Intelligent and environment-friendly blast hole drainage vehicle for open-pit blasting engineering

A kind of blasting engineering and environmental protection technology, applied in blasting and other directions, can solve the problem of high dust concentration, achieve the effect of improving the working environment, reducing the cost of explosives, and avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

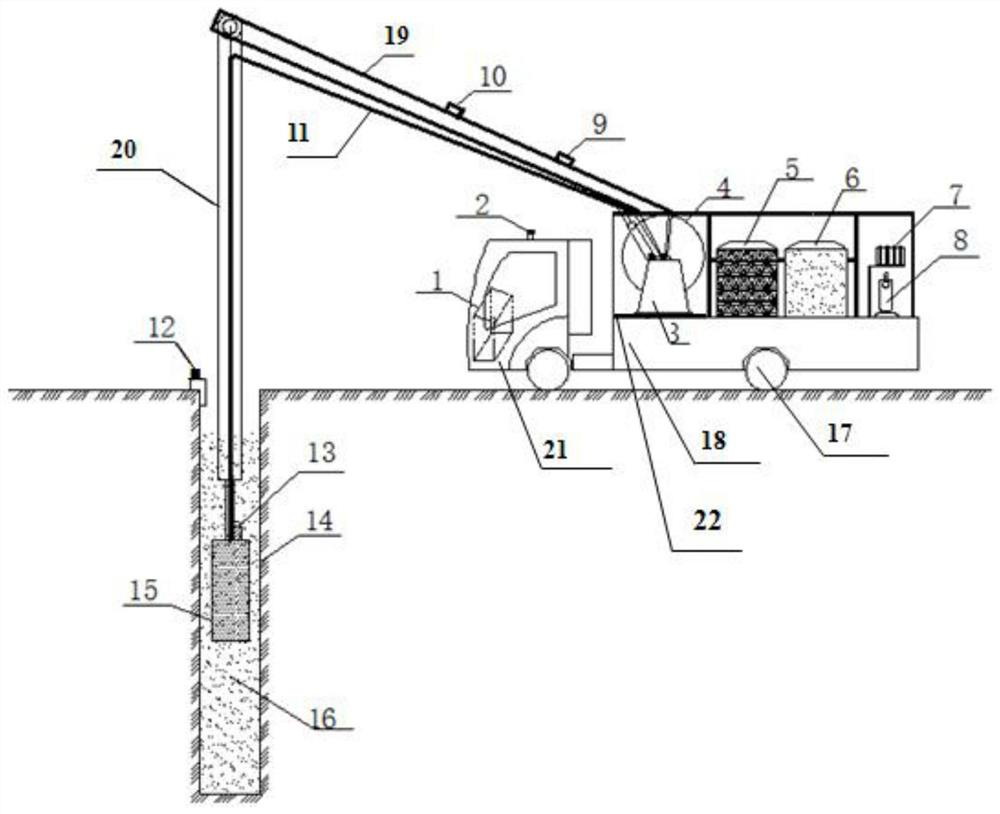

[0019] In order to better describe the present invention, below in conjunction with accompanying drawing, the intellectualized, environment-friendly blast hole drainage vehicle of the present invention used for open-pit blasting engineering is further described in detail.

[0020] Depend on figure 1 The intelligentized, environment-friendly type blast hole drainage vehicle structural connection schematic diagram of shown open-air blasting engineering of the present invention finds out, blast hole ponding water 16 is housed in the blast hole 14. The intelligent and environment-friendly blast hole drainage vehicle used in the open-air blasting project of the present invention includes a traveling mechanism 17, a vehicle-mounted platform 18, a control room 21, a hydraulic system, a rotating mechanism 3, a reel mechanism 4, an intelligent control system 1, and a telescopic cantilever 19 , submersible pump 15, rubber hose 11, sewage purification barrel 5, vehicle-mounted platform 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com