Boiling-oil prevention type oil-water separation fryer and using method thereof

A technology of oil-water separation and frying machine, which is applied in the direction of oil/fat baking, etc. It can solve the problems of unfavorable continuous frying and safety accidents, and achieve the effect of avoiding the phenomenon of boiling oil and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those of ordinary skill in the art can implement it after referring to this specification.

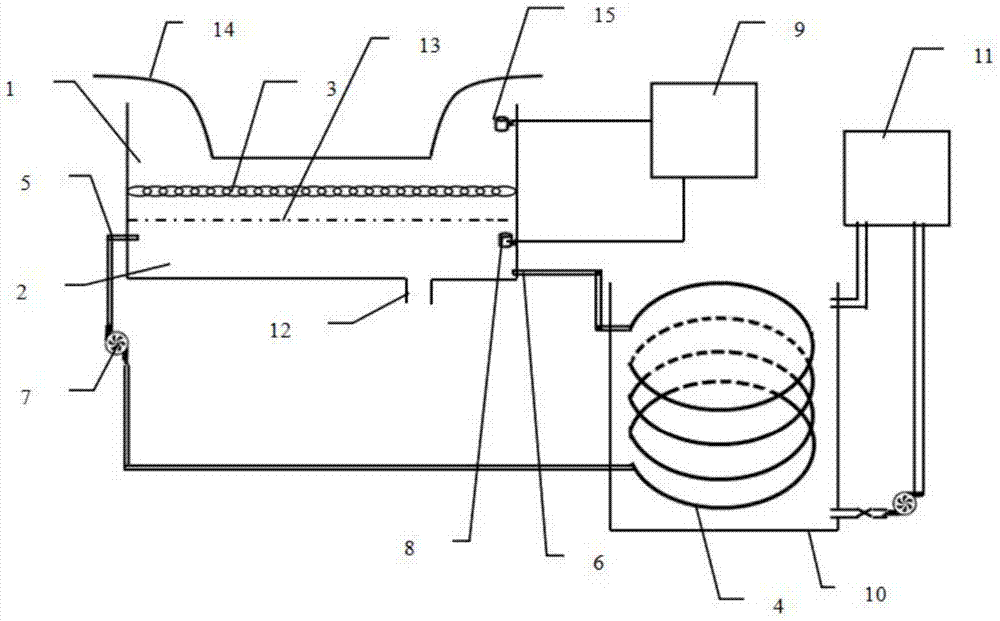

[0028] Such as figure 1 Shown, a kind of anti-boiling oil type oil-water separation frying machine comprises:

[0029] The pot body, its upper part is set as a frying chamber 1, and its lower part is set as a water storage chamber 2, the frying chamber 1 and the water storage chamber 2 are connected; the frying chamber 1 is provided with a heating device 3;

[0030] Water circulation system, it comprises water inlet pipe 5, water outlet pipe 6 and cooling pipe 4, and described water inlet pipe 5 and water outlet pipe 6 are respectively arranged on the water storage chamber 2 wall of pot body and communicates with water storage chamber 2 inside, and described cooling pipe 4. Both ends are respectively connected with the water inlet pipe 5 and the water outlet pipe 6 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com