Treatment method of emulsified waste medicine

A treatment method and emulsified explosive technology, which is applied in explosives, explosives processing equipment, offensive equipment, etc., can solve the problems of high cost and difficult recycling of organic solvents, and achieve low cost, obvious economic and social benefits, and safety Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

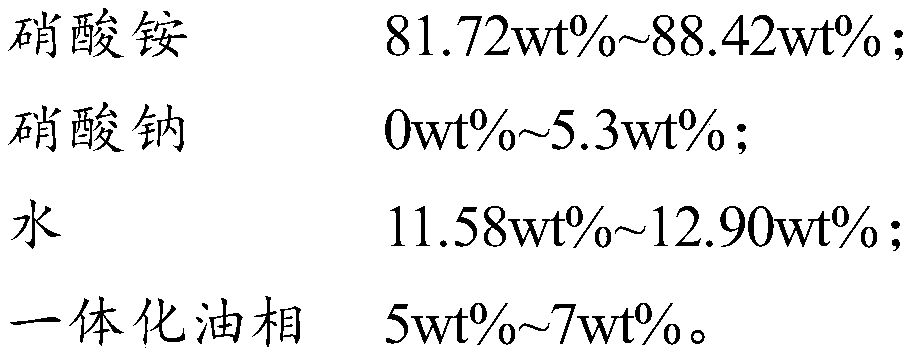

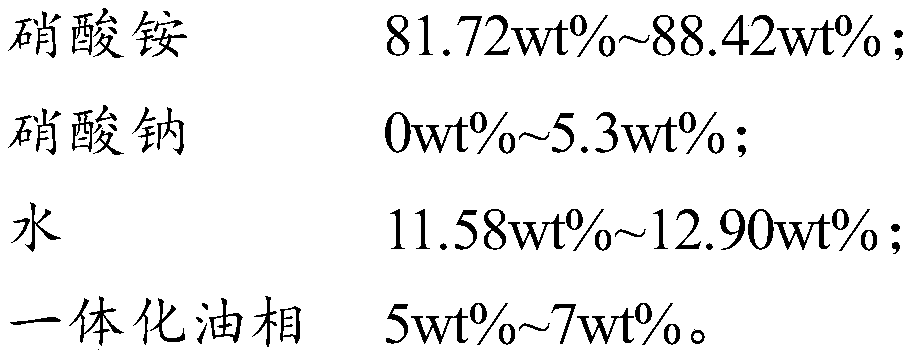

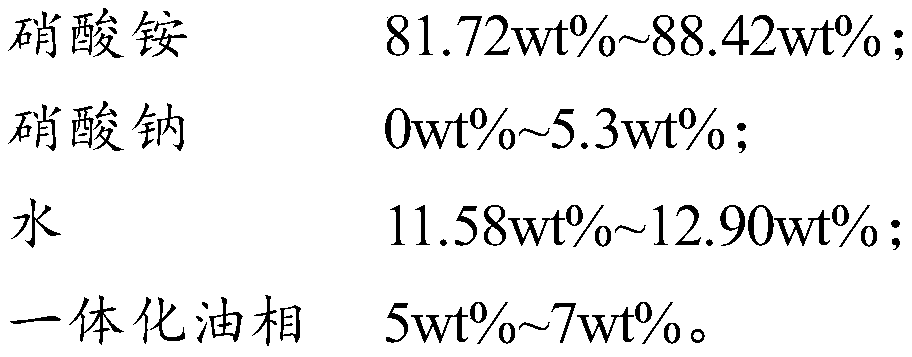

[0031] The raw materials for the preparation of the emulsion explosive include 81.72wt% to 88.42wt% of ammonium nitrate, preferably 83wt% to 86wt%.

[0032] The raw materials for the preparation of the emulsion explosive also include 0wt%-5.3wt%, preferably 1wt%-4wt%.

[0033] The raw materials for the preparation of the emulsion explosive also include 11.58wt% to 12.90wt% of water, more preferably 11.6wt% to 12.5wt%.

[0034] The raw materials for the preparation of the emulsion explosive also include 5wt%-7wt% of the integrated oil phase, more preferably 5.5wt%-6.5wt%.

[0035] The emulsion explosive is prepared according to the following method:

[0036] a) Water phase preparation of emulsion explosives:

[0037] The ammonium nitrate and sodium nitrate are dissolved in water to obtain a water phase; the temperature at which the ammonium nitrate and sodium nitrate are dissolved in water is 100-110°C.

[0038] b) Oil phase preparation of emulsion explosives:

[0039] The ...

Embodiment 1

[0047] 1. Preparation of emulsion explosives

[0048] (1) Preparation of the water phase of the emulsion explosive: 85.03% ammonium nitrate and 2.14% sodium nitrate were dissolved in 12.83% water, and the temperature was controlled at 100-110°C.

[0049] (2) Preparation of the oil phase of the emulsion explosive: the integrated oil phase is put into a wax melting tank for melting, and the temperature is controlled at 90-100°C.

[0050] (3) The above-mentioned water phase and oil phase are pumped into a dynamic emulsifier at a certain ratio for emulsification, and the discharge temperature after emulsification is controlled at 100-110°C.

[0051] (4) The material emulsified by the emulsifier is cooled and transported by the steel belt, and is chemically sensitized to make an emulsion explosive.

[0052] (5) The normal and qualified No. 2 rock emulsion explosive product prepared above is placed for 6 months and above, and the expired product is peeled off the package, and the p...

Embodiment 2

[0057] 1. Preparation of emulsion explosives

[0058] (1) Preparation of the water phase of the emulsion explosive: 85.03% ammonium nitrate and 2.14% sodium nitrate were dissolved in 12.83% water, and the temperature was controlled at 100-110°C.

[0059] (2) Preparation of the oil phase of the emulsion explosive: the integrated oil phase is put into a wax melting tank for melting, and the temperature is controlled at 90-100°C.

[0060] (3) The above-mentioned water phase and oil phase are pumped into a dynamic emulsifier at a certain ratio for emulsification, and the discharge temperature after emulsification is controlled at 100-110°C.

[0061] (4) The material emulsified by the emulsifier is cooled and transported by the steel belt, and is chemically sensitized to make an emulsion explosive.

[0062] (5) The normal and qualified No. 2 rock emulsion explosive product prepared above is placed for 6 months and above, and the expired product is peeled off the package, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com