Energetic compound sensitizer for emulsified explosive and preparation method of energetic compound sensitizer

A technology of emulsion explosives and sensitizers, applied in the field of sensitizers, can solve the problems of metal powder storage stability explosives safety, reduce the explosive power of emulsion explosives, reduce the safety of emulsion explosives, etc., to improve storage stability, The effect of increasing charge density and reducing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

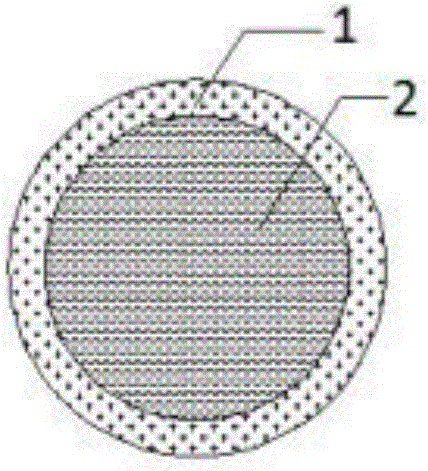

[0034]The energy-containing composite sensitizer containing aluminum powder: the mass ratio of aluminum powder in the energy-containing sensitizer is 58%, the mass ratio of coating agent paraffin is 5%, and the mass ratio of silicon dioxide is 37%.

[0035] The preparation method of the composite energy-containing sensitizer containing aluminum powder, the specific method steps are as follows:

[0036] St1: Preparation of modified aluminum powder: first dissolve paraffin in gasoline at room temperature, then add aluminum powder, mix and stir evenly, and dry in a vacuum drying box filled with argon to obtain modified aluminum powder, The particle size of the aluminum powder is 40 μm, the purity is greater than 99%, and the temperature of the vacuum drying oven is controlled at room temperature-80°C.

[0037] St2: Melamine formaldehyde resin coating: adopt in-situ polymerization method, mix 12 parts of melamine and 37% formaldehyde solution (containing 10 parts of formaldehyde),...

Embodiment 2

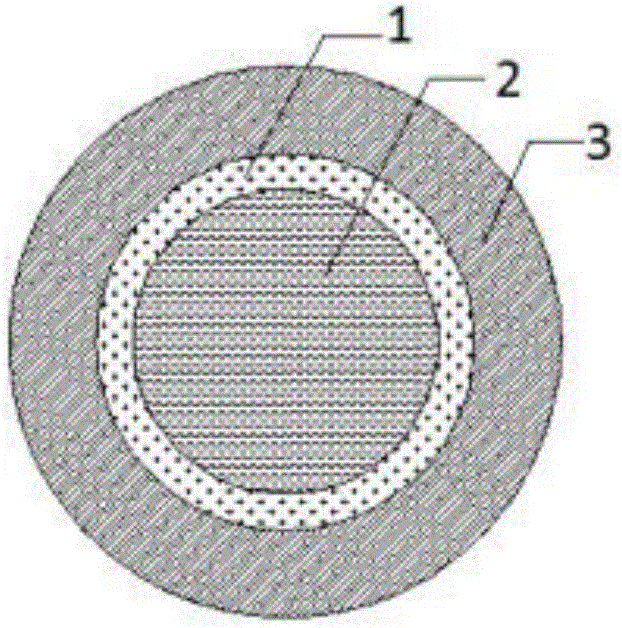

[0041] The energy-containing composite sensitizer containing magnesium powder: the mass ratio of magnesium powder in the energy-containing sensitizer is 61%, the mass ratio of coating agent fluororubber is 6%, and the mass ratio of silica is 33%.

[0042] The preparation method of the composite energy-containing sensitizer containing magnesium powder, the specific method steps are as follows:

[0043] St1: Preparation of modified magnesium powder: First dissolve fluororubber in ethyl acetate at room temperature, then add magnesium powder, mix and stir evenly, and dry in a vacuum drying box filled with argon to obtain modified magnesium powder. Magnesium powder, the particle size of the magnesium powder is 48 μm, the purity is greater than 99%, and the temperature of the vacuum drying oven is controlled at room temperature-80°C.

[0044] St2: melamine formaldehyde resin coating: adopt the in-situ polymerization method, mix 14 parts of melamine and 37% formaldehyde solution (con...

Embodiment 3

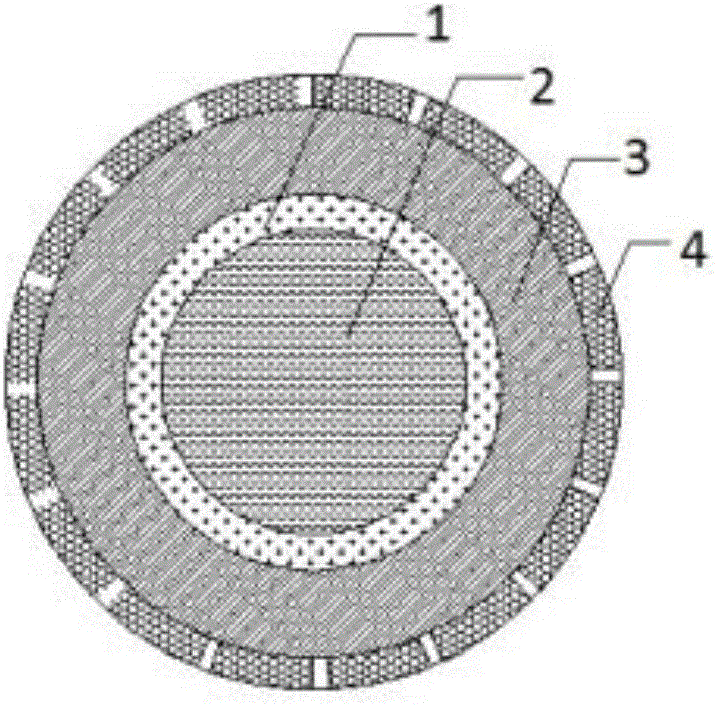

[0048] Energy-containing composite sensitizer containing titanium powder: the mass ratio of titanium powder in the energy-containing sensitizer is 55%, the mass ratio of coating agent stearic acid is 6%, and the mass ratio of silicon dioxide is 39% .

[0049] The preparation method of the composite energy-containing sensitizer containing titanium powder, the specific method steps are as follows:

[0050] St1: Preparation of modified titanium powder: first dissolve stearic acid in alcohol at room temperature, then add titanium powder, mix and stir evenly, and dry in a vacuum drying box filled with argon to obtain modified titanium The particle size of the titanium powder is 45 μm, the purity is greater than 99%, and the temperature of the vacuum drying oven is controlled at room temperature-80°C.

[0051] St2: melamine formaldehyde resin coating: adopt the in-situ polymerization method, mix 15 parts of melamine and 37% formaldehyde solution (containing 12 parts of formaldehyde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com