Water hole charging device and charging method thereof

A technology of charging and water holes, applied in blasting and other directions, can solve the problem of difficulty in reaching the bottom of the blast hole, and achieve the effects of simple structure, ensuring safety and improving construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

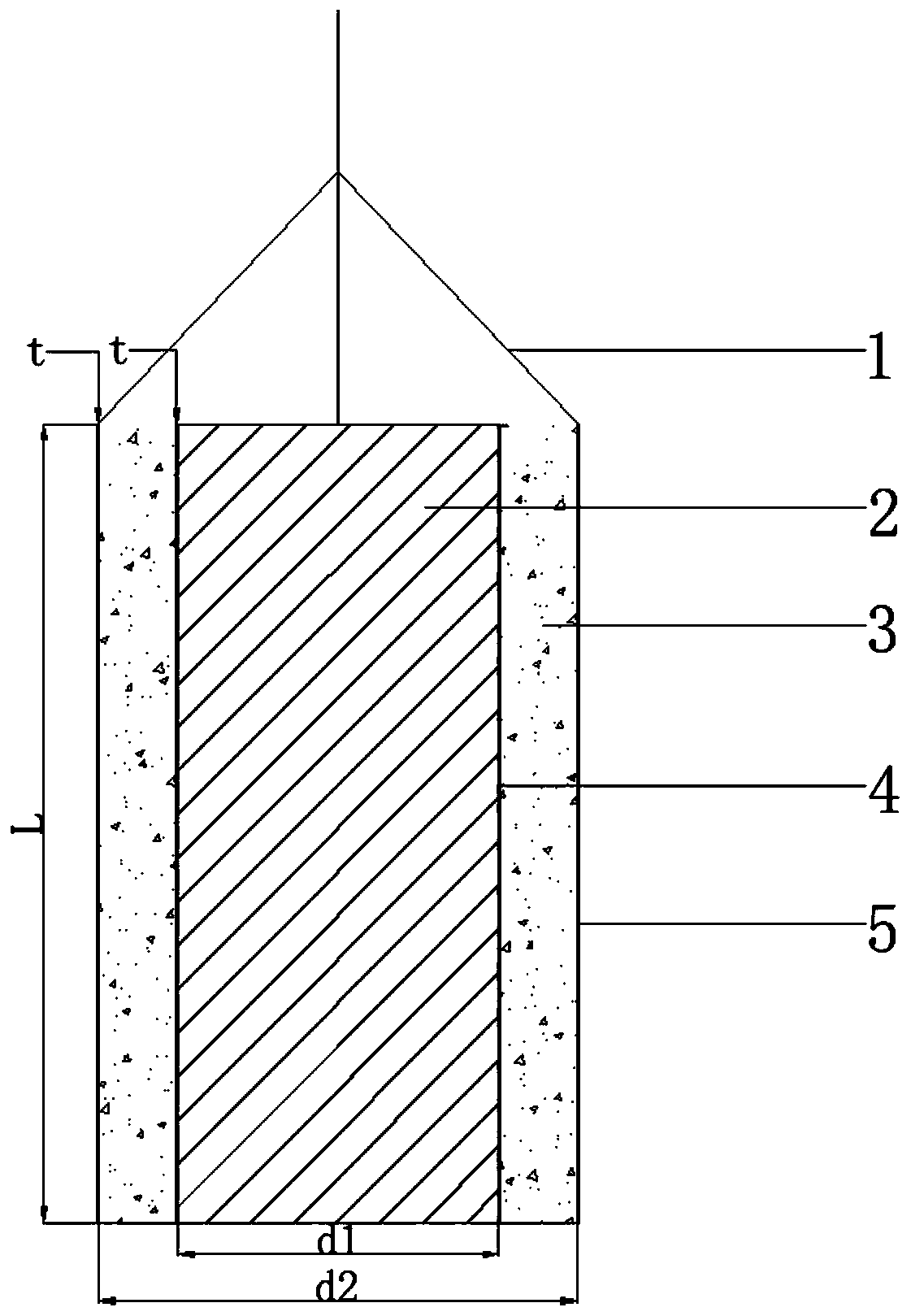

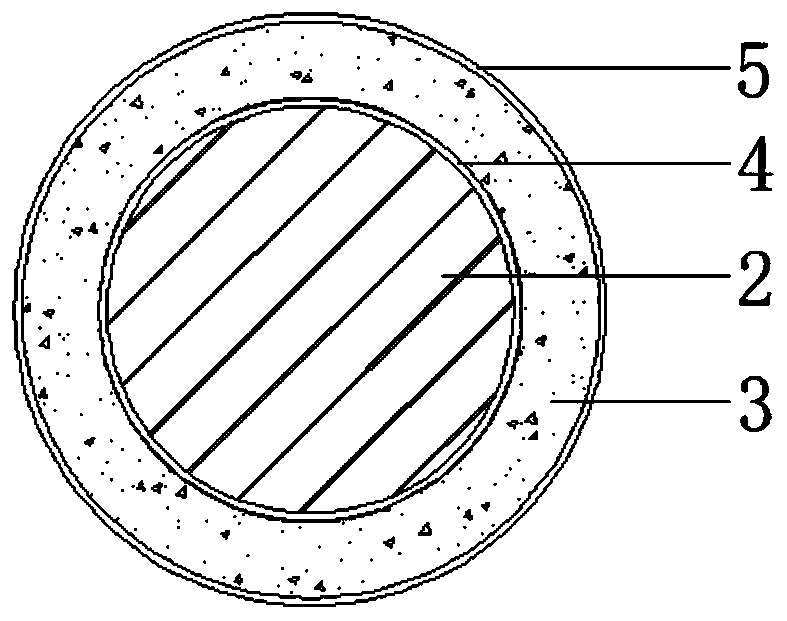

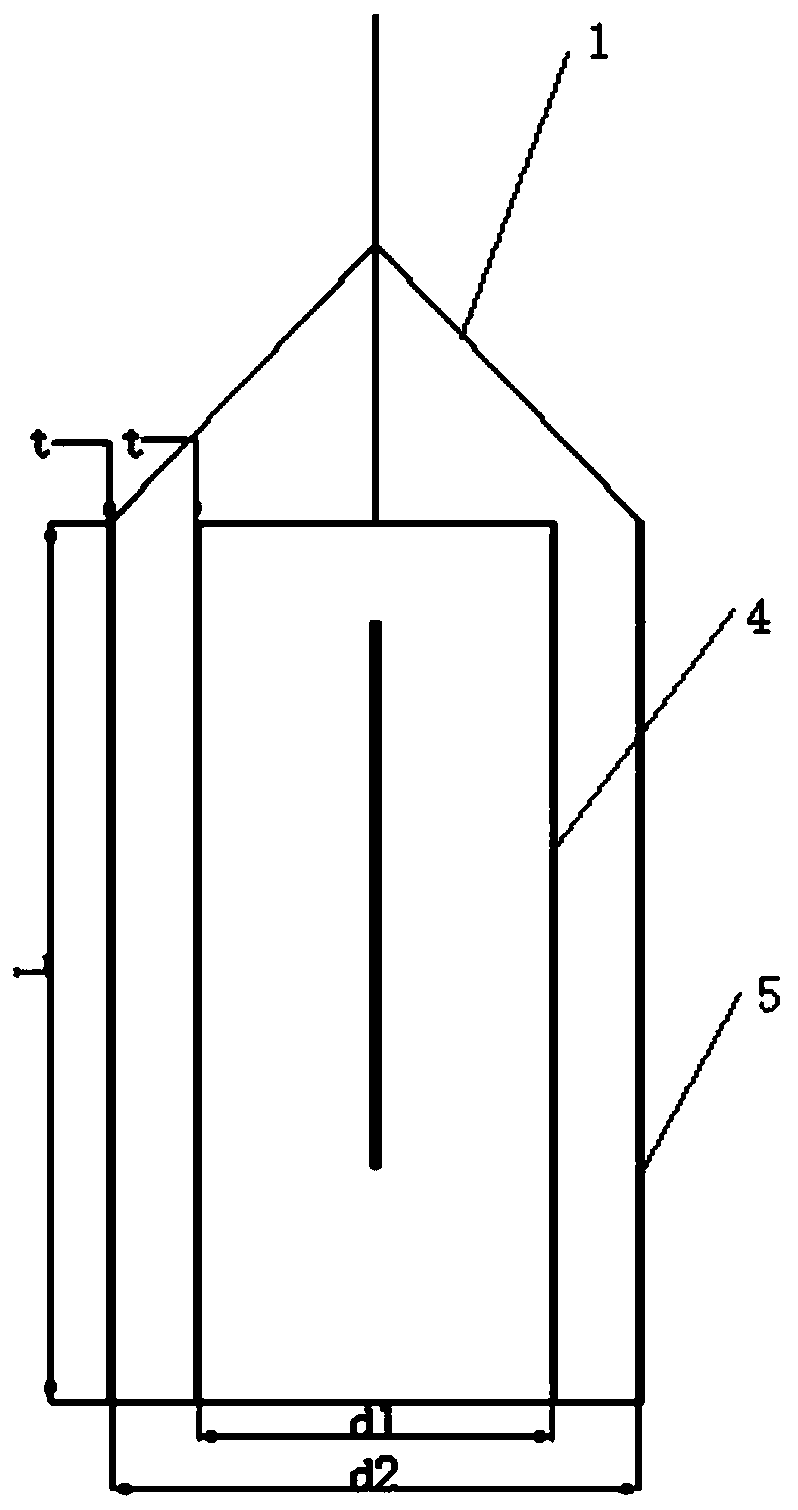

[0017] Example 1: as Figure 1-2 As shown, a device for water hole charging includes a first cylinder 4, a second cylinder 5, cuttings 3, No. 2 rock emulsion explosive 2 and a nylon rope 1, and the second cylinder 5 is sleeved on On the outside of the first cylinder 4, the central axes of the two coincide, and the bottoms of the two are connected, such as image 3 As shown, the top of the first cylinder 4 is sealed and has a strip-shaped hole on the side, and a 15 cm long mouth can be vertically downwards at the side at 5 cm from the top for charging, and the top of the second cylinder 5 is open. ,like Figure 4 As shown, the top of the second cylinder 5 is provided with a plurality of small holes symmetrically, and the nylon rope 1 is fixed. Specifically, four circular holes with a diameter of 1 cm can be evenly opened along the top periphery of the second cylinder 5. The nylon rope 1 Tethered on four round holes, the four symmetrical round holes make the nylon rope 1 more ...

Embodiment 2

[0023] Embodiment 2: In this embodiment, the device of the first specification in Embodiment 1 is used for charge, i.e. d 1 = 32mm, d' 1 =33mm,,d 2 = 45mm, d' 2 =46mm, l=300mm,

[0024] (1) The density of cuttings 3 is generally 2-3g / cm 3 , calculated to take 2g / cm 3 , the volume of cuttings 3 Mass of cuttings 3 m 1 =V 1 ×ρ 岩屑 =440.86g

[0025] (2) The density of No. 2 rock emulsion explosive 2 is generally 0.95-1.30g / cm 3 , calculated to take 0.95g / cm 3 , the mass of explosive m 2 =ρ 炸药 ×πL d 2 / 4=229.09g;

[0026] (3) The total density of the drug pack The density of the original No. 2 rock emulsion explosive 2 is ρ 炸药 =0.95g / cm 3 , it is obvious that ρ>ρ 炸药 , the device obviously increases the density of the finished No. 2 rock emulsion explosive 2.

Embodiment 3

[0027] Embodiment 3: when adopting the second kind of specification device charging in embodiment 1 in the present embodiment, namely d 1 = 35mm, d' 1 =36mm,d 2 = 48mm, d' 2 =49mm, l=300mm, the calculation is as follows:

[0028] (1) The density of cuttings 3 is generally 2-3g / cm 3 , calculated to take 2g / cm 3 , the volume of cuttings 3 Mass of cuttings 3 m 1 =V 1 ×ρ 岩屑 =474.76g

[0029] (2) The density of No. 2 rock emulsion explosive 2 is generally 0.95-1.30g / cm 3 , calculated to take 0.95g / cm 3 , the mass of explosive m 2 =ρ 炸药 ×πL d 2 / 4=274.06g;

[0030] (3) The total density of the drug pack The density of the original No. 2 rock emulsion explosive 2 is ρ 炸药 =0.95g / cm 3 , it is obvious that ρ>ρ 炸药 , this device obviously increases the density of No. 2 rock emulsion explosive 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com