Blast hole blocking device for tunnel blasting

A blast hole plugging and tunneling technology, which is applied in the field of blasting engineering auxiliary devices, can solve the problems of poor filling quality assurance and inconvenient operation, and achieve the effect of high filling quality assurance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate understanding and implementation of the present invention, preferred embodiments of the present invention are selected for further description in conjunction with the accompanying drawings.

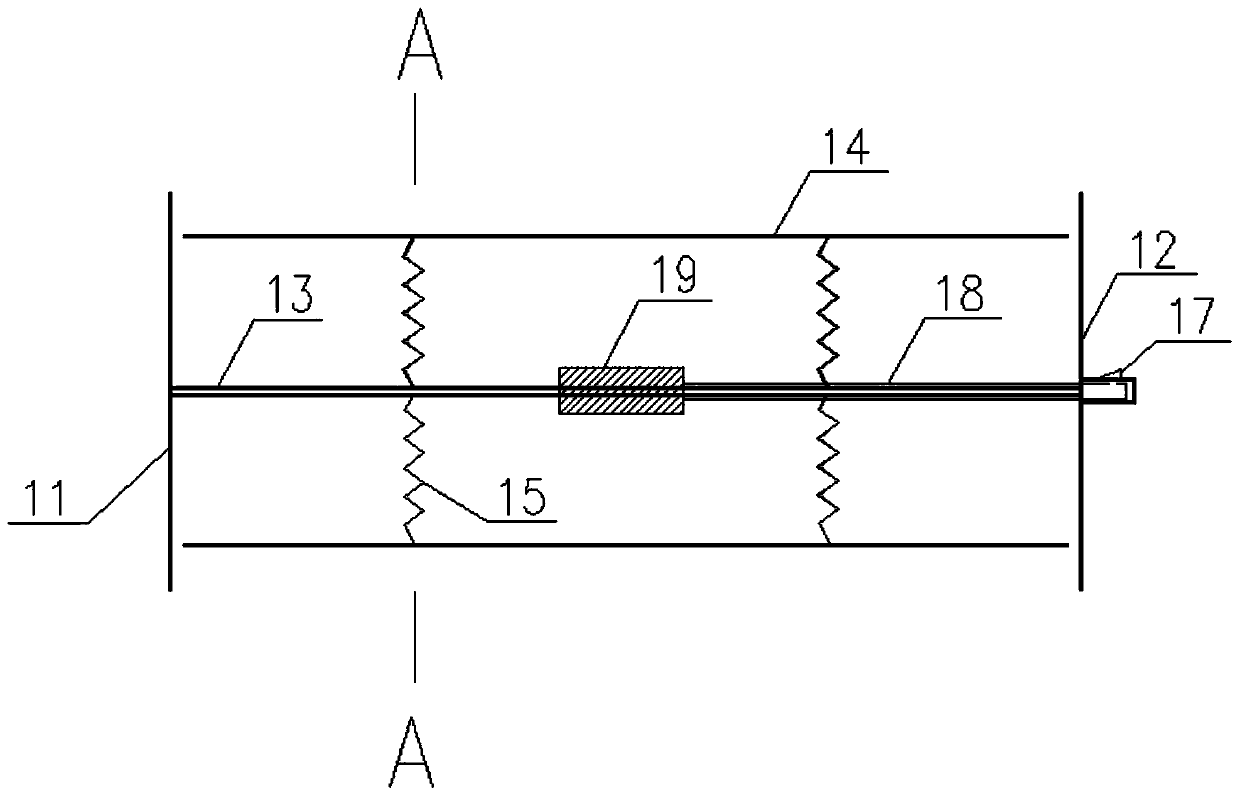

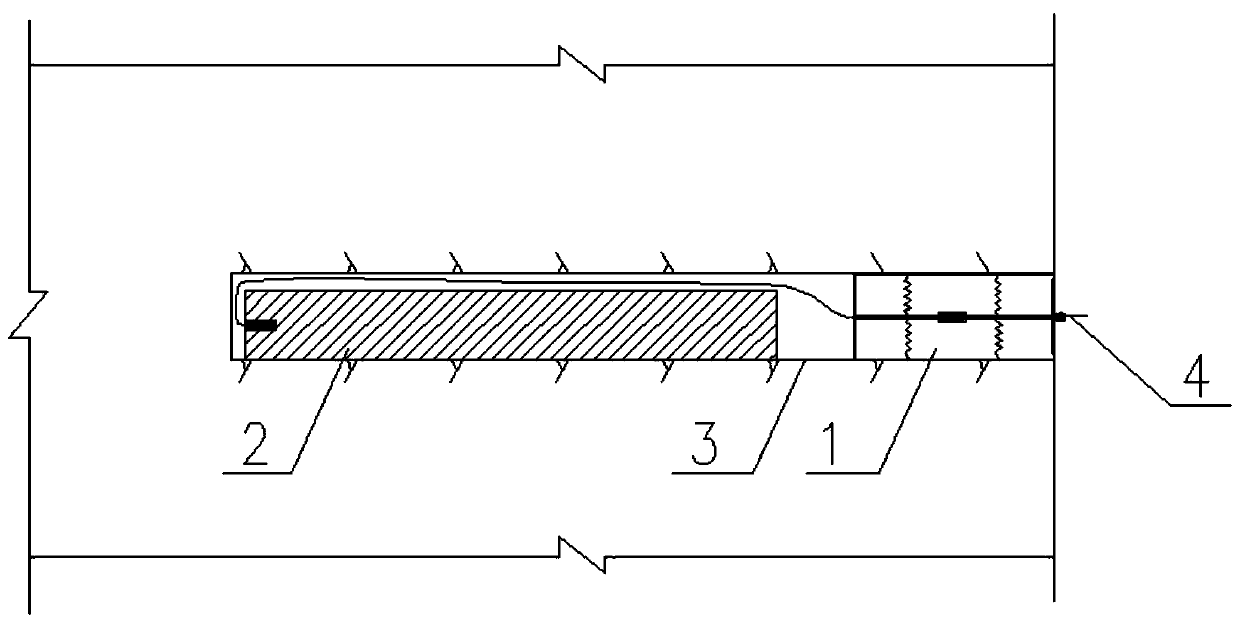

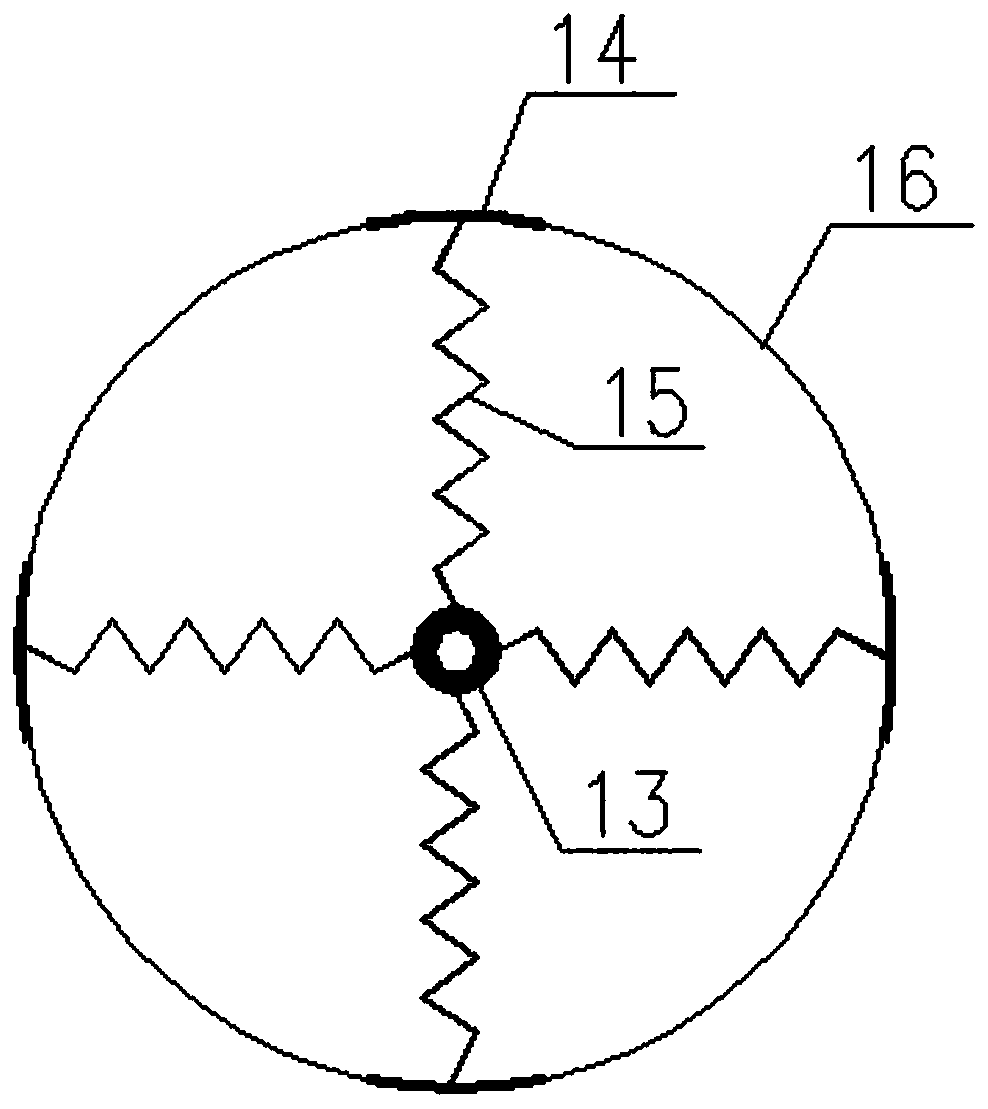

[0020] like Figure 1 to Figure 3 As shown, the blasthole blocking device in the present invention includes a stuffing structure 1, and the stuffing structure 1 includes a baffle 11 and a connecting rod 13, one end of the connecting rod 13 is vertically fixedly connected to the middle of the baffle 11, and the other end is used for setting operation At the end, the connecting rod 13 has multiple pieces of force-bearing rods 14 arranged in parallel around the circumference of the connecting rod 13, the axis of the force-bearing rod 14 is parallel to the axis of the connecting rod 13, and each piece of the force-bearing rod 14 is connected with the connecting rod 13 through at least two springs 15. , the connecting rod 13 is provided with an electromagnet 19. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com