A charging method for deep hole blasting in rock roadway

A technology of deep hole blasting and charging, which is applied in blasting, earth square drilling, mining equipment, etc. It can solve the problems of high failure rate of filling explosives, deformation of explosives, time-consuming and labor-intensive charging, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

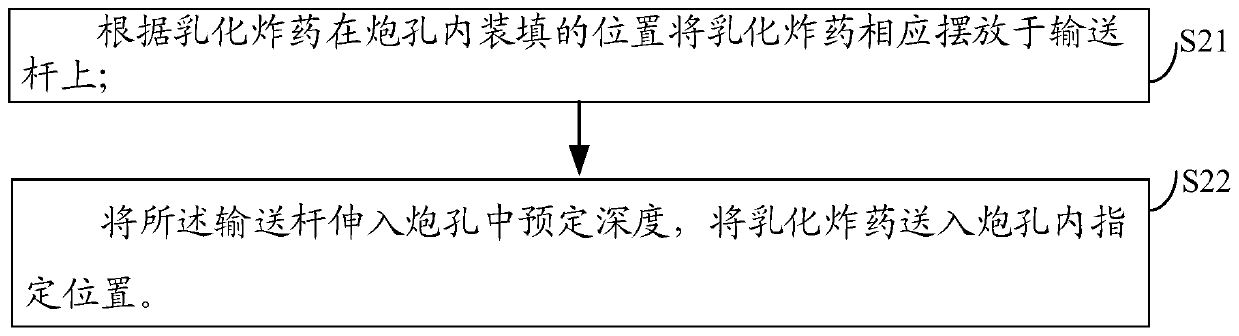

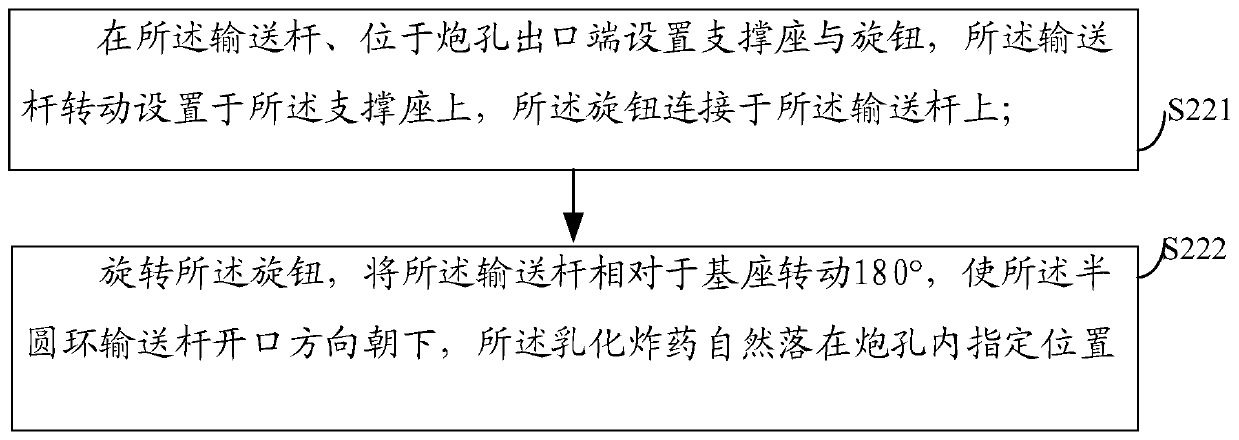

[0033] see figure 1 As shown, the embodiment of the present invention is a method for charging explosives in deep hole blasting in rock roadways, which is mainly used in blasting projects such as roadways, tunnels, mines, etc., comprising steps:

[0034] Step S1, place the emulsion explosive on the conveying rod according to the filling position of the emulsion explosive in the blast hole;

[0035] In this step, it can be understood that the length of the delivery rod is at least the same as the depth of the blasthole; Same, for example, the depth of the blasthole is 5m, the length of the conveying rod is 5.5m, the actual length of the conveying rod that needs to extend into the blasthole is 5m, and the exposed 0.5m, the blasting requires that the emulsified explosives be filled between 4m and 5m in sequence, then according to the emulsified The position where the explosives are finally placed in the blast hole is to place the emulsion explosives sequentially between 4.5m and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com