Umbrella-shaped detent hanger and method for charging blast hole through umbrella-shaped detent hanger

A hanger and umbrella-shaped technology, which is applied in the field of umbrella-shaped clamping hangers and the use of umbrella-shaped clamping hangers to charge blastholes, can solve the problems of easy leakage of explosives, low efficiency, and damage to explosive packaging, and achieve easy Large-scale industrial production and use, simple device structure and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

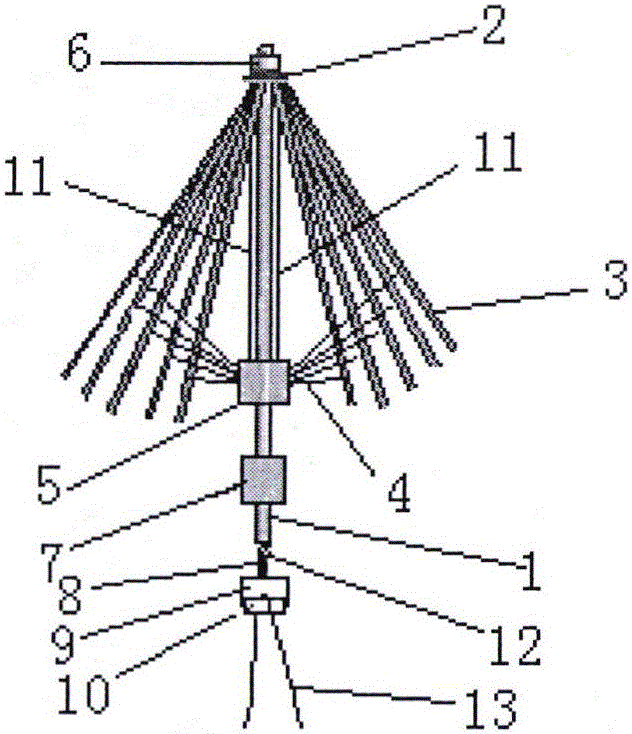

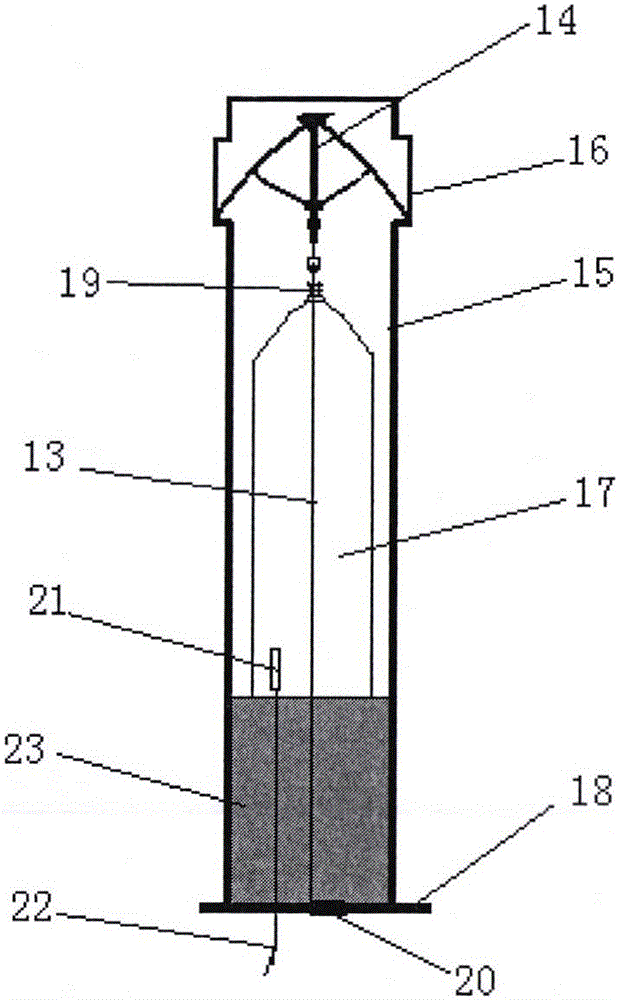

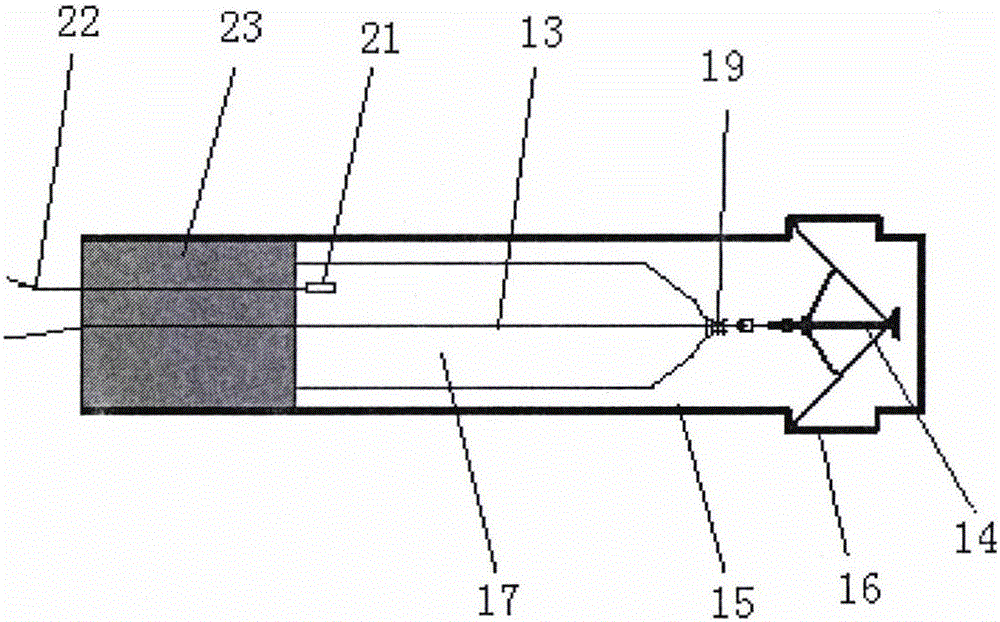

[0080] An upward facing rock hole needs to be blasted. The blast hole is 10m deep and 110mm in diameter.

[0081] The specifications of the various parts of the umbrella-shaped clamp hanger are: the straight rod is made of HRB400 steel pipe, the specification is Φ33×5 (unmarked length units are mm, the same below); the 6 face bones and support bones are made of HRB500 rectangular steel bars , the length of the facial bone is 100mm, the cross-sectional dimension is height×width=20×10, and the front end is polished into a smooth spherical surface; the ramus is 75mm long, and the cross-sectional dimension is height×width=10×10; the ramus is 20mm away from the front end of the facial bone and The facial bones are hinged. The fixed nest seat and the movable nest seat are made of low carbon steel Q235, with an inner diameter of Φ33, and the specification of the ring-shaped fixed iron wire is 3#; two extension springs (specification A0. Zn) Both ends are symmetrically fixed on the ...

Embodiment 2

[0095] A blast hole in a gently inclined rock needs to be blasted. The angle between the blast hole and the horizontal plane is 10°, the hole depth is 6m, and the diameter is 90mm.

[0096] The specifications of the various parts of the umbrella-shaped card position hanger are: the straight rod is made of HRB400 steel pipe, and the specification is Φ27×5; the 5 face bones and support bones are all made of HRB500 rectangular steel bars, the length of the face bone is 80, and the cross-sectional size is height × width = 15×8, the front end is polished into a smooth spherical surface; the length of the ramus is 60, and the cross-sectional size is height×width=9×9; the ramus is hinged with the facial bone at a distance of 15mm from the front end of the facial bone. The fixed nest seat and the movable nest seat are made of low carbon steel Q235, with an inner diameter of Φ27, and the specification of the circular fixed iron wire is 4#; two tension springs (specification A0.20*3.20*8...

Embodiment 3

[0109] A reinforced concrete beam needs to be blasted, the beam is 15m long, and the cross-sectional size is 1.8m×1.0m. Along the longitudinal axis of the beam, two 7.2m-long plastic pipes are pre-embedded at intervals of 0.6m as blastholes, with a diameter of 70mm. The diameter of the embedded section at the bottom of the hole is enlarged to 100mm, and the length is 6cm.

[0110] The specifications of the various parts of the umbrella-shaped card position hanger are: the straight rod is made of HRB400 steel pipe, and the specification is Φ27×5; the 4 face bones and support bones are all made of HRB500 rectangular steel bars, the length of the face bone is 60mm, and the cross-sectional size is height × width = 12×7, the front end is polished into a smooth spherical surface; the ramus is 45mm long, and the cross-sectional size is height×width=8×8; the ramus is hinged with the facial bone at a distance of 10mm from the front end of the facial bone. The fixed nest seat and the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com