A Method for Cracking Coal and Rock Mass by Impacting Gas Explosion with Supercritical CO2 Point Jet

A technology of jet impact, coal and rock mass, applied in the direction of mining fluid, earthwork drilling, wellbore/well parts, etc., can solve problems such as unfavorable, poor fracturing effect, unsatisfactory blasting and rock breaking effect, etc., and achieve cost Low, improve the blasting range and rock breaking effect, and expand the effect of effective cracking range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

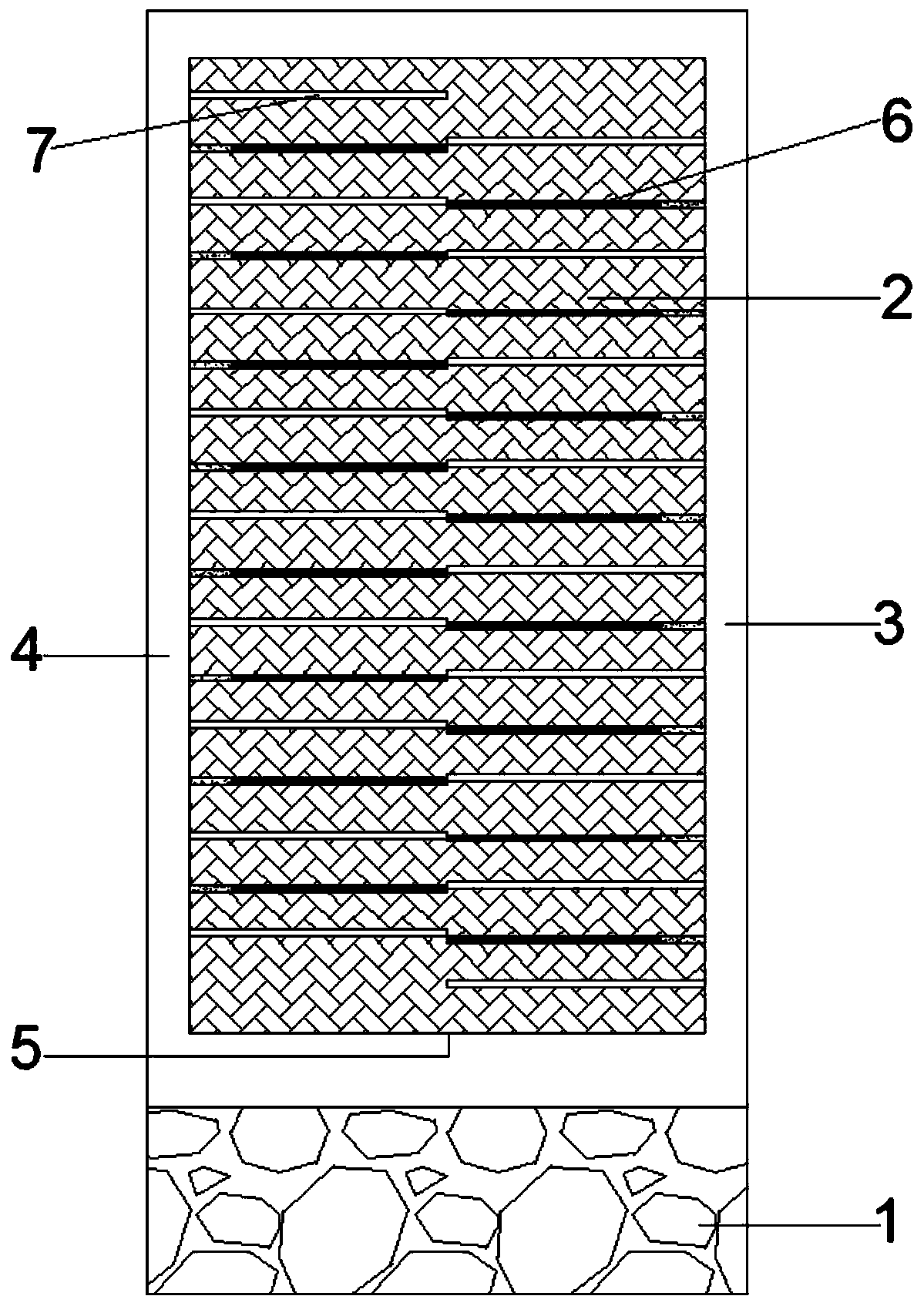

[0052] a supercritical CO 2 The method for cracking coal and rock mass caused by point-type jet impacting gas explosion, this embodiment is a method for increasing the permeability of coal mass, and its specific implementation is as follows: figure 1 , figure 2 shown:

[0053] Step 1. From the air inlet road (4) and the return air road (3) to the coal seam (2), make the working face (5) half-length and staggered drill holes as blasting holes (6), observation For the hole / drainage hole / control hole (7), the distance from the blasting hole (6) to the working face (5) is greater than the minimum resistance line of coal blasting;

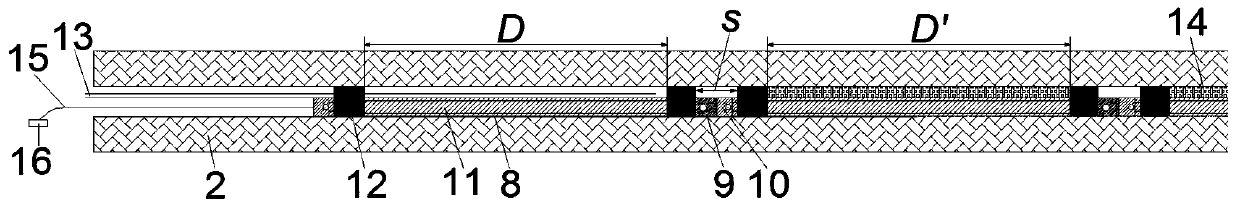

[0054] Step 2. Liquid CO employed 2 One end of the cracker (8) is provided with an energy discharge valve (9), the other end is provided with a charging valve (10), and the pipe body between the energy discharge valve (9) and the charging valve (10) is an energy storage pipe (11). ), the liquid CO 2 The cracker (8) is provided with a detonation ci...

Embodiment 2

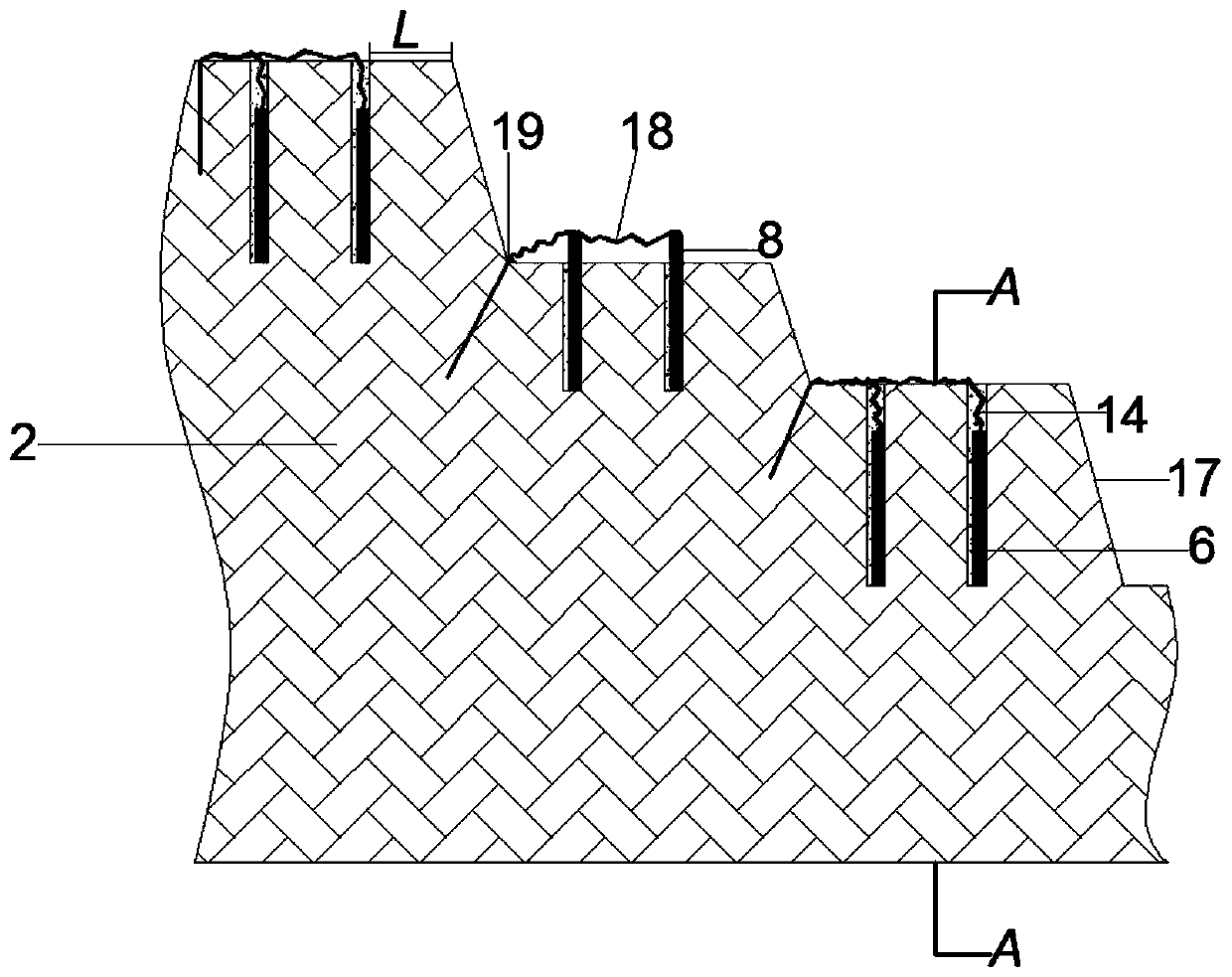

[0063] a supercritical CO 2 The method for cracking coal and rock mass caused by point jet impact gas explosion, this embodiment is a method for blasting open-pit coal seam, and its specific implementation is as follows: image 3 , Figure 4 , Figure 5 (b) shows:

[0064] Step 1. On the steps of the open-pit coal seam (2), drill vertical holes row by row as blasting holes (6). (2) The shortest distance (L) from the outermost blasting hole (6) of the step to its surrounding empty surface (17) is less than the minimum resistance line of coal blasting;

[0065] Step 2. Using chains (18) and liquid CO 2 The fracturing device (8) is bundled with the filling valve (10), and the chain (18) is anchored in the stable coal and rock body outside the blasting affected area through the anchor (19) to prevent liquid CO 2 The cracker (8) is thrown away, and then the liquid CO 2 The cracker (8) is pushed to the bottom of the blasting hole (6), and the end of the energy release valve (9...

Embodiment 3

[0070] a supercritical CO 2 The method for cracking coal rock mass caused by point jet impact gas explosion, this embodiment is a method for blasting residual top coal, and its specific implementation is as follows: Image 6 , Figure 7 , Figure 8 shown:

[0071] Utilize supercritical CO 2 The method of blasting residual top coal by point jet impingement gas blasting and fracturing coal mass is basically the same as that in Example 2, and the difference lies in Step 1 and Step 5.

[0072] Wherein, step 1 is as follows: in the residual top coal (22), inclining boreholes are sequentially performed row by row as blasting holes (6), and the hole depth and row spacing are respectively based on the thickness of the residual top coal (22), the length of the overhang and the The physical and mechanical properties of the coal body are set, and the shortest distance from the outermost blasting hole (6) to its surrounding empty surface (17) is less than the minimum resistance line o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com