Safe and efficient mining method for segmented medium-length hole stope

A mining method and deep hole technology, applied in surface mining, mining equipment, underground mining, etc., can solve the problems of roof blasting, inaccurate blasting position, and inability to effectively collapse suspended roofs, etc., to improve utilization, improve Mining efficiency, the effect of reducing the number of blasts and firing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

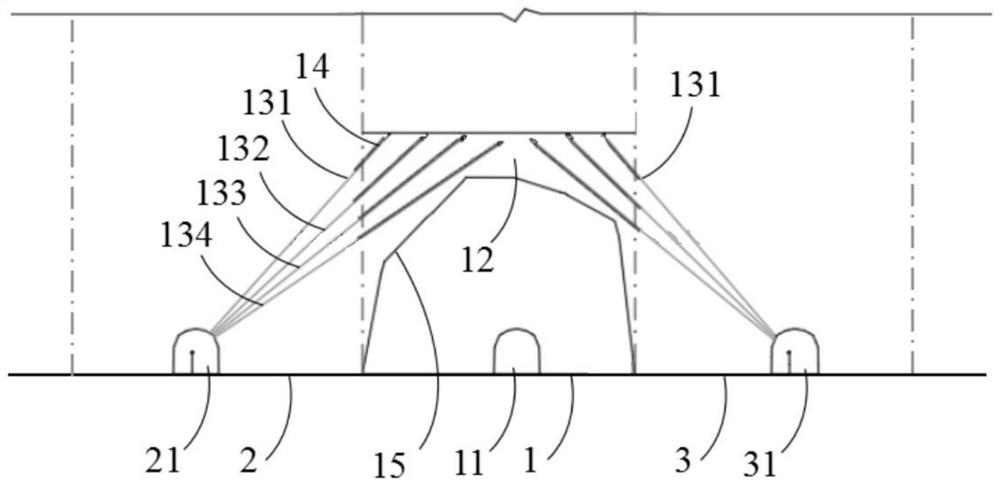

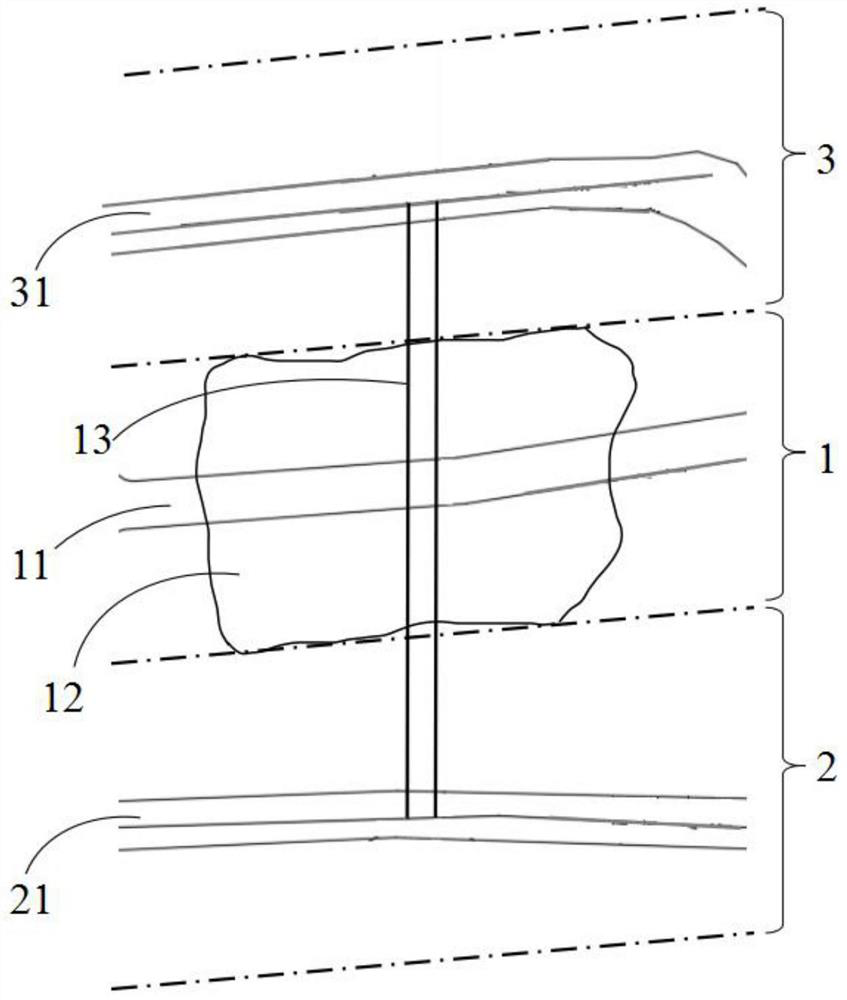

[0049] see Figure 1-Figure 2 As shown, a kind of safe and efficient mining method of segmented deep hole stope of the present invention first divides the ore body to be exploited into panels, at least three segmented stopes in the panel stope, and each subsection in the panel area Excavate parallel rock-drilling roadways in the section stope, and begin to carry out the mining of the deep-hole stope 1 in one step to the rock-drilling roadway in the middle stope. When a suspended roof 12 appears in the deep hole stope 1 in a step of mining, three-dimensional scanning technology is used to measure, so as to determine the position and occurrence status of the suspended roof 12 . Then, in the left and right adjacent stope rock drilling roadways of the deep hole stope 1 in a step (respectively being the rock drilling roadway 21 of the left side stope 2, the rock drilling roadway 31 of the right side stope 3), to a step A medium-deep hole blasthole is constructed above the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com