Tunnel blasting construction blast hole blocking device

A blast hole plugging and tunneling technology, which is applied in the field of blasting engineering auxiliary devices, can solve the problems of inconvenient operation and poor guarantee of filling quality, and achieve the effect of convenient operation and high guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to facilitate the understanding and implementation of the present invention, the preferred embodiments of the present invention are selected for further description in conjunction with the accompanying drawings.

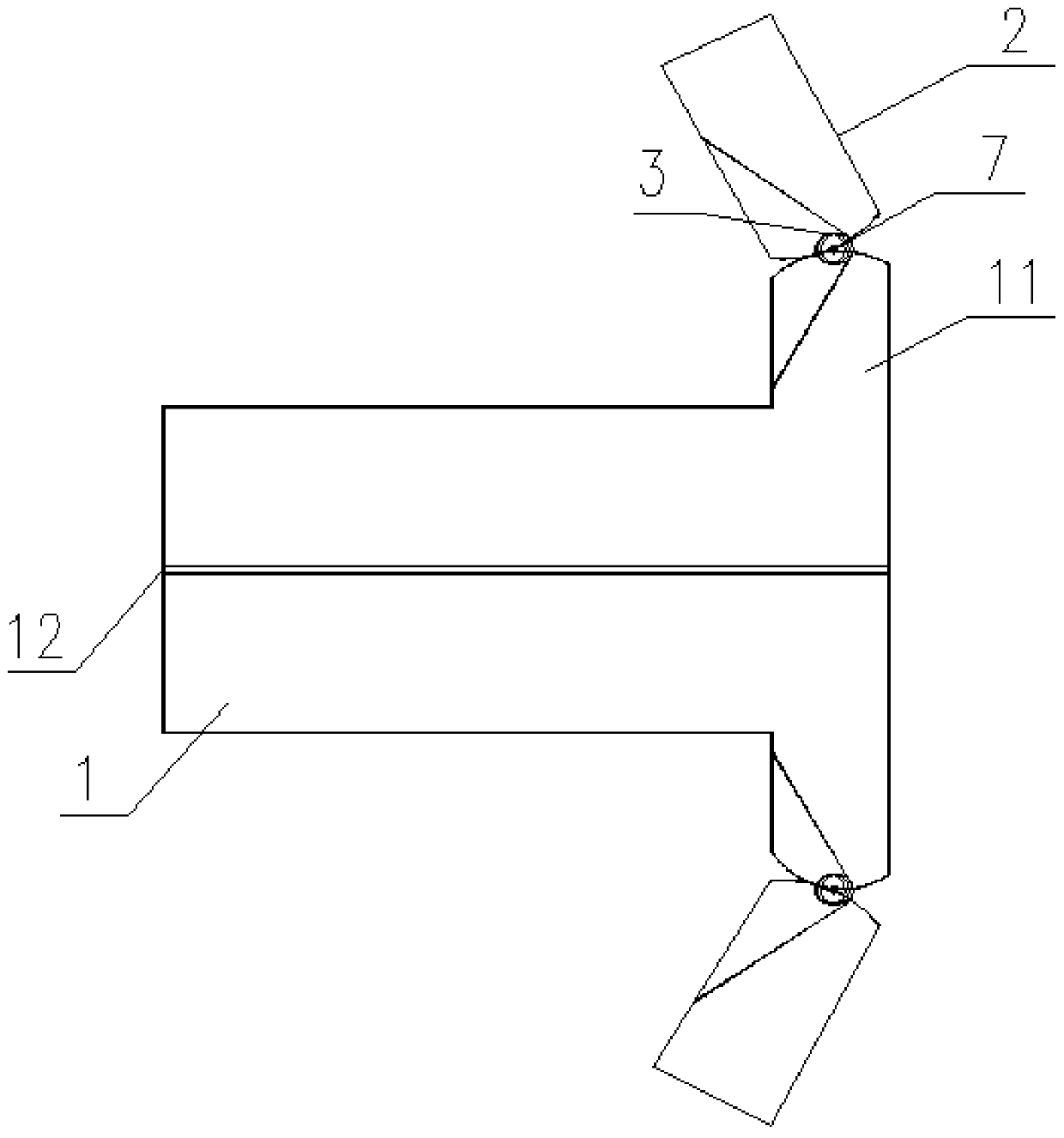

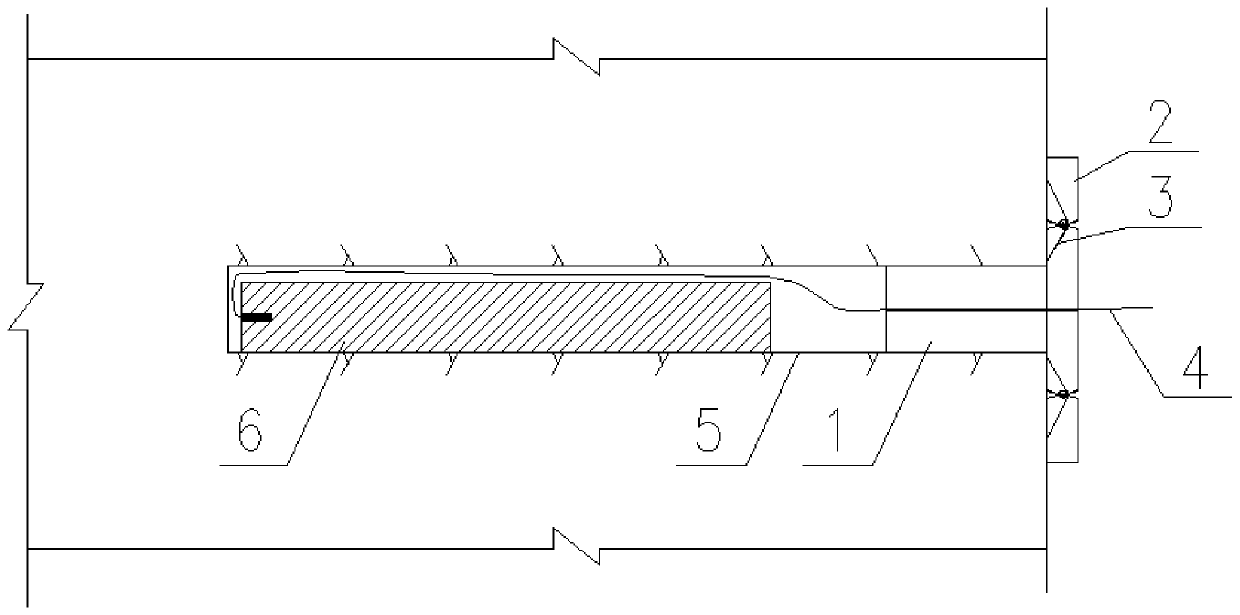

[0015] Such as figure 1 and figure 2 As shown, the tunnel blasting construction blast hole plugging device in the present invention includes a packing structure 1 and a movable rod 2, and a plurality of movable rods 2 are arranged at intervals along the circumference of the packing structure 1, and each movable rod 2 passes through a pivot 7 Hinged to the same end of the filling structure 1, and the torsion spring 3 is sleeved on the pivot 7; when the torsion spring 3 is in the natural state, the angle formed by the axis of the movable rod 2 and the axis of the filling structure 1 is less than 90° °; when the angle formed by the axis of the movable rod 2 and the axis of the packing structure 1 is 90°, the return elastic force of the torsion spring 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com