Method for self-template and self-doping preparation of supercapacitor phosphorus rich mesoporous carbon

A technology for supercapacitors and phosphorus-rich media, applied in the field of phosphorus mesoporous carbons, to achieve the effects of improving conductivity and wettability, reducing volume shrinkage, and improving rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Weigh 30g of calcium and magnesium phytate in a clean nickel boat, place it in the center of the tube furnace, and blow it with high-purity nitrogen for 30 minutes to force out the air in the tube;

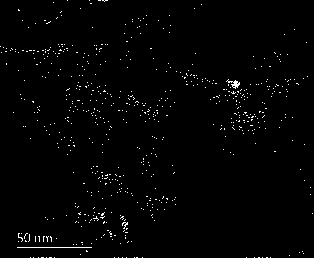

[0035] (2) Under the protection of high-purity nitrogen, raise the temperature of the tube furnace to 1100°C at a heating rate of 15°C / min, keep the temperature constant for 2 hours, and cool naturally to room temperature (such as figure 1 The TEM image of the carbonized product before washing is shown, and the black small molecular salt impurities are evenly distributed in the carbon matrix material);

[0036] (3) Take out the nickel boat, put the carbonized product into a three-necked flask filled with 1mol / L sulfuric acid, heat and boil for 3 hours, filter and wash until neutral, add deionized water and boil for 3 hours;

[0037] (4) Suction filtration, drying in a blast oven at 90°C for 11 hours to obtain the phosphorus-rich mesoporous carbon electrode material;

...

Embodiment 2

[0041] (1) Weigh 25g of calcium and magnesium phytate in a clean nickel boat, place it in the center of the tube furnace, and blow it with high-purity nitrogen for 30 minutes to force out the air in the tube;

[0042] (2) Under the protection of high-purity nitrogen, raise the temperature of the tube furnace to 500°C at a heating rate of 5°C / min, keep the temperature for 3 hours, and naturally cool to room temperature;

[0043] (3) Take out the nickel boat, put the carbonized product into a three-necked flask filled with 3mol / L phosphoric acid, heat and boil for 2.5h, filter and wash until neutral, add deionized water and boil for 2.5h;

[0044] (4) Suction filtration, drying in a blast oven at 100°C for 12 hours to obtain phosphorus-rich mesoporous carbon electrode materials;

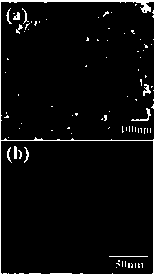

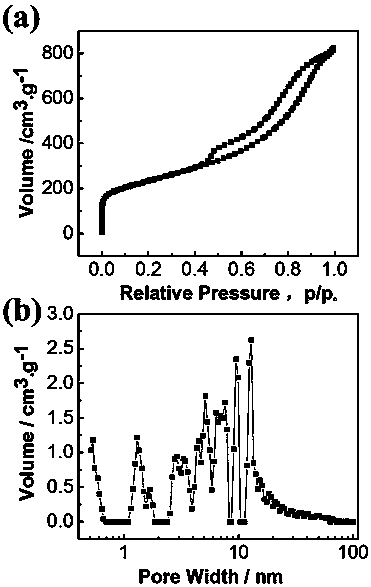

[0045] (5) figure 2 It is the SEM and TEM images of the porous carbon material. It can be seen from the SEM image that the carbon material with a honeycomb porous structure is obtained directly by hi...

Embodiment 3

[0048] (1) Weigh 27g of zinc phytate in a clean nickel boat, place it in the center of the tube furnace, blow it with high-purity nitrogen for 30 minutes, and force out the air in the tube;

[0049] (2) Under the protection of high-purity nitrogen, raise the temperature of the tube furnace to 900°C at a heating rate of 15°C / min, keep the temperature constant for 3 hours, and cool down to room temperature naturally;

[0050] (3) Take out the nickel boat, put the carbonized product into a three-necked flask filled with 4mol / L oxalic acid, heat and boil for 3 hours, filter and wash until neutral, add deionized water and boil for 3 hours;

[0051] (4) Suction filtration, drying in a blast oven at 110°C for 10 hours to obtain phosphorus-rich mesoporous carbon electrode materials;

[0052] (5) Carry out XPS test analysis on the material, the results are as follows Figure 4 As shown, the peak spectrum of P2p shows that P is mainly in the form of [PO 3 ] - Form exists mainly, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com