Explosion-method quick hole-blocking device

An explosion method and hole plugging technology, applied in the field of blasting, can solve the problems of high cost, limited device length, limited effect of increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

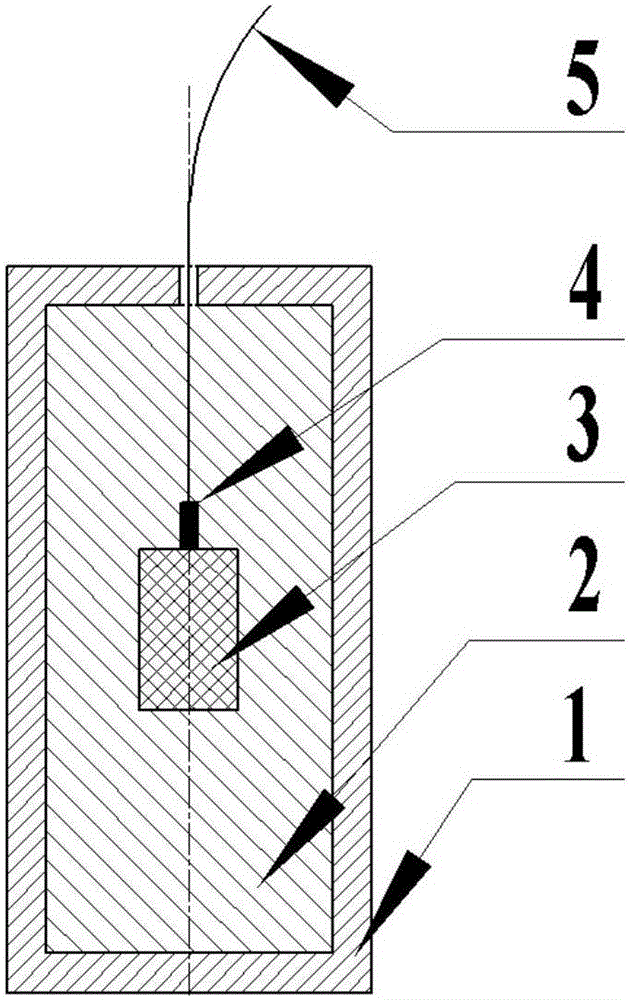

[0017] Such as figure 1 As shown, a plugging device with a cylindrical structure is designed, and the plugging device is composed of a shell 1, a filler 2, a plugging charge 3, an electric detonator 4, and an electric wire 5. Shell 1 is made of iron. According to the diameter of the blast hole used, the outer diameter of shell 1 is designed to be 130mm, the wall thickness is 5mm, and the length is 50cm; the plugging charge 3 is a piece of emulsion explosive with a specification of φ32mm3150g, which is located in the center of the plugging device. ; The filler 2 is sand; the detonating electric detonator 4 is a commonly used delayed electric detonator, MS5 (110ms).

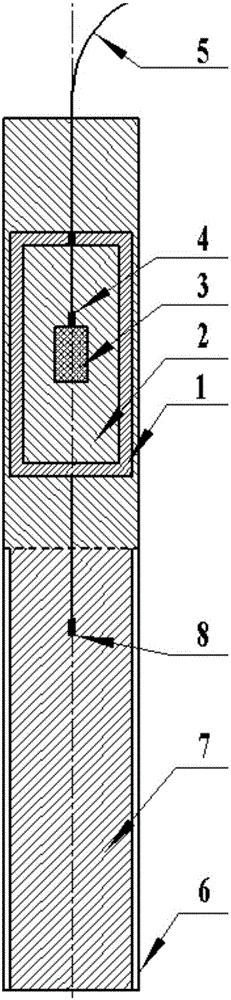

[0018] When using, see figure 2 , The blast hole 6 is a water hole with a diameter of 140mm and a depth of 10.0m. First, the main charge 7 and the detonator 8 (MS15, 880ms) are loaded into the blast hole 6. The main charge 7 is a strip-packed emulsion explosive with a diameter of φ130mm and a weight of 4kg. The ...

Embodiment 2

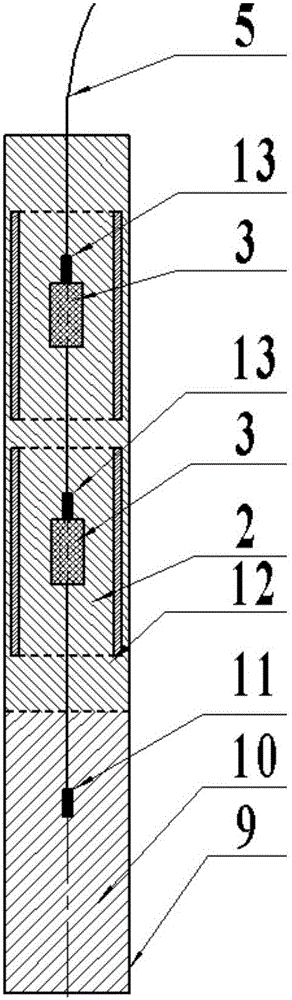

[0021] see image 3 . The hole plugging shell of embodiment 2 uses an open iron cylindrical structure. The blast hole 9 is a dry hole with a diameter of φ160mm and a depth of 12.0m. The used shell 12 has an outer diameter of 150 mm, a wall thickness of 10 mm, and a length of 40 cm; the emulsion explosive 3 is used as a plugging charge in the shell, and its specification is φ32mm3150g, which is arranged in the center of the shell. Each housing cooperates with a plugging drug pack to form the quick plugging device described in this patent. In Example 2, two plugging devices were used. The charge 10 at the bottom of the blast hole 9 uses powdery emulsion explosive, coupled charge, and the charge length is 10.0m. The plugging section 2 uses rock-soil and sand mixture, and two of the same plugging devices are set in the filling section, and the total length of the plugging section can be reduced to 2.0m. blocking device such as image 3 Arrangement, the distance from the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com