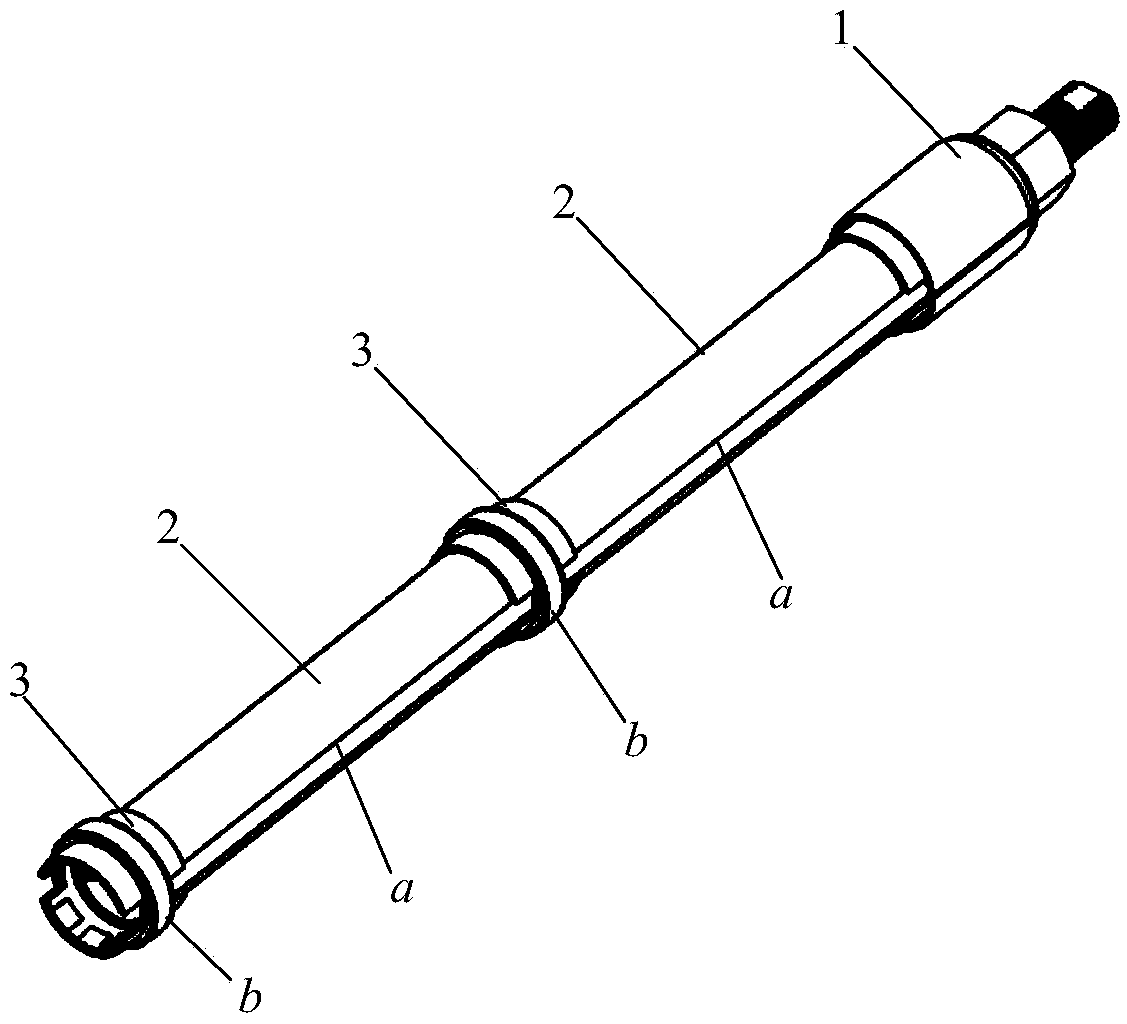

Linear energy gathering smooth blasting device

A smooth blasting and energy-gathering technology, which is applied in the field of rock blasting equipment, can solve problems such as difficult installation, inability to center pre-splitting blasting devices, and large deviation, and achieve the effects of easy installation, convenient transportation, and reduced deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

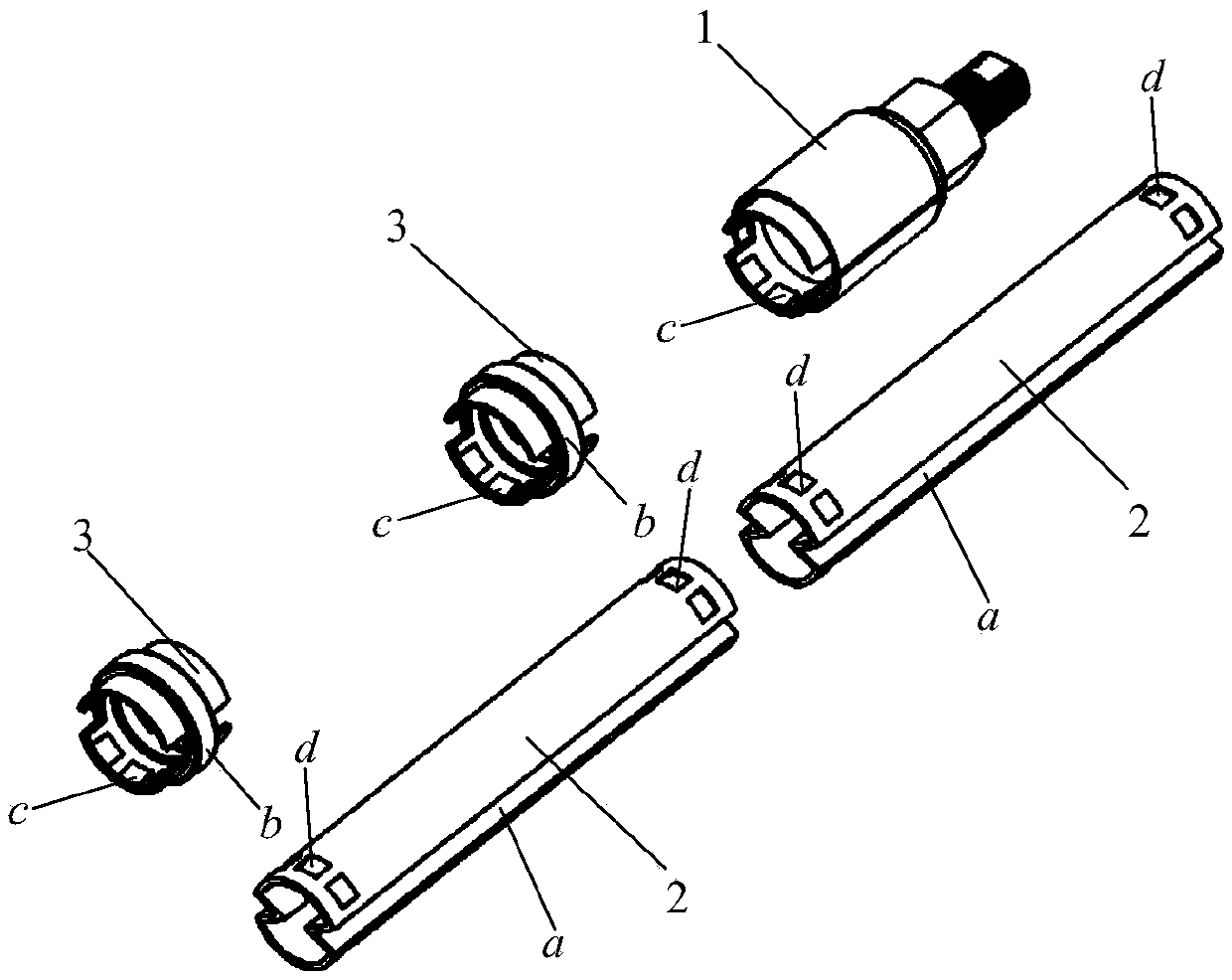

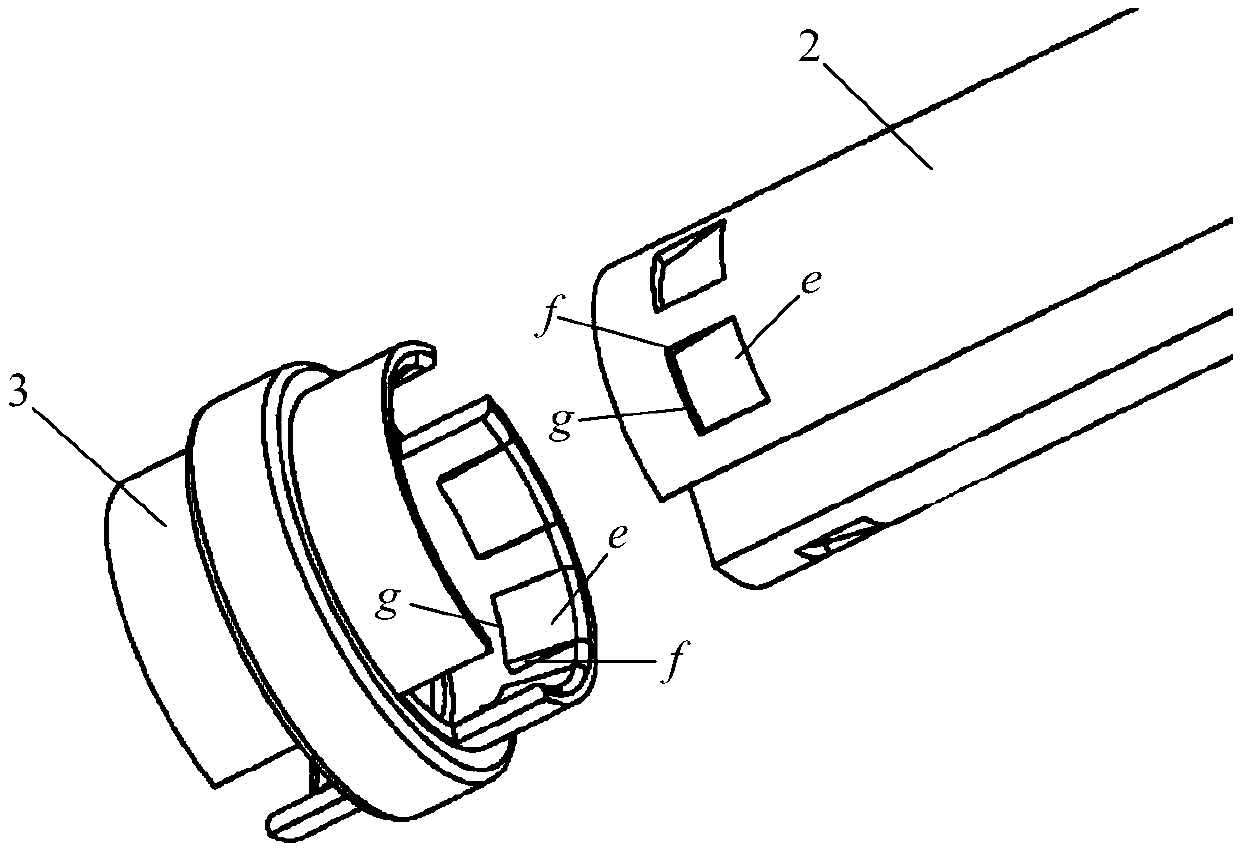

[0043] The orifice fixing device 1 and the energy-gathering standard section 2 of the present invention must meet the requirements of being fixed together, and at the same time meet the requirements of being fixed on the orifice according to the pre-cracking direction;

[0044] For the requirement of being fixed together, the present invention has a permanent unilateral buckle or a permanent ring buckle fixed together with the connecting energy-gathering standard section 2 on the connecting rod 11 of the orifice fixing device 1, and it can be made into a protruding surface as required The inner buckle (or outer buckle) or the outer buckle (or inner buckle) of the concave surface, the optimal solution of the present invention is: the inner buckle of the protruding surface;

[0045] For the requirement of being fixed on the orifice according to the pre-splitting direction, the present invention is based on the characteristics of the present invention being fixed in the blast hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com