Self-propelled jet drill bit forradial horizontal well

A self-propelled, horizontal well technology, applied in the direction of liquid/gas jet drilling, drill bits, and driving devices for drilling in boreholes. Insufficient and other problems, to achieve the effect of improving rock breaking effect, improving stability, and improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

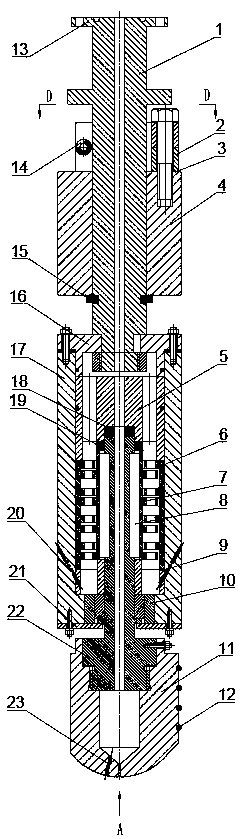

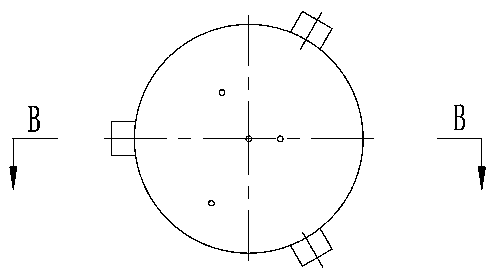

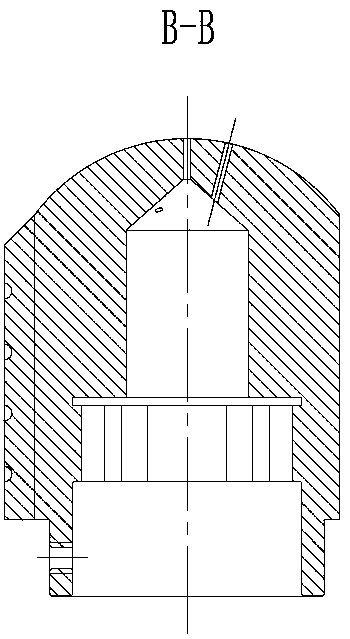

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] See attached figure 1 ~ attached Figure 8 As shown, a self-propelled jet drill bit for radial and horizontal wells provided in this embodiment mainly includes a drill bit 11, a drill tooth 12, a rotating shaft 22, a housing 17, a turbine stator 6, a turbine rotor 7, and a rear subsection 5. The centralizer 3 and the rear connecting pipe 1 are characterized in that: the casing 17 is equipped with a turbine system inside, the casing 17 is placed between the drill bit 11 and the centralizer 3, the front part is connected with the drill bit 11 through the rotating shaft 22, and the rear The central part is connected with the centralizer 3 through the rear connecting pipe 1, the turbine rotor 7 is fastened on the rotating shaft 22 through the rotor nut and two flat keys 8, and the rear part of the rotating shaft 22 is connected with the rear short joint 5 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com