Lithium battery negative electrode active material as well as preparation method and application thereof

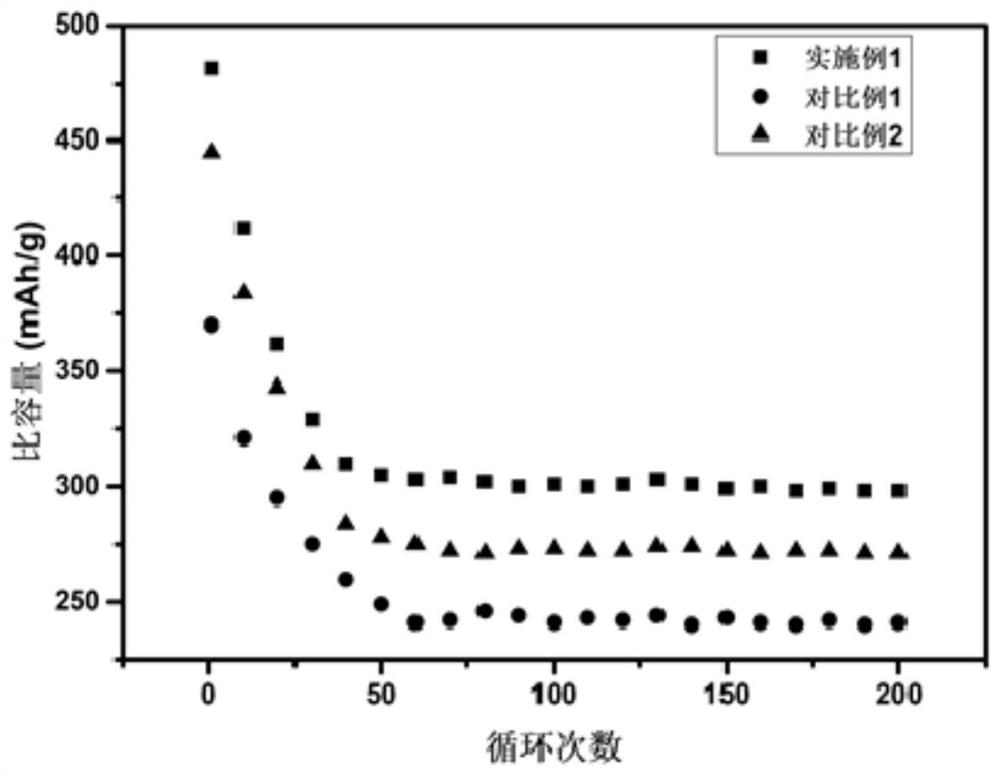

A technology of active materials and lithium batteries, which is applied in the direction of battery electrodes, lithium batteries, non-aqueous electrolyte battery electrodes, etc., can solve the problems of low specific capacity, high rate continuous charge and discharge capability improvement, unfavorable development and application of lithium ion batteries, etc. Achieve the effect of improving rate performance and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention provides a specific preparation method for the provided covalent organic framework derived carbon material, the steps of which are as follows:

[0030] S1: Preparation of covalent organic framework materials: add a certain amount of p-toluenesulfonic acid monohydrate as a catalyst in the mortar, then add amine monomers to grind for a certain period of time, and then add aldehyde monomers to continue grinding for a certain period of time , then add a small amount of deionized water to grind for a certain period of time, then place the resulting mixture in an oven at a certain temperature to react for a certain period of time, after cooling, wash the solid with water, ethanol, water, acetone and other solvents, and finally place the washed solid in vacuum drying Dry in an oven to obtain the desired covalent organic framework material.

[0031] S2: Preparation of covalent organic framework derived carbon material: put the covalent organic framework ma...

Embodiment 1

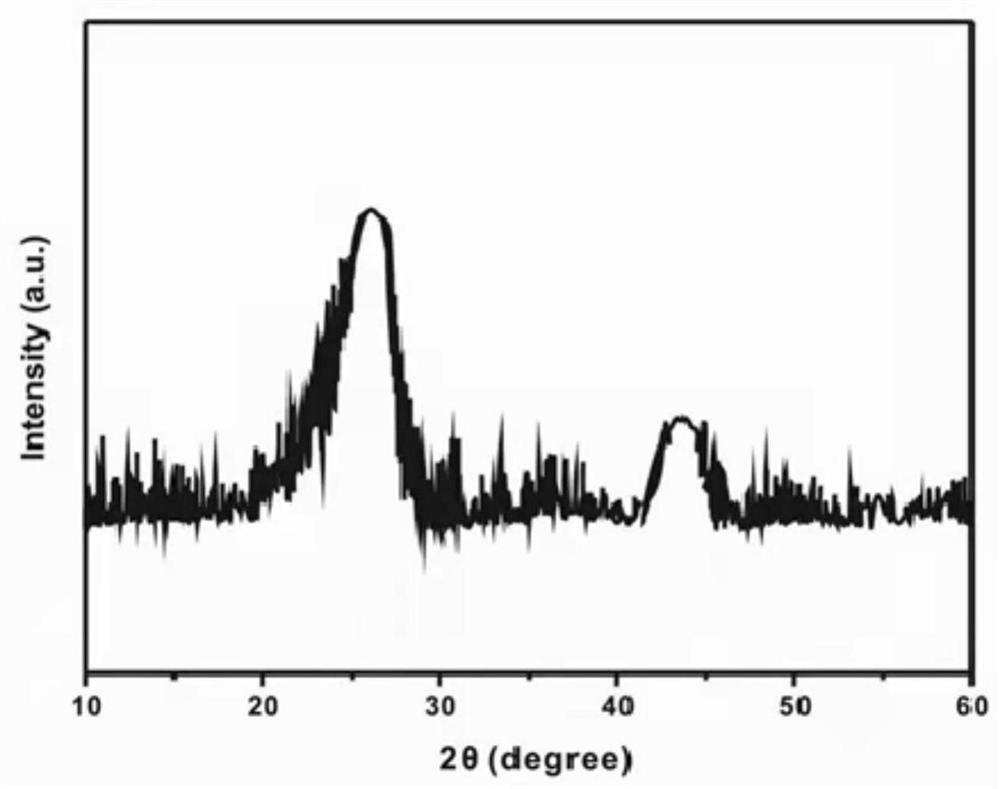

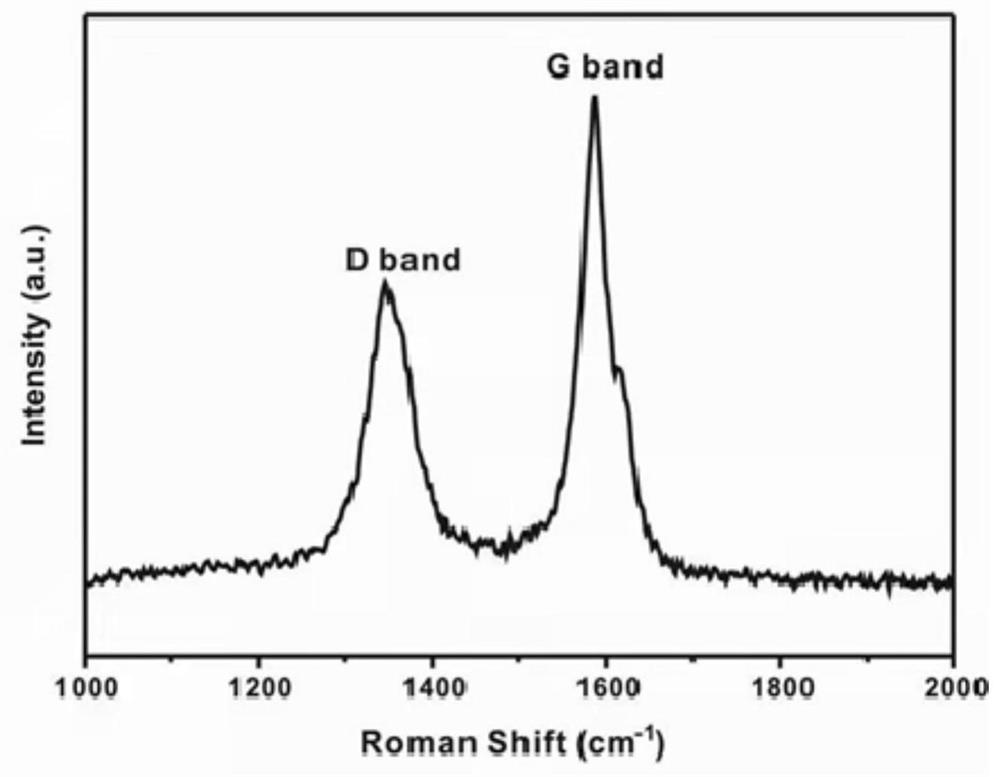

[0043] Example 1: Preparation of covalent organic framework derived carbon materials

[0044] S1: Add 28.5315g (0.15mol) p-toluenesulfonic acid monohydrate as a catalyst in a mortar, add 3.2442g (0.03mol) p-phenylenediamine (Pa-1) and grind for 10min, then add 4.2028g ( 0.02mmol) of 2,4,6-trihydroxy-triphenylenetricarbaldehyde continued to grind for 10min, then added 5.9466mL (0.33mol) of deionized water to grind for 5min, then placed the resulting mixture in an oven at 120°C for 5min, and after cooling, water , ethanol, water, acetone and other solvents to wash the solid, and finally put the washed solid in a vacuum oven at 60°C to dry to obtain the desired covalent organic framework material TpPa-1.

[0045] S2: Put the covalent organic framework material TpPa-1 prepared in step S1 in a tube furnace, heat it to 900°C at 0.5°C / min under nitrogen atmosphere, react for 3h, wash with water and ethanol after cooling, place in drying and grinding in an oven, and finally passing t...

Embodiment 2

[0047] Example 2: Preparation of covalent organic framework derived carbon materials

[0048] S1: Add 28.5315g (0.15mol) p-toluenesulfonic acid monohydrate as a catalyst in a mortar, add 5.5272g (0.03mol) benzidine (BD) and grind for 10min, then add 4.2028g (0.02mol) 2 , 4,6-trihydroxy-triphenylenetricarbaldehyde continued to grind for 15 minutes, then added 5.9466mL (0.33mol) deionized water to grind for 8 minutes, then placed the resulting mixture in an oven at 130°C for 10 minutes, cooled it with water, ethanol, water , acetone and other solvents to wash the solid, and finally put the washed solid in a vacuum oven at 60°C to dry to obtain the desired covalent organic framework material TpBD.

[0049] S2: Place the covalent organic framework material TpBD prepared in step S1 in a tube furnace, heat it to 950°C at 0.6°C / min in a helium atmosphere, react for 3h, wash with water and ethanol after cooling, and place in an oven Dry and grind in medium, and finally pass through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com