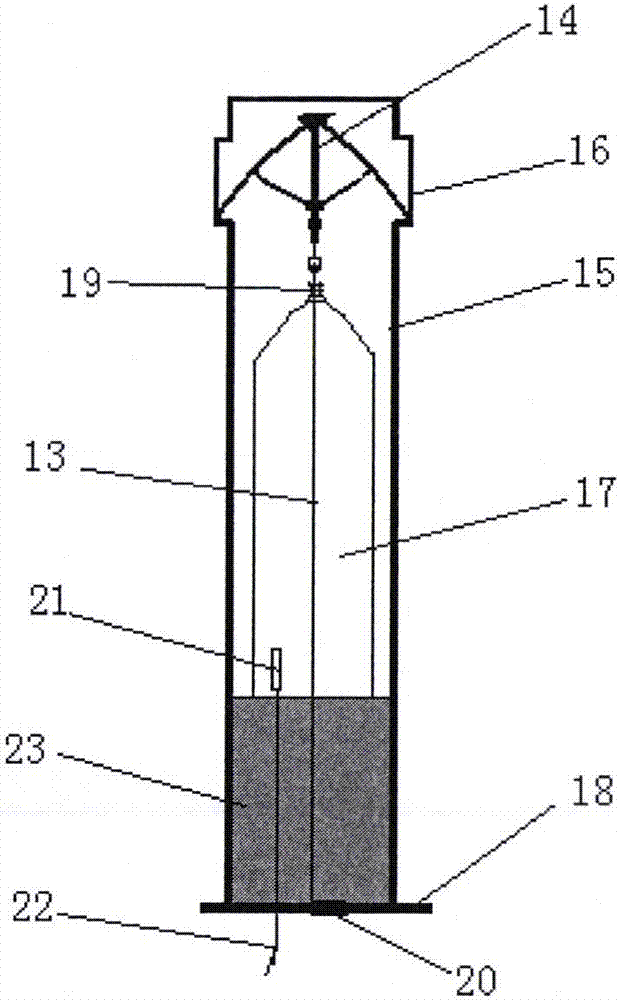

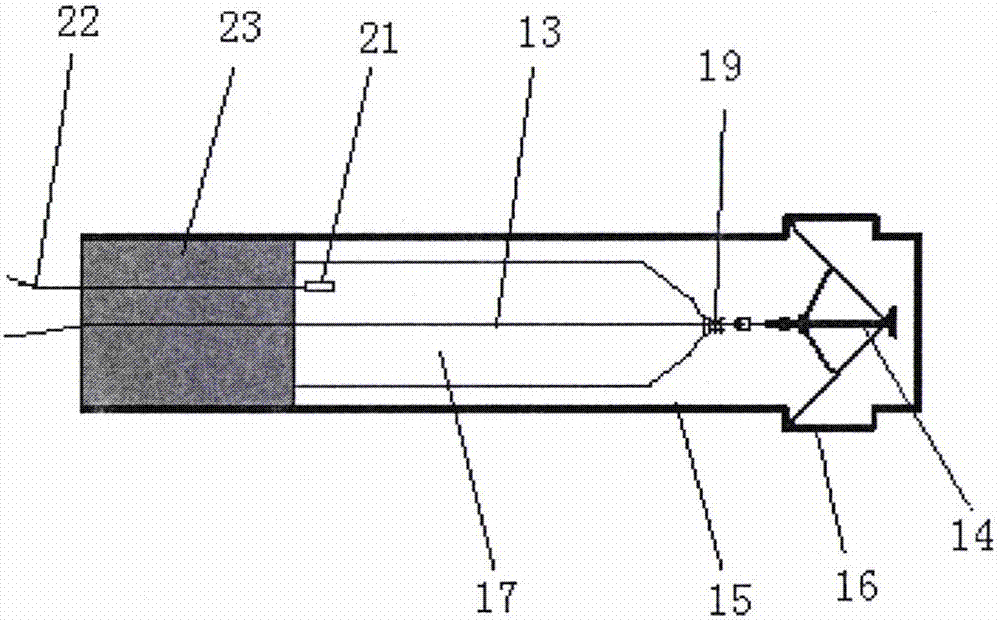

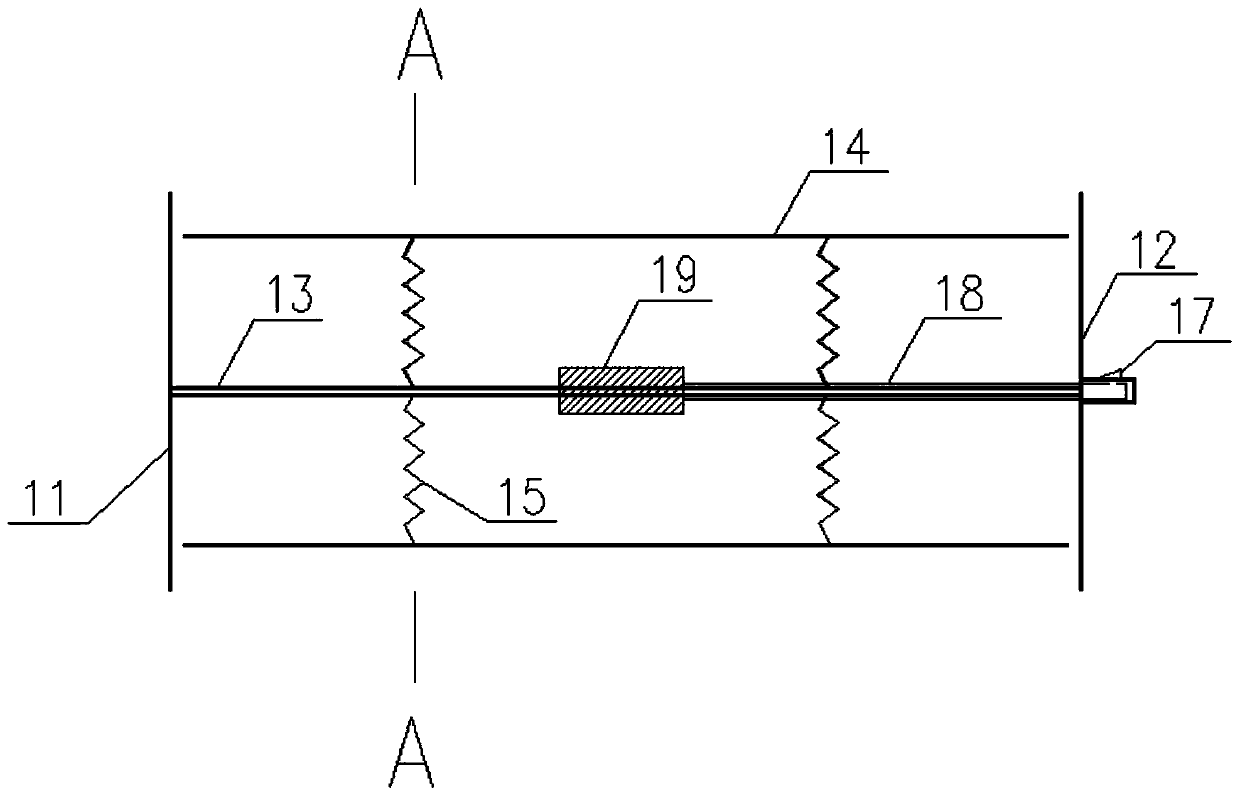

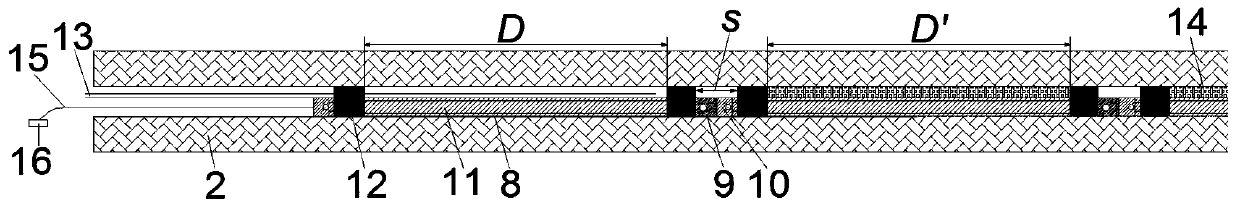

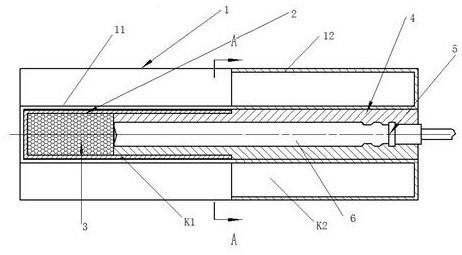

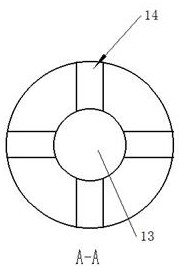

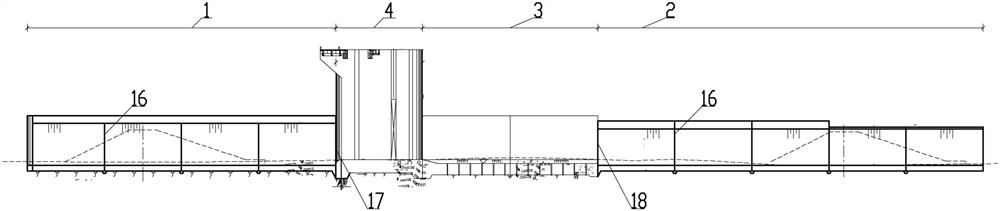

Long charging bag and method for charging blast holes through long charging bag

ActiveCN105627845ASimple structureWide range of materials availableBlastingDeep holeElectrical and Electronics engineering

The invention discloses a long charging bag. A zipper or a hook-and-loop fastener belt is installed on the bag body in the length direction. A plurality of hollow cylindrical partitions with one ends opened are arranged in the bag body. Each cylindrical partition is stitched through more than half of a circle of yarn thread or bonded or welded in the bag body. The long charging bag is used for charging the deep blast holes so that an explosive package can be prevented from being broken and deformed, accurate spaced charging and uncoupled charging can be achieved for downward blast holes or horizontal or slowly-inclined blast holes with two opened ends. The long charging bag can also be used for accurate charging of bent blast holes. The long charging bag is simple in structure, wide in usable material and capable of being easily used for large-batch industrial production and use. A construction method is wide in application range and capable of being widely used in engineering of demolition blasting, presplitting blasting, smooth blasting and underwater blasting, and the purpose of accurate charging of deep holes in the engineering is achieved.

Owner:叶建军

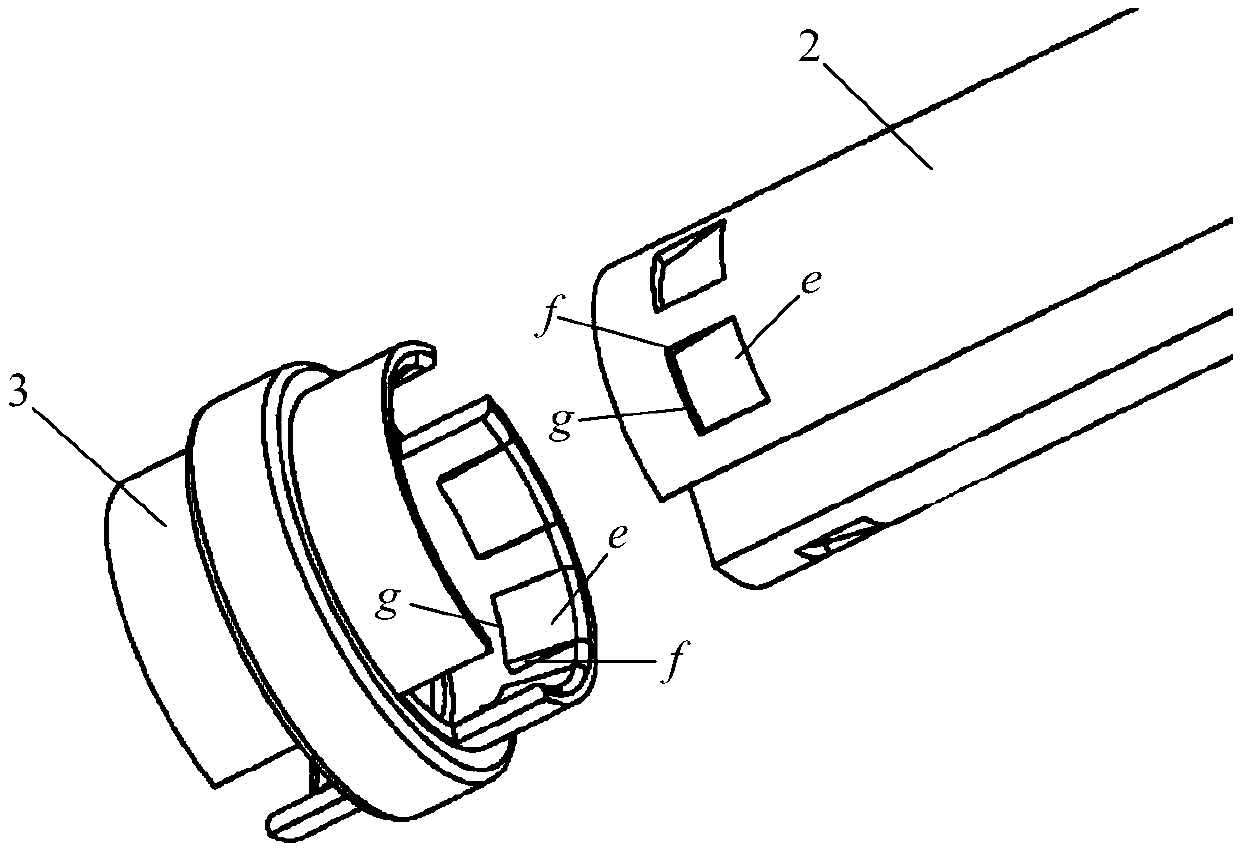

Linear energy gathering smooth blasting device

InactiveCN105547063AAvoid damageQuick installationBlastingStructural engineeringExplosives engineering

The invention provides a linear energy gathering smooth blasting device. The device at least comprises an energy gathering standard knot, a centering connecting sleeve and an orifice fixing device opened in the radial direction; and a buckle connecting structure of a permanent single-edge buckle or a permanent annular buckle is used for connecting. The buckle connecting structure realizes fast installation of an energy gathering blasting device; a centering ring structure is adopted to guarantee an energy gathering device to be positioned in the center position of a blast hole so as to reduce the deviation of pre-splitting direction; and the orifice fixing device realizes fast installation of the device after being aligned to the pre-splitting direction. The invention provides the linear energy gathering smooth blasting device with concentrated energy, directional splitting, no coupling charging and convenience for installation for pre-splitting blasting of latent holes and smooth blasting of tunnels. A new product is provided to enterprises for producing blasting devices; a blasting appliance with simplicity, practicability, fast installation and convenience for transportation is provided for construction enterprises performing the pre-splitting blasting engineering operation; and excellent conditions for popularizing and applying the energy gathering smooth blasting technology are satisfied.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

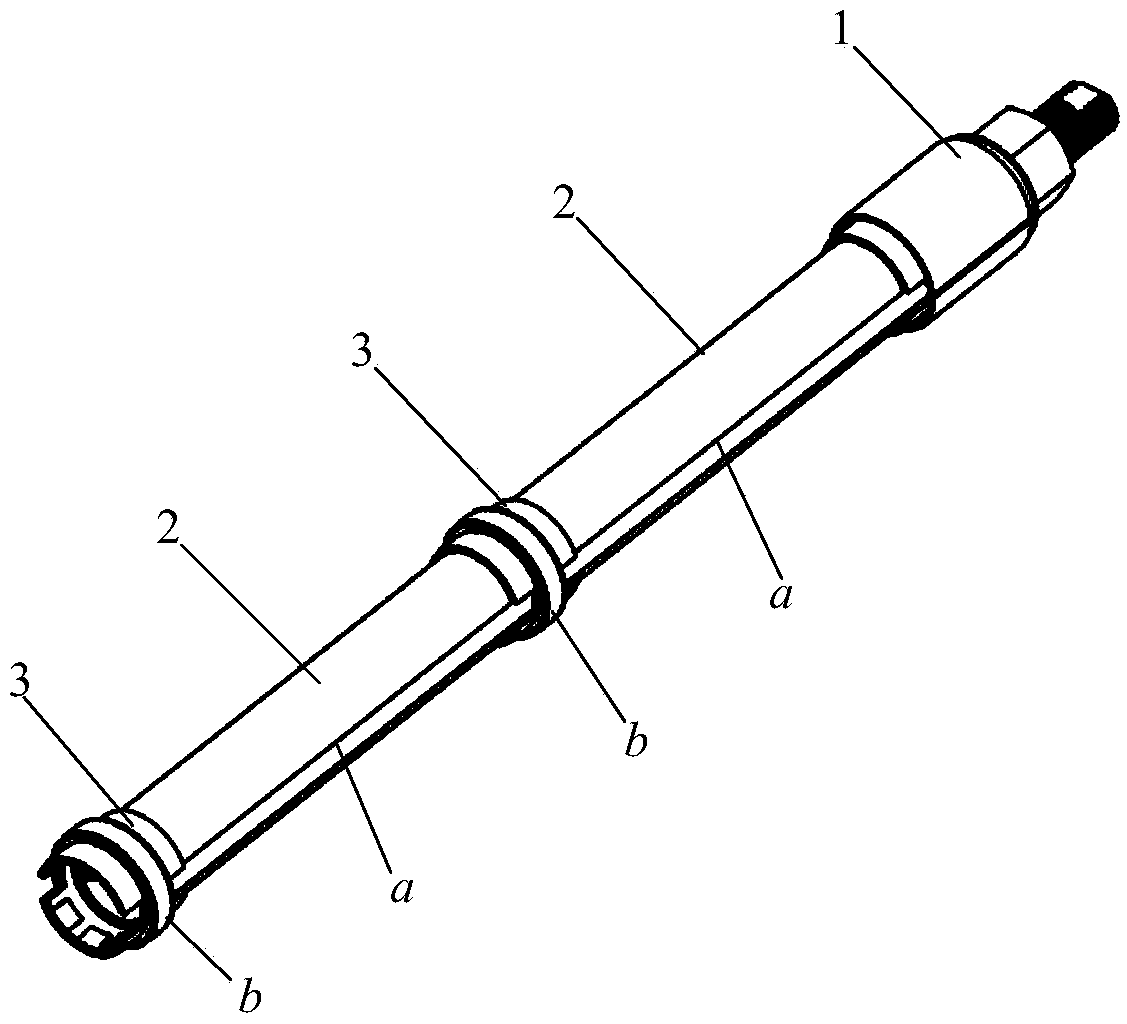

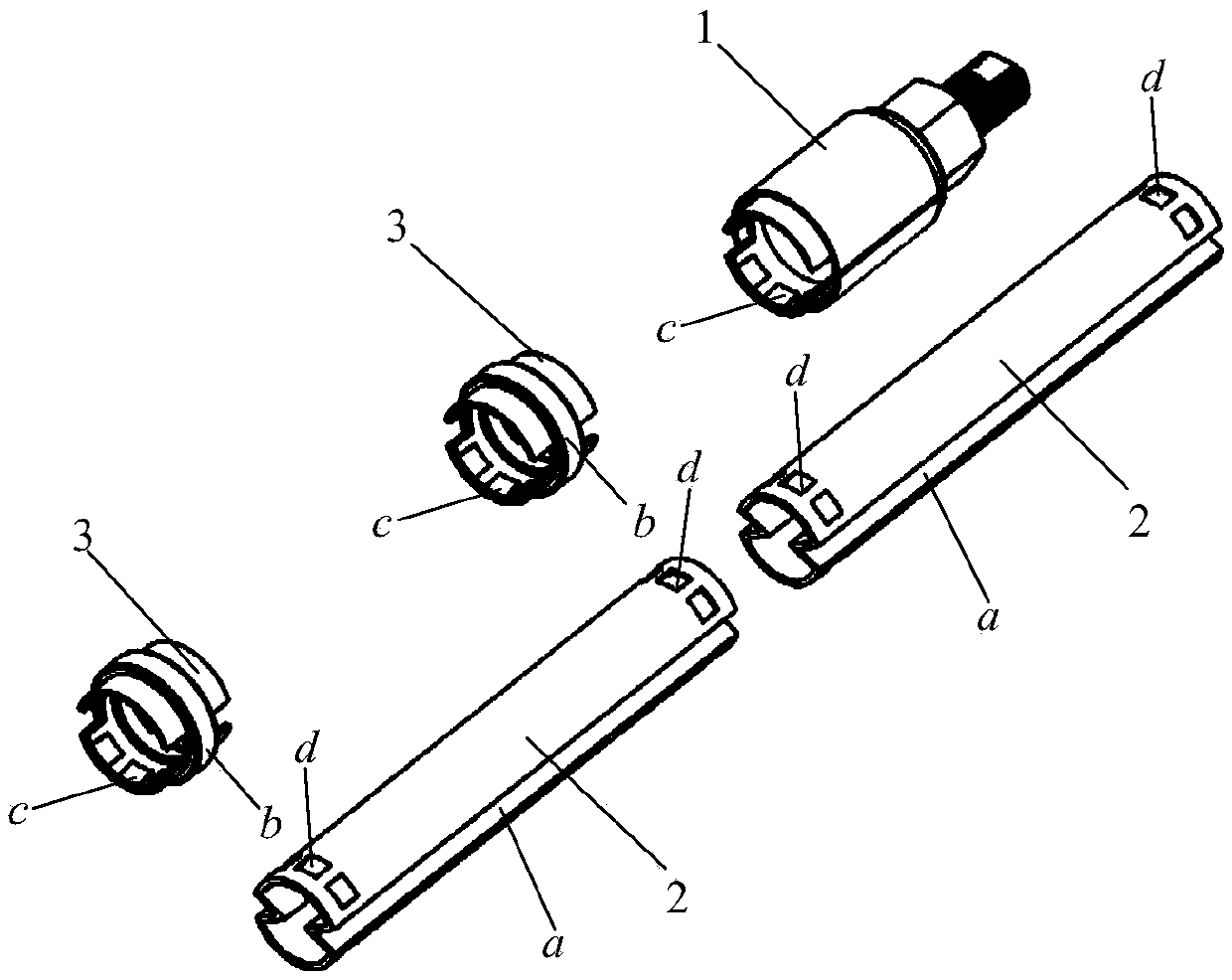

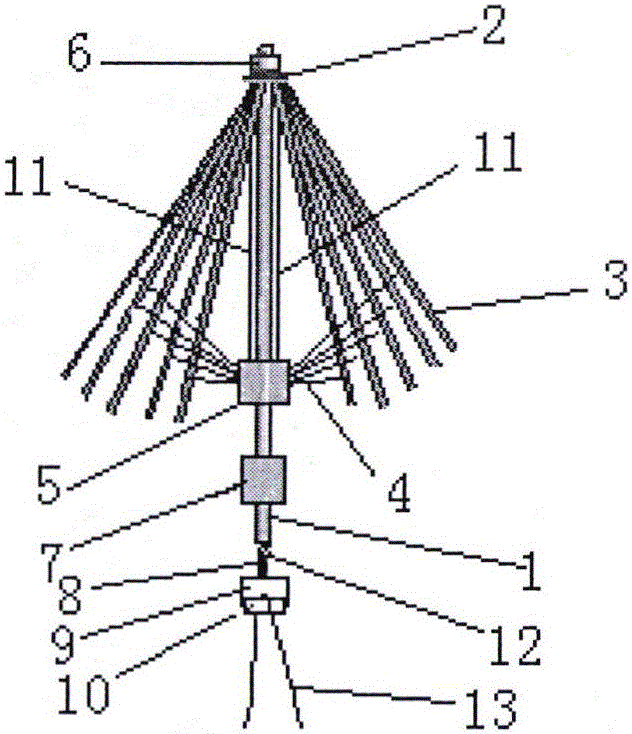

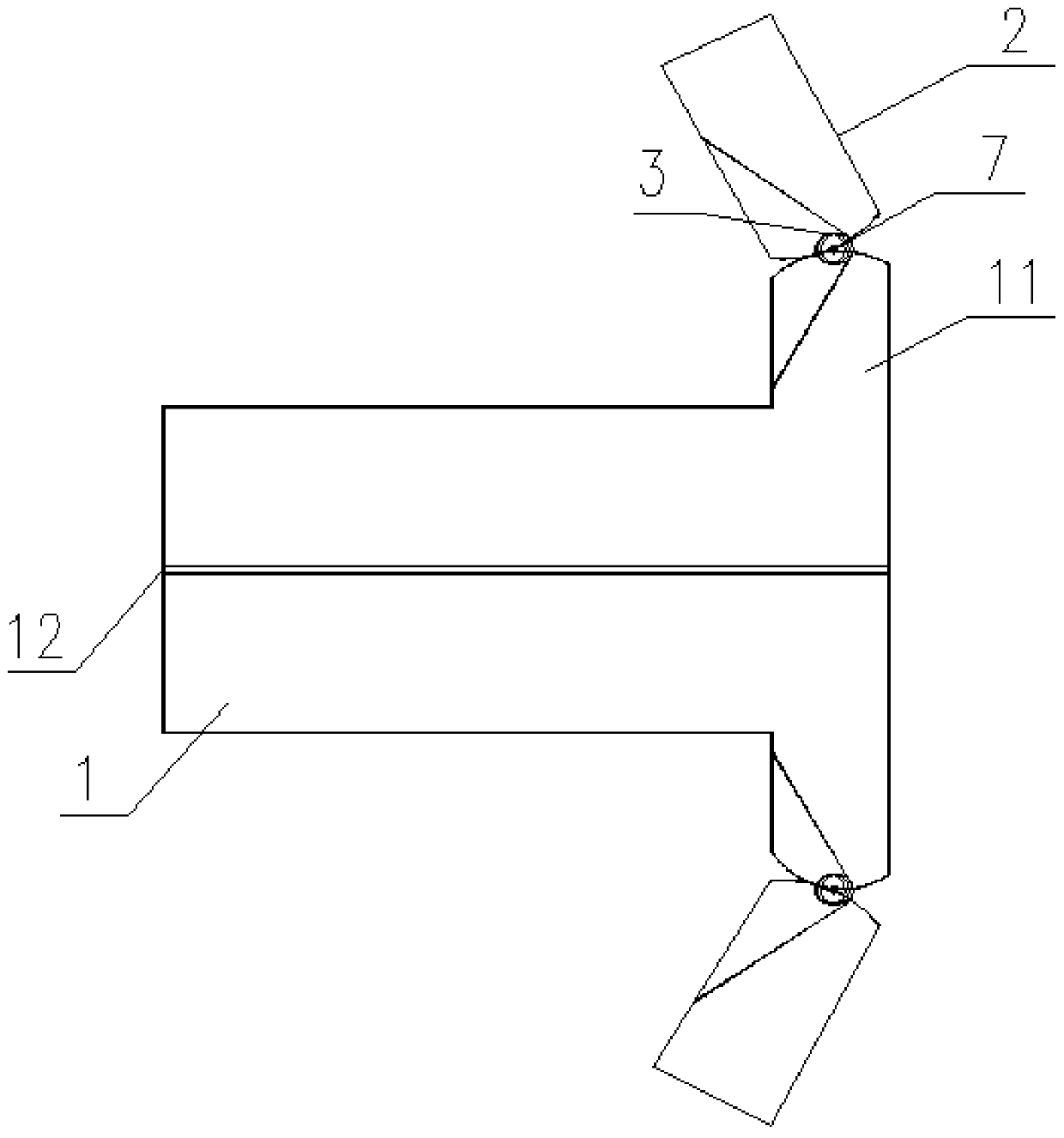

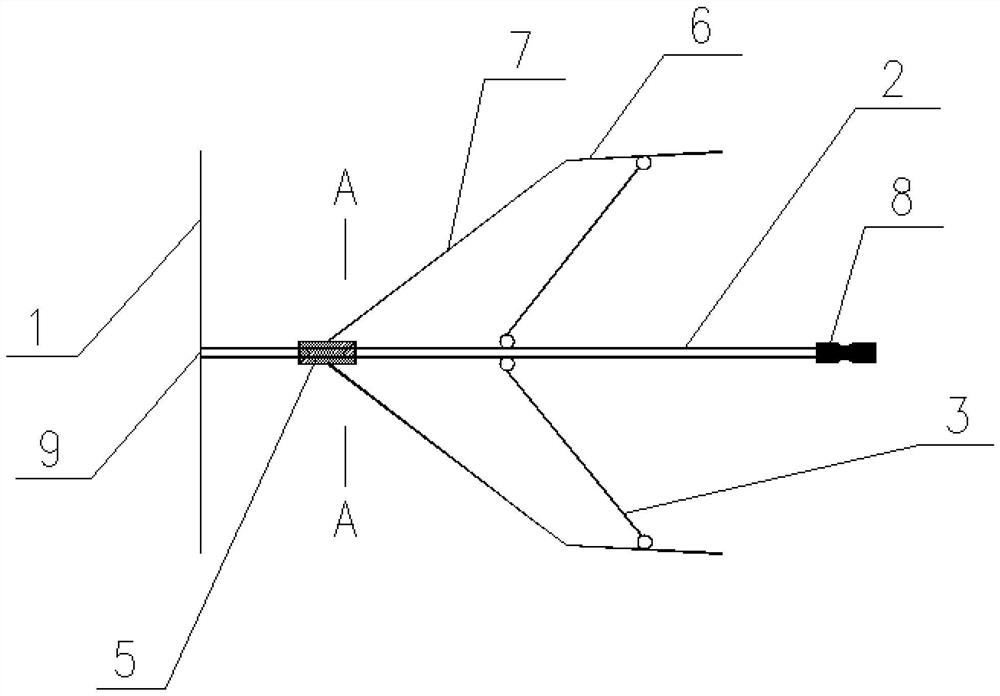

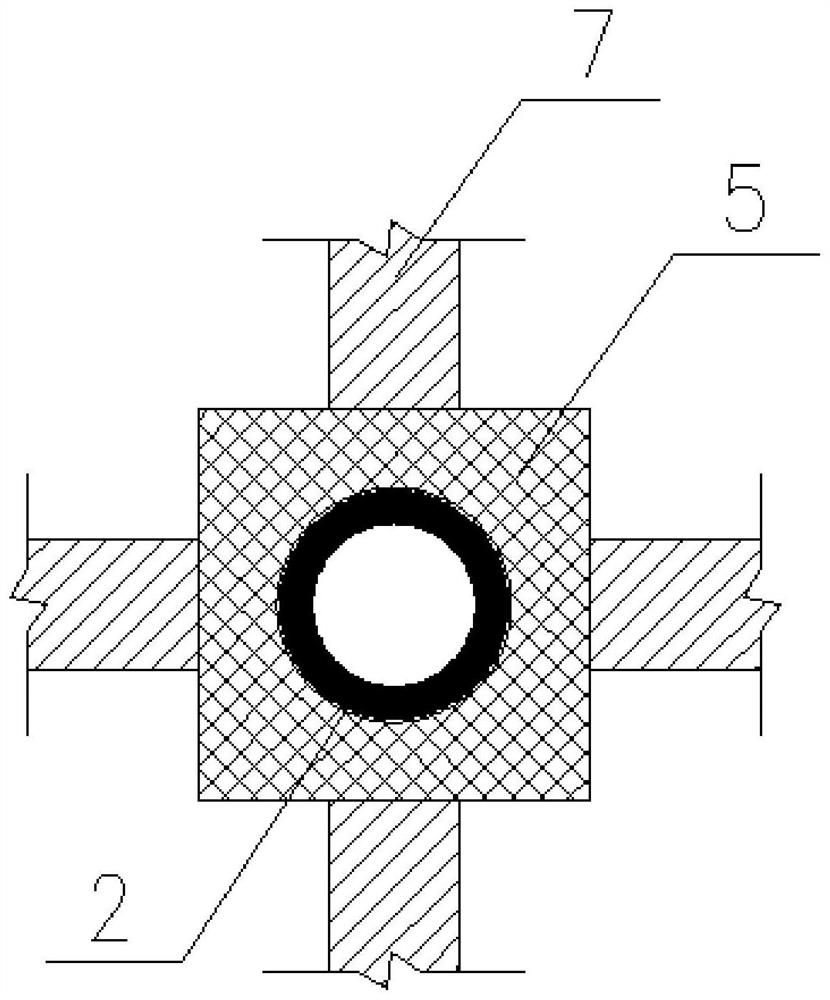

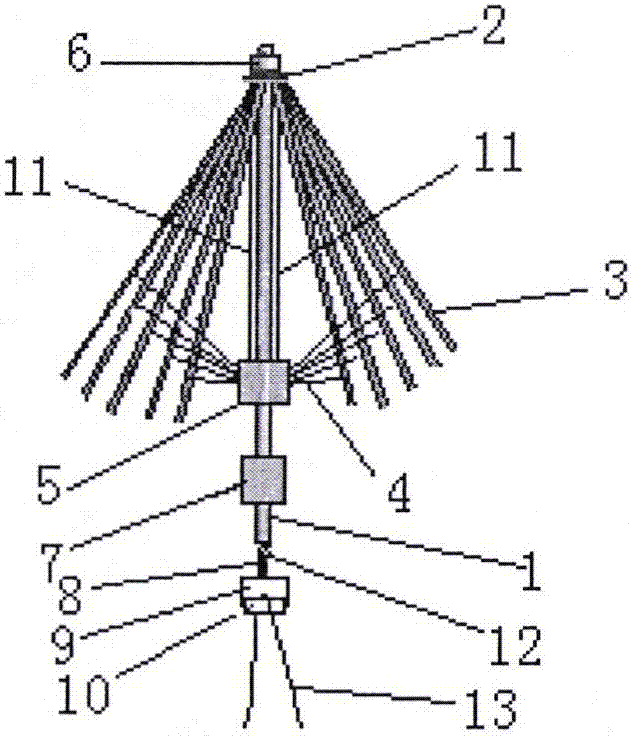

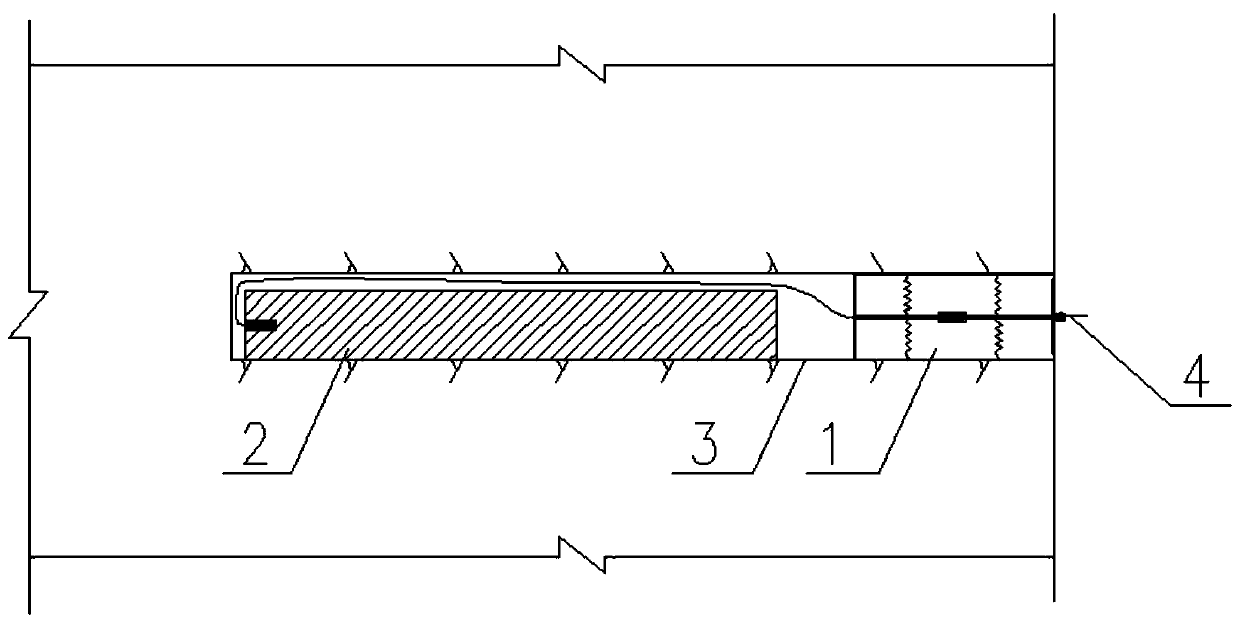

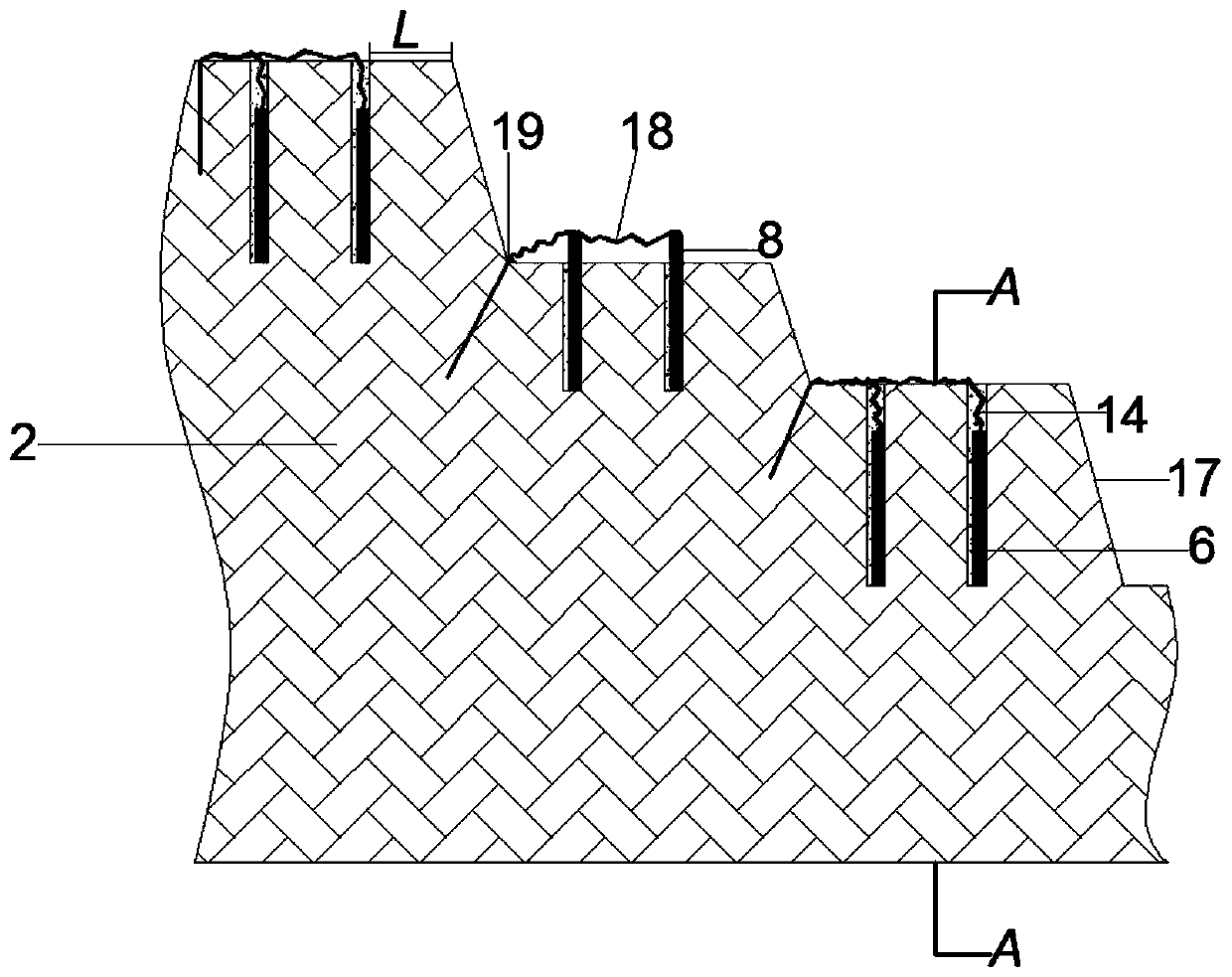

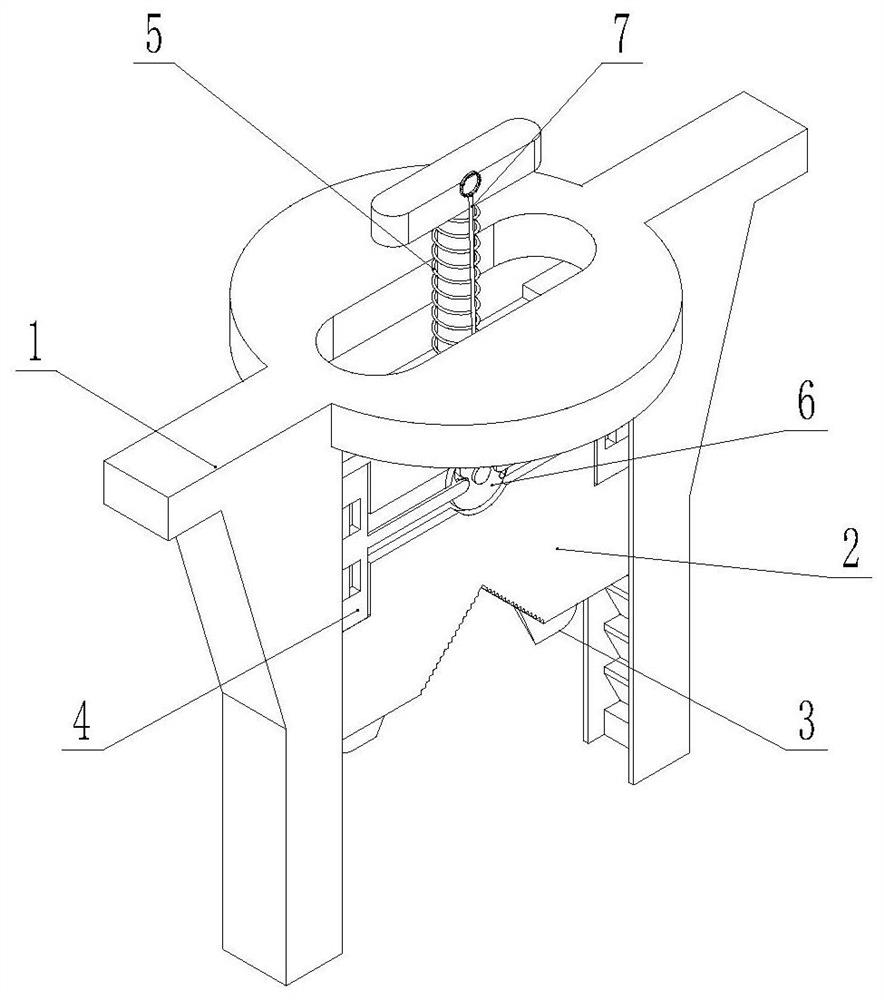

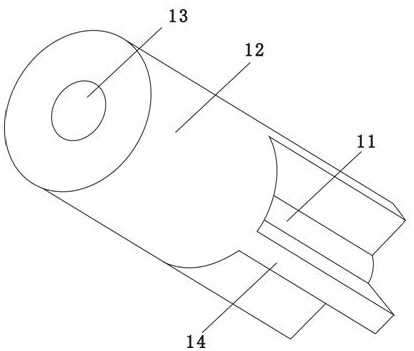

Umbrella-shaped detent hanger and method for charging blast hole through umbrella-shaped detent hanger

The invention discloses an umbrella-shaped detent hanger. An umbrella framework structure is used for reference, elastic rope yarns or springs are mounted to make surface frames have the unfolding trend, and a hanging fixed pulley is further arranged at the lower end of the structure. When the umbrella-shaped detent hanger is matched with a charging long bag for charging an upward or horizontal or downward gently inclined deep blind hole with the enlarged hole bottom, the umbrella-shaped detent hanger is clamped at the hole bottom, the charging long bag is dragged into the blast hole through a rope winds around the fixed pulley, breakage and deformation of a blasting charge can be avoided, accurate spacing charging and non-coupling charging are achieved, and the problems of charging and blockage of upward or horizontal or downward gently inclined deep blind holes are solved. The umbrella-shaped detent hanger is simple in structure and wide in available material source, and mass industrial production and usage are easy. The construction method provided by the invention is wide in application range and can be widely used for projects of demolition blasting, soil and rock blasting, controlled blasting and mine blasting, and the technical scheme with the high cost performance is provided for deep hole charging.

Owner:叶建军

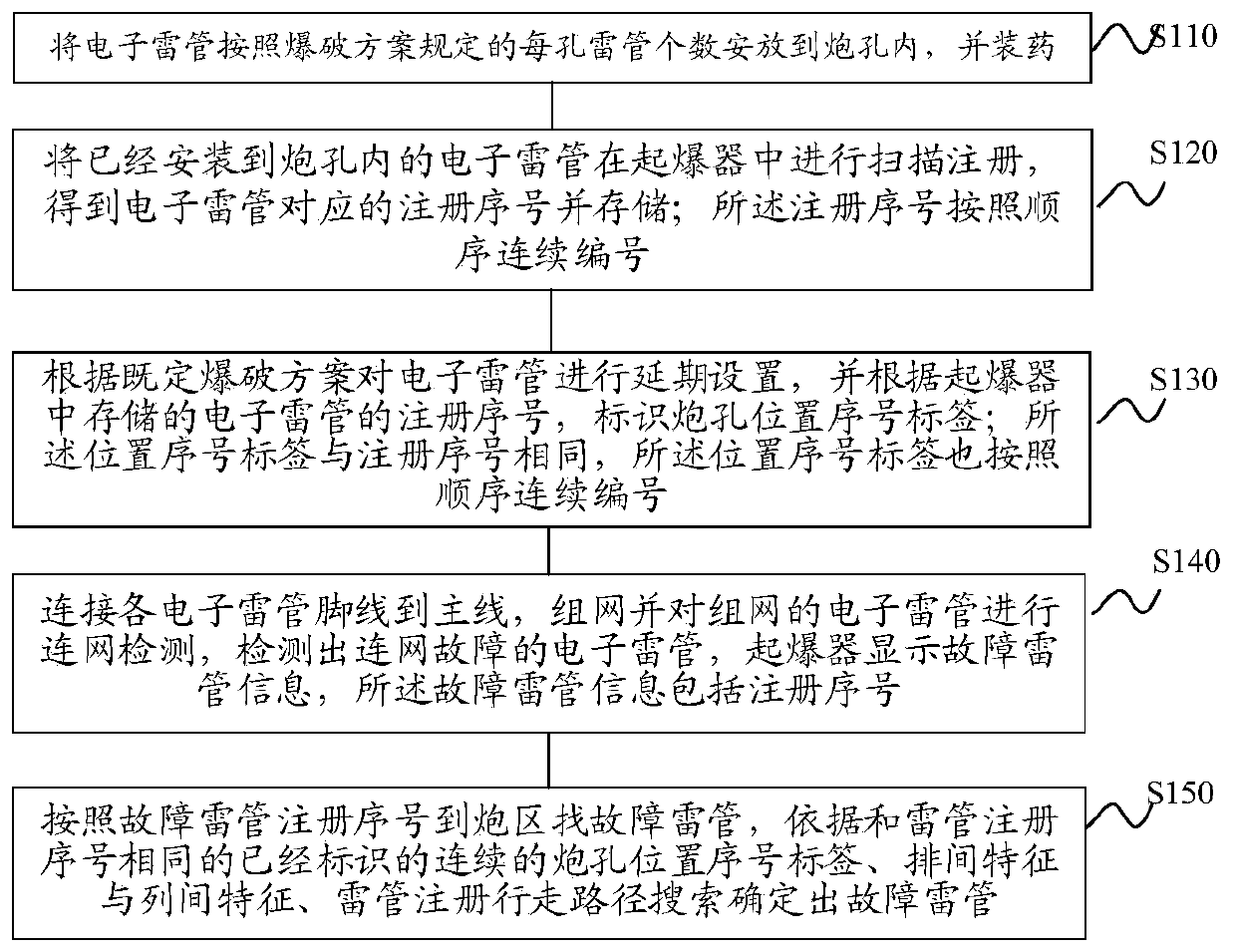

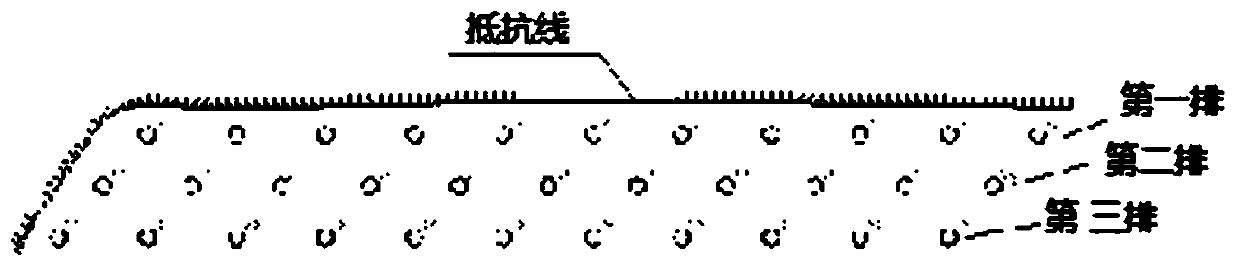

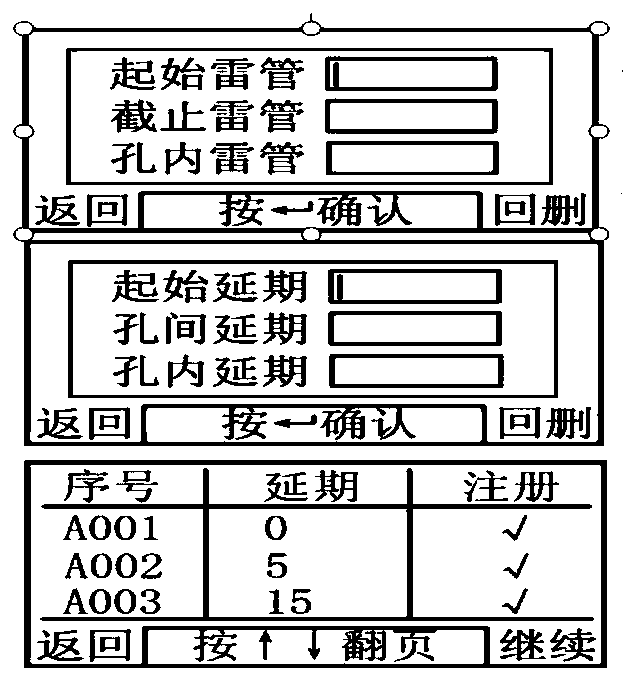

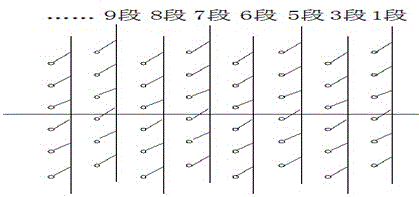

Method for quickly determining faulted detonator

The embodiment of the invention discloses a method for quickly determining a faulted detonator, and relates to the technical field of blasting engineering. The method for quickly determining the faulted detonator comprises the steps that electronic detonators installed in blast holes are scanned and registered in a blasting initiator, and registering serial numbers corresponding to the electronicdetonators are obtained and stored; the electronic detonators are delayed according to an established blasting scheme, and position serial number labels of the blast holes are identified according tothe registering serial numbers of the electronic detonators in the blasting initiator; the position serial number labels and the registering serial numbers are same and are both continuously numberedaccording to the Sichuan page sequence; networking detection is conducted on the networked electronic detonators, and the networking faulted electronic detonator is detected out; and the faulted detonator is determined according to the identified continuous blast hole position serial number labels same as the detonator registering serial numbers, the characteristics among rows, the characteristicsamong columns and registered detonator walling paths. The method for quickly determining the faulted detonator is suitable for blasting engineering operation adopting the electronic detonators, and the faulted detonator and the position where the faulted detonator is located can be quickly and accurately determined.

Owner:北京中大爆破工程有限公司

Method and device for improving blasting propagation reliability of plastic film-packaged emulsified explosive

The invention provides a method and device for improving the blasting propagation reliability of a plastic film-packaged emulsified explosive. The method is characterized by comprising the steps that when blasting charging is conducted on site, the plastic film-packaged emulsified explosive is taken out first, one end of a plastic film-packaged emulsified explosive cartridge is inserted into the device, the explosive cartridge is rotated a round when the explosive cartridge is inserted into the portion, where a blade is arranged, of the bottom of the device, an explosive cartridge buckle and plastic film remnants are cut off and fall from a hole formed in the bottom, operation in the above steps is conducted on the other end of the explosive cartridge, blast hole charging is conducted on the explosive cartridge of which the two-end remnants are cut off, and then the charging continuity is guaranteed. The device is portable, simple and convenient to carry and can be used on a blasting construction site. The blade is arranged, and therefore the buckles and the plastic film remnants on the two end faces of the plastic film-packaged emulsified explosive can be cut off through the blade. According to the device, the buckles can be efficiently and quickly cut off, the on-site charging efficiency is improved, the blasting propagation reliability is improved, blasting sympathetic detonation incompletion is avoided, and the safety in blasting engineering is improved.

Owner:FUJIAN HAIXIA KEHUA FUXING CONSTR ENG CO LTD

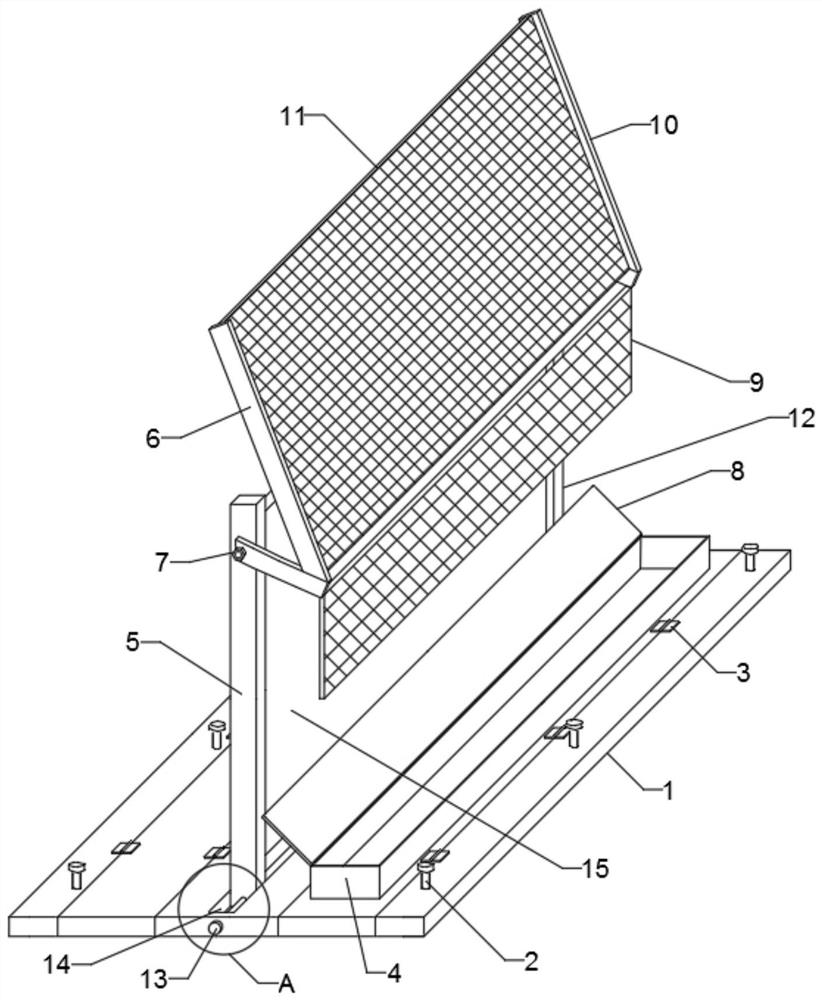

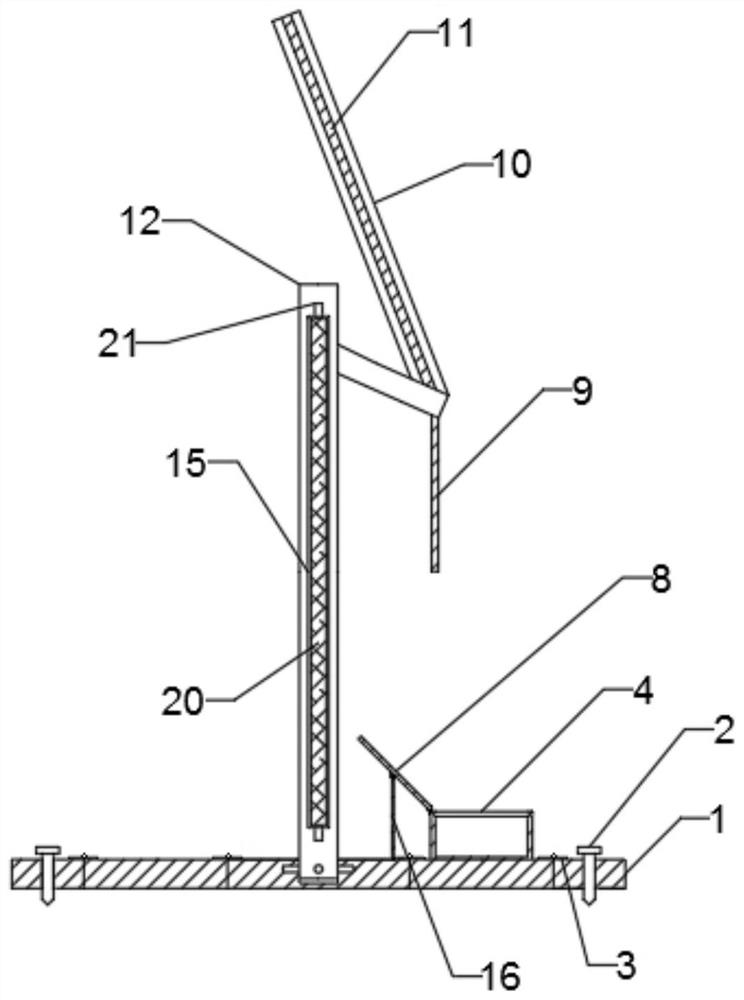

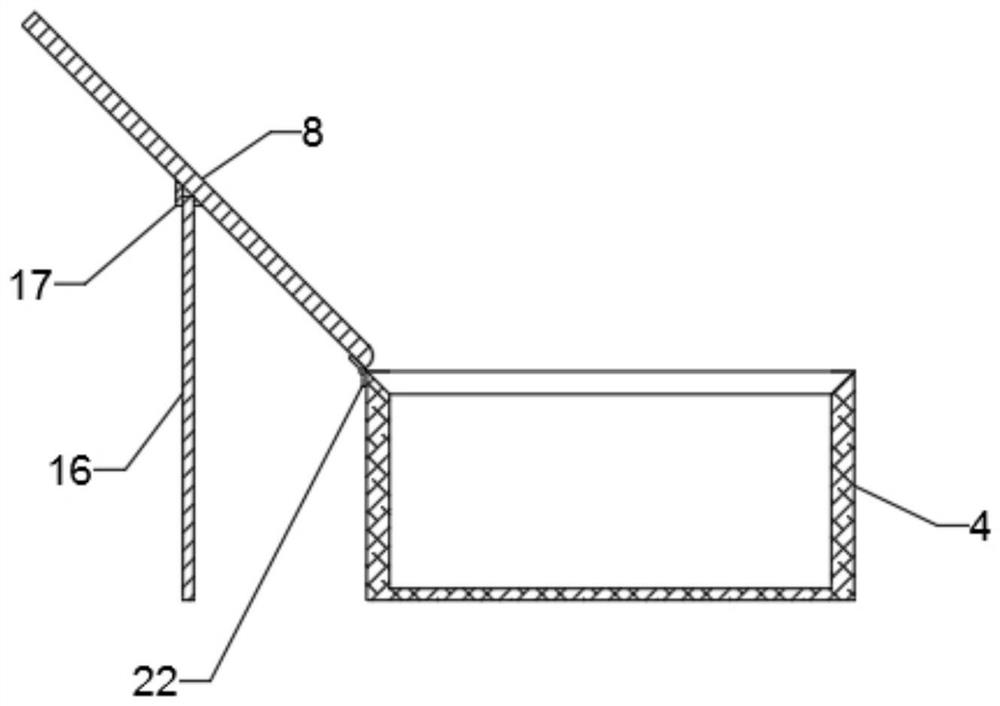

Flying stone protection equipment for surface blasting engineering and protection method of flying stone protection equipment

The invention discloses flying stone protection equipment for surface blasting engineering and a protection method of the flying stone protection equipment, and belongs to the technical field of flying stone protection equipment. The flying stone protection equipment comprises a bottom plate, a groove is formed in the bottom plate, a first supporting rod is rotatably installed in the groove, a second supporting rod is arranged on one side of the first supporting rod, second through holes are formed in the front face and the back face of the bottom plate, and fixing screws are arranged in the second through holes. Through the arrangement of a protection bag and a non-Newtonian fluid layer, flying stones generated by blasting can be better protected, the flying stones are prevented from penetrating through the protection equipment to injure personnel, the non-Newtonian fluid layer can be conveniently wound under the condition that the non-Newtonian fluid layer is not stressed, through the arrangement of the bottom plate, the groove, the first supporting rod and the second supporting rod, the equipment can be conveniently folded and stored, mounting and dismounting are convenient, the assembling time of the equipment during use is saved, and the occupied space of the equipment during transportation can be further facilitated.

Owner:湖南南岭民爆工程有限公司

Water hole charging device and charging method thereof

The invention belongs to the field of blasting engineering, and mainly relates to a water hole charging device and a charging method thereof. The device consists of two light, thin and brittle plasticcylinders with different radiuses and the same heights: a first cylinder is embedded in a second cylinder, and the bottoms are connected; a strip opening is vertically formed in the closed side surface of the top of the first cylinder for charging; and a nylon rope is fixed around the top end, communicating with the atmosphere, of the second cylinder. The charging process is as follows: the charging is performed in the first cylinder according to the designed quantity and the calculated filling density; a cavity between the two cylinders is fully filled with fine rock chips; and the rock chips are fed to the bottom of a blasthole through the smooth nylon rope. Through the cartridge bag density increasing method, the condition of difficult sinking of general water hole charging cartridge bags is overcome, the cartridge bags can reach the bottom of the blasthole more quickly and accurately, the construction efficiency is greatly improved, and the device is suitable for deeper water holes.

Owner:KUNMING UNIV OF SCI & TECH

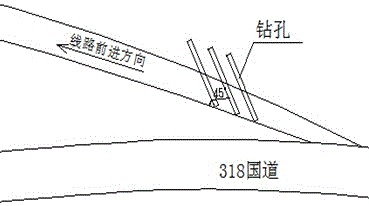

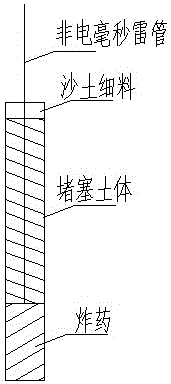

Blasting construction method used before construction of mountain shortcuts above existing roads

The invention belongs to the field of mountain blast working, and particularly relates to a blasting construction method used before construction of mountain shortcuts above existing roads. Step shallow hole blasting is adopted for mountain excavation road sections, the blasting area above the existing roads is covered with a protective net, the blasting work amount is checked according to the construction scheme, friable rock and surface soil above rock are removed, the plum blossom type hole distribution mode is adopted for blast holes, micro-delay detonation between rows is adopted for the detonation order, and the peak vibration velocity of the surface of the area with a power grid tower foundation is smaller than 5.0 cm / s. According to the method, the blasting accuracy and the direction of flying stones generated by blasting can be effectively controlled, and the blasting requirements before construction of the mountain shortcuts can be met on the basis of guaranteeing the safety of the existing roads and nearby residents.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

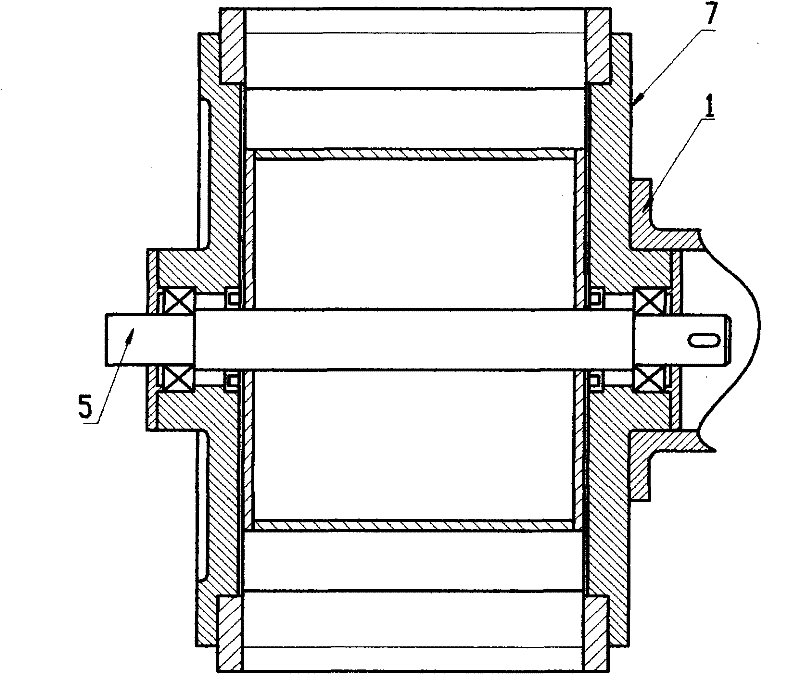

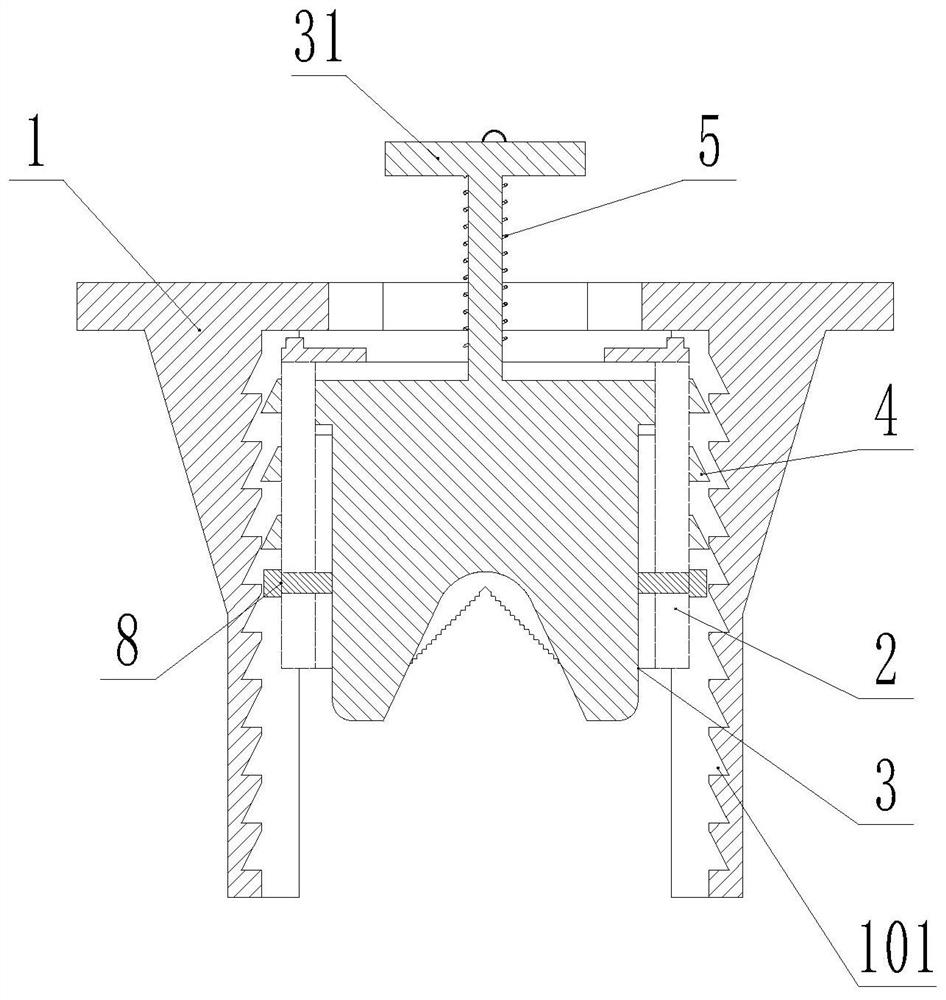

Tunnel blasting construction blast hole blocking device

InactiveCN111457808AEasy to operateHigh packing quality assuranceBlastingArchitectural engineeringSpring force

The invention relates to a tunnel blasting construction blast hole blocking device, and belongs to the technical field of blasting engineering auxiliary devices. The tunnel blasting construction blasthole blocking device comprises a filling structural part and movable rods, wherein the movable rods are disposed at intervals along the circumferential direction of the filling structural part, eachmovable rod is hinged to the same end of the filing structural part through a pivot shaft, and a torsion spring sleeves each pivot shaft; when the torsion springs are in the natural state, the included angle formed by the axis of the movable rods and the axis of the filling structural part is less than 90 degrees; when the included angle formed by the axis of the movable rods and the axis of the filling structural part is equal to 90 degrees, the return spring force of the torsion springs points to the other end of the filling structural part; and the filling structural part is provided with apassage for allowing a detonating fuse to pass through. The tunnel blasting construction blast hole blocking device is convenient to operate and high in filling quality assurance.

Owner:POWERCHINA CHENGDU ENG

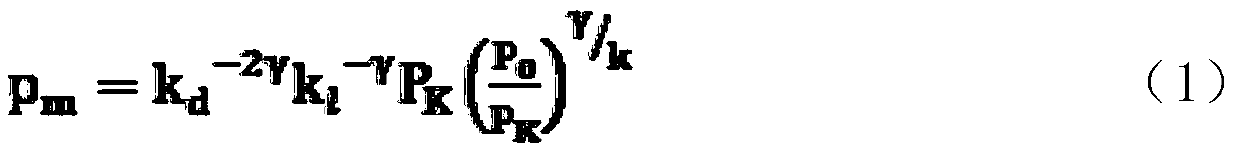

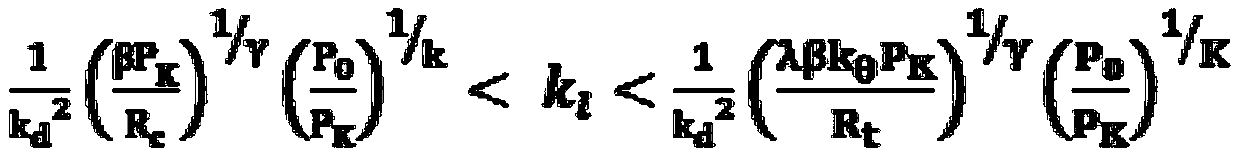

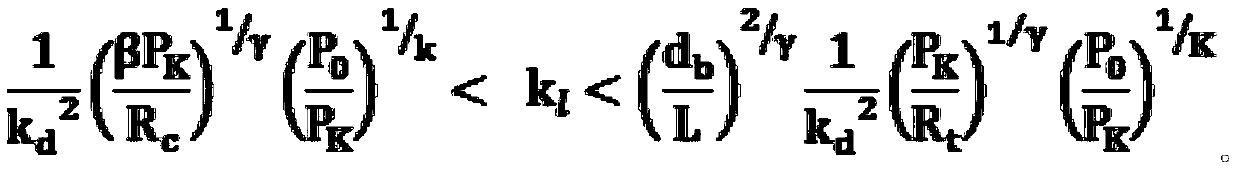

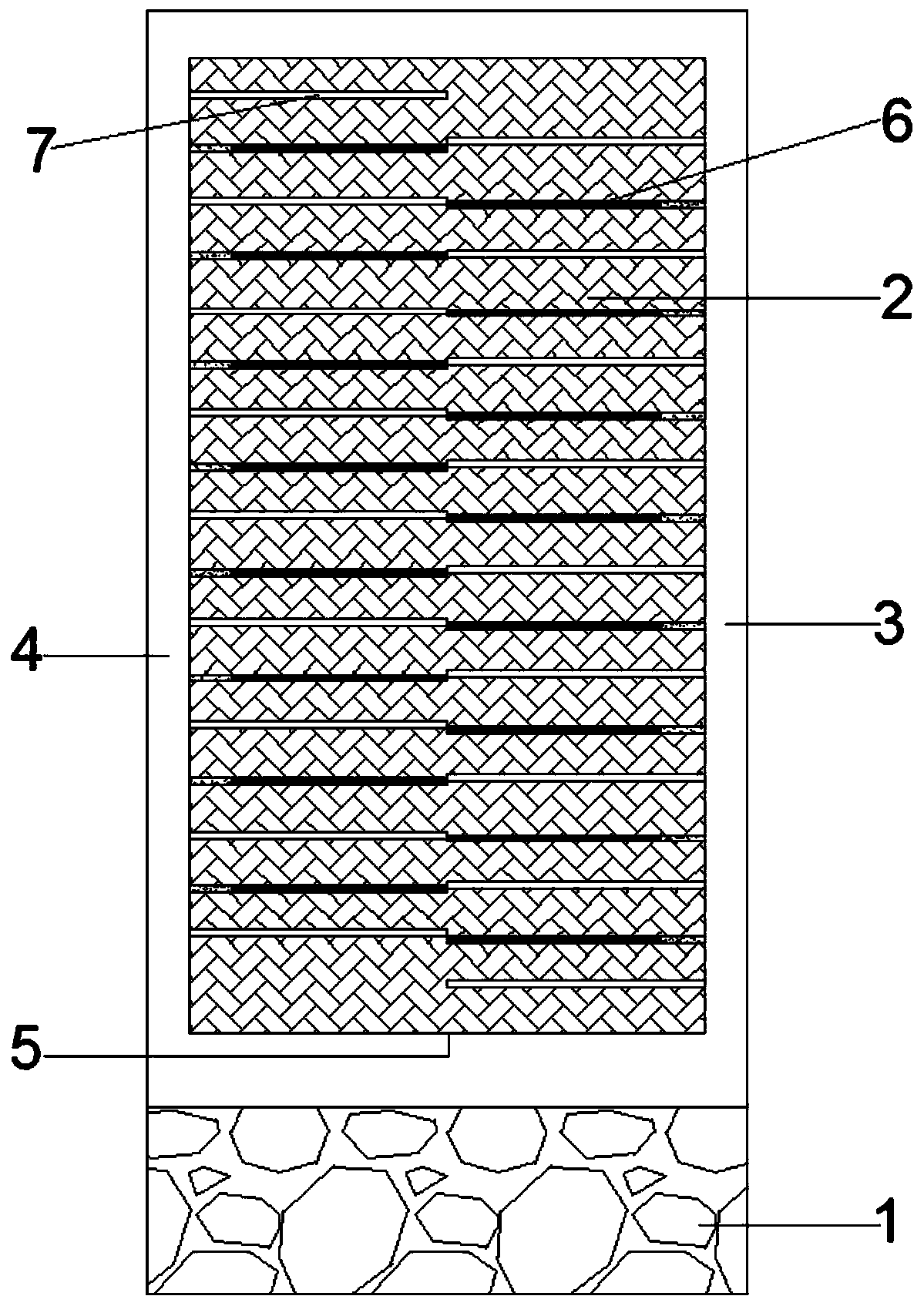

Method for determining axial decoupling coefficient of charge structure of cavity in bottom of hole

The invention provides a method for determining an axial decoupling coefficient of a charge structure of a cavity in the bottom of a hole. The method is applied to the technical field of blasting engineering, and is designed comprehensively based on various factors such as failure characteristics of rock, the relation between initial tensile stress of rock of a hole wall and tensile strength of the rock and action time of quasi-static pressure of exploding gas in a blast hole. The method is used in the field of engineering blasting to overcome bottom resistance, eliminate a tight bottom and improve the circumstance that a method of ultra-deep reinforced charge at the bottom of the hole or adopting high explosive at the bottom when a blasting effect is achieved; and the method is used for digging protection layers of permanent buildings and structures.

Owner:湖北三鑫金铜股份有限公司

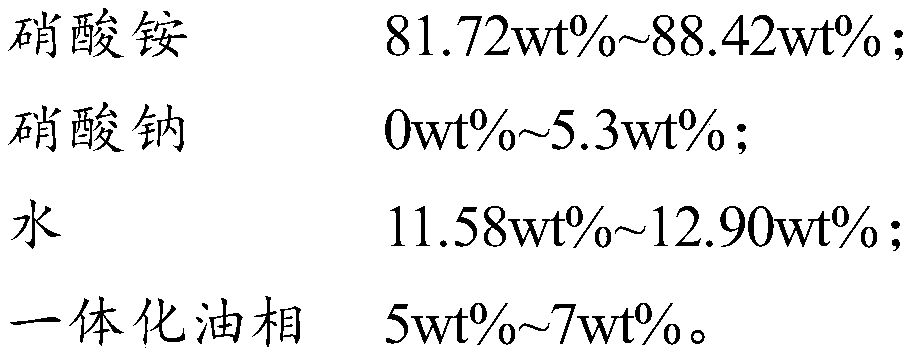

Treatment method of emulsified waste medicine

InactiveCN110950721AEasy to handleLow costExplosive working-up apparatusSocial benefitsExplosive Agents

The invention provides a treatment method of emulsified waste medicine. The method comprises the steps that porous granular ammonium nitrate, diesel oil and emulsified waste medicine are mixed according to the mass ratio of (60-72):(3-5):(25-35). The emulsified waste explosive can be recycled through simple mixing at normal temperature, the obtained industrial explosive has certain free-running property and certain cohesiveness, and the obtained product has the advantages of the low cost, the good performance and the good safety, and can meet the requirements of open-air rock blasting engineering for explosion performance. Compared with an existing treatment method of emulsified waste medicine, the emulsified waste medicine can be well recycled, the treatment process is safe, simple and environmentally friendly, and obvious economic benefits and social benefits are achieved.

Owner:雅化集团雅安实业有限公司

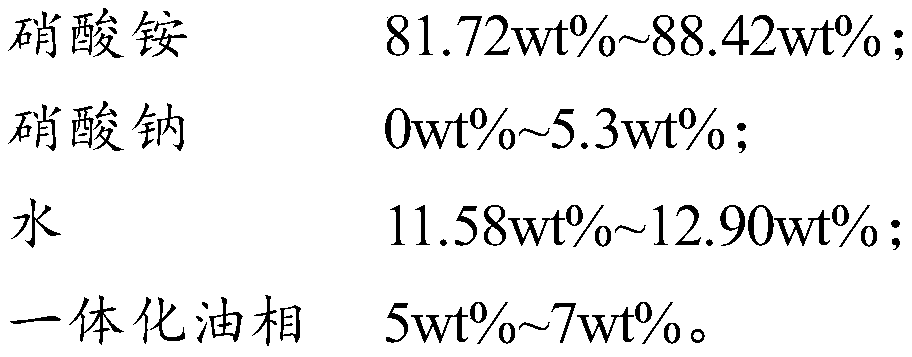

Intelligent and environment-friendly blast hole drainage vehicle for open-pit blasting engineering

ActiveCN109238063BPrecise positioningImprove drainage efficiencyBlastingEnvironmental resource managementTelescopic cylinder

Owner:SINOSTEEL MAANSHAN INST OF MINING RES CO LTD

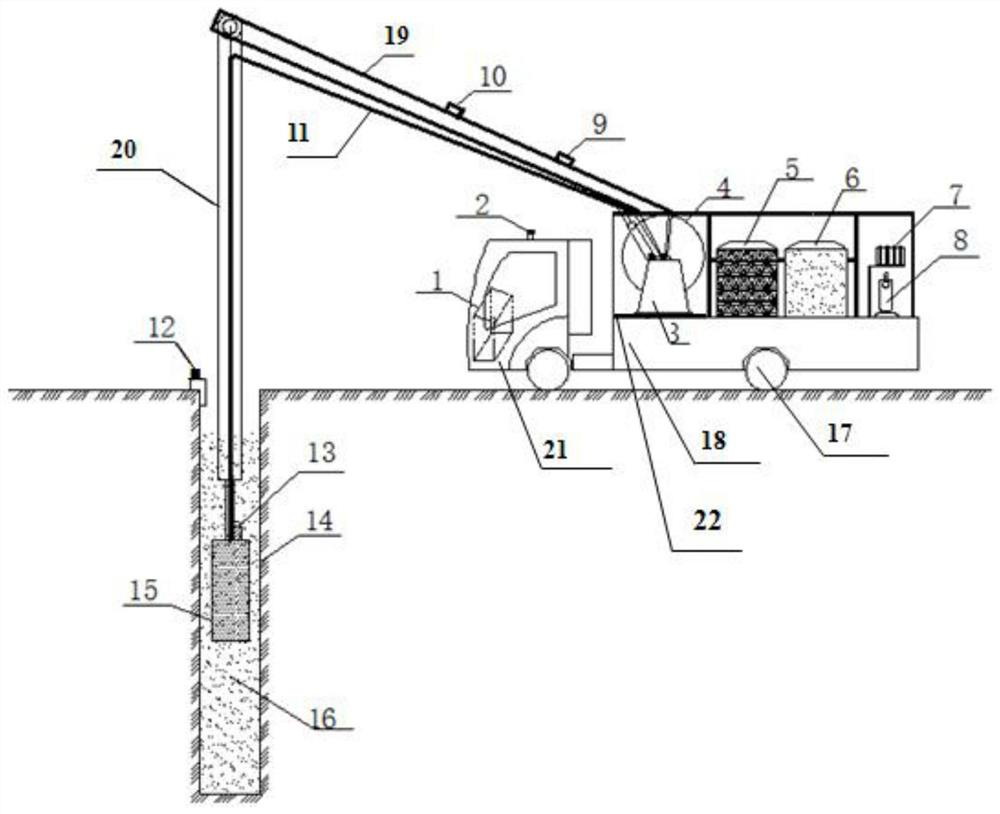

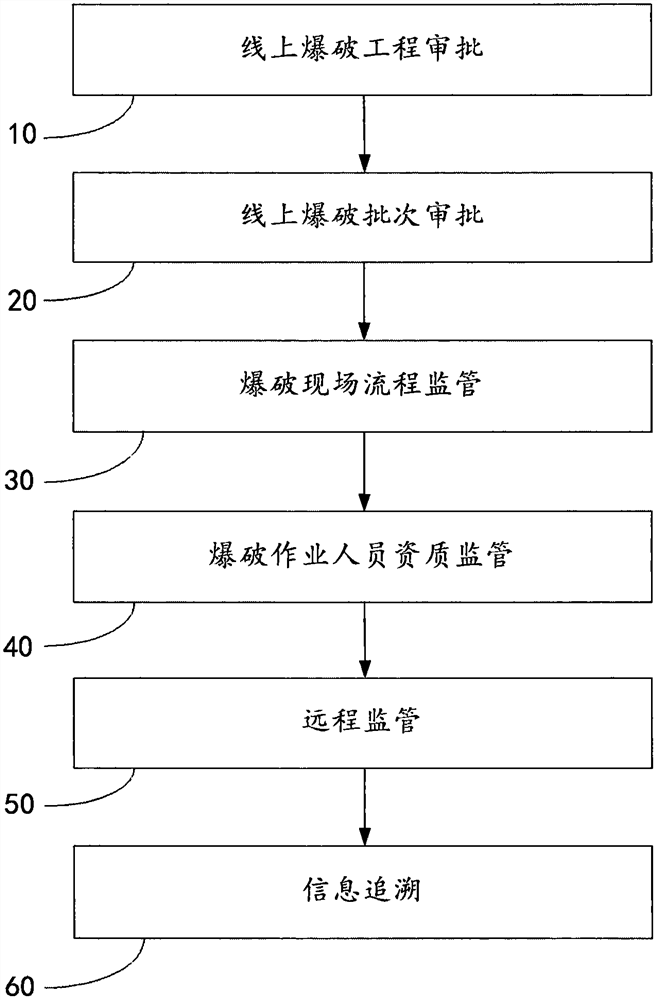

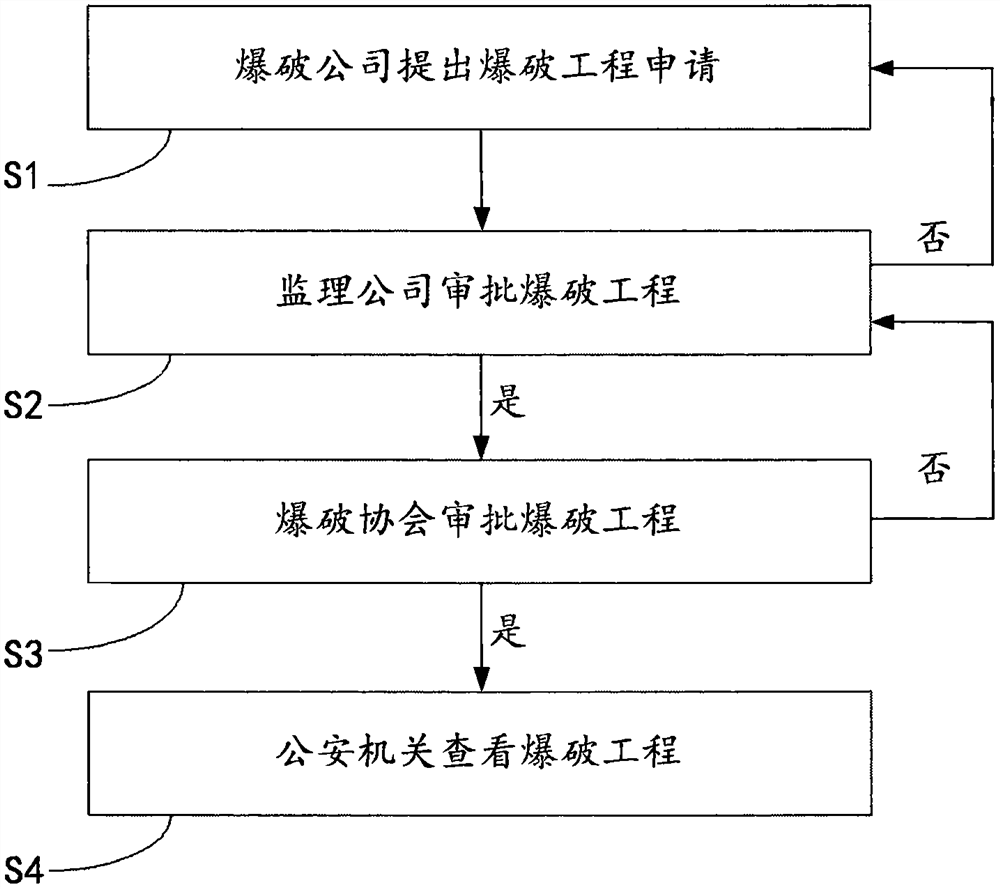

Blasting operation site management method

The invention provides a blasting operation site management method, belongs to the technical field of civil blasting, and solves the problems that only execution management can be realized on a blasting operation site, the execution safety and normalization of the blasting site are not supervised, and data acquisition, tracing and statistical analysis are lacked. The method comprises the steps of online blasting engineering approval, online blasting batch approval, blasting field process supervision, blasting operator qualification supervision, remote supervision and information tracing. According to the method, electronization and informatization of blasting operation site supervision are realized, pictures of blasting site operation personnel are automatically compared with personnel information recorded in blasting engineering information, the blasting site construction process is standardized, the safety and normalization of site construction are guaranteed, comprehensive information acquisition and real-time monitoring are realized, and each implementation link has traceability; and the method can help enterprises to carry out engineering operation frequency statistics, initiating explosive device usage statistics, personnel operation condition statistics and analysis of problems encountered in blasting engineering.

Owner:北京云晨联拓科技有限公司

Method for determining maximum single-shot explosive quantity during blasting

ActiveCN113051717ANarrow down the range of valuesImprove selection accuracyDesign optimisation/simulationComputational theoretical chemistryClassical mechanicsExplosives engineering

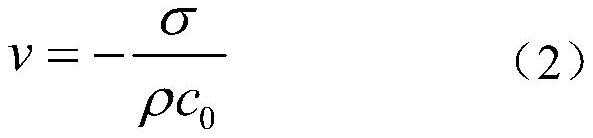

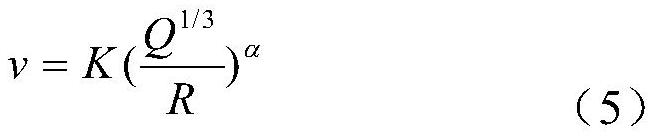

The invention discloses a method for determining the maximum single-shot explosive quantity during blasting, and belongs to the technical field of blasting engineering. The method comprises the steps: manufacturing a cemented filling body test piece according to the mine filling condition, and obtaining the maximum dynamic compressive strength sigma<emax> of the graded tailing cemented filling body in the mass point elastic deformation stage and the maximum dynamic compressive strength sigma<pmax> when the mass points of the graded tailing cemented filling body are completely damaged through an SHPB impact test; based on the combination of a one-dimensional stress wave propagation formula and a Sadov's formula of field monitoring regression, determining a stable area and a damaged area of the filling bodies with different strengths, and determining the maximum-section simultaneous explosive quantity corresponding to the damaged area.

Owner:KUNMING UNIV OF SCI & TECH

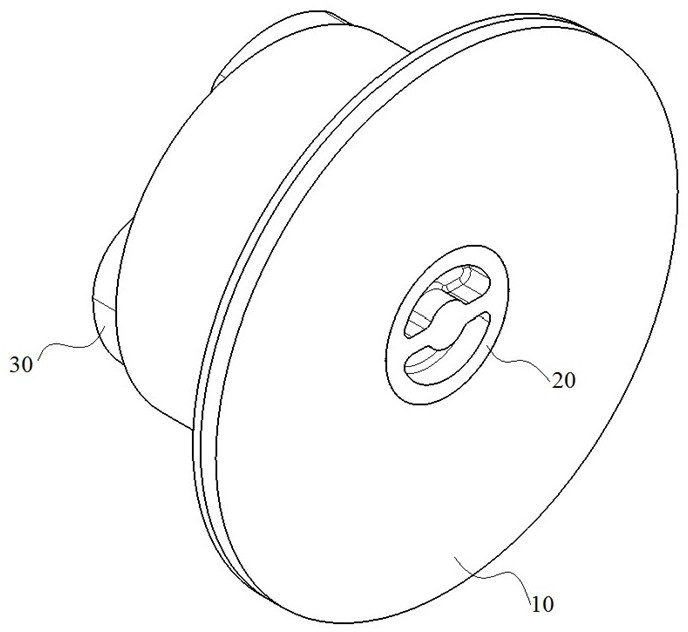

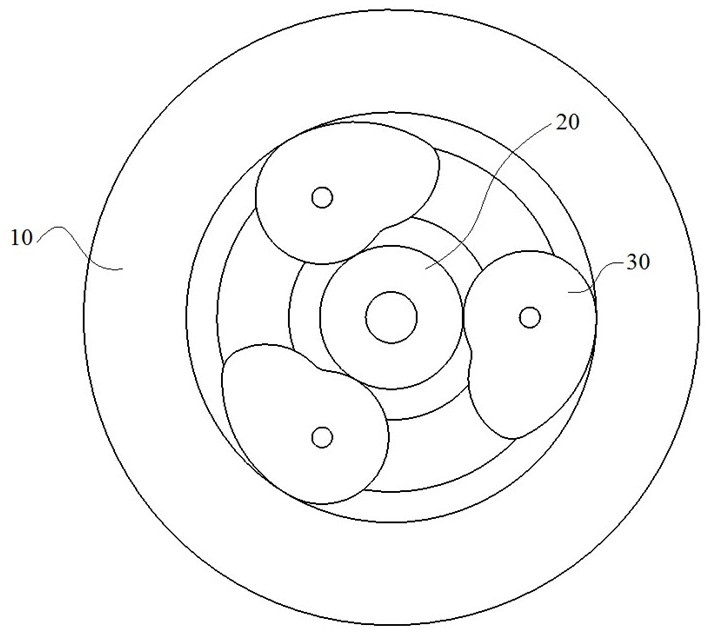

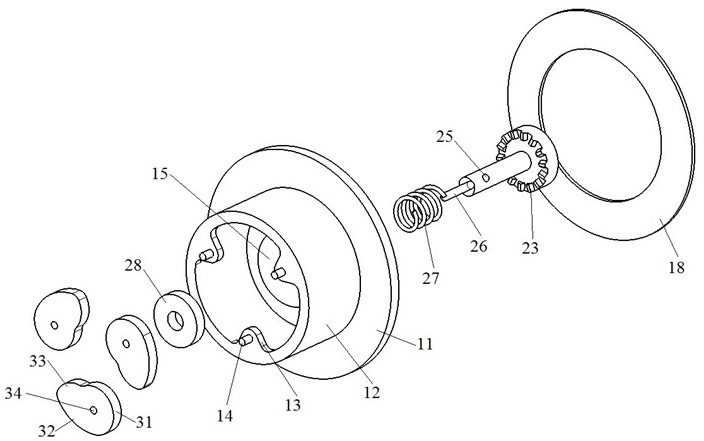

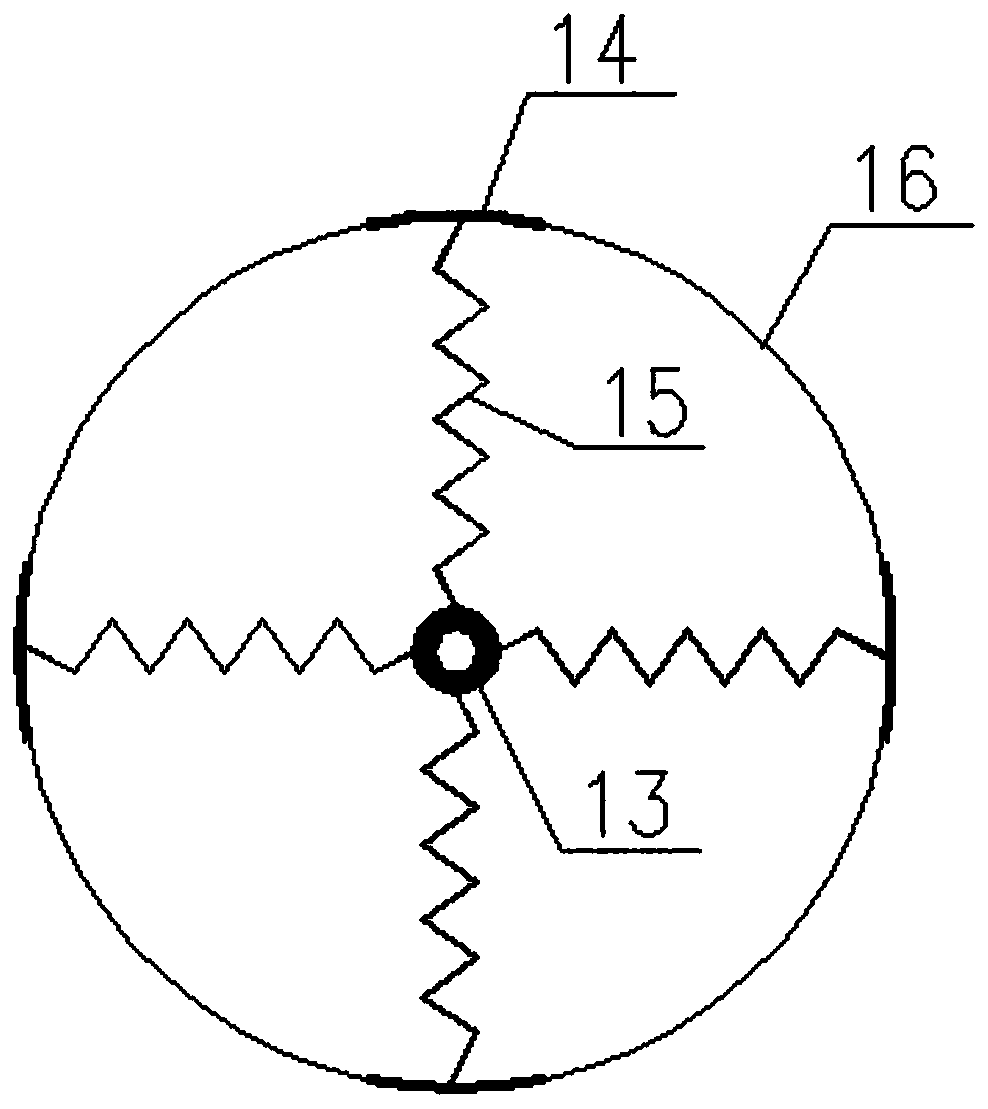

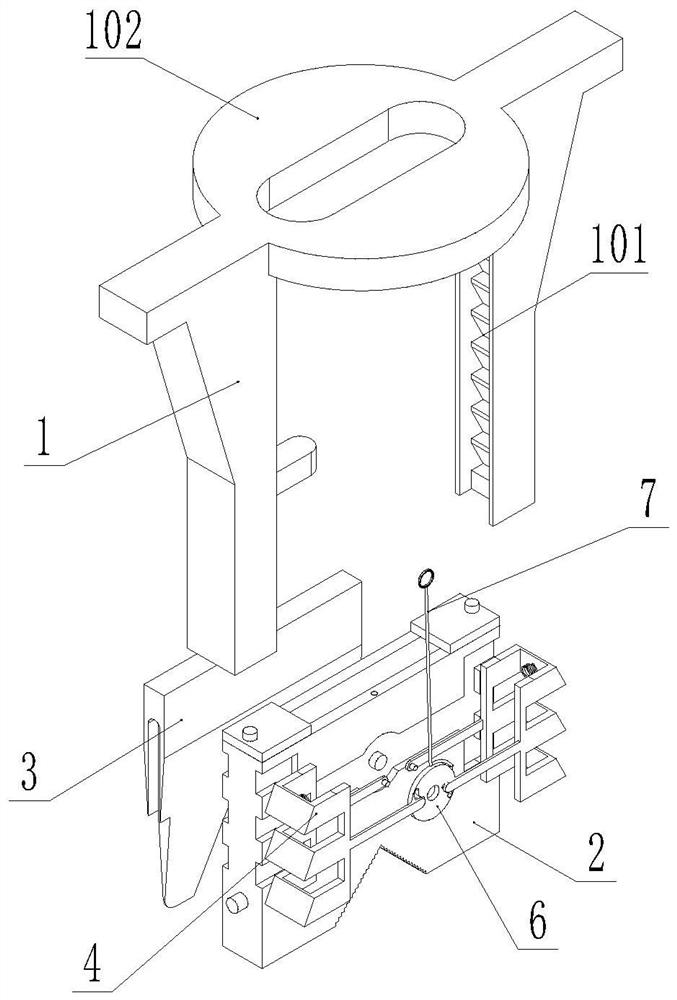

Blast hole plugging device

A blasthole plugging device belongs to the field of blasting engineering and comprises a covering part, an adjusting part and a supporting part, the covering part covers a blasthole, the adjusting part is mounted on the covering part, and the supporting part is mounted at the front end of the adjusting part. The covering part comprises a cover plate, a cylinder body, lugs, shaft pins, bosses, grooves and lower convex teeth, the rear end of the cover plate extends to the cylinder body, the three lugs are evenly distributed at the rear end of the cylinder body in a circumferential array mode, each lug is provided with one shaft pin, the bosses are arranged on the cover plate towards the interior of the cylinder body, the grooves are formed in the front end face of the cover plate, and a circle of lower convex teeth are arranged in an inner cavity of each groove. The adjusting part comprises a round cover, upper protruding teeth, an extension rod, a through hole, a pin, a spring and a driving wheel, the rear end face of the round rod is provided with the upper protruding teeth, the extension rod is arranged in the middle of the rear end of the round rod, the through hole is formed in the rear portion of the extension rod, the pin is installed in the through hole, the spring is installed between the pin and the boss and sleeved on the extension rod, and the driving wheel is fixedly installed at the tail end of the extension rod. The three supporting parts are hinged to the shaft pins respectively, and each supporting part is of a cam structure.

Owner:江西国泰五洲爆破工程有限公司

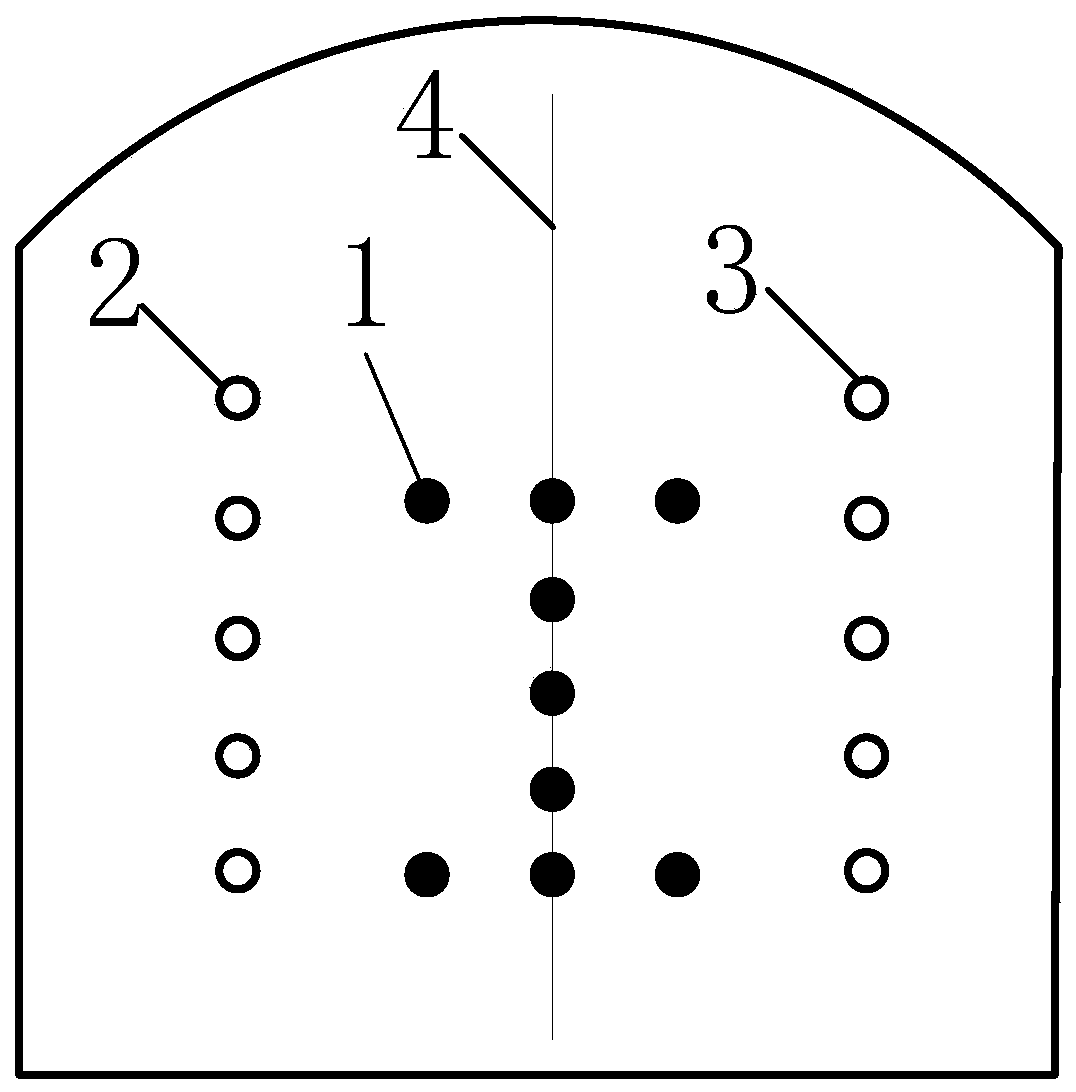

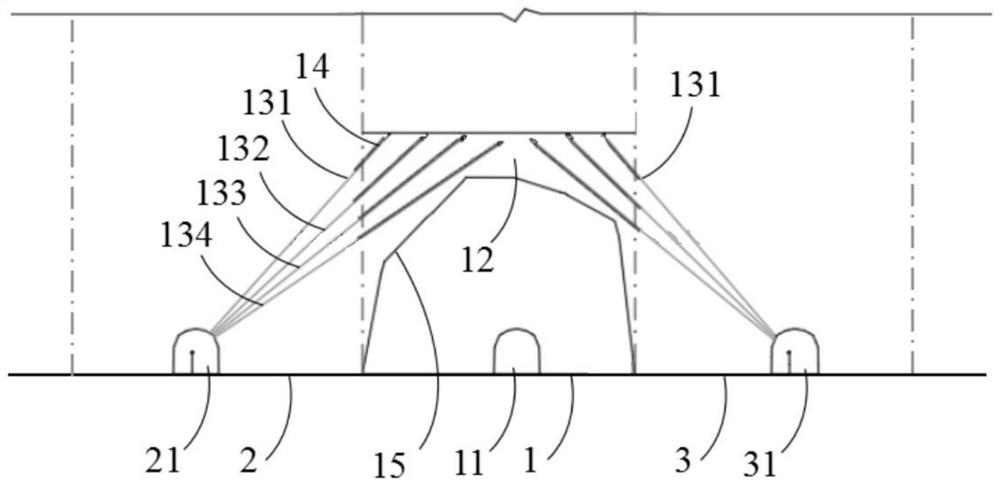

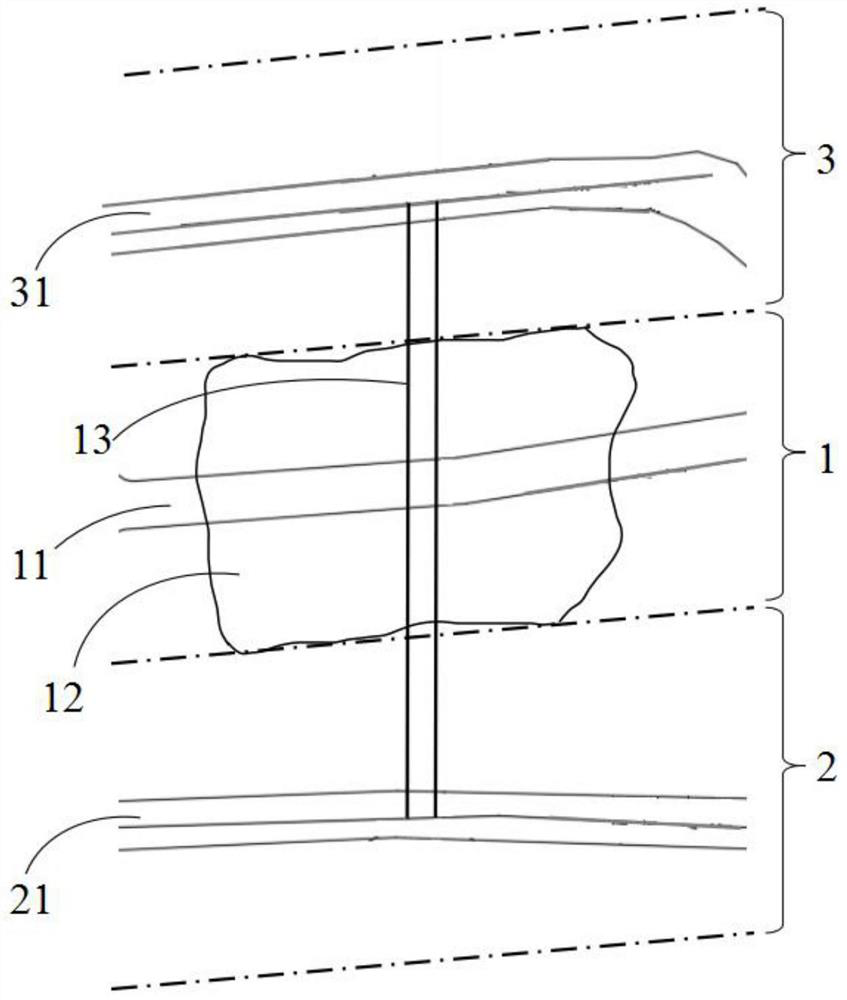

A kind of H-shaped reinforced cutout structure and cutout method

The invention relates to the technical field of tunnel rock mass tunneling blasting engineering and discloses an I-shaped reinforcing underholing structure and an underholing method. The I-shaped reinforcing underholing structure comprises blastholes distributed in a blasting network, wherein the blastholes comprise middle underholing holes (1), left underholing holes (2) and right underholing holes (3), wherein the middle underholing holes (1) are uniformly formed in the central line (4) of a tunnel face; the left underholing holes (2) are formed in the left side of the central line (4); theright underholing holes (3) are formed in the right side of the central line (4); and the middle underholing holes (1) are I-shaped reinforcing underholing holes. For tunnel blasting tunneling, the I-shaped reinforcing underholing structure can obtain an ideal blasting effect when the space between two adjacent underholing holes is excessively large, can reduce the influence caused by excessivelylarge space between two adjacent underholing holes, and provides engineering reference for rapid tunneling of a lithological tunnel of the same type.

Owner:CHENGDU UNIV

Blast hole blocking device for blasting construction

PendingCN112629348AImprove the blocking effectEasy to operateBlastingClassical mechanicsStructural engineering

The invention relates to a blast hole blocking device for blasting construction and a blast hole blocking method, and belongs to the technical field of blasting engineering. The device is provided with a channel allowing a detonating cord to penetrate through, and meanwhile the device further comprises an end plate, a shaft rod, connecting rods, a support, elastic stress rods, supporting rods and the like. In the implementation process, the overall specification of the device is matched with the diameter of a blast hole, and the device is integrally placed at a blast hole blocking position. During blasting, blasting impact waves act on the end plate, the shaft rod moves outwards through the instantly-generated blasting impact force, connecting ends of the connecting rods and connecting ends of the elastic stress rods form the expansion effect through hinge structures of the connecting rods, and therefore the elastic stress rods are tightly attached to the wall of the blast hole, and the better blast hole blocking effect is achieved. The device can be applied to horizontal blast holes and can also be applied to various blast holes such as vertical blast holes and inclined blast holes. The device is convenient to operate and high in packing quality assurance.

Owner:POWERCHINA CHENGDU ENG

Safe and efficient mining method for segmented medium-length hole stope

ActiveCN113605895AReduce loss rateSafe and Efficient Mining OperationsUnderground miningBlastingTEX-explosiveMining engineering

The invention provides a safe and efficient mining method for a segmented medium-length hole stope. The method comprises the steps that an ore body to be mined is divided into segmented stopes and mined step by step, when a hanging roof occurs in the mining process, medium-length hole blast holes are constructed in rock drilling roadways of the left and right adjacent stopes to the hanging roof area for millisecond blasting treatment, continuous deterioration of the normal row face blasting hanging roof condition is avoided, and smooth proceeding of medium-length hole stope mining operation is guaranteed. The medium-length hole blast hole charging part is the range with the hanging roof in the medium-length hole stope in one step, the charging method can achieve efficient and accurate blasting of the hanging roof, waste of explosives cannot be caused, and the stability of the ore body and surrounding rock mass in the adjacent stopes is not affected. According to the method, timely treatment can be carried out when the hanging roof occurs in the segmented medium-length hole stope, the method has the advantages of being accurate in blasting, high in construction efficiency and low in cost, the ore loss rate can be effectively reduced, the ore crushing quality can be improved, and a guarantee is provided for efficient and safe operation of subsequent normal row face blasting engineering of the stope.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Blasting expanding element special for underground blasting engineering

ActiveCN111238325AAchieve detonation efficiencyImprove detonation performanceBlastingDetonatorDetonation

The invention discloses a blasting expanding element special for underground blasting engineering, and belongs to the field of blasting instruments and the blasting engineering. The blasting expandingelement comprises a fixing block. The fixing block comprises a sub-fin section and a barrel section. The fixing block is provided with a fixing block center hole, the fixing block center hole penetrates through the sub-fin section and the barrel section, the end, away from the barrel section, of the sub-fin section is closed, and 3-6 fin blocks are arranged on the portion, on the periphery of thefixing block center hole, of the sub-fin section. The blasting expanding element further comprises a blasting expanding powder column pipe shell, a blasting expanding powder column is pressed in theblasting expanding powder column pipe shell, and the blasting expanding powder column pipe shell is located at the position, at the bottom of the sub-fin section, of the center hole. The blasting expanding element further comprises a sealing plug, a sealing plug center hole is formed in the center of the sealing plug, and the sealing plug is arranged in the fixing block center hole and makes contact with the end face of the blasting expanding powder column. Automatic assembly can be achieved, the production efficiency is high, the cost is low, and meanwhile the problems that in the undergroundblasting engineering, as detonation waves compress adjacent detonators, blasting failure or a groove effect is caused, and explosive is under blasting failure are solved.

Owner:YAHUA GROUP MIANYANG INDAL

Umbrella-shaped snap-in hanger and method of using the umbrella-shaped snap-in hanger to charge blast holes

The invention discloses an umbrella-shaped detent hanger. An umbrella framework structure is used for reference, elastic rope yarns or springs are mounted to make surface frames have the unfolding trend, and a hanging fixed pulley is further arranged at the lower end of the structure. When the umbrella-shaped detent hanger is matched with a charging long bag for charging an upward or horizontal or downward gently inclined deep blind hole with the enlarged hole bottom, the umbrella-shaped detent hanger is clamped at the hole bottom, the charging long bag is dragged into the blast hole through a rope winds around the fixed pulley, breakage and deformation of a blasting charge can be avoided, accurate spacing charging and non-coupling charging are achieved, and the problems of charging and blockage of upward or horizontal or downward gently inclined deep blind holes are solved. The umbrella-shaped detent hanger is simple in structure and wide in available material source, and mass industrial production and usage are easy. The construction method provided by the invention is wide in application range and can be widely used for projects of demolition blasting, soil and rock blasting, controlled blasting and mine blasting, and the technical scheme with the high cost performance is provided for deep hole charging.

Owner:叶建军

A blast hole plugging device

ActiveCN111336879BEasy to operateHigh packing quality assuranceHydro energy generationBlastingEngineeringExplosives engineering

The invention relates to a blast hole plugging device, which belongs to the technical field of blasting engineering auxiliary devices. The invention includes a positioning structure, an extrusion plug and a fastening bolt. The positioning structure includes an end plate, a central column, a connecting rod and an extrusion strip. One end of the central column is fixed and vertically connected to the center of the end plate, and the other end is provided with a External thread structure, the connecting rod is a plurality of pieces arranged at intervals along the circumference of the central column, one end of the connecting rod is fixedly connected to the end plate, the other end has an outwardly bent convex section, and the extruded bar is along the center There are multiple pieces arranged at intervals in the circumferential direction of the column, and the extrusion strip is arranged at the position between the connecting rods, and there is a fixed connection between the extrusion strip and the positioning structural member; the extrusion plug has a through hole for the central column to pass through, and the connection The inner space enclosed by the rod can allow the extrusion plug to be inserted, and the fastening bolt has a threaded hole adapted to the external thread on the central column. The invention is convenient to operate and has high packing quality assurance.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

Heavy ammonium nitrate-fuel oil explosive with detonator sensitivity produced by using chemical sensitization

InactiveCN101967073BSmall critical diameterGood detonator sensitivityExplosivesDetonatorFoaming agent

The invention relates to a heavy ammonium nitrate-fuel oil explosive with detonator sensitivity produced by using chemical sensitization and a preparation method thereof. The heavy ammonium nitrate-fuel oil explosive comprises the following components in percentage by mass: 5-55 percent of emulsion explosive and 45-95 percent of porous granular ammonium nitrate-fuel oil explosive. The preparationmethod comprises the following steps of: preparing the porous granular ammonium nitrate-fuel oil explosive; preparing a latex matrix; sensitizing the latex matrix; and mixing the emulsion explosive with the porous granular ammonium nitrate-fuel oil explosive. The heavy ammonium nitrate-fuel oil explosive with detonator sensitivity has small critical diameter, favorable detonator sensitivity and large capacity power without igniting an igniting primer, and can be used for various blasting engineering, such as medium-small blast hole, big hole diameter and upward fan-shaped medium-length hole, and the like. In the invention, the chemical sensitization is carried out by utilizing a brand new and quick chemical foaming agent at the same time. The novel quick chemical foaming agent has the characteristics of high foaming speed, thoroughly eliminated after-effect and fine and stable bubbles, and is a novel safe and effective chemical sensitization technique.

Owner:谢斌

Blast hole blocking device for tunnel blasting

PendingCN111220038AEasy to operateHigh packing quality assuranceBlastingExplosives engineeringMechanical engineering

The invention relates to a blast hole blocking device for tunnel blasting and belongs to the technical field of blasting engineering auxiliary devices. The blast hole blocking device comprises a packing structural component, wherein the packing structural component comprises a baffle plate and a connecting rod; one end of the connecting rod is perpendicularly and fixedly connected into the middleof the baffle plate; an operating end is arranged at the other end of the connecting rod; a plurality of parallel stressed rods are arranged on the periphery of the connecting rod; the axis of each ofthe stressed rods is parallel with that of the connecting rod; each of the stressed rods is connected with the connecting rod through at least two springs; an electromagnet is arranged on the connecting rod; the electromagnet, a wire, a switch and a power supply are cooperated to form an operating circuit; the switch is arranged at the operating end of the connecting rod; the stressed rods are made of magnetic attraction material; and the packing structural component is provided with a passage allowing a detonating cord to penetrate through. The blast hole blocking device is convenient to operate and is high in packing quality guarantee.

Owner:POWERCHINA CHENGDU ENG

A Method for Cracking Coal and Rock Mass by Impacting Gas Explosion with Supercritical CO2 Point Jet

ActiveCN108999596BSolve the defects of gas explosion fracturing technologyImprove rock breaking abilityFluid removalThermodynamicsEngineering

Owner:LIAONING TECHNICAL UNIVERSITY

A device for removing tree roots from blast holes in dangerous rock masses

ActiveCN113575347BImprove the effect of choppingEasy to operateForestryTree rootStructural engineering

The invention discloses a device for removing roots from blast holes in dangerous rock mass blasting, belonging to the technical field of blasting engineering. The two ends of the fixed seat are stored in the chute opened by the support rods on both sides of the fixed bracket, the fixed seat is movably connected with the fixed bracket, and there is a clamping mechanism between the fixed seat and the fixed bracket for fixing The fixed seat and the fixed bracket, the top of the cutting knife is provided with a connecting rod, the top of the connecting rod is provided with a force plate, the connecting rod and the force plate are detachably connected, and the bottom end of the force plate and the top of the fixed seat are provided with There is a first spring, and the top of the fixed seat is provided with a limit plate to prevent the cutting knife from coming out of the fixed seat; the connecting rod at the top of the cutting knife can be split into multiple pieces, and the connecting rods are connected by threads. In the fixed seat, a tool is used to tap the chopper to cut off the root of the tree, which is convenient to operate and improves the operation safety.

Owner:ANHUI UNIV OF SCI & TECH

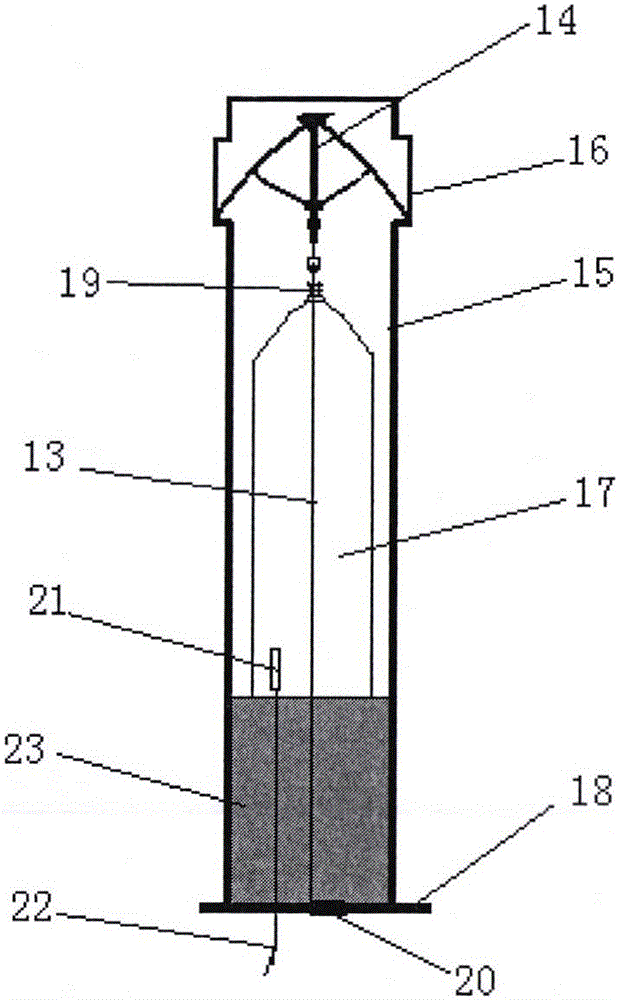

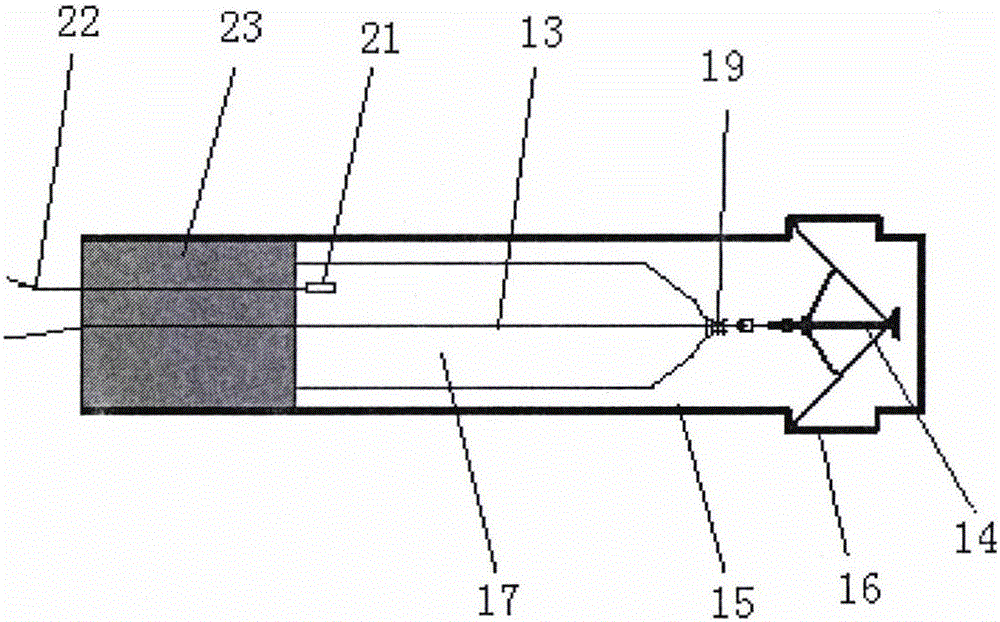

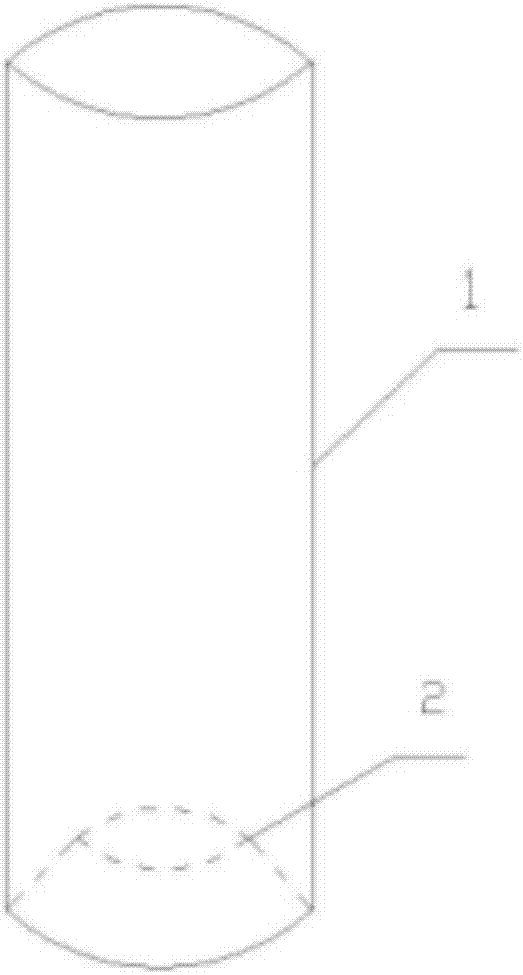

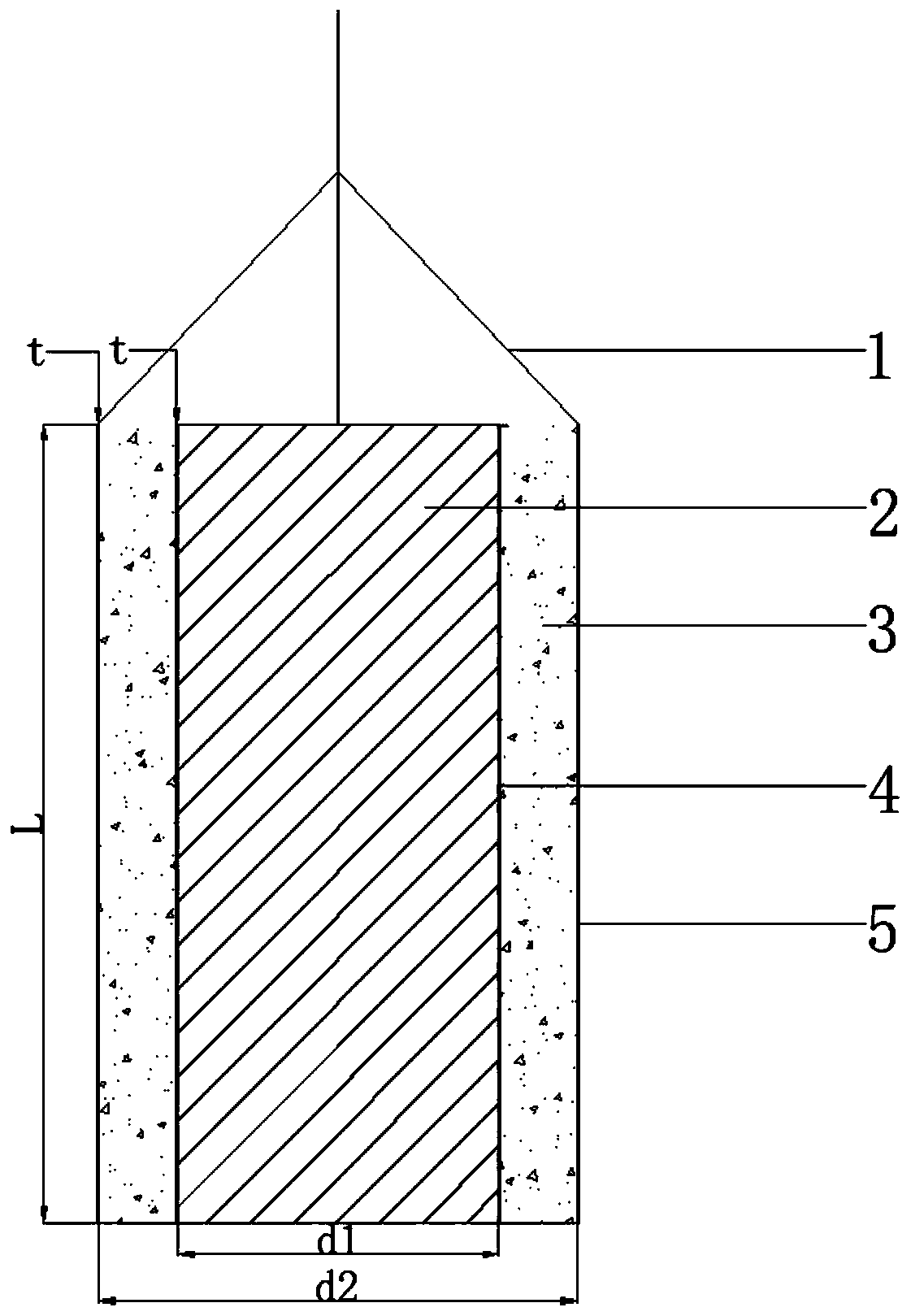

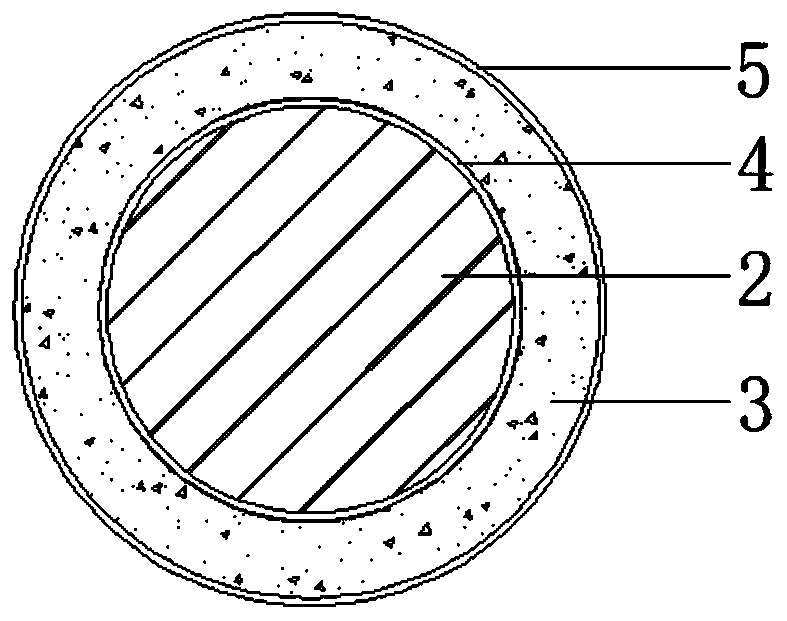

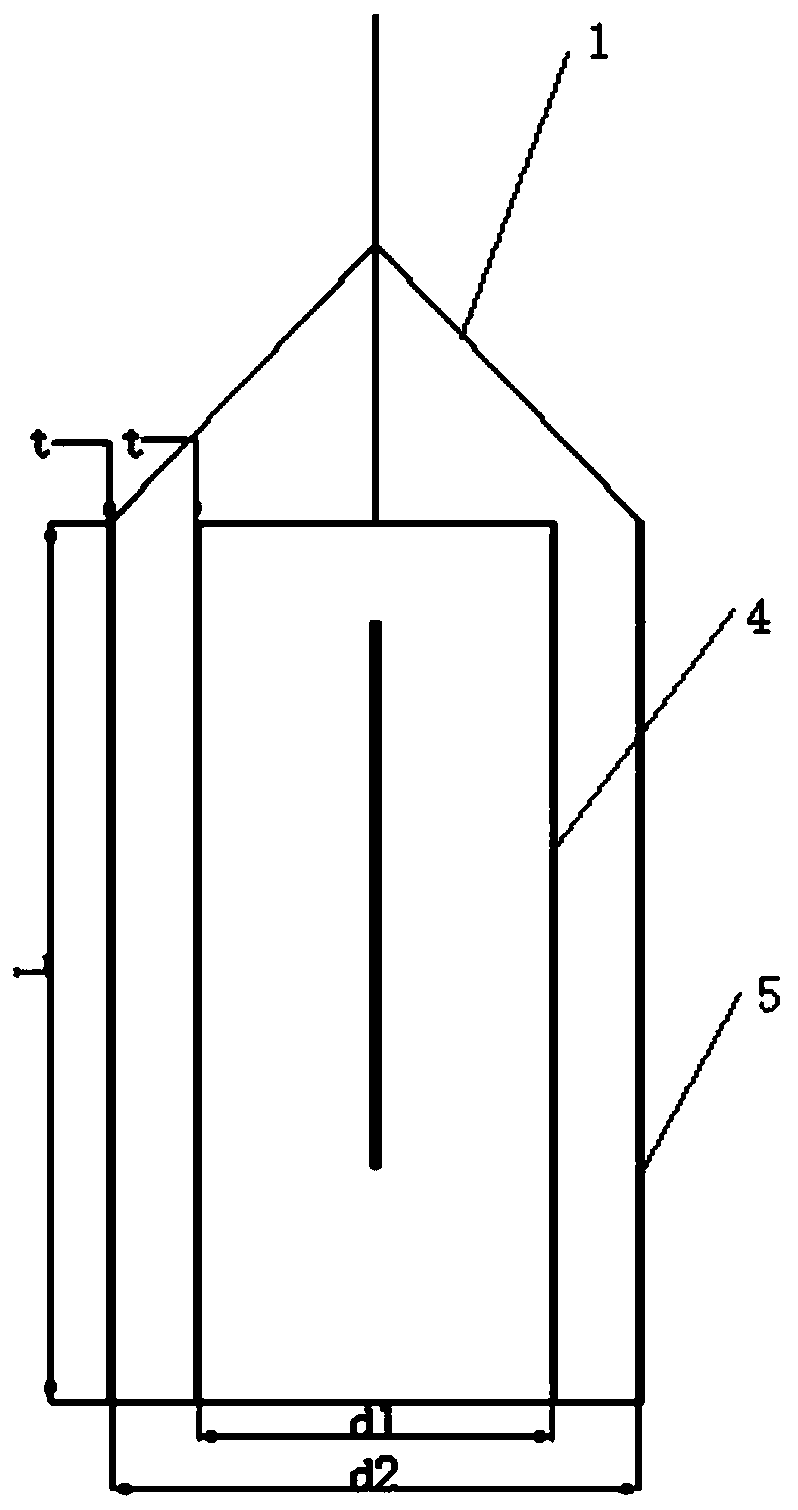

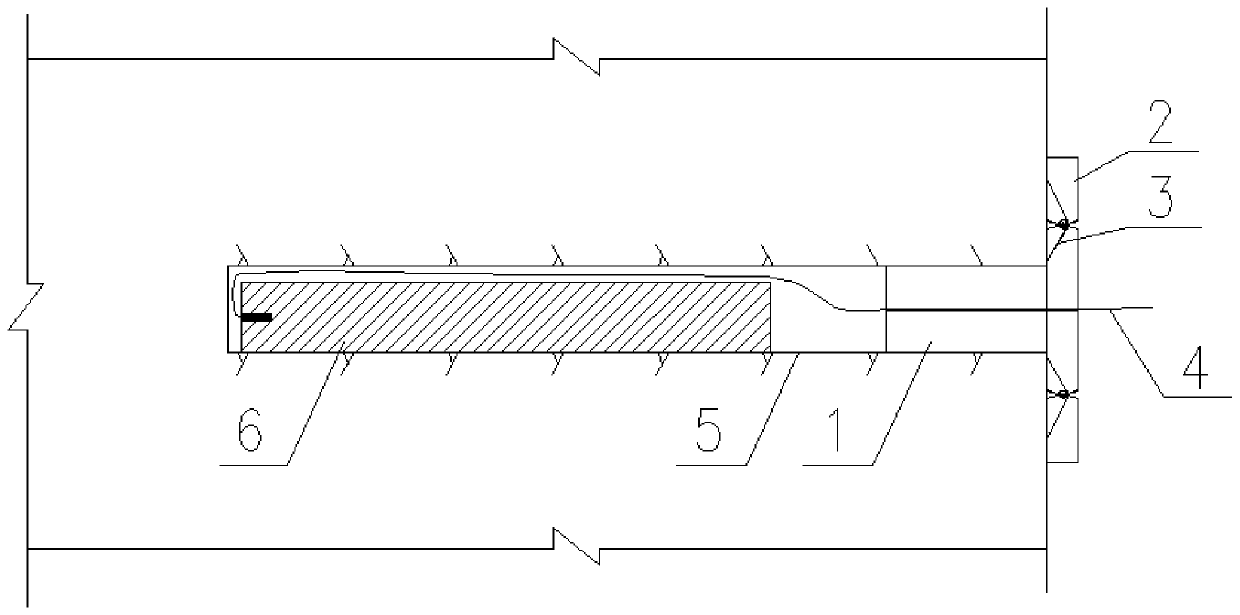

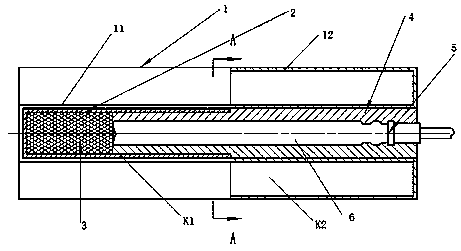

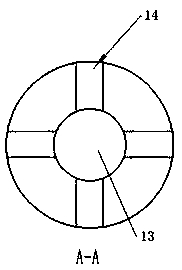

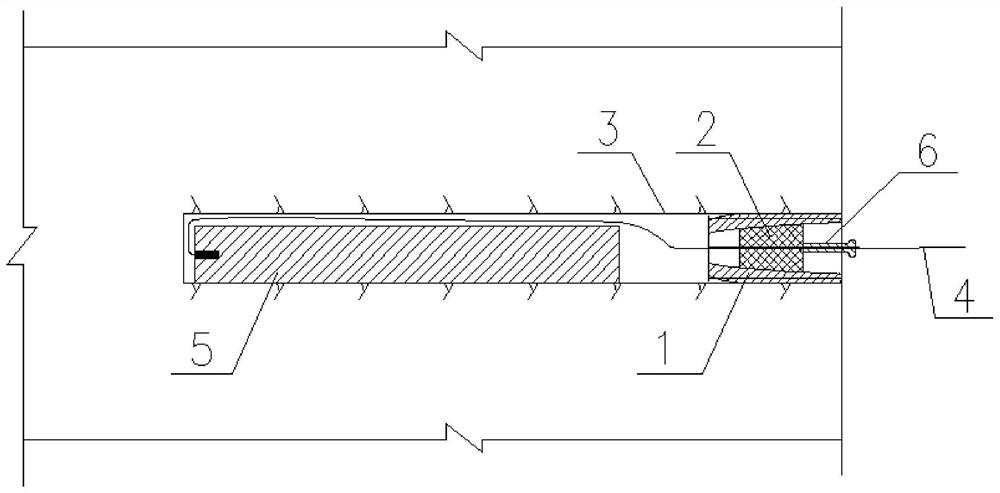

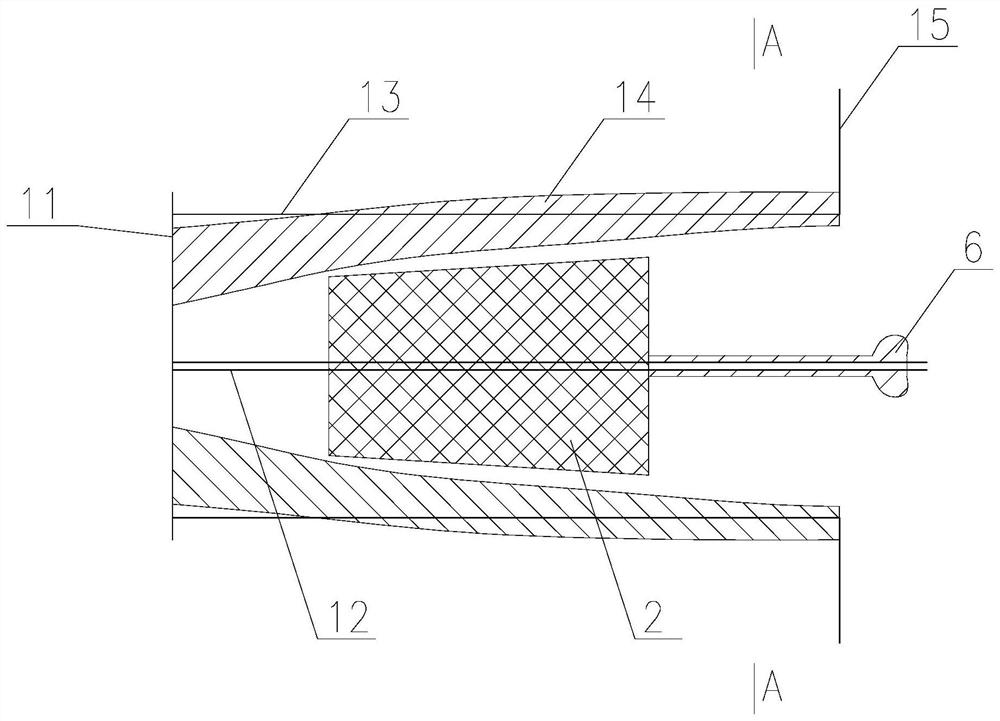

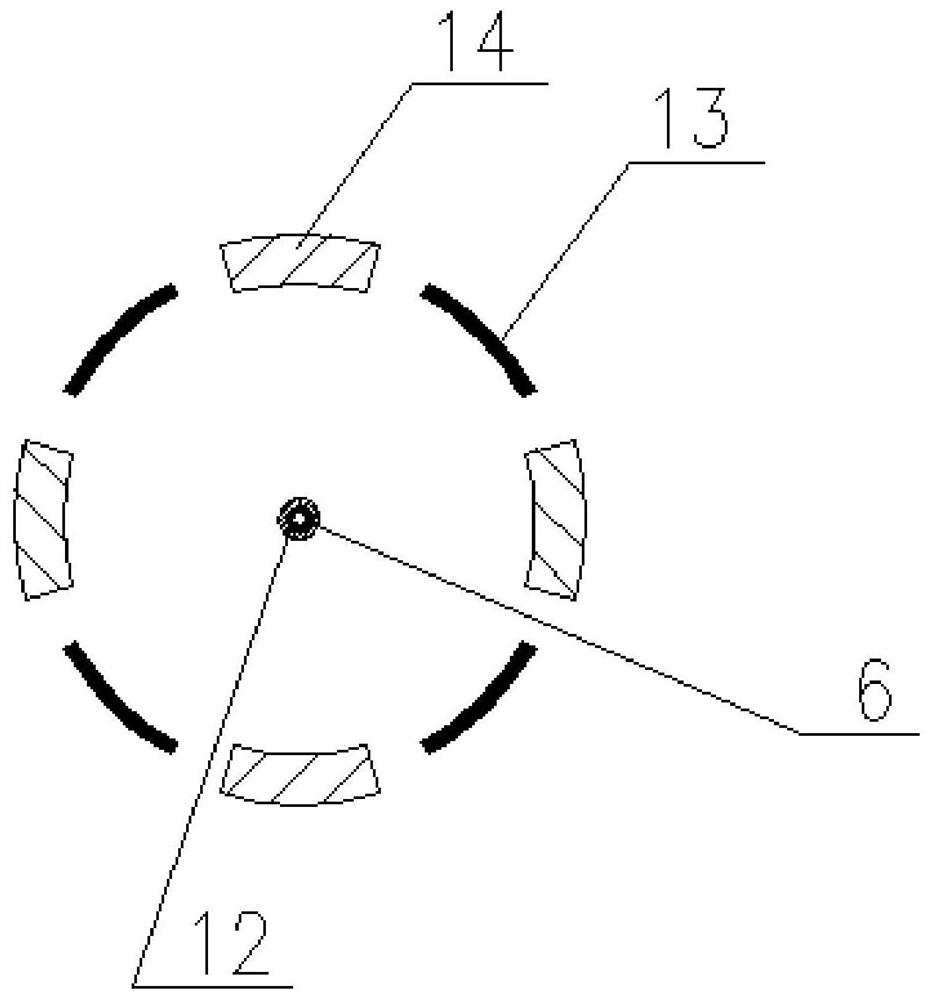

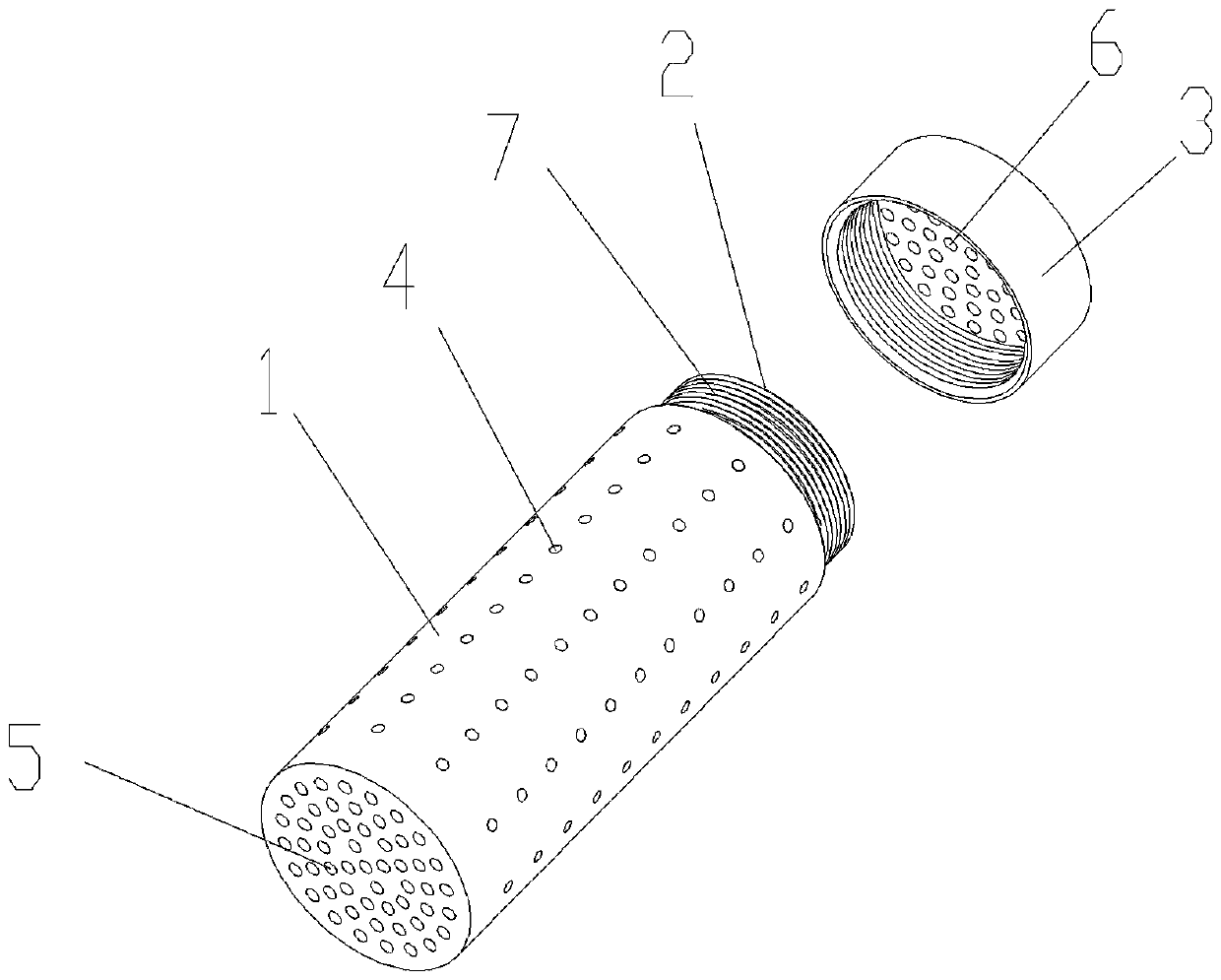

Explosive explosion-proof tube device for thermal analysis experiments

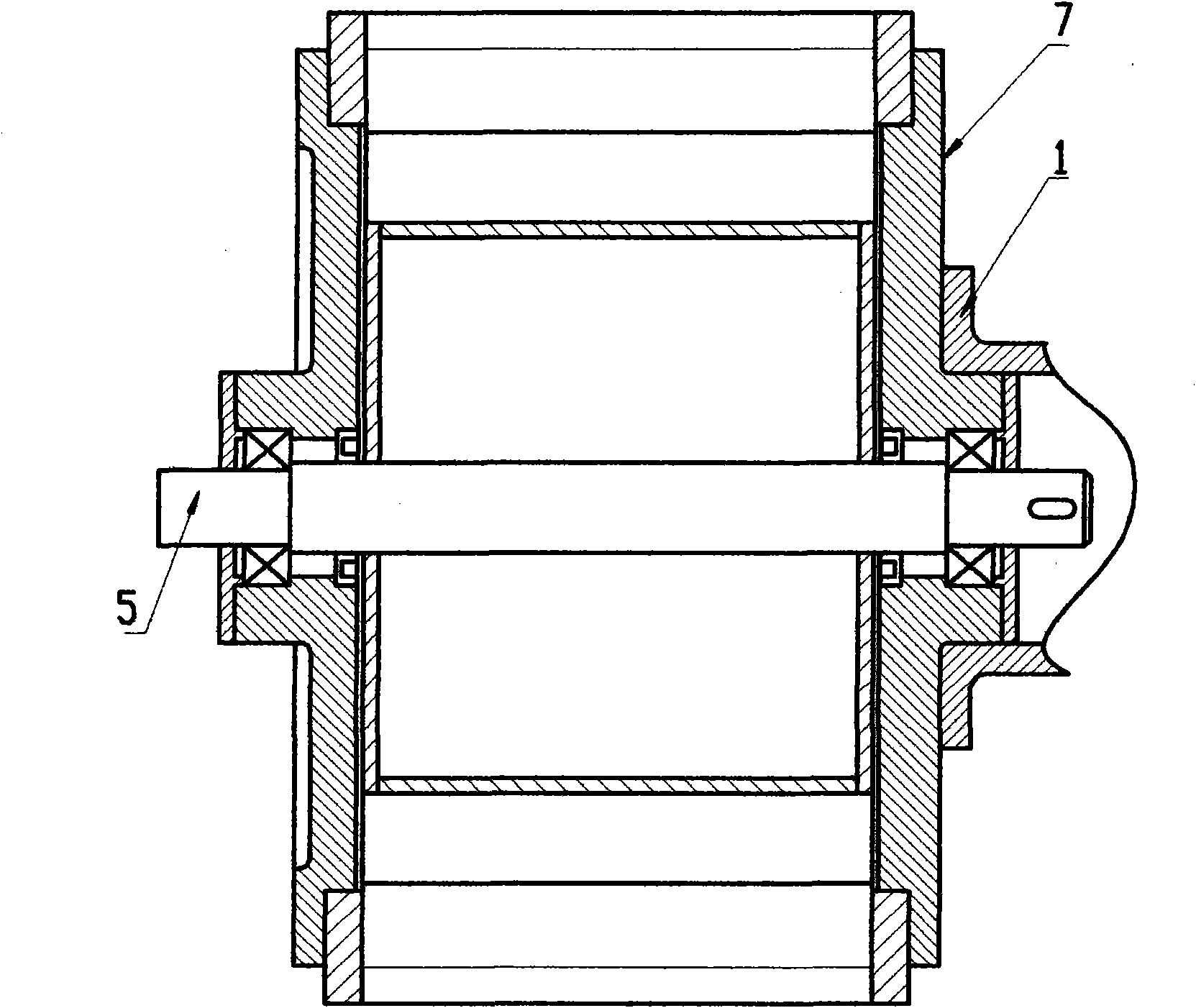

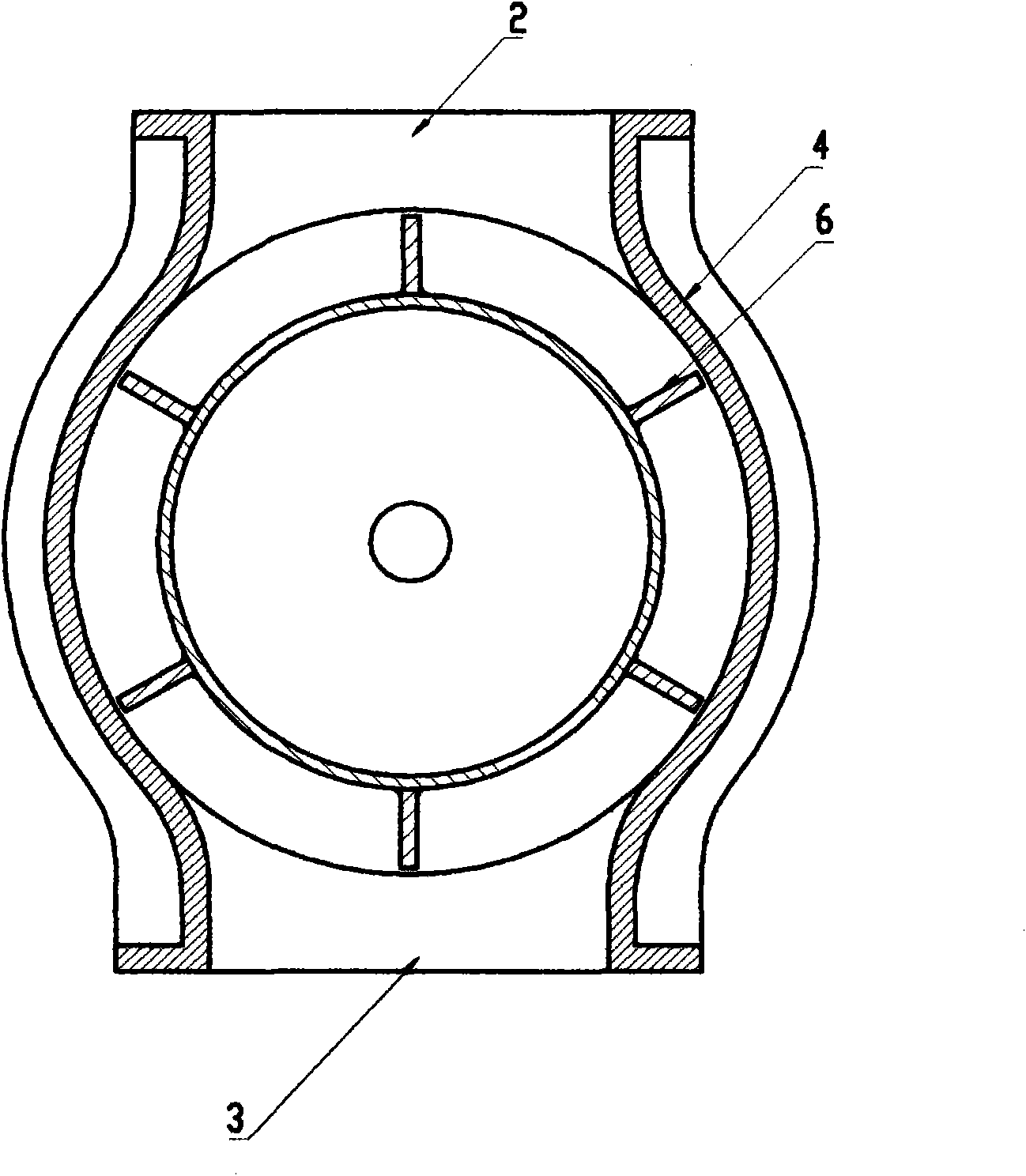

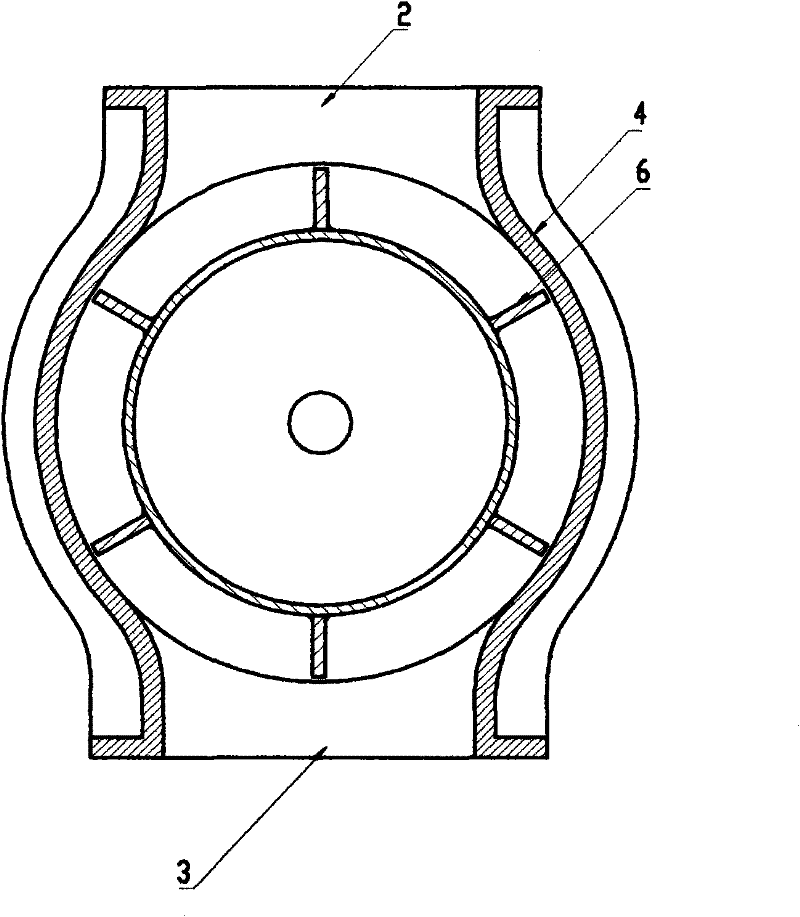

The invention relates to an explosive explosion-proof tube device for thermal analysis experiments, comprising a cylinder body (1). An end of the cylinder body (1) is provided with an opening (2), atwhich an end cap (3) is connected cooperatively. A set of lateral explosion venting holes (4) are arranged on the sidewall of the cylinder body (1); a set of bottom explosion venting holes (5) are arranged at the bottom of the cylinder body (1); and a set of end explosion venting holes (6) are arranged on the end cap (3). The invention has the following advantages: as the cylinder body of the device is in the shape of a cylinder, the cylinder body can simulate a blast hole of a blasting engineering practice, and the experimental result is closer to the engineering practice; the cylinder body is made of high-strength stainless steel to ensure rigidity of the cylinder body, and the cylinder body is rust-proof and corrosion resistant, the life is long; and with the arrangement of the lateralexplosion venting holes, the bottom explosion venting holes and the end explosion venting holes, blast wave generated by explosive blasting can be effectively released, the amount of explosive samplesfor thermal analysis experiments is increased, and safety of the experimental process is guaranteed.

Owner:ANHUI FANGYUAN MECHANICAL & ELECTRICAL

Explosion expansion element specially used for underground blasting engineering

ActiveCN111238325BAchieve detonation efficiencyImprove detonation performanceBlastingDetonatorDetonation

Owner:YAHUA GROUP MIANYANG INDAL

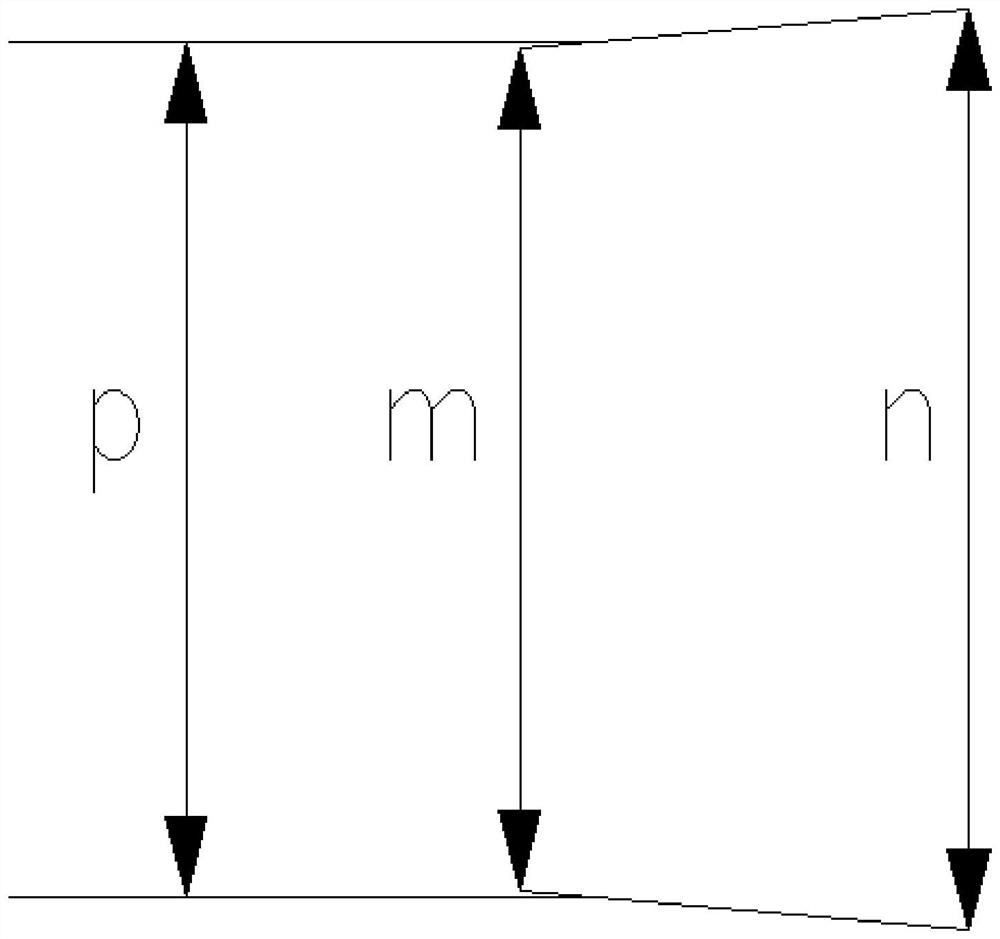

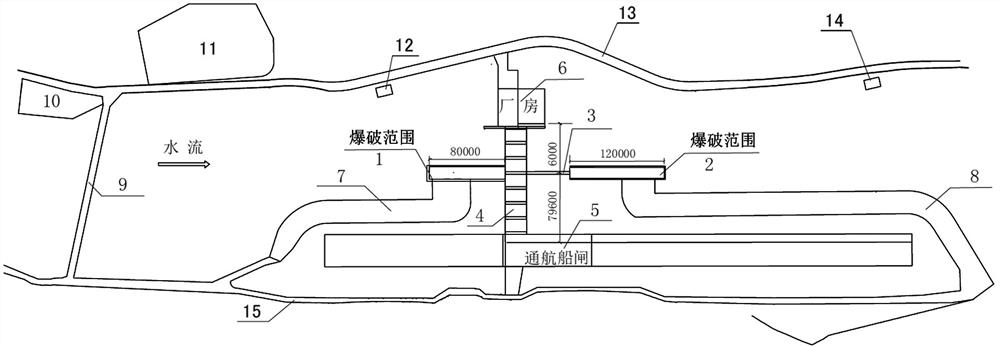

Cofferdam blasting demolition method based on combination of variable linear density charging and digital electronic detonator

ActiveCN113137898AAvoid dangerEnsure safetyBlastingFoundation engineeringArchitectural engineeringCofferdam

The invention provides a cofferdam blasting demolition method based on combination of variable linear density charging and digital electronic detonators. According to the cofferdam blasting demolition method based on the combination of the variable linear density charging and the digital electronic detonators, blasting demolition is successfully carried out on the cofferdam by researching the surrounding environment of a blasting area and a blasting scheme and adopting a digital electronic detonator detonating network and variable linear density charging method, the expected effect can be achieved through the method, safety of permanent buildings is guaranteed, and reference significance is achieved for similar blasting engineering.

Owner:中国能源建设集团广西水电工程局有限公司

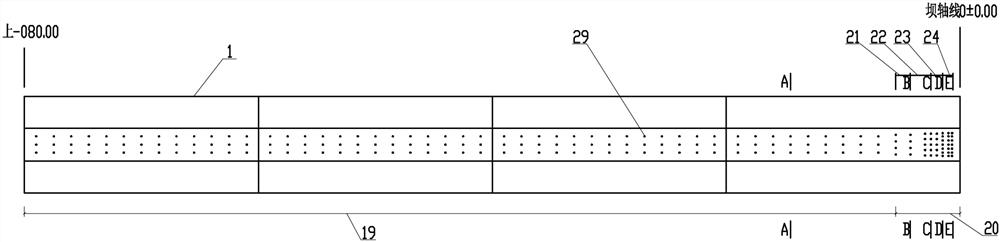

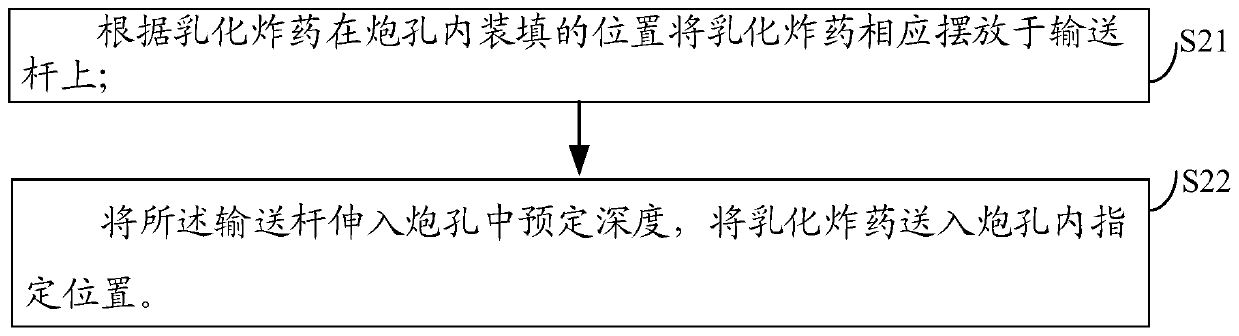

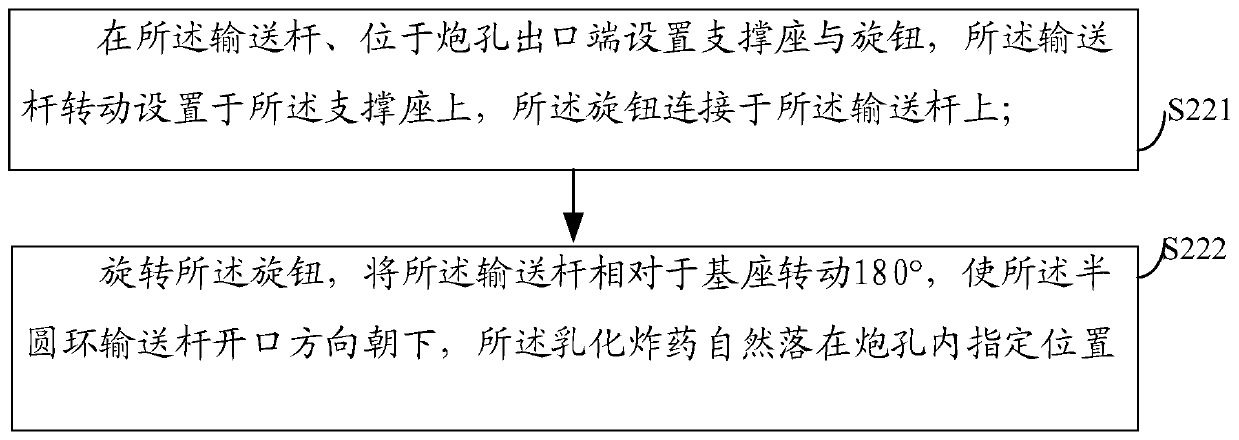

A charging method for deep hole blasting in rock roadway

The embodiment of the invention discloses a charging method for medium deep hole blasting in a rock roadway, and relates to the technical field of medium deep hole blasting engineering. The failure rate is low, and the simple and convenient and labor-saving effects during charging are achieved. The charging method comprises the steps that emulsion explosive is placed on a conveying rod according to the filling position of the emulsion explosive in a blasthole; the section of the conveying rod is in a semi-circular-ring shape and used for bearing the emulsion explosive, and a wire winding structure is arranged in the length direction of the conveying rod and used for fixing an ignition guide wire; and the conveying rod extends into the blasthole by the predetermined depth, and the emulsionexplosive is conveyed into the specified position in the blasthole. The charging method for medium deep hole blasting in the rock roadway is suitable for blasting engineering such as roadways, tunnelsand mines.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com