Long charging bag and method for charging blast holes through long charging bag

A blast hole charging and charging technology, which is applied in blasting and other directions, can solve problems such as charging failure, displacement of charge packs, uneven distribution, etc., and achieve the effects of wide range of available materials, accurate charging at intervals, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

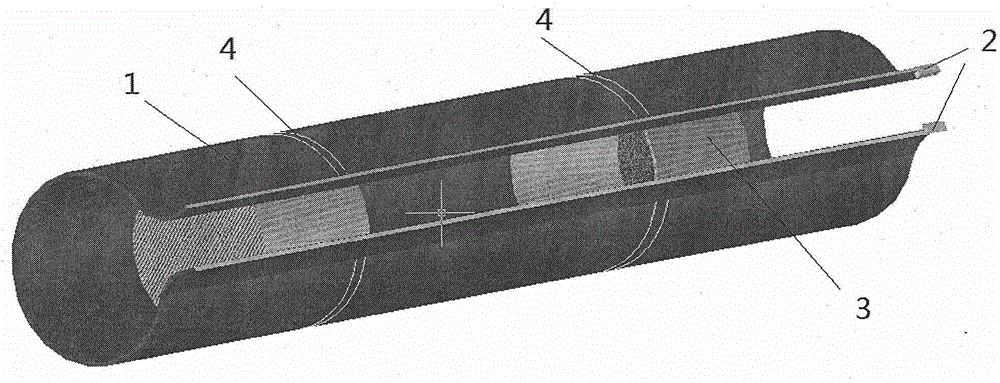

[0057] A reinforced concrete beam needs to be demolished by blasting. Its size is 7.2m in length, and its cross-sectional dimension is 0.6m×0.9m in width×height. A PVC plastic pipe with a diameter of 38mm is pre-buried on the neutral axis of the beam as a blasthole. section.

[0058] The long drug-loading bag made of 0.16mm thick nylon film is 6m long and 35mm in inner diameter, and a long plastic slider zipper is arranged along the length direction of the bag body and parallel to the longitudinal axis. A hollow cylindrical partition (cylindrical diameter 35mm, height 4mm) with one end open is arranged every 20cm in the long bag. The cylindrical partition is made of 0.1mm thick nylon film, which is glued into the bag body (the long bag and the cylindrical partition are placed coaxially).

[0059] Utilize above-mentioned charge long bag to carry out blasting charge to above-mentioned reinforced concrete beam, the steps are as follows:

[0060] 1) Open the zipper of the long ...

Embodiment 2

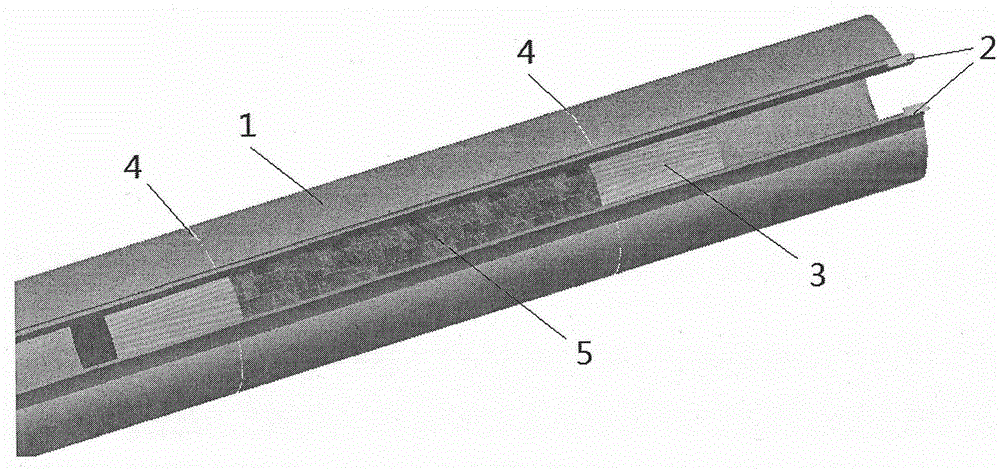

[0064] A reinforced concrete column needs to be demolished by blasting. Its size is 8m high, the diameter of the circular section is 1m, and a 7.7m-long blast hole with a diameter of 38mm is arranged on the central axis of the column, and the top opening is on the upper surface of the column.

[0065] The long charge bag made of polyester cloth has a length of 7.2m and an inner diameter of 35mm. Ordinary plastic zippers are arranged along the length direction of the bag parallel to the longitudinal axis. Hollow cylindrical partitions with one end open (cylindrical diameter 35mm, height 7mm) are arranged alternately at intervals of 20cm and 15cm in the long bag. The cylindrical partition is made of polyester fabric, and is sewn into the bag body with two semi-circular silk threads (the long bag and the cylindrical partition are placed coaxially).

[0066] The blasting charge of the above-mentioned reinforced concrete column is carried out by using the above-mentioned charge lo...

Embodiment 3

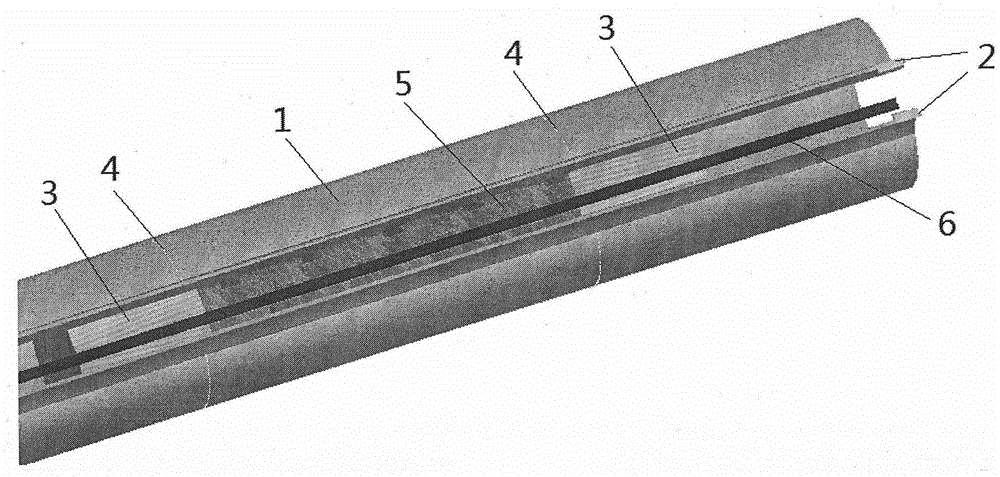

[0070] A semi-circular reinforced concrete curved beam needs to be demolished by blasting. The radius of the neutral axis of the curved beam is 1m, and the cross-sectional dimension width × height is 0.8m × 1.0m. A PVC plastic pipe with a length of 3.14m and a diameter of 36mm is pre-buried on the neutral axis of the beam as a blast hole, which is opened at both ends of the beam. section.

[0071] Use 250g / m 2 The long drug-charging bag made of polypropylene non-woven fabric is 2m long and 35mm in inner diameter, and a long plastic hook and loop is arranged along the length direction of the bag body and parallel to the longitudinal axis.

[0072] Utilize above-mentioned charge long bag to carry out blasting charge to above-mentioned reinforced concrete curved beam, the steps are as follows:

[0073] 1) Unzip the hook and loop tape of the long charge bag, fill the long bag with a diameter of 32 mm and a length of 20 cm emulsion explosive charge, charge without intervals (the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com