Patents

Literature

66results about How to "Play the effect of saving energy and reducing consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

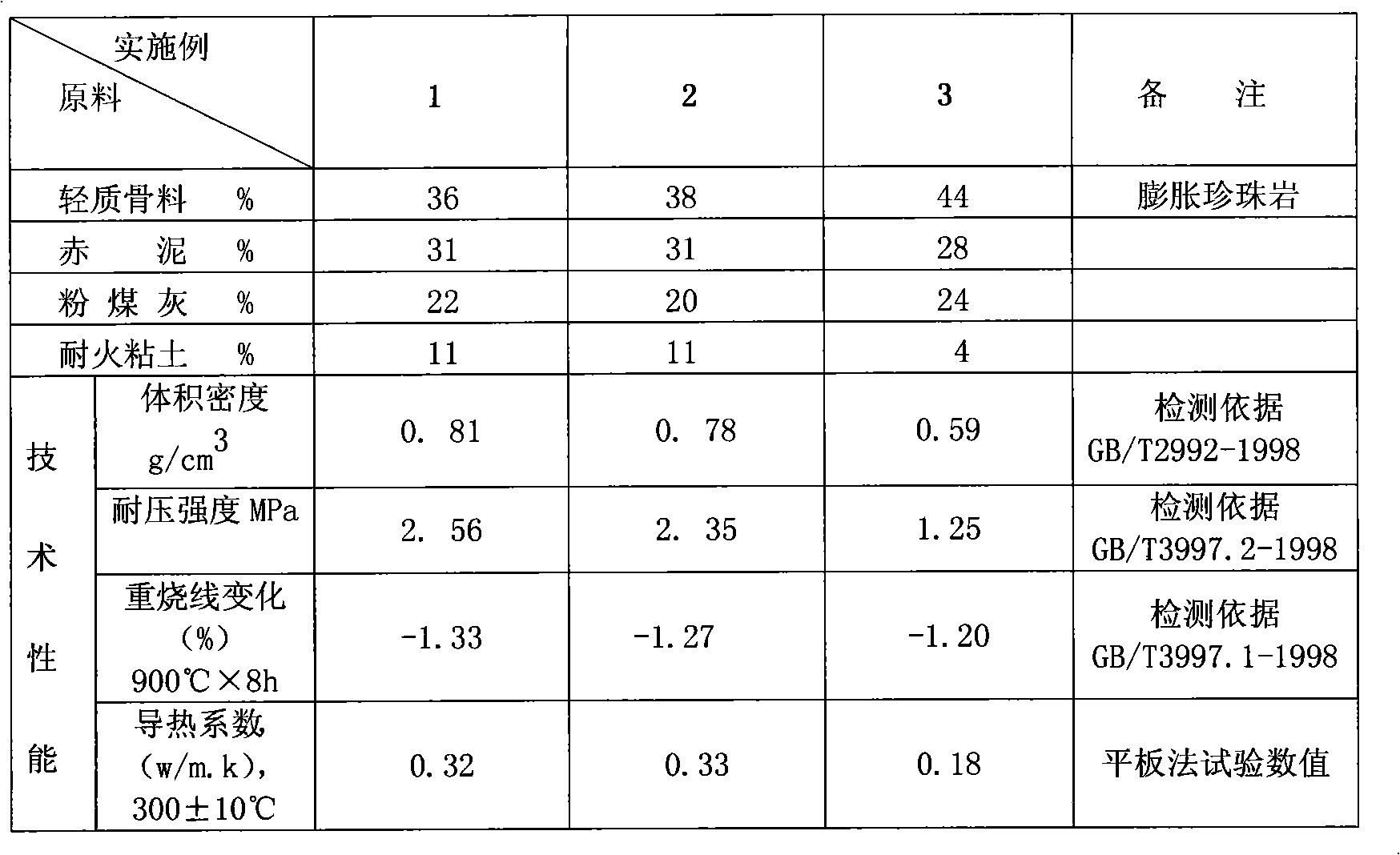

Red mud and fly ash fireproof insulation brick

InactiveCN101514110ALow thermal conductivityPlay a role in heat preservationChemical industryInsulation layer

The invention provides red mud and fly ash fireproof insulation brick which use solid waste red mud produced by alumina industry and solid waste fly ash in fuel electric plant as main raw materials and uses lightweight aggregate and fireproof clay as auxiliary materials. The weight percentage of each component is 10-60 of red mud, 10-50 of fly ash, 15-48 of lightweight aggregate, 4-18 of fireproof clay and 12-25 of water. The used lightweight aggregate is lightweight ceramsite, floating bead, vermiculite, expansion perlite or other lightweight fireproof raw material. The red mud and the fly ash fireproof insulation brick of the present invention have advantages of small volume density and low heat conduction coefficient, can be used for heat-insulation layer of industrial high temperature kiln in industries such as metallurgy, machinery, non-ferrous metal, power, chemical industry and building material, can insulate heat for thermal source, can prevent heat loss in with temperature higher than ambient temperature, and reaches purpose of utilizing industrial waste material, saving resource and energy and reducing emission.

Owner:阮克胜

Sulfur-resisting and nitrogen-removed oxide compound metallic oxide SCR (Selective Catalytic Reduction) catalyst and preparation method thereof

InactiveCN101972661AEasy to prepareEasy to operateDispersed particle separationCatalyst activation/preparationMuffle furnaceChemistry

The invention discloses a sulfur-resisting and nitrogen-removed oxide compound metallic oxide SCR catalyst and a preparation method and applications thereof. The catalyst contains the following elements in the molar ratio: 0.2-2 percent of structural auxiliary element M, 2-4 percent of chromium element and 5-8 percent of manganese element. The preparation method comprises the following steps of: (1) respectively dissolving metal precursors into a citric acid, and evenly stirring and standing for 1-5 hours to respectively obtain an M metal citric acid solution, a chromium metal citric acid solution and a manganese metal citric acid solution; (2) simultaneously and evenly dropwise adding all the metal citric acid solutions to a container and stirring without stop, and continuing to stir for 0.5-3 hours after all the metal citric acid solutions are dropwise added completely; (3) placing the container in a drying oven for drying for 8-15 hours at the temperature of 90-150 DEG C, and then calcining in a muffle furnace for 100-350 min; and (4) tabletting calcined products and then grinding and sieving. The catalyst can be applied to automobile exhaust NOx treatment devices or the denitrification devices of stationary source coal fired power plants.

Owner:SOUTH CHINA UNIV OF TECH

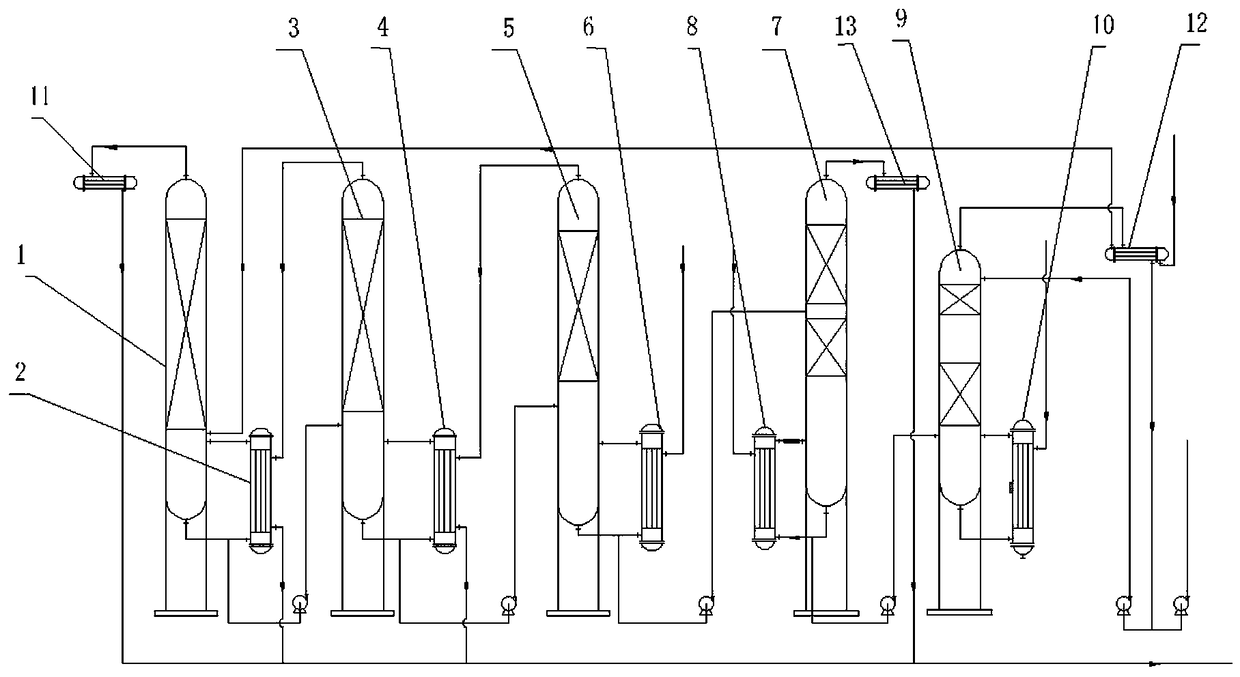

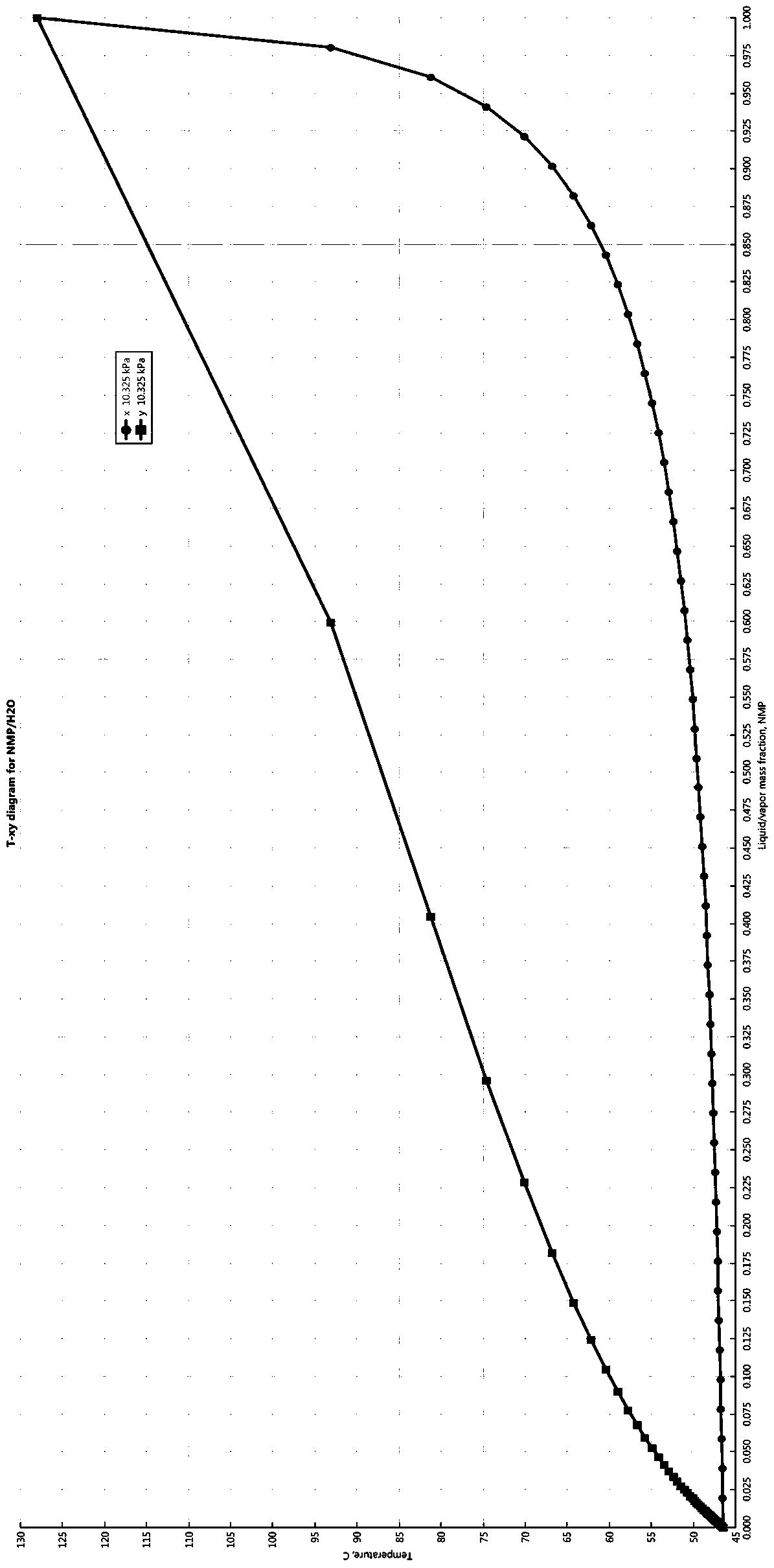

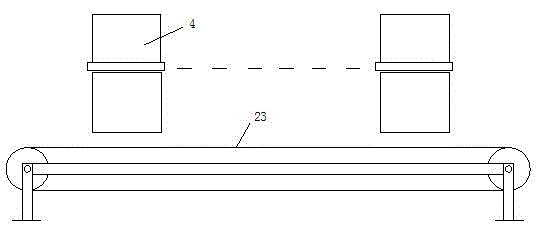

NMP (N-Methyl Pyrrolidone) wastewater low-temperature recycling system and method thereof

InactiveCN108218756ARelieve production pressureIncrease productivityOrganic chemistryNature of treatment waterGas phaseDecomposition

The invention provides an NMP (N-Methyl Pyrrolidone) wastewater low-temperature recycling system and a method thereof. The system comprises a first-stage concentration tower, a second-stage concentration tower, a third-stage concentration tower, a vacuum distillation tower and a refining tower which are connected in sequence through pipelines, wherein the gas-phase discharge hole of the first-stage concentration tower is connected with a heating medium inlet of a first condenser; the liquid-phase discharge hole of each tower is connected with the liquid-phase inlet of a tower of a next stage.By using a negative pressure separation method, effective components of a waste liquid can be separated at a low temperature, decomposition of effective components in the separation process is greatlyreduced, and meanwhile functions of energy conservation and consumption reduction can be achieved.

Owner:梁沛文

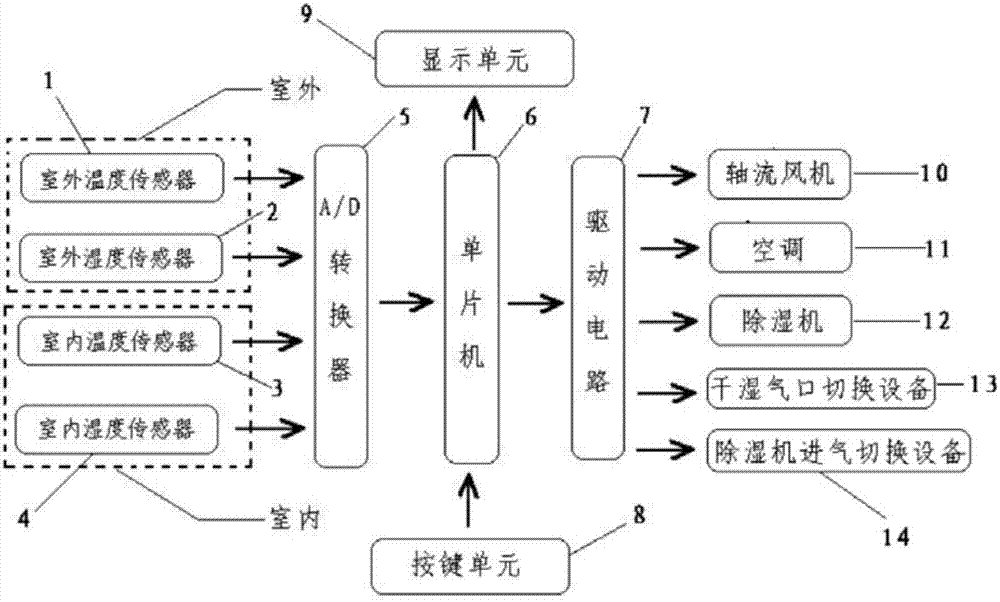

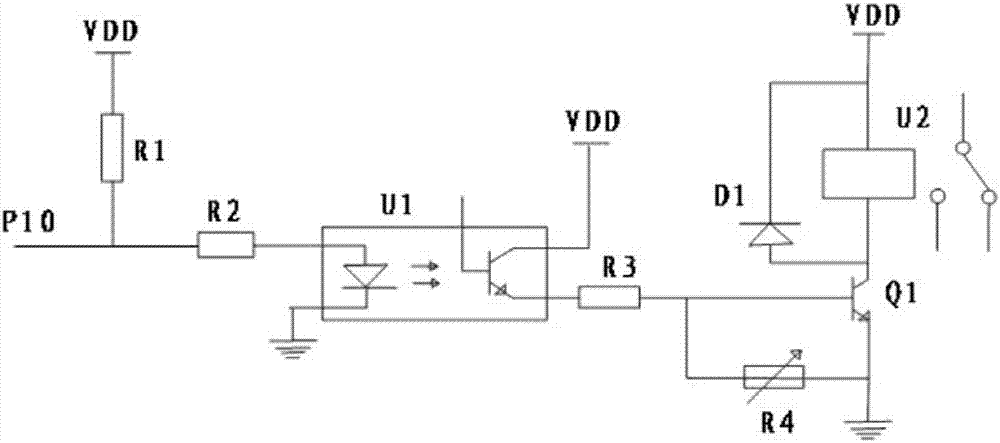

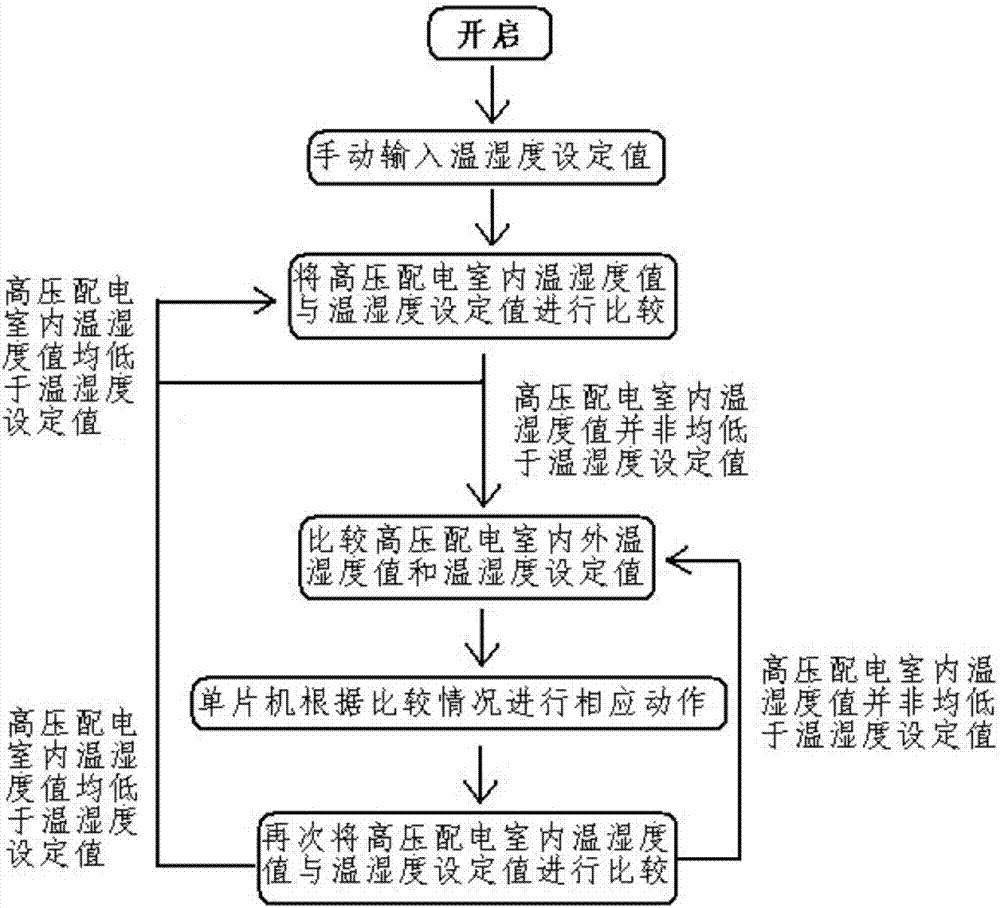

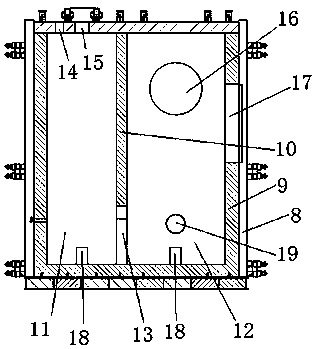

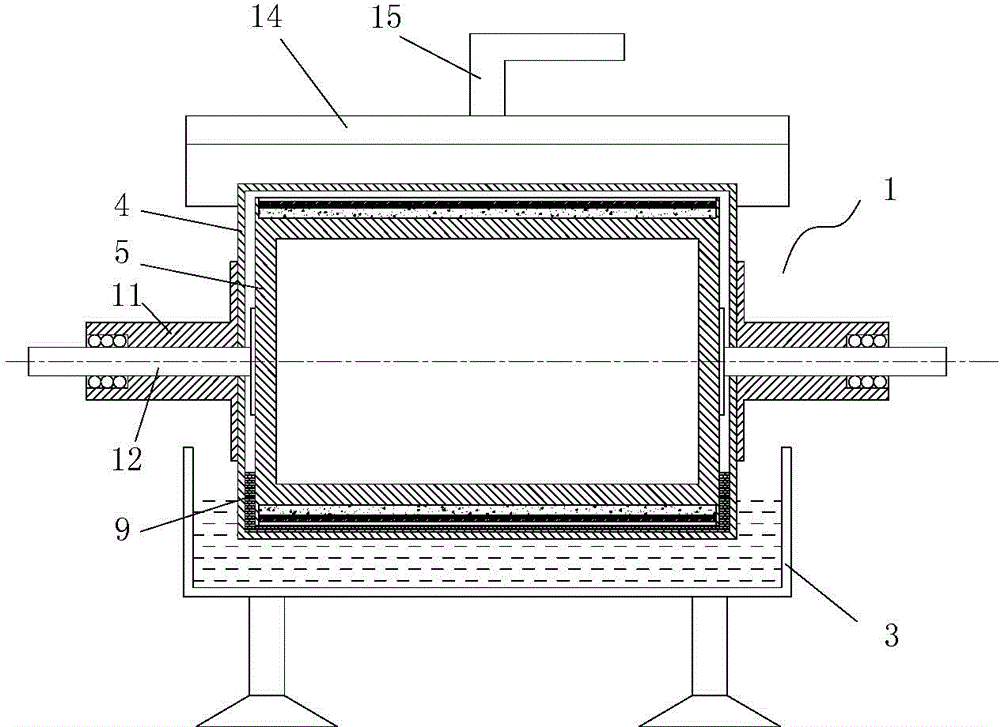

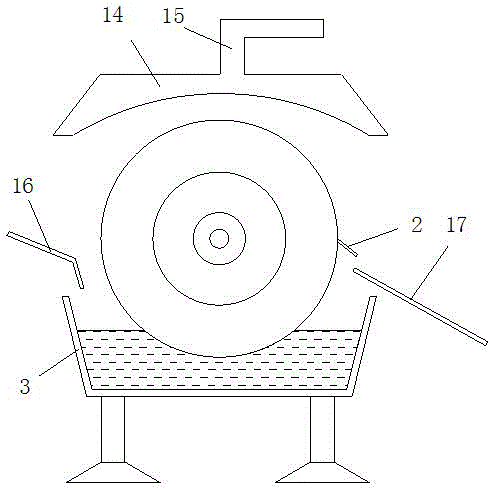

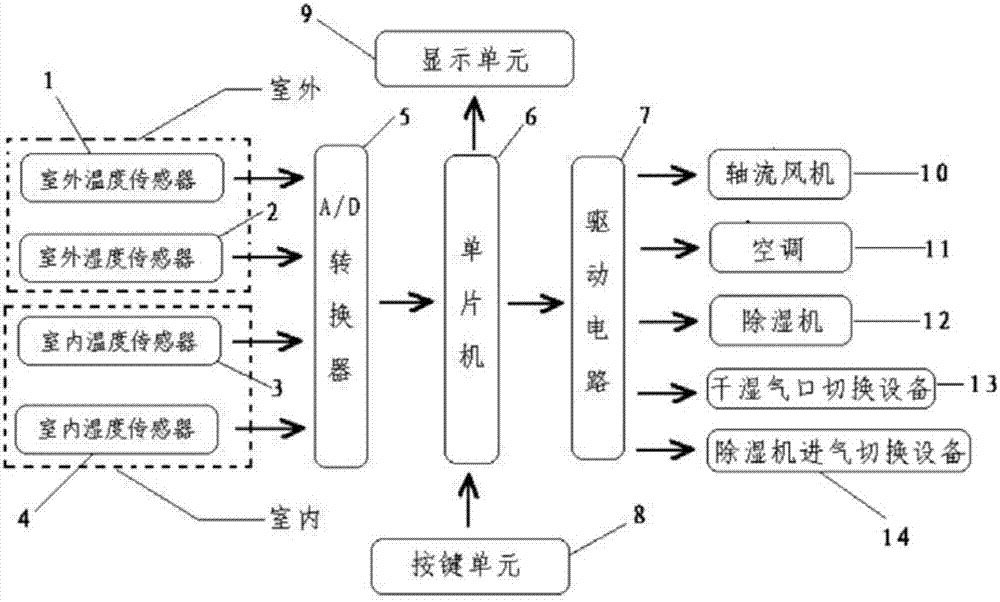

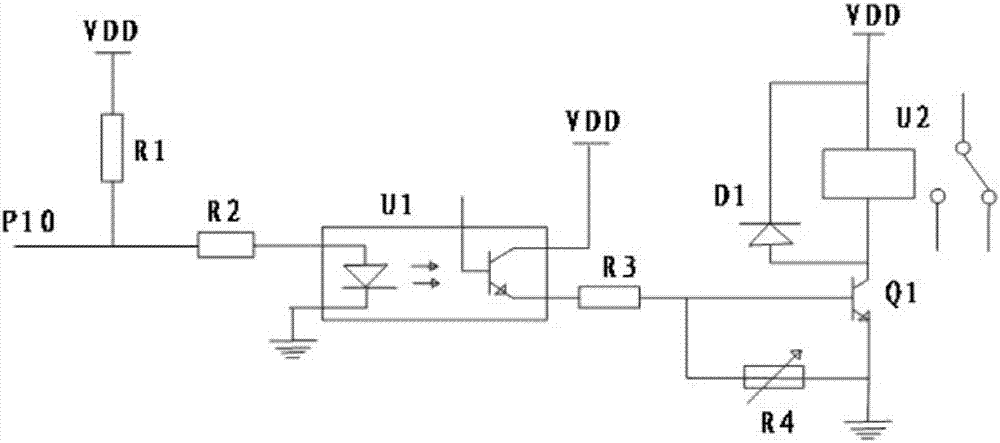

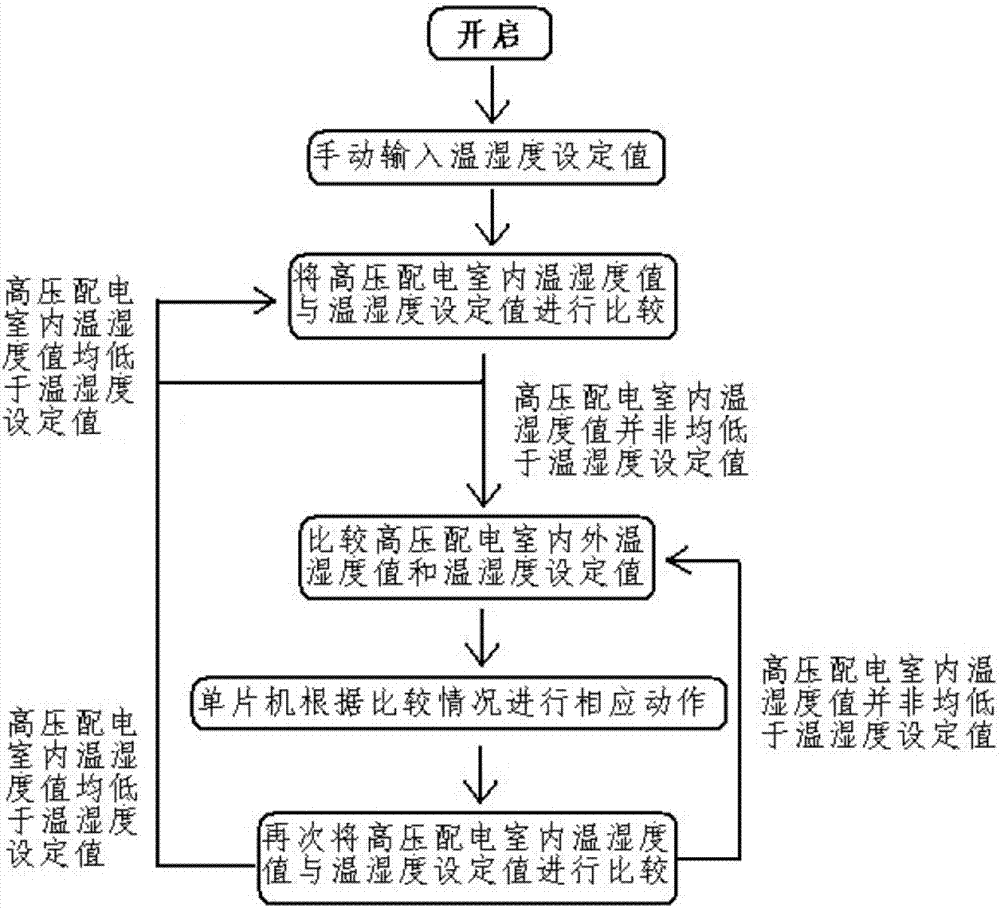

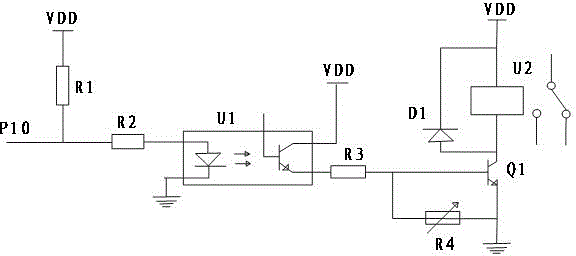

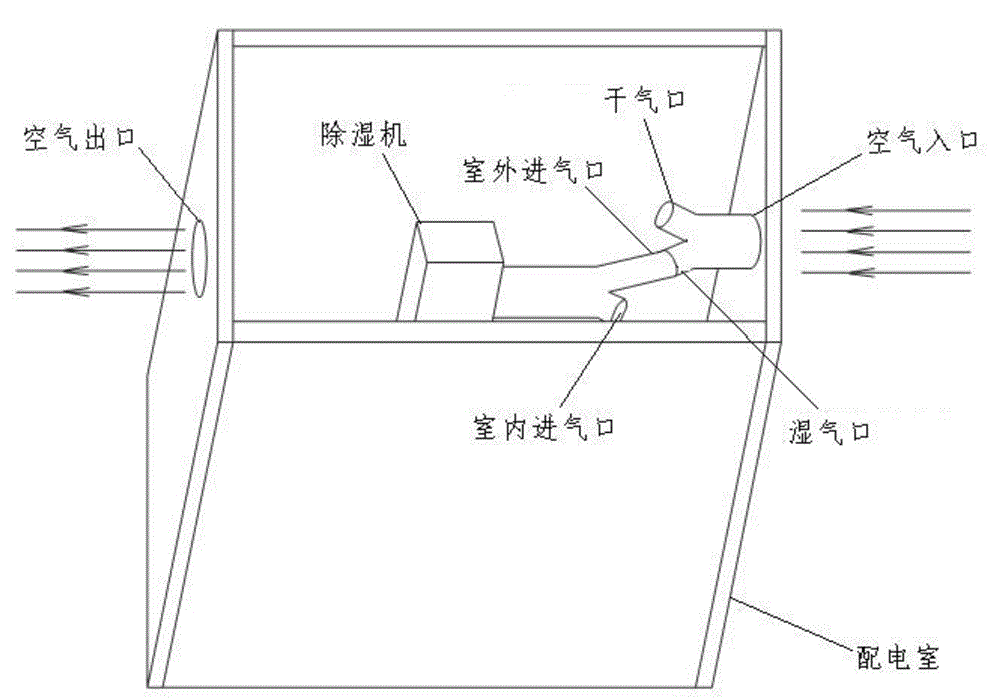

High-voltage power distribution room

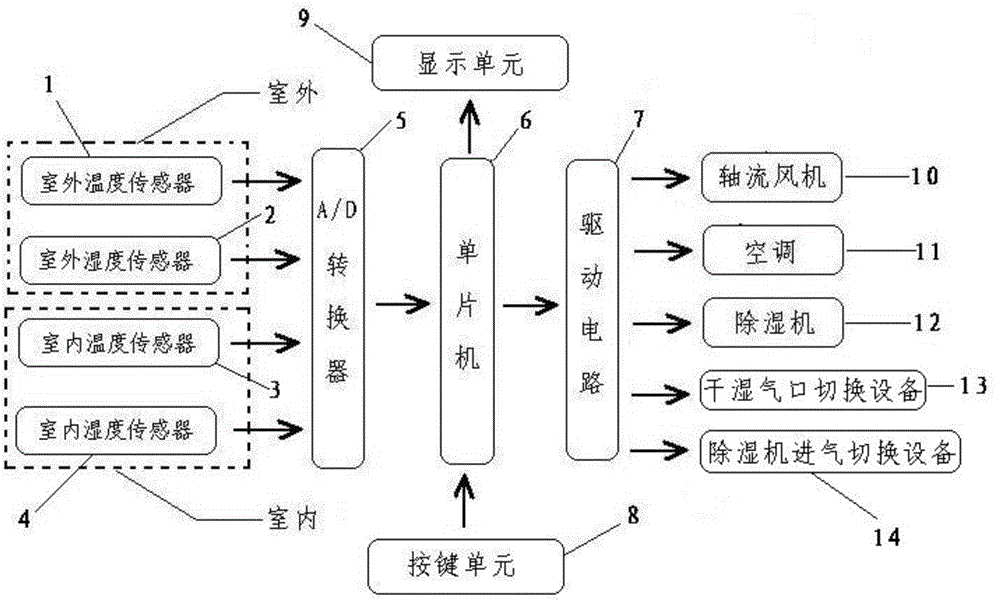

ActiveCN107171223AReduce usage timeSave energy and reduce consumptionBoards/switchyards circuit arrangementsLighting and heating apparatusEngineeringHigh pressure

The invention relates to a high-voltage power distribution room. By adoption of a method, working time of an axial flow fan, an air conditioner and a dehumidifier can be given an overall consideration, the working efficiency of the dehumidifier can be improved, and energy conservation and emission reduction can be realized under the premise of ensuring that the temperature and humidity in the high-voltage power distribution room are in a normal state. When external air enters the high-voltage power distribution room, and if the outdoor humidity is greater than indoor humidity, a single chip microcomputer controls dry and wet air opening switching equipment to close a dry air opening; dehumidifier air inlet switching equipment closes an indoor air inlet opening, and meanwhile, air entering the room is dehumidified; if the outdoor humidity is lower than indoor humidity, the single chip microcomputer controls the dry and wet air opening switching equipment to close a wet air opening, to enable external air to directly enter the high-voltage power distribution room from the dry air opening; and if the air humidity in the high-voltage power distribution room exceeds a normal range, the single chip microcomputer controls the dehumidifier air inlet switching equipment to close an outdoor air inlet, and meanwhile, the air in the room is dehumidified, so as to enable the air humidity in the high-voltage power distribution room to be lowered to the normal range.

Owner:北京明昊鹏程电气安装有限责任公司

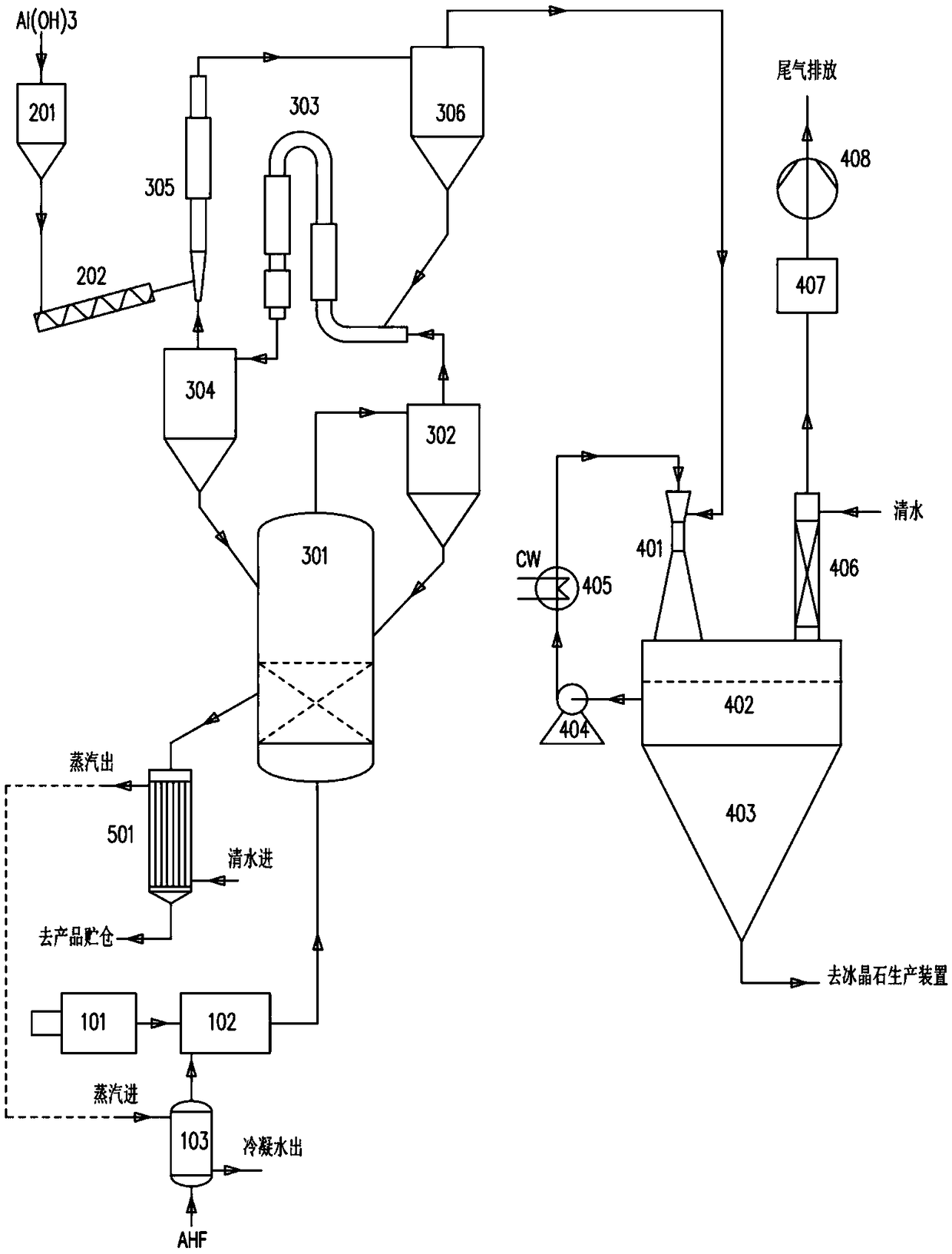

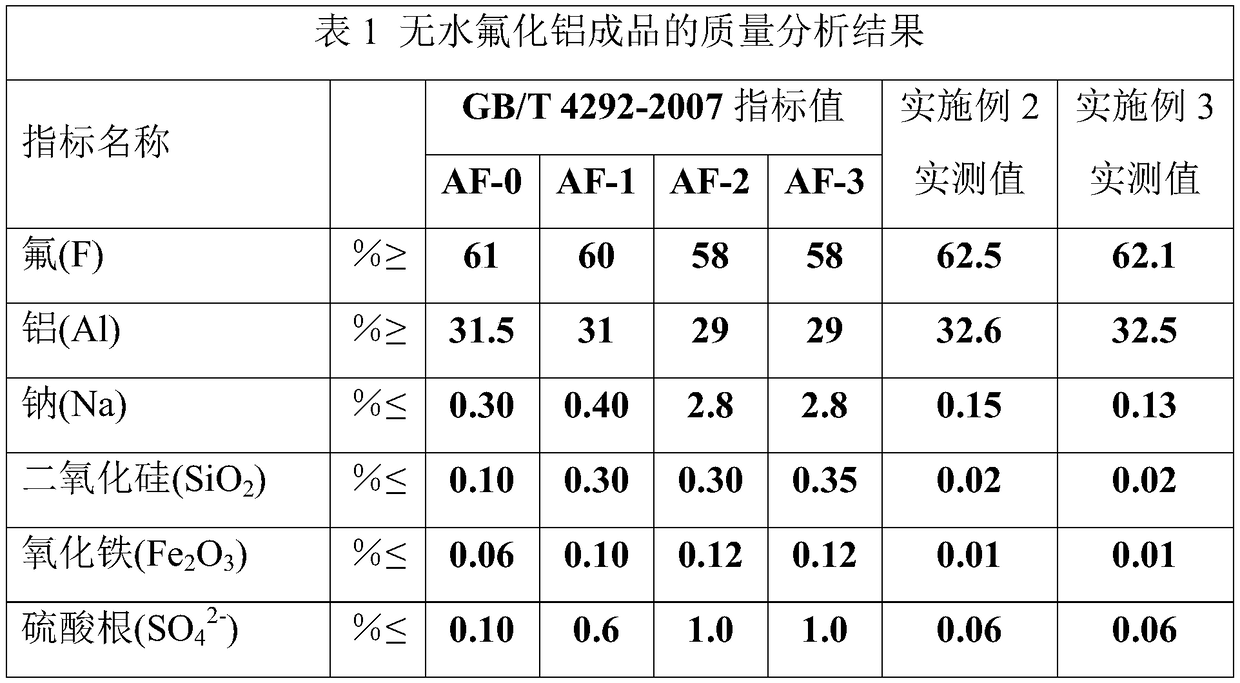

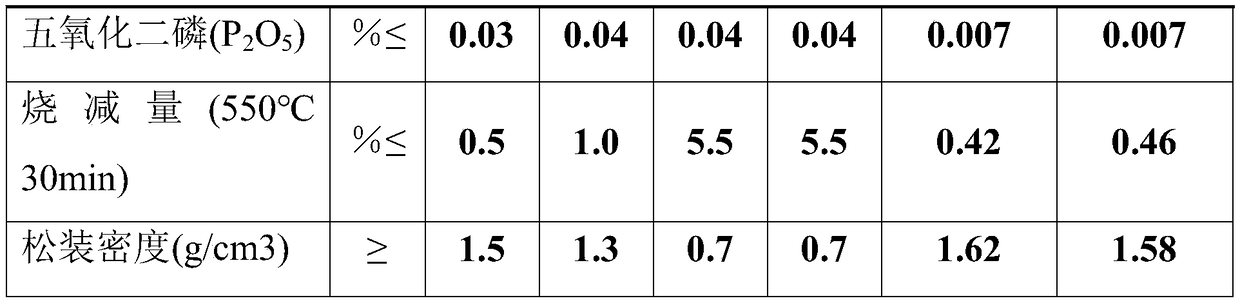

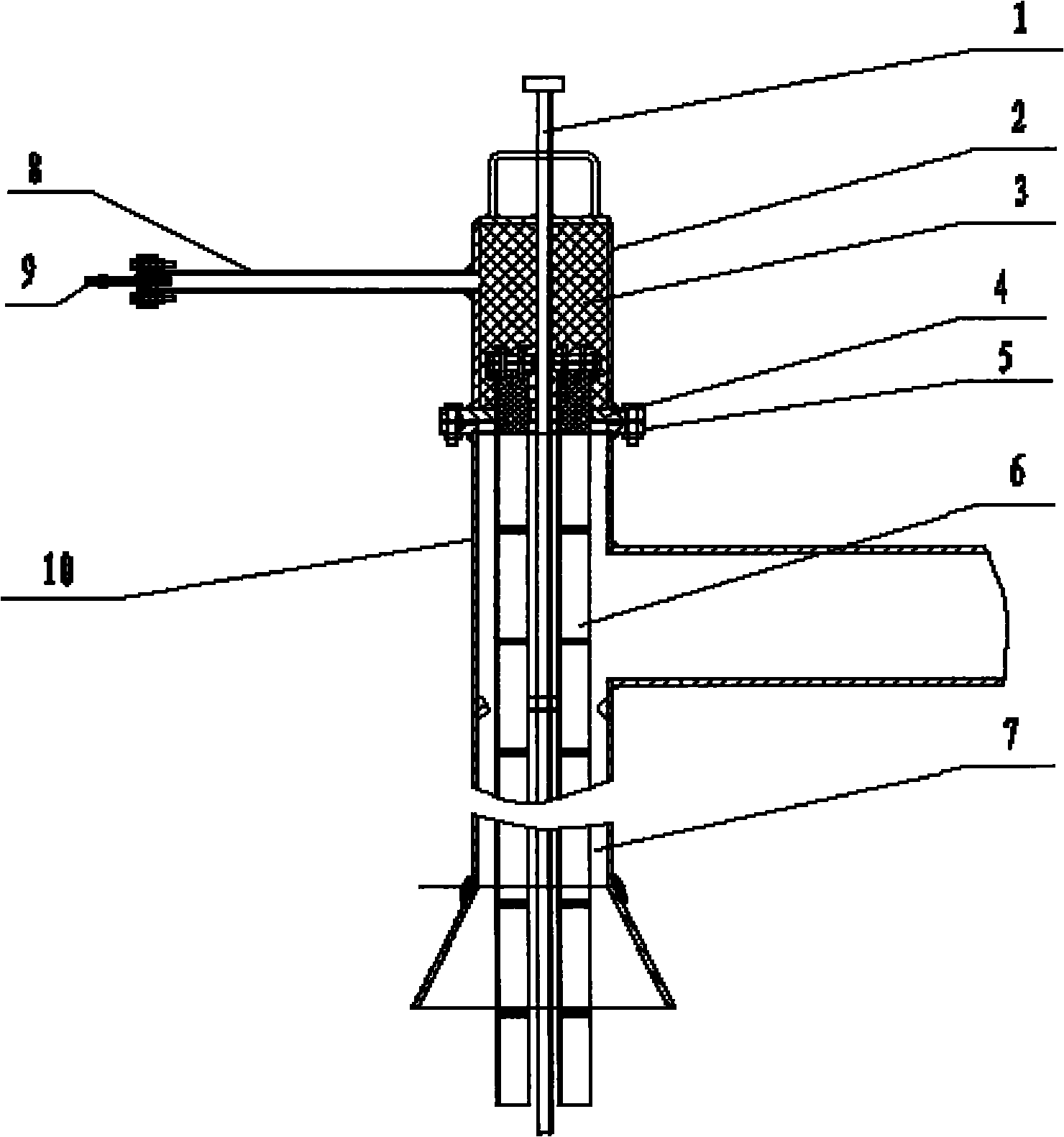

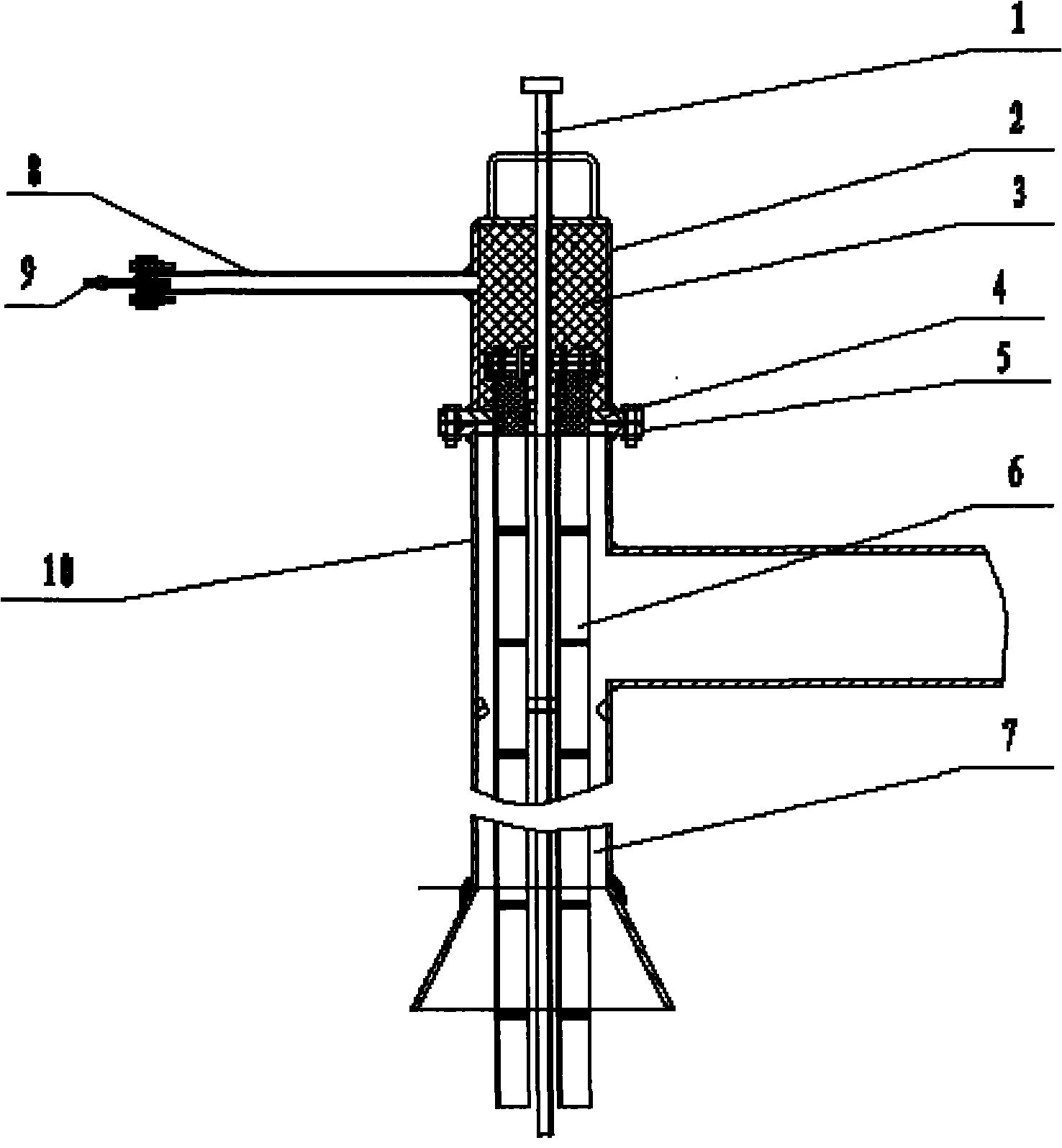

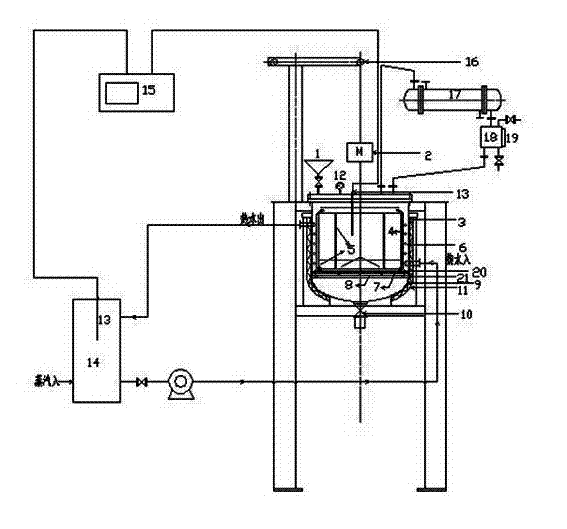

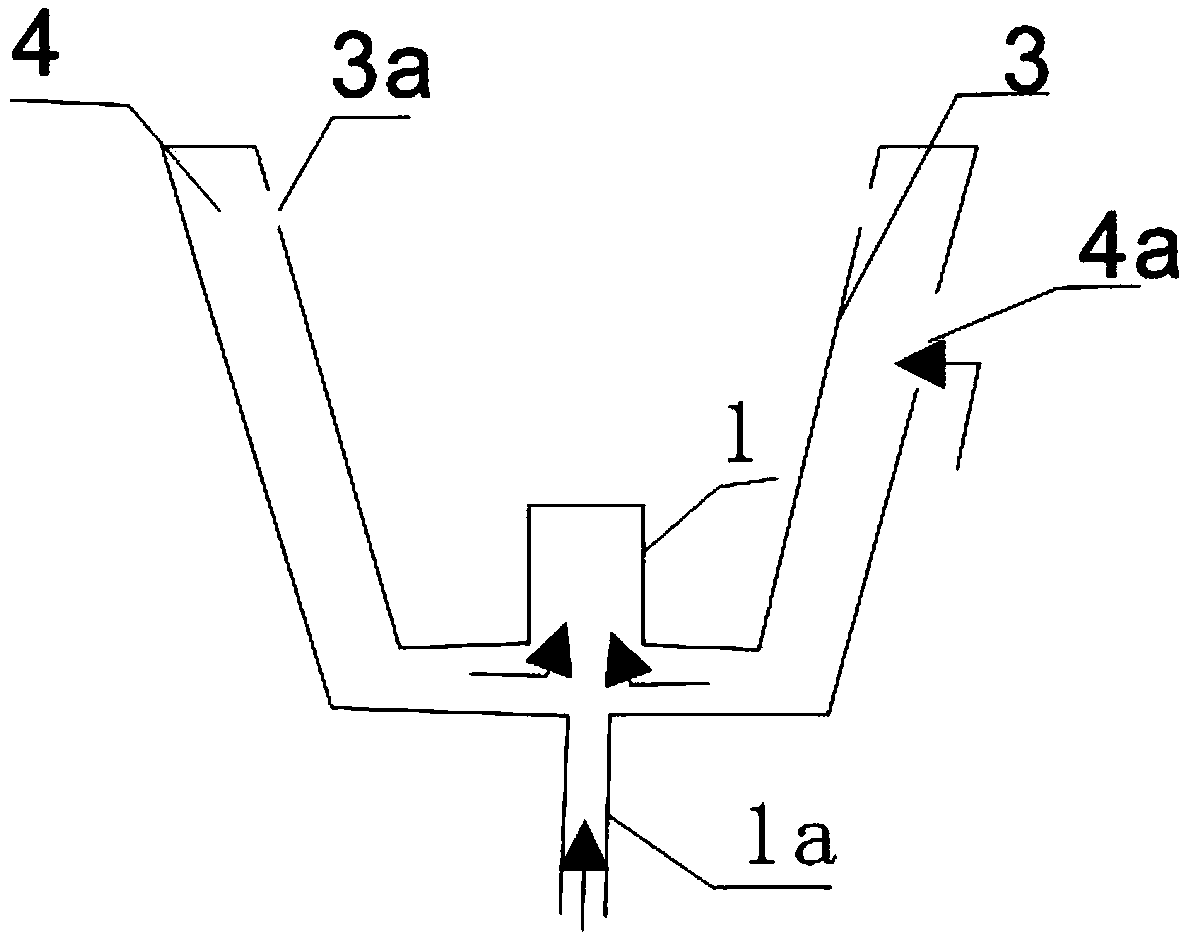

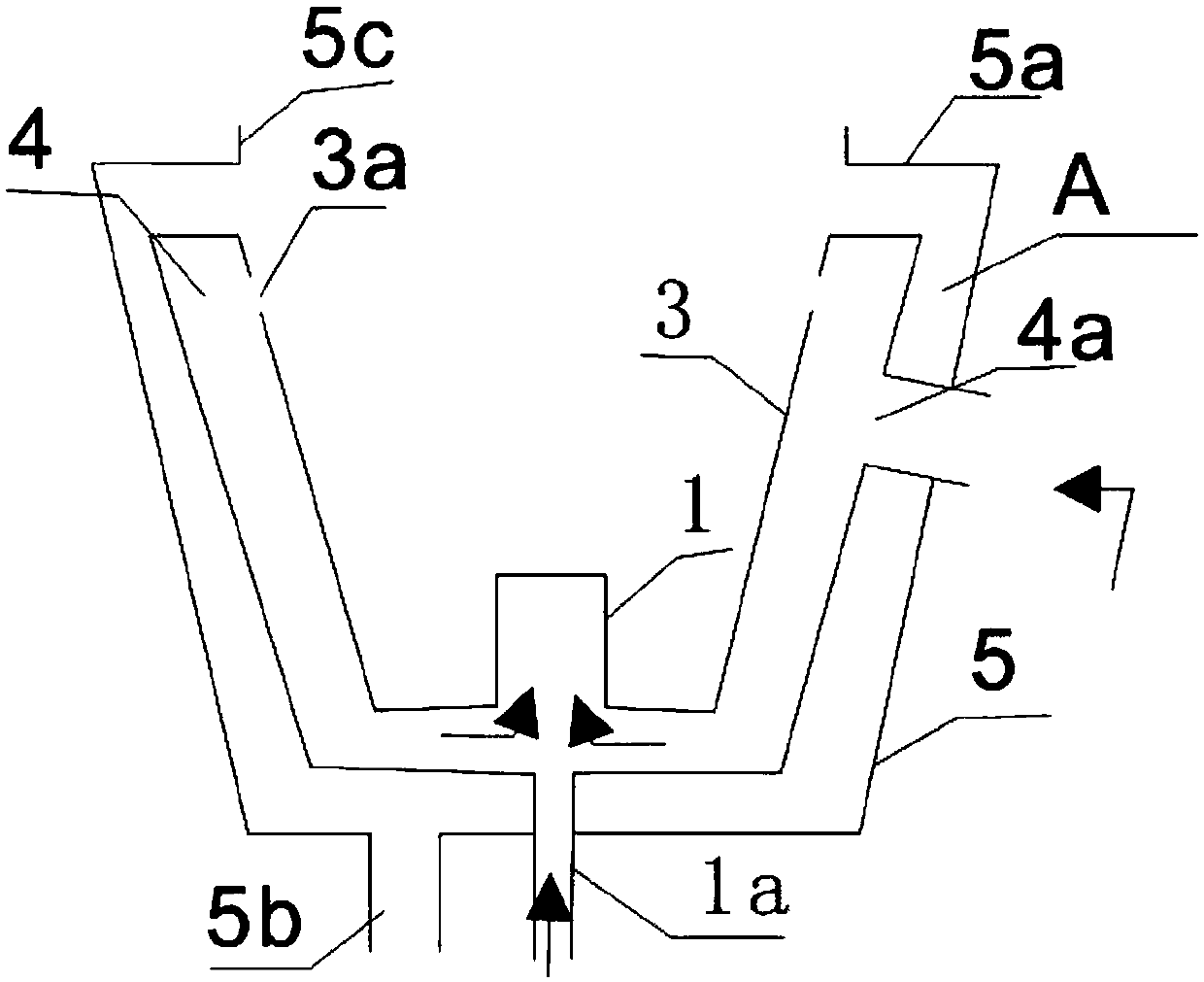

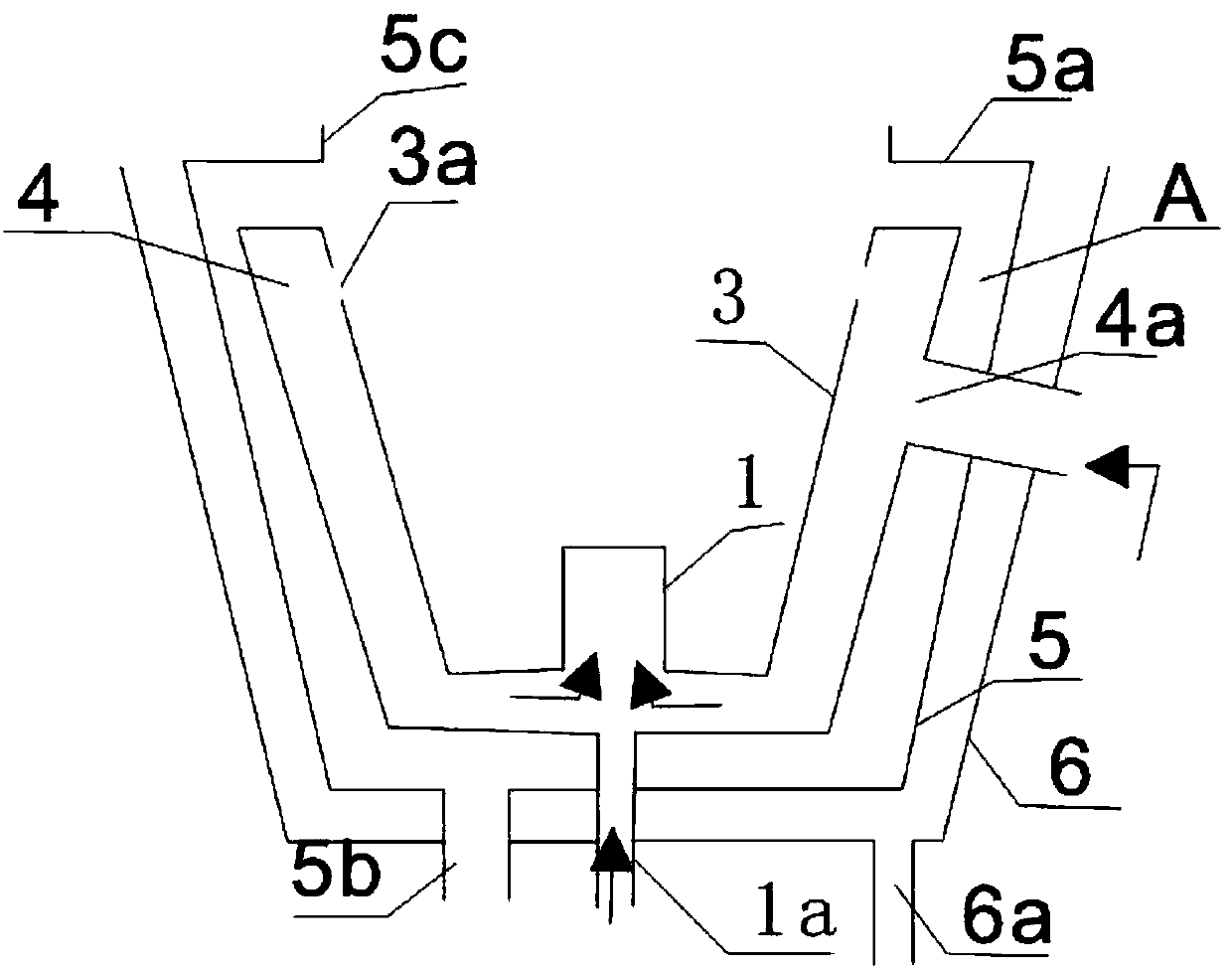

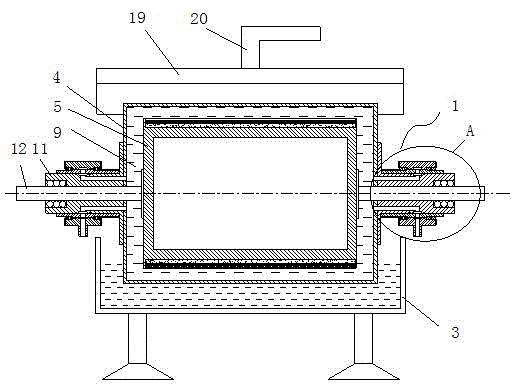

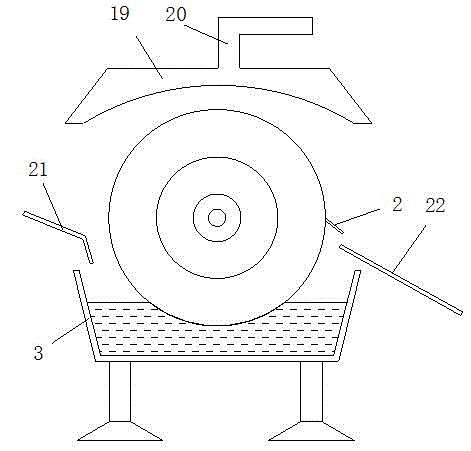

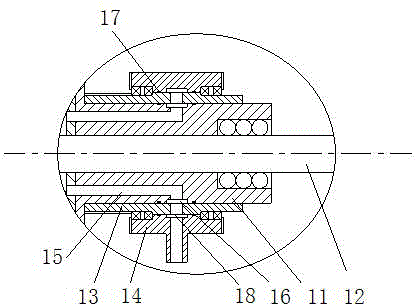

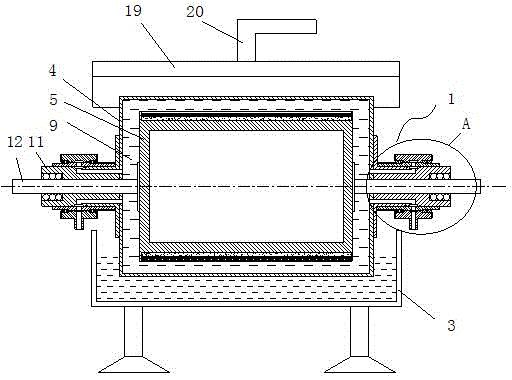

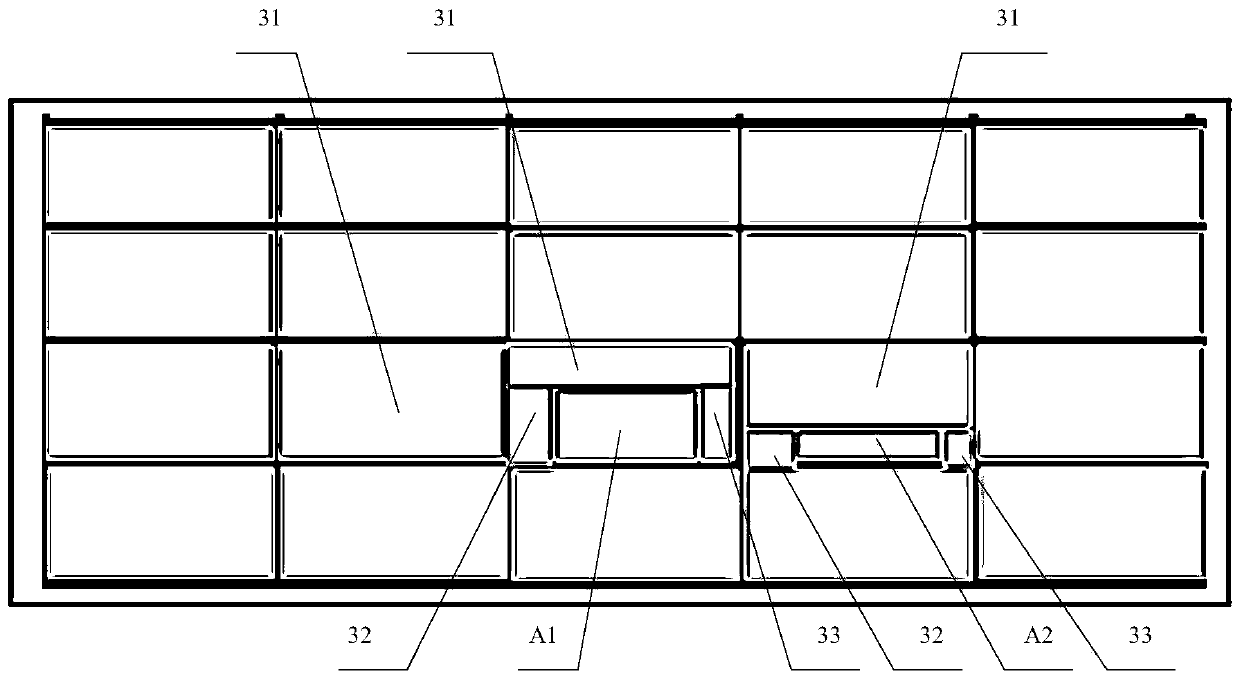

Device and method for preparing anhydrous aluminum fluoride

ActiveCN108840358APlay the effect of saving energy and reducing consumptionPrevent poppingAluminium fluoridesAluminum fluorideHydrogen fluoride

The invention relates to a device and a method for preparing anhydrous aluminum fluoride. The device comprises a gas inlet device, a wet aluminum hydroxide metering and feeding device, a single-layerfluidized bed reactor (301), an aluminum fluoride gas-solid separator (302), an aluminum oxide reactor (303), an aluminum oxide gas-solid separator (304), an aluminum hydroxide dryer (305), an aluminum hydroxide gas-solid separator (306), an aluminum fluoride static cooler (501) and a tail gas treatment device, wherein the gas inlet device comprises an air heater (101), a hydrogen fluoride vaporizer (103) and a hydrogen fluoride mixer (102); the air heater (101) and the hydrogen fluoride vaporizer (103) are connected with the hydrogen fluoride mixer (102) respectively; the hydrogen fluoride mixer (102) is connected with the single-layer fluidized bed reactor (301). Through the device and the method, a prepared product has better quality, namely high content, low impurity, large specific gravity and good fluidity, and the energy consumption is low.

Owner:衢州市鼎盛化工科技有限公司

Anti-blocking tube heating device for sponge production

InactiveCN101812601ASolve the problem of pipe blockageReduce the number of open checksInsulation layerDistillation

The invention discloses an anti-blocking tube heating device for sponge production. The heating device consists of a temperature measuring tube, a sleeve, a heat insulation layer, a sleeve flange, an inverse U-shaped connecting tube, an inverse U-shaped connecting tube flange, a U-shaped resistance wire, two heat radiation sleeves, a contact rod sleeve and a contact rod, wherein one end of the heat radiation sleeve is closed and provided with a pore communicated with the inverse U-shaped connecting tube at the position close to the inverse U-shaped connecting tube flange; the U-shaped resistance wire is arranged inside the heat radiation sleeve, the heat insulation layer is formed in the sleeve, and the sleeve is sealed through the sleeve flange and the inverse U-shaped connecting tube flange; and a U-shaped resistance wire binding post is connected with the contact rod, and the contact rod is sealed in the contact rod sleeve. The heating device effectively solves the problem that a passageway standpipe at the distillation stage of the titanium sponge production is blocked, shortens the distillation time, reduces the times of opening a condenser for examination, reduces the probability of air inlet pollution of a titanium sponge product, saves energy, reduces consumption, and prolongs the service life of the product by about 2 to 3 times.

Owner:洛阳双瑞万基钛业有限公司

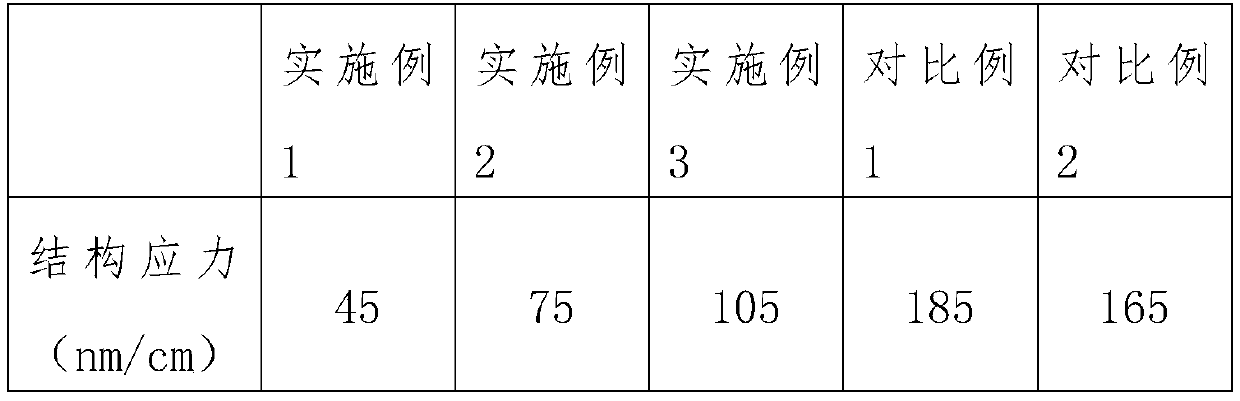

Low-temperature annealing process for reducing stress of glass-metal connection sealing structure

InactiveCN111039579AReduce stress valueImprove safety and reliabilitySolar heating energySolar heat collectors with working fluidsComposite material

The invention discloses a low-temperature annealing process for reducing stress of a glass-metal connection sealing structure. The low-temperature annealing process comprises the following steps: 1, putting a connected and sealed glass-metal connection sealing section into an annealing furnace; 2, increasing the temperature to 200 DEG C from the room temperature; 3, increasing the temperature to 350 DEG C from 200 DEG C; 4, increasing the temperature to 450 DEG C from 350 DEG C; 5, increasing the temperature to 520 DEG C from 450 DEG C; 6, reducing the temperature to 470 DEG C from 520 DEG C;7, reducing the temperature to 370 DEG C from 470 DEG C; 8, reducing the temperature to 300 DEG C from 370 DEG C; and 9, reducing the temperature to the room temperature from 300 DEG C. According to the invention, the glass metal connection sealing part is subjected to annealing treatment at the temperature below the glass strain point, so that the stress value of the connection sealing part is greatly reduced, the safety and the reliability of the connection sealing part are improved, the qualification rate of the product is improved, and the effective life of the whole product is prolonged.

Owner:北京天瑞星光热技术有限公司

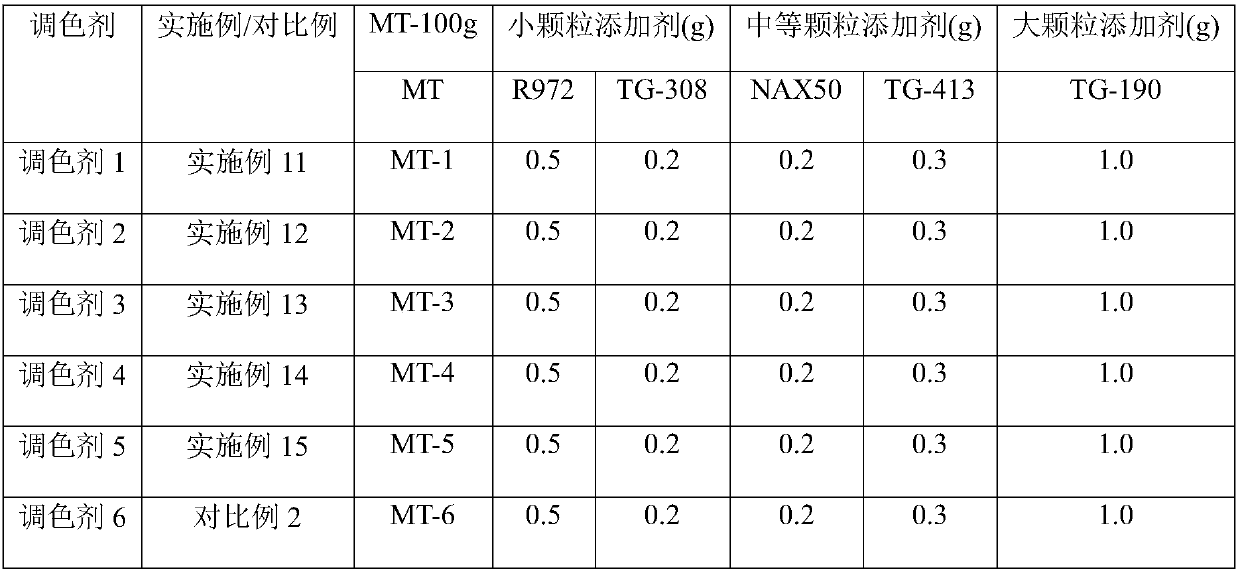

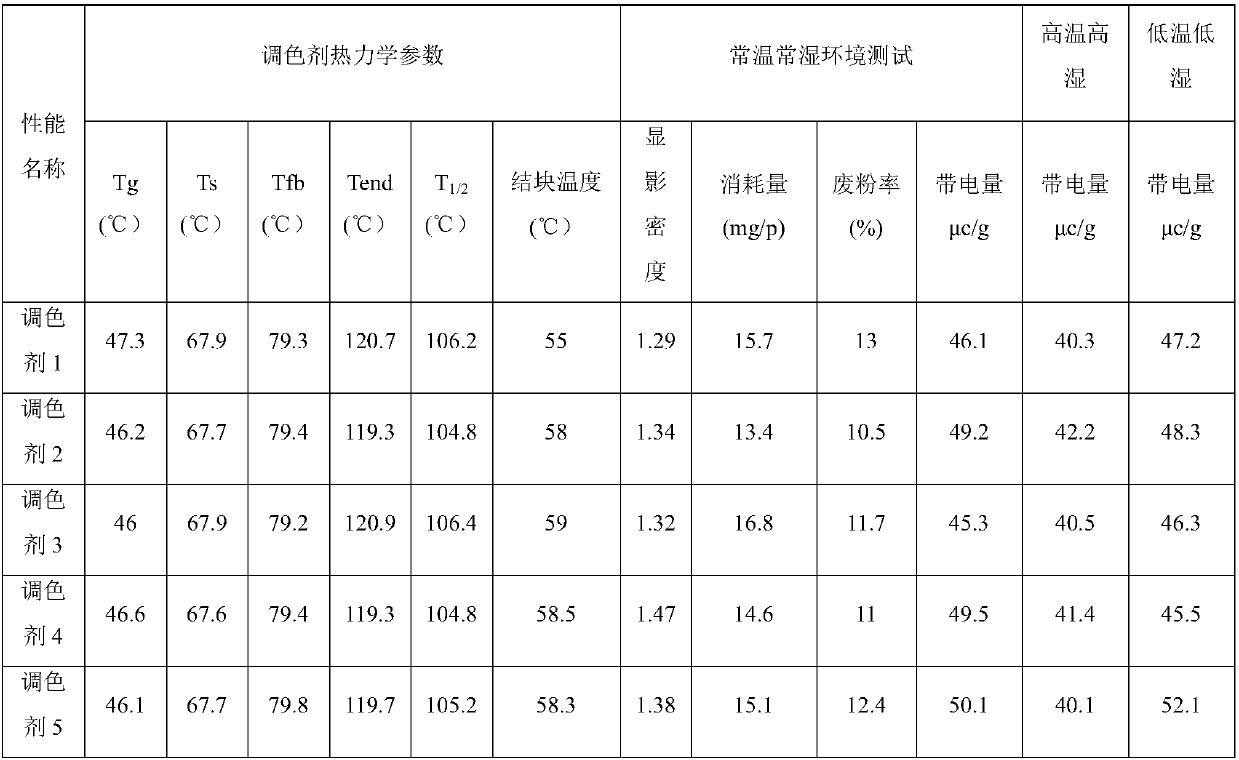

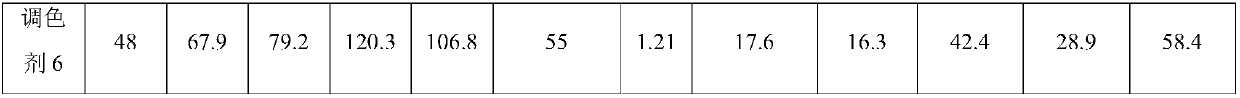

Additive for toner and preparation method thereof

The invention provides an additive for a toner and a preparation method thereof and relates to the field of toners. The additive for the toner, provided by the embodiment of the invention, is a modified nano silicon dioxide compound of hyperbranched polyester; the additive for the toner is obtained by the specific steps of modifying nano silicon dioxide and grafting hyperbranched polyester resin on the surface of the nano silicon dioxide. The preparation method is simple, and the electrifying effect and the stability can be increased; adhesive emulsion provided by the embodiment of the invention is obtained by shearing and dispersing the polyester resin and the additive for the toner, and has good compatibility; the toner provided by the embodiment of the invention is prepared by coagulating the adhesive emulsion, a color agent dispersion solution and a release agent dispersion solution; the electrifying amount and the stability can be increased; the vitrification and rheological parameters are improved; the image quality and gloss of printed and copied images are improved and the effects of saving energy and reducing consumption are realized.

Owner:HUBEI DINGLONG CO LTD

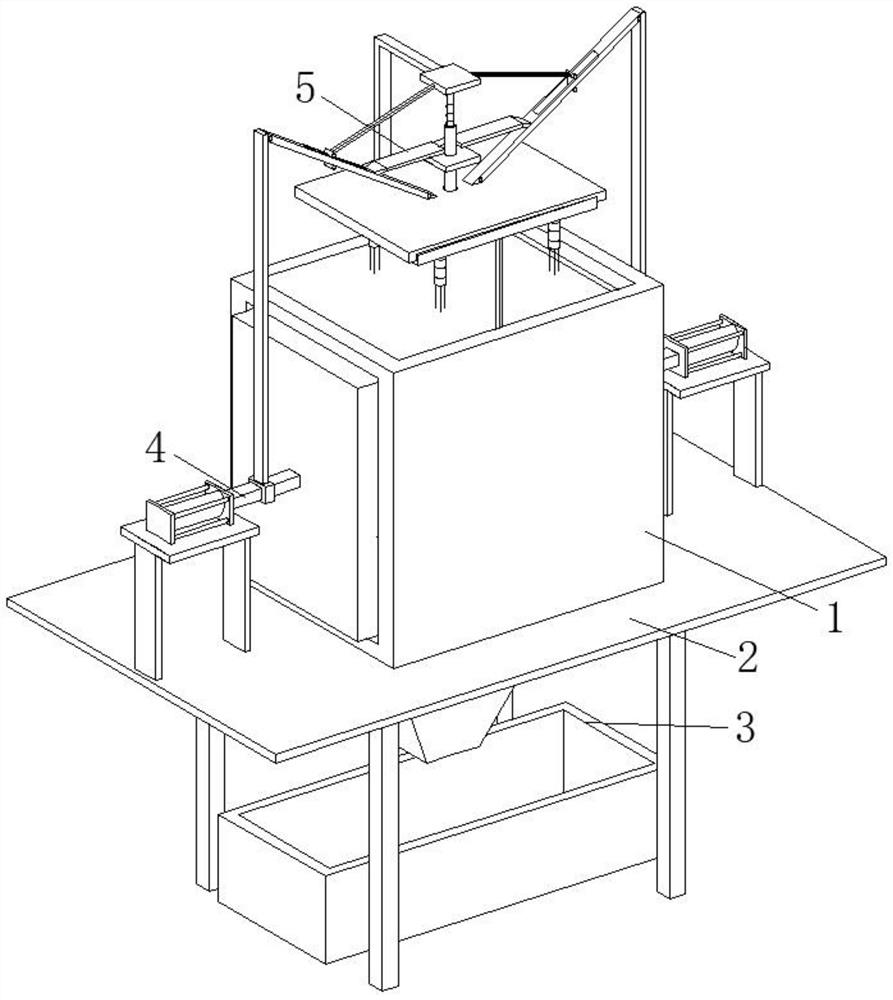

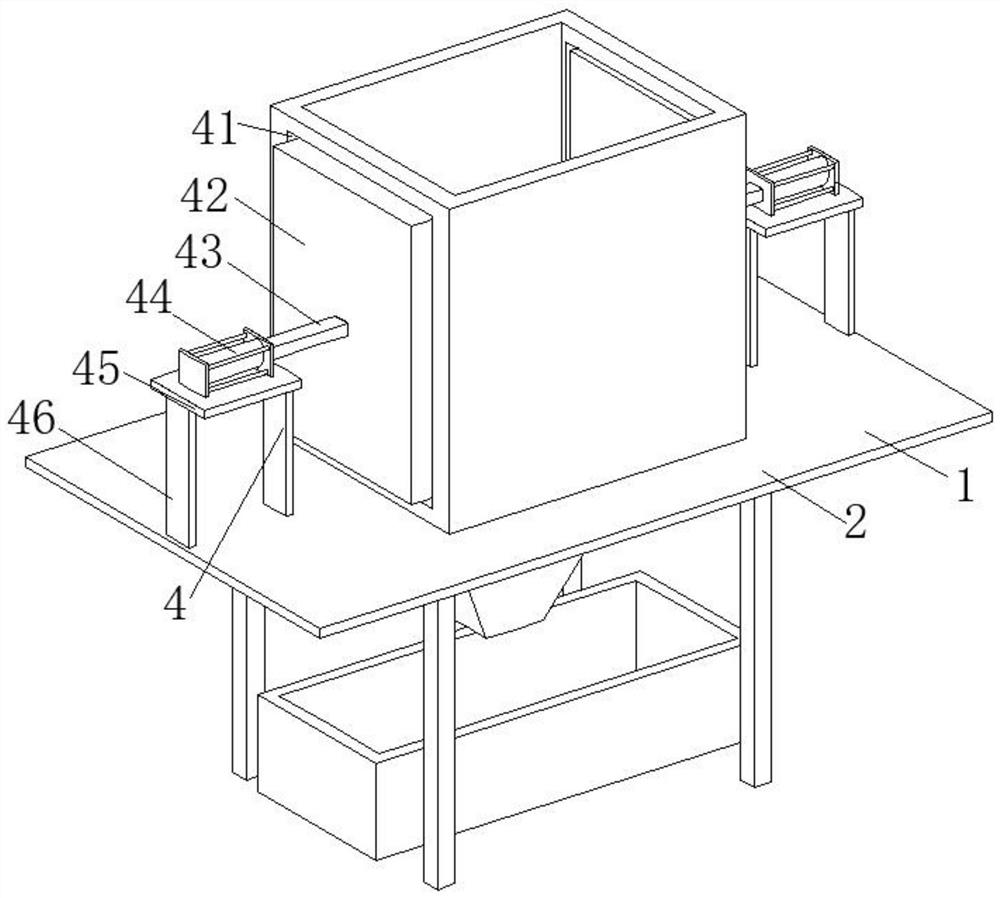

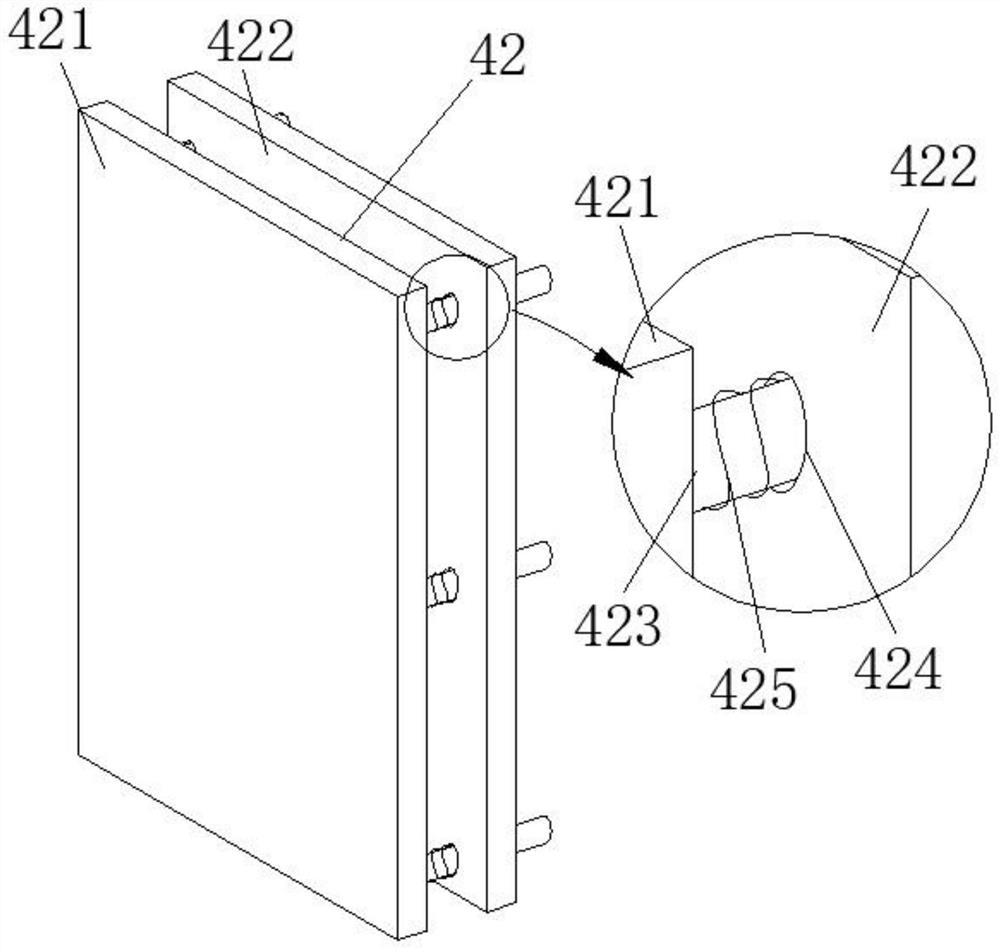

Sludge dewatering device and using method thereof

InactiveCN112661377AReasonable dehydration structure designEasy to operateSludge treatmentProcess engineeringWorkbench

The invention relates to a sludge dewatering device and a using method thereof. The sludge dewatering device comprises a sludge dewatering box, a workbench and a storage box, the sludge dewatering box is arranged on the workbench, the storage box is arranged under a drain pipe of the sludge dewatering box, and side extrusion mechanisms are arranged on the sludge dewatering box and the workbench; according to the sludge dewatering device, an extrusion dewatering mode is adopted for dewatering, the dewatering mode can be suitable for dewatering a large amount of sludge, the effect of efficient dewatering can be achieved in the dewatering process, the arrangement and dewatering structure of the dewatering device is reasonable in design, operation is easy, and in the dewatering process, dewatering can be conducted through cooperation of multiple steps, the dewatering effect is achieved, the dewatering time in the sludge dewatering process can be greatly saved, saves the cost investment in the dewatering process can be saved, and the market requirements can be better met.

Owner:HANGZHOU YUEQI ENVIRONMENTAL PROTECTION TECH CO LTD

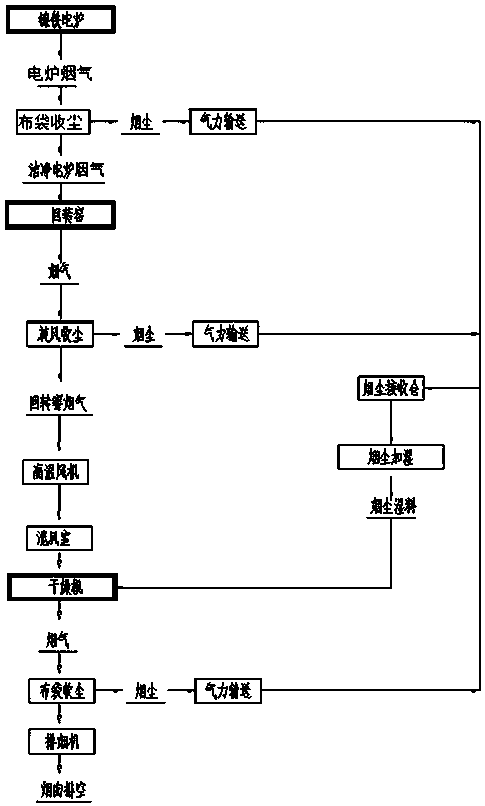

Laterite-nickel ore RKEF smelting process smoke comprehensive treatment system and method

InactiveCN108411116ASmall scaleNot easy to damageProcess efficiency improvementCombustion chamberSmelting process

The invention discloses a laterite-nickel ore RKEF smelting process smoke comprehensive treatment system which comprises a ferronickel electric furnace, a water cooling flue, a first bag collector, arotary kiln, a cyclone dust collector, a combustion air mixing chamber, a drying machine and a second bag collector; a gas outlet of the ferronickel electric furnace is connected with the lower end ofthe water cooling flue; the upper end of the water cooling flue is connected with a gas inlet of the first bag collector through a pipeline; a gas outlet of the first bag collector is connected witha gas inlet of the rotary kiln through a pipeline; a gas outlet of the rotary kiln is connected with a gas inlet of the cyclone dust collector through a pipeline; the combustion air mixing chamber comprises a combustion chamber and a smoke mixing chamber; a gas inlet of the smoke mixing chamber is connected with a gas outlet of the cyclone dust collector through a pipeline; a gas outlet of the smoke mixing chamber is connected with a gas inlet of the drying machine; and a gas outlet of the drying machine is connected with a gas inlet of the second bag collector through a pipeline. The laterite-nickel ore RKEF smelting process smoke comprehensive treatment system saves energy, is environmentally friendly and is high in smoke utilization ratio.

Owner:JINCHUAN GROUP LIMITED

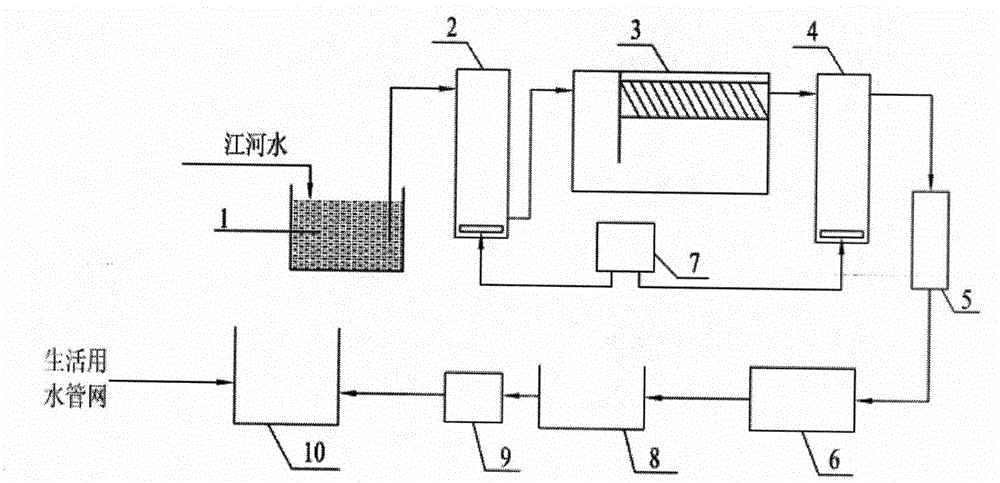

Circulating cooling water filling purification system

InactiveCN104355467AImprove hydration water qualityIncrease the concentration factorWater treatment parameter controlWater treatment compoundsOzone generatorDistributed control system

The invention discloses a circulating cooling water filling purification system which comprises a reservoir, a pre-ozone contact tower, a coagulative precipitation tank, a post-ozone contact tower and an electrochemical processor which are sequentially communicated, wherein a filter is arranged between the post-ozone contact tower and the electrochemical processor; an ozone generator is arranged between the pre-ozone contact tower and the post-ozone contact tower; the water outlet of the post-ozone contact tower is connected to the water inlet of the filter; the electrochemical processor is communicated with the reservoir; the reservoir is communicated with a circulating cooling tank; the circulating cooling tank is connected to a domestic water supply pipe network; a water filling pump is arranged on a pipeline between the reservoir and the circulating cooling tank; a high-low level gauge is mounted in the circulating cooling water tank; and the water filling pump and the high-low level gauge are connected to a distributed control system (DCS) in a control room. The circulating cooling water filling purification technology disclosed by the invention can be used for improving the operating efficiency and concentration multiple of circulating water, and is beneficial to energy conservation and emission reduction; moreover, the purification device is also conductive to relieving equipment corrosion during working, and the serve life of the equipment is prolonged.

Owner:浙江安耐杰科技股份有限公司

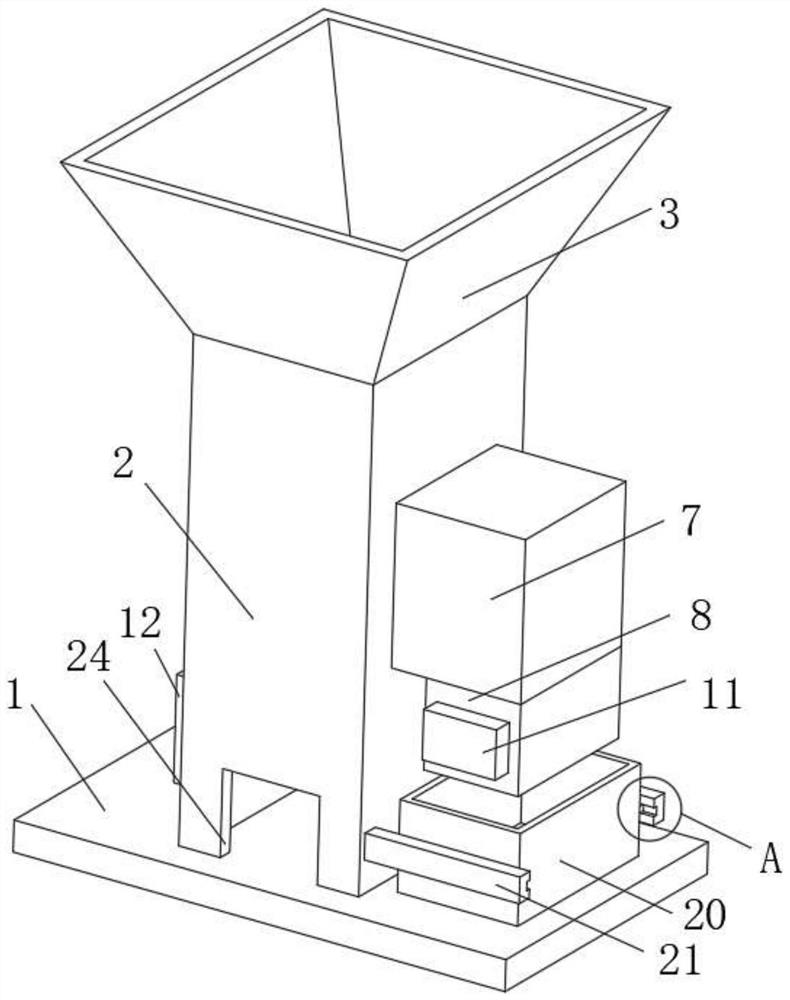

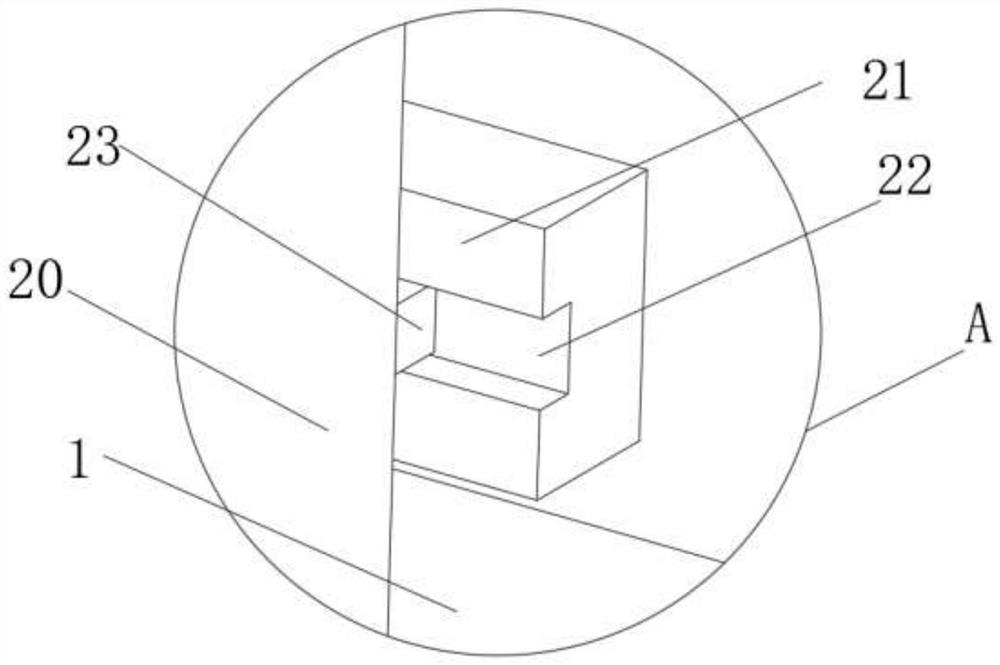

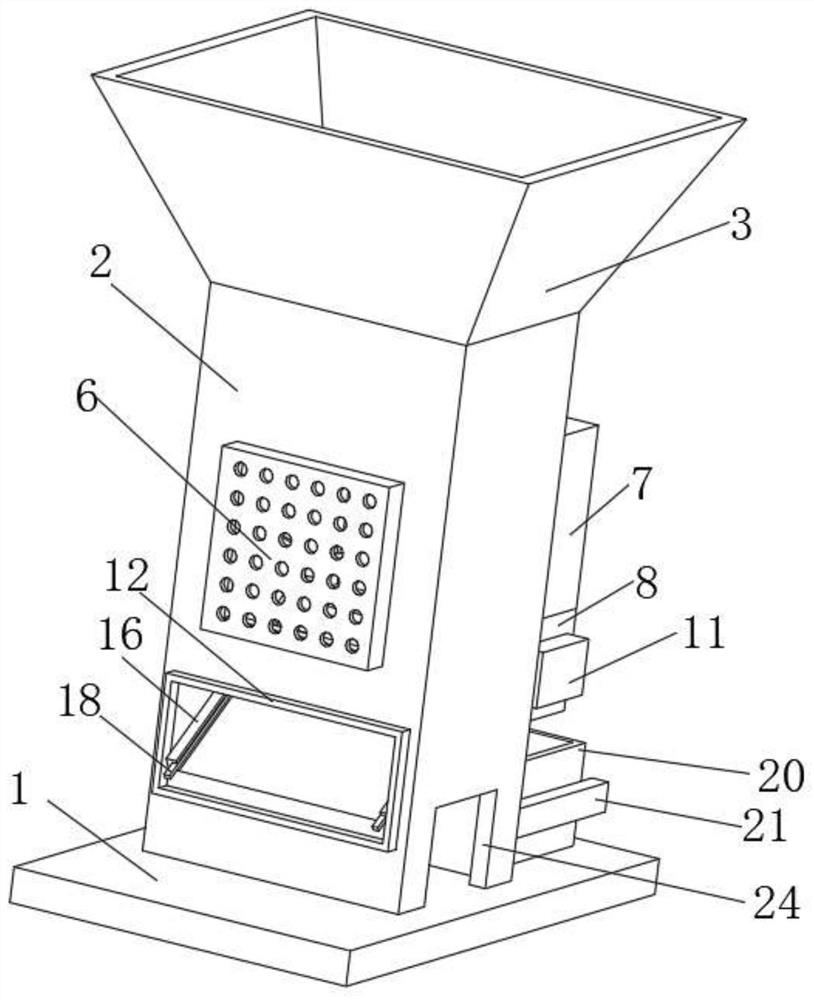

Solid waste sorting device

ActiveCN112157112AFunction increaseRealize processingGas current separationUsing liquid separation agentMechanical engineeringWaste management

The invention relates to the technical field of sorting equipment, and discloses a solid waste sorting device. The solid waste sorting device comprises a bottom plate; a vertical pipe is fixedly connected to the top surface of the bottom plate; a feeding funnel fixedly communicates with the top surface of the vertical pipe; a mounting groove is formed in the left side surface of the vertical pipe;and a fan is fixedly mounted on the inner surface of the mounting groove. According to the solid waste sorting device, a discharging box fixedly communicates with the bottom of a feeding box, a rotating shaft is movably sleeved with the discharging box, the rotating shaft is sleeved with a crushing roller, the crushing roller is driven by a power box to rotate, light waste blown into the feedingbox and falling into the discharging box is crushed, the crushed light waste falls into a collecting box, treatment of the light waste is timely and effectively realized, additional collection and transportation of the light waste are avoided, the light waste is transferred to crushing treatment equipment, the treatment process is shortened, the treatment time is shortened, the treatment efficiency is improved, the functions of the sorting device are expanded, and the use effect is good.

Owner:深圳市前海极智创新科技有限公司

Efficient environment-friendly papermaking production line

ActiveCN112342811AQuality improvementReduce labor intensityWashing/displacing pulp-treating liquorsPaper recyclingPaper dustPapermaking

The invention relates to an efficient environment-friendly papermaking production line, belonging to the technical field of papermaking mechanical equipment. The efficient environment-friendly papermaking production line is characterized by comprising pulping equipment, wherein a feeding device of the pulping equipment can feed waste paper raw materials into a coarse crushing device; the coarse crushing device can crush the waste paper raw materials into coarse paper pulp; the coarse paper pulp is conveyed into a screening device through water flow assistance; the coarse paper pulp enters a pulp washing device after being screened and filtered by the screening device; and the pulp enters a fine grinding device after being cleaned by the pulp washing device, and enters a storage device after being finely ground by the fine grinding device. According to the invention, fine paper pulp can be finally obtained through automatic feeding, coarse crushing, paper material circulating and infiltrating, screening and paper scrap grinding and refining, and is stored for papermaking operation.

Owner:山东海天造纸机械有限公司

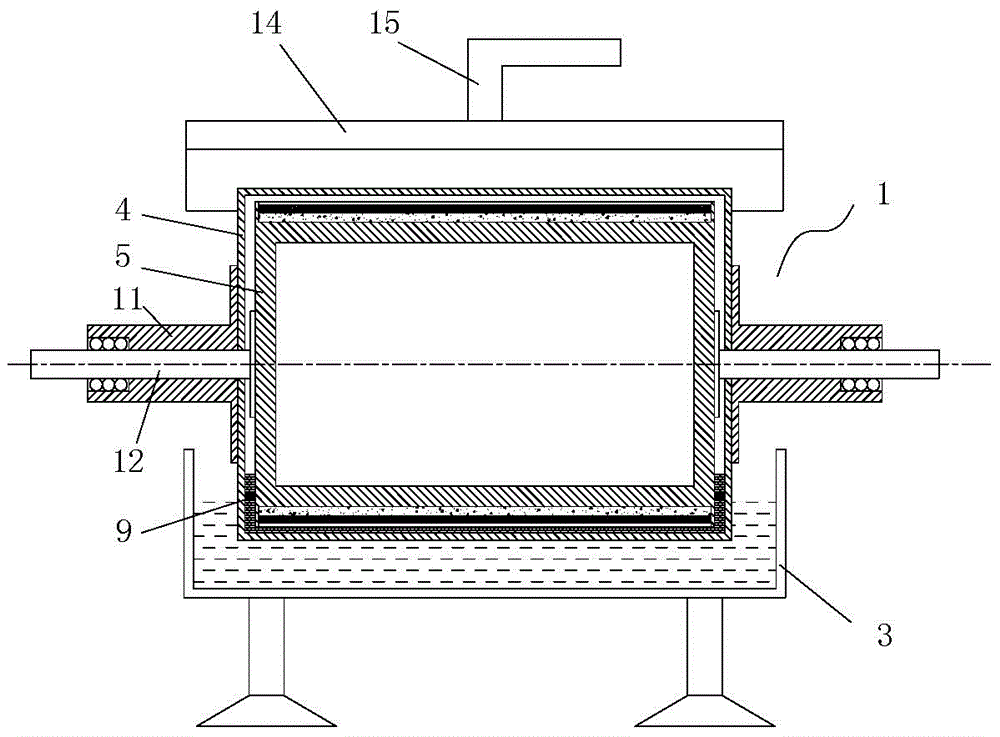

Washing machine for conveniently separating granules of different granularities in solution

ActiveCN103170174AReduce lossesAvoiding Leakage ProblemsStationary filtering element filtersViscous liquidEngineering

The invention relates to a washing machine for conveniently separating granules of different granularities in a solution. The washing machine is characterized in that a main body part comprises a stirring device, a washing chamber, a filtering bag, a support frame, a heating jacket, an insulating layer, a filtering net, a support isolating grid, a micro granule collecting chamber and a discharge valve; the washing chamber and the micro granule connecting chamber are connected together in a welding mode; washed granules are put into the filtering bag which is expanded by the support frame; the filtering net is put on the filtering net; not only can viscous liquid be adhered to the surface of the granules washed off by a washing agent, but also small granules adhered to the surfaces of large granules are separated in time, and micro granules of which the diameters are smaller than the apertures of the filtering bag and the filtering net can penetrate through the holes and deposited into the micro granule collecting chamber, so that the sediment is not easy to arise to cover the surface of the large granules, the situation that the granules of different granularities are not thoroughly separated in the conventional method is avoided, the washing and separation effects are greatly improved, and a product can be conveniently taken out.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +1

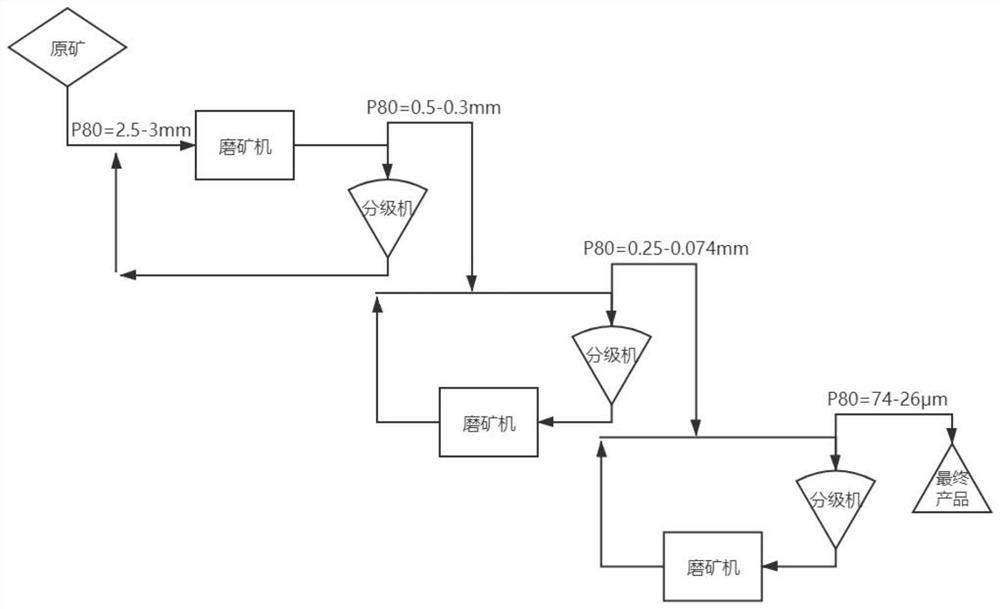

Steel-ball-free ore grinding method

ActiveCN112958258AReduce incidenceEfficient grindingCement productionGrain treatmentsSteel ballBall mill

The invention discloses a steel-ball-free ore grinding method. The steel-ball-free ore grinding method comprises the following steps: ore with the grinding particle size P80 of 2.5-3.0 mm is fed into an ore grinding machine, and first-stage ore grinding is carried out; an ore grinding medium of a mixed ceramic section is loaded into the ore grinding machine, and the mixed ceramic section comprises cylindrical ceramic sections with different lengths and different diameters; the P80 of an overflow product of a classifier is controlled to be 0.5-0.3 mm, and if the ore dressing granularity requirement is met, only first-stage ore grinding is carried out; and if the ore dressing granularity requirement is not met, second-stage ore grinding is carried out, and during second-stage ore grinding, an ore grinding medium mixed with ceramic balls is loaded into the ore grinding machine. According to the steel-ball-free ore grinding method, the mixed ceramic section is used as the ore grinding medium, crushing is carried out mainly by line contact and supplemented by surface contact, efficient grinding can be carried out in the ore grinding process, and the over-crushing generation rate of ore grinding products can be reduced; and besides, an ore grinding section can be a one-section ore grinding process or a multi-section ore grinding process, and the ore grinding machine mainly adopts a horizontal ball mill, so that the ore grinding requirements of different ores and different metal disseminated particle sizes can be met.

Owner:JIANGXI UNIV OF SCI & TECH +1

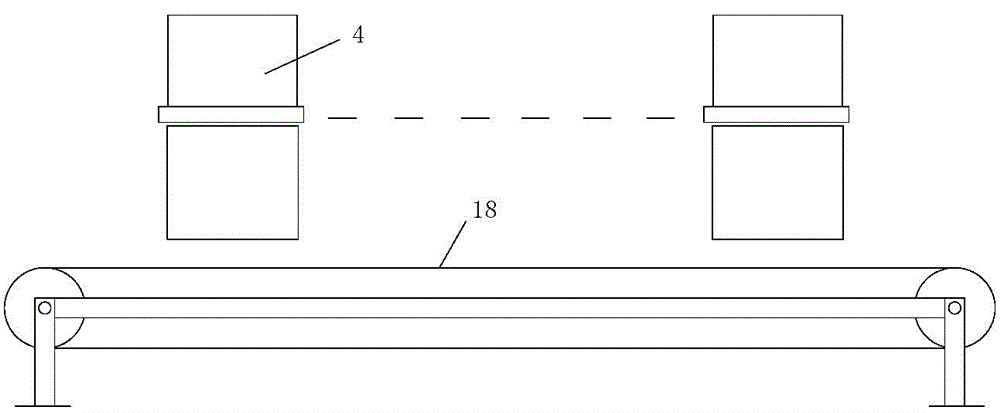

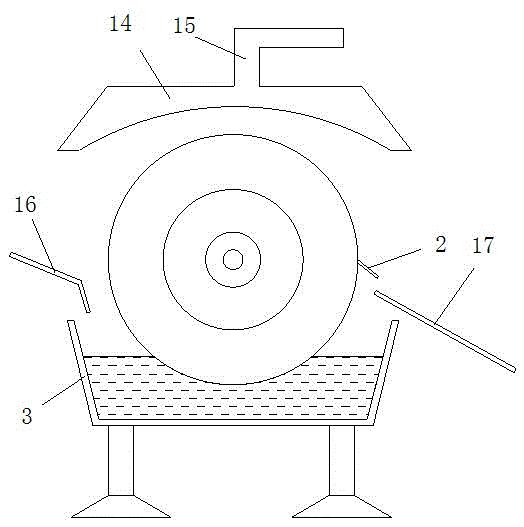

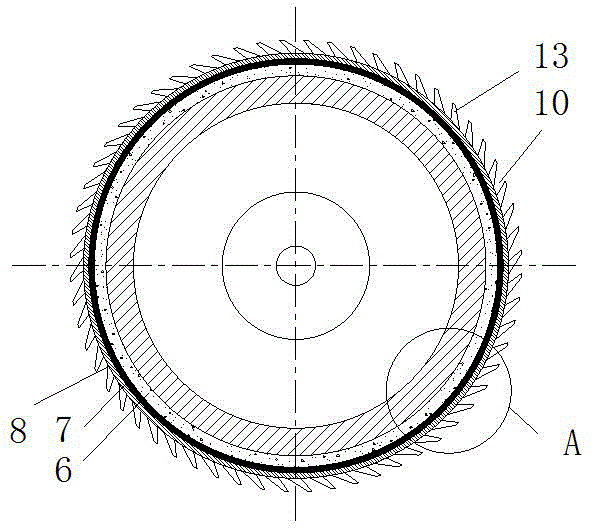

Self-heating drum drying system

InactiveCN105783454AConstant usageImprove heat exchange efficiencyDrying solid materialsDrying machines with non-progressive movementsHeat conductingThermal insulation

The invention discloses a self-heating drum drying system. The self-heating drum drying system comprises a material conveying device, and at least one self-heating drum drying machine arranged along the material conveying device; the self-heating drum drying machines include drying drums, scrapers and liquid discs; the drying drums include outer cylinders; inner cylinders rotationally matched and coaxial with the outer cylinders are arranged in the outer cylinders; thermal insulation layers, electric heating layers and thin-wall heat conducting layers are arranged on the outer peripheral walls of the inner cylinders in sequence from inside to outside; heat conducting mediums are arranged in cavities between the outer cylinders and the inner cylinders; grooves for accommodating the heat conducting mediums are annularly and uniformly distributed in the outer peripheral walls of the thin-wall heat conducting layers; the bottoms of the outer cylinders are positioned in the liquid discs; edges of the scrapers are tightly bonded on the outer surfaces of the outer cylinders; and receiving plates leaded to the material conveying device are arranged below the scrapers. The self-heating drum drying system not only can satisfy the use requirements, but also can effectively improve the heat exchange efficiency.

Owner:CHONGQING HUAXU ENERGY TECH

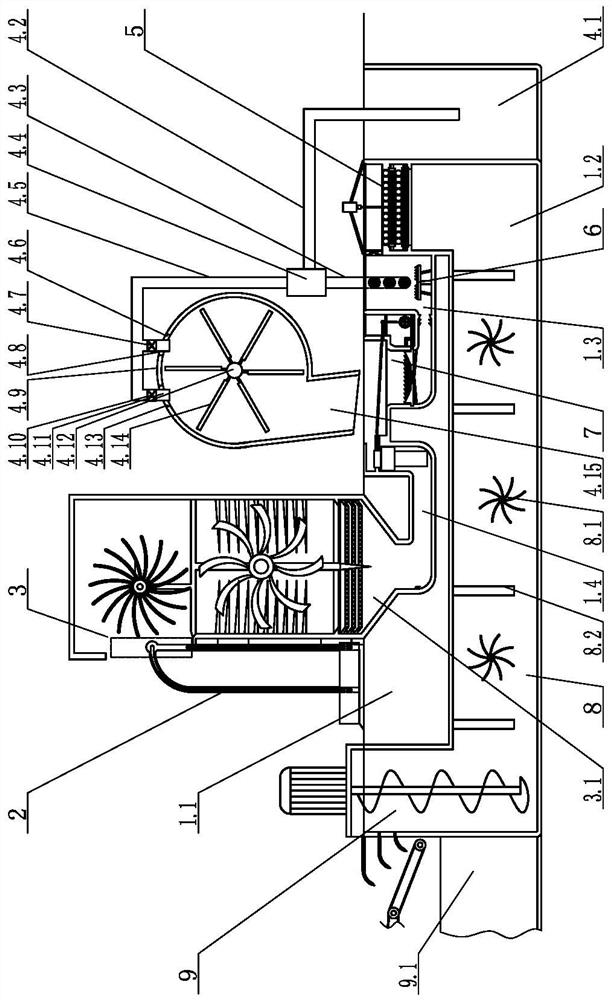

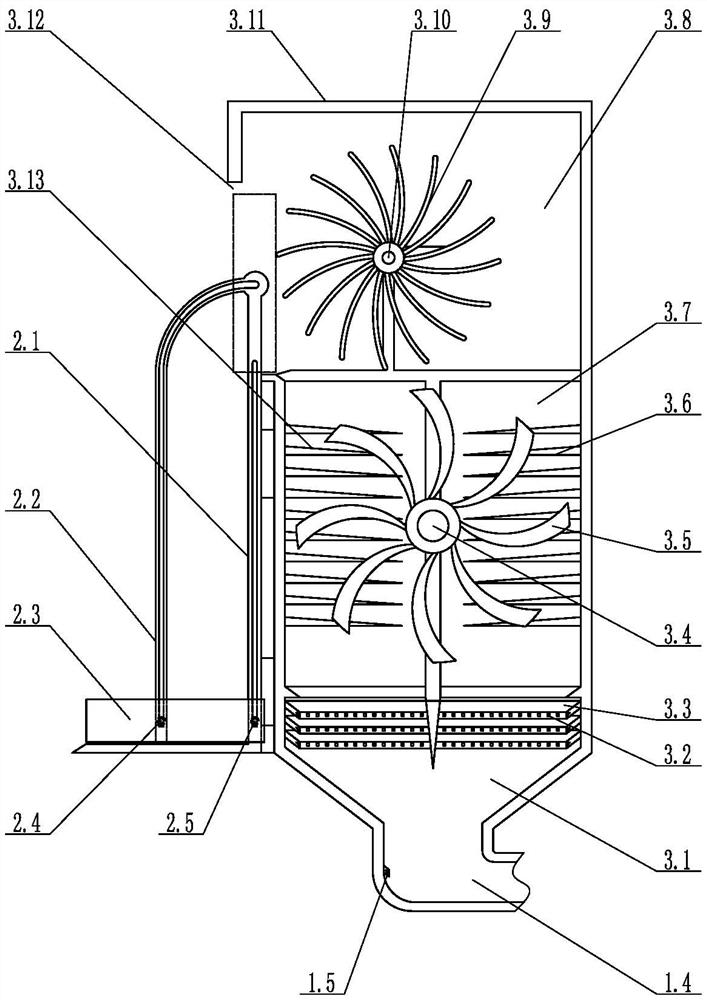

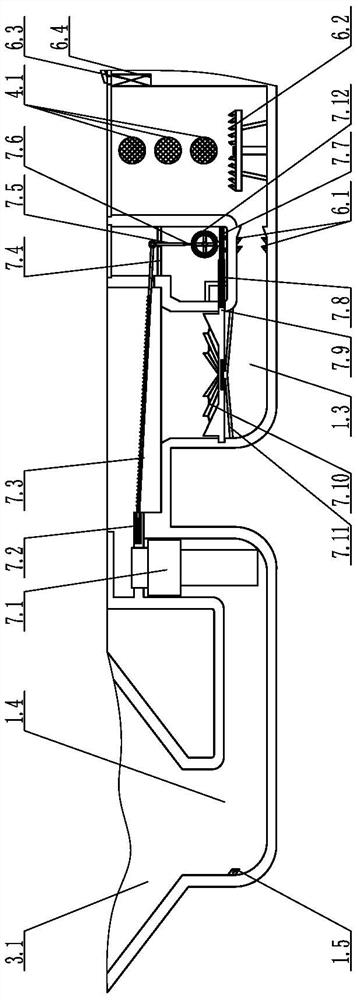

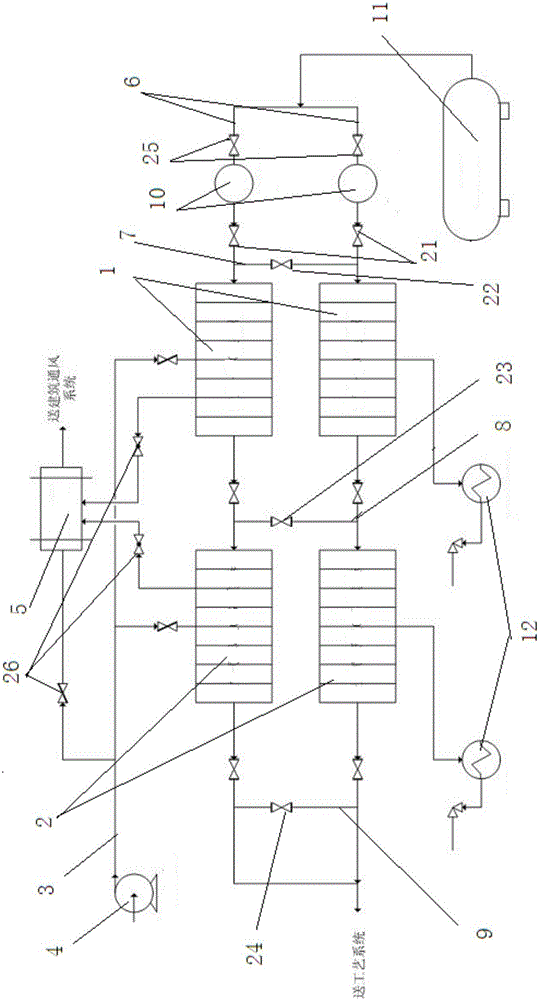

Refrigerating system using liquefied natural gas cold energy

ActiveCN106839563APlay the effect of saving energy and reducing consumptionReduce manufacturing costDomestic cooling apparatusLighting and heating apparatusCompressed natural gasRecuperator

The invention relates to a refrigerating system using liquefied natural gas cold energy, which comprises a first-stage indirect type heat exchanger, a second-stage indirect type heat exchanger, an air inlet pipeline, a fan and an air mixing device. The inlet of the air inlet pipeline is connected with the fan, the outlet of the air inlet pipeline is connected with the air inlets of the first-stage indirect type heat exchanger and the second-stage indirect type heat exchanger and the inlet of the air mixing device, the fuel gas inlet of the first-stage indirect type heat exchanger is used for receiving liquefied natural gas, the fuel gas outlet of the first-stage indirect type heat exchanger is connected with the fuel gas inlet of the second-stage indirect type heat exchanger, the inlet of the air mixing device is further connected with the air outlet of the first-stage indirect type heat exchanger and the air outlet of the second-stage indirect type heat exchanger, the outlet of the air mixing device is used for outputting cooled air. When the liquefied natural gas enters the first-stage indirect type heat exchanger, heat exchanging with the air in the first-stage indirect type heat exchanger is carried out, and the liquefied natural gas is heated and enters the second-stage indirect type heat exchanger after being converted into compressed natural gas. The invention not only can fully use the cold energy generated in a gasification process of the liquefied natural gas, but also can reduce cost of heat-exchange equipment.

Owner:BAOTOU ENG & RES CORP OF IRON & STEEL IND CHINA METALLURGY CONSTR GROUP BERIS

Energy-saving hot air premixed type fierce-fire stove

PendingCN108050514AIncrease temperatureReduce the temperatureDomestic stoves or rangesIndirect carbon-dioxide mitigationEngineeringHearth

The invention discloses an energy-saving hot air premixed type fierce-fire stove comprising a stove body, a stove core and a fuel gas intake pipe. The energy-saving hot air premixed type fierce-fire stove is characterized in that the stove body comprises an inner shell with the upper end provided with a stove mouth, the stove core is installed at the center of a base plate of the inner shell, a sealed hot air interlayer is arranged outside the inner shell, a lower end opening of the stove core communicates with the sealed hot air interlayer, the upper side of the side wall of the sealed hot air interlayer is provided with air inlets communicating with an air intake device, the fuel gas intake pipe is arranged at the center of the bottom end of the sealed hot air interlayer, and fuel gas and intake air are mixed and then enters the stove core from the lower end of the stove core. According to the energy-saving hot air premixed type fierce-fire stove, through the improvement on the structure of the stove body of the fierce-fire stove, waste heat is fully utilized to preheat air, and the energy-saving and consumption-reduction purposes are achieved.

Owner:重庆憬言农机制造有限公司

Stirring and heating type drum dryer

InactiveCN105783451AImprove heat exchange efficiencyConstant usageDrying chambers/containersDrying machines with non-progressive movementsThin walledDrying drum

Owner:CHONGQING SUTEXIN ELECTRONICS CO LTD

Preparation method of sodium sulfide

InactiveCN108910832AIncrease contact areaIncrease productionChemical industryAlkali metal sulfides/polysulfidesCalcinationCoal

The invention discloses a preparation method of sodium sulfide, the preparation method comprises the following steps: a, adding raw coal powder and anhydrous sodium sulphate into a mixer to obtain a mixture for standby use; b, spraying the mixture into a calcining furnace to obtain sodium sulfide alkali billet for standby use; c, thermally melting the sodium sulfide alkali billet into a liquid toobtain a reducing leaching solution; d, evaporating the reducing leaching solution to about 250 g / L to obtain a sodium sulfide semi-finished product leaching solution; e, removing heavy metal ions inthe leaching solution until the total content of metal ions in the leaching solution is less than that of 10ppm filtrate; f, pumping the filtrate into a crystallization tank, and performing rapid vacuum freeze-crystallizing and centrifugal dehydration to obtain high-purity sodium sulfide. The raw coal powder is ground and crushed, so that the contact area of the raw coal powder and the anhydrous sodium sulphate is bigger, the reaction is more sufficient when heating and reducing, and the yield of the sodium sulfide is improved; by negative pressure calcination and temperature control, the content of soluble impurities of the product can be reduced, the conversion rate of raw materials can be improved, consumption is reduced, and the effect of energy saving and consumption reduction can beobtained.

Owner:铜陵铜冠环保科技有限公司

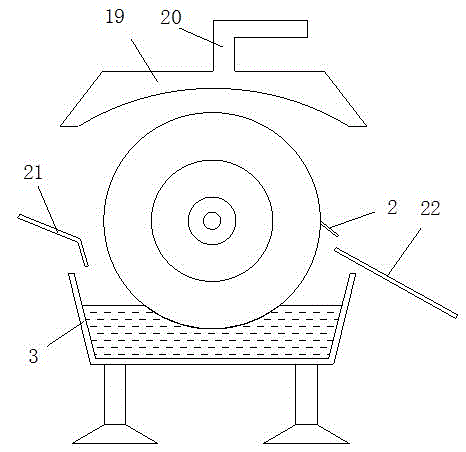

Self-heating roller dryer

InactiveCN105783461AConstant usageImprove heat exchange efficiencyDrying solid materialsDrying machines with non-progressive movementsInsulation layerEngineering

The invention discloses a self-heating roller dryer. The self-heating roller dryer comprises a drying roller, a scraper and a feed liquid plate; the drying roller comprises an outer cylinder, an inner cylinder which is matched with the outer cylinder in a rotating mode and is coaxial with the outer cylinder is arranged inside the outer cylinder, a heat insulation layer, an electrical heating layer and a thin-wall heat conduction layer are sequentially arranged on the peripheral wall of the inner cylinder from inside to outside, heat conduction media are arranged in a cavity between the outer cylinder and the inner cylinder, and a groove used for containing the heat conduction media is annularly and uniformly formed in the peripheral wall of the thin-wall heat conduction layer; the bottom of the outer cylinder is located in the feed liquid plate, and a blade of the scraper is closely attached to the outer surface of the outer cylinder. The self-heating roller dryer can meet the use requirements and effectively improve the heat exchange efficiency.

Owner:CHONGQING HUAXU ENERGY TECH

Working method of high-voltage distribution room

InactiveCN107166665AReduce usage timeSave energy and reduce consumptionBoards/switchyards circuit arrangementsSpace heating and ventilation safety systemsHigh pressureHigh voltage

The invention provides a working method of a high-voltage distribution room. The working time of an axial flow fan, the working time of an air conditioner and the working time of a dehumidifier can be given overall consideration, the working efficiency of the dehumidifier can be improved, and on the premise of guaranteeing that the temperature and humidity in the high-voltage distribution room are in normal states, the technical purposes of saving energy and reducing consumption are achieved.

Owner:张琴

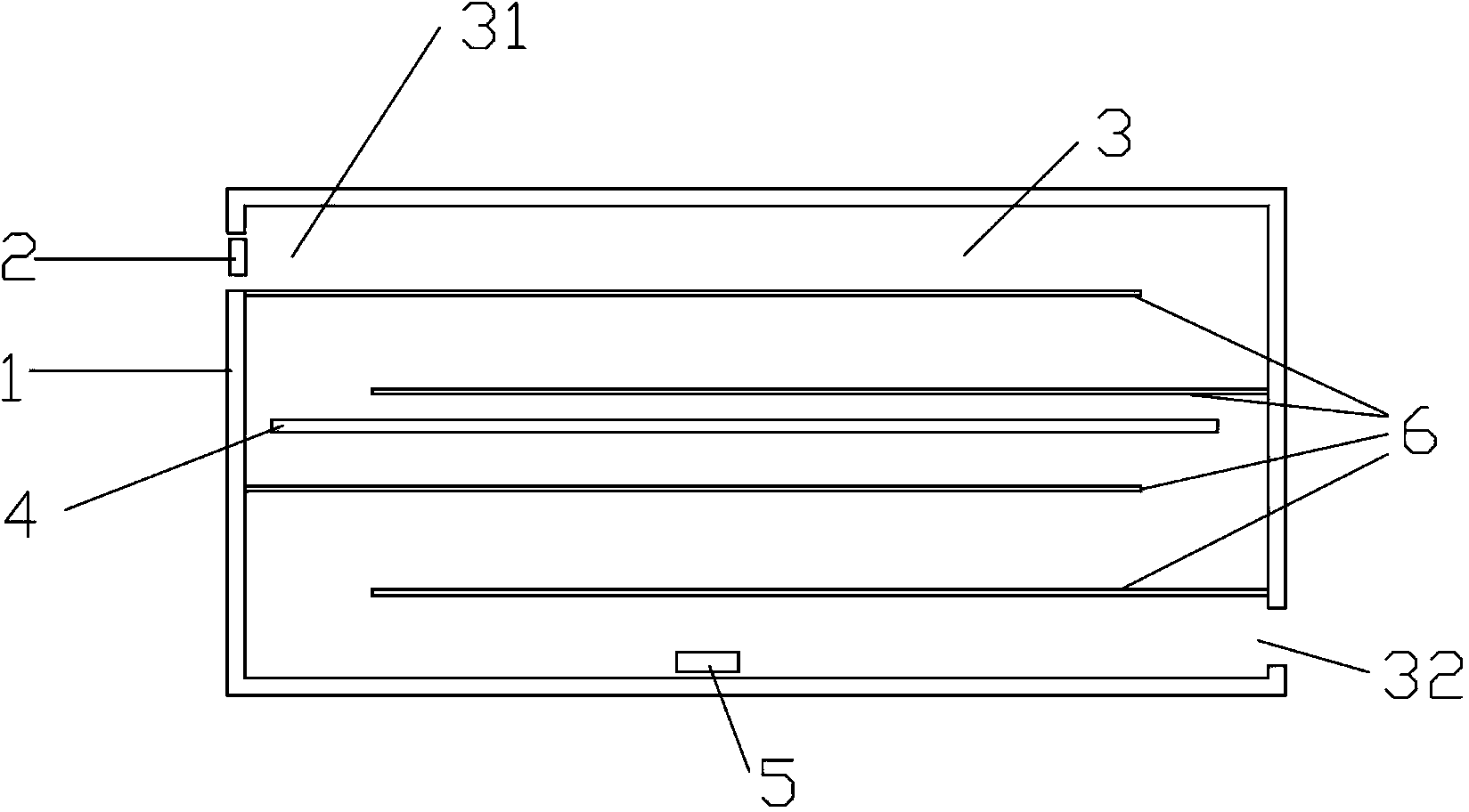

Channel type ultraviolet air disinfector

The invention relates to a channel type ultraviolet air disinfector, which comprises a box, wherein a folded air channel is formed inside the box; at least one ultraviolet disinfecting lamp is arranged in the air channel; one end of the air channel is an air inlet, and the other end of the air channel is an air outlet; the air channel is communicated with the outside through the air inlet and the air outlet; a fan is arranged at the air inlet; a plurality of spacers are fixedly arranged on the inner wall of the box, and are used for partitioning the inside of the box into the folded air channel. The air inlet and the air outlet are formed in the channel type ultraviolet air disinfector, intersecting air channels ranging from the inlet and the outlet are formed by isolating by using glass through which ultraviolet rays can pass, so that the flowing time of pumped air in the box is prolonged. The transmission of ultraviolet rays in the box is not blocked by the glass through which ultraviolet rays can pass, so that the pumped air is fully exposed in the irradiation of ultraviolet rays, the aim of fully disinfecting is fulfilled, and the effects of saving energy and lowering consumption can be achieved. A negative-ion generator is arranged in the box.

Owner:SHANGHAI TIANTIAN LIGHTING DECORATION ENGCO

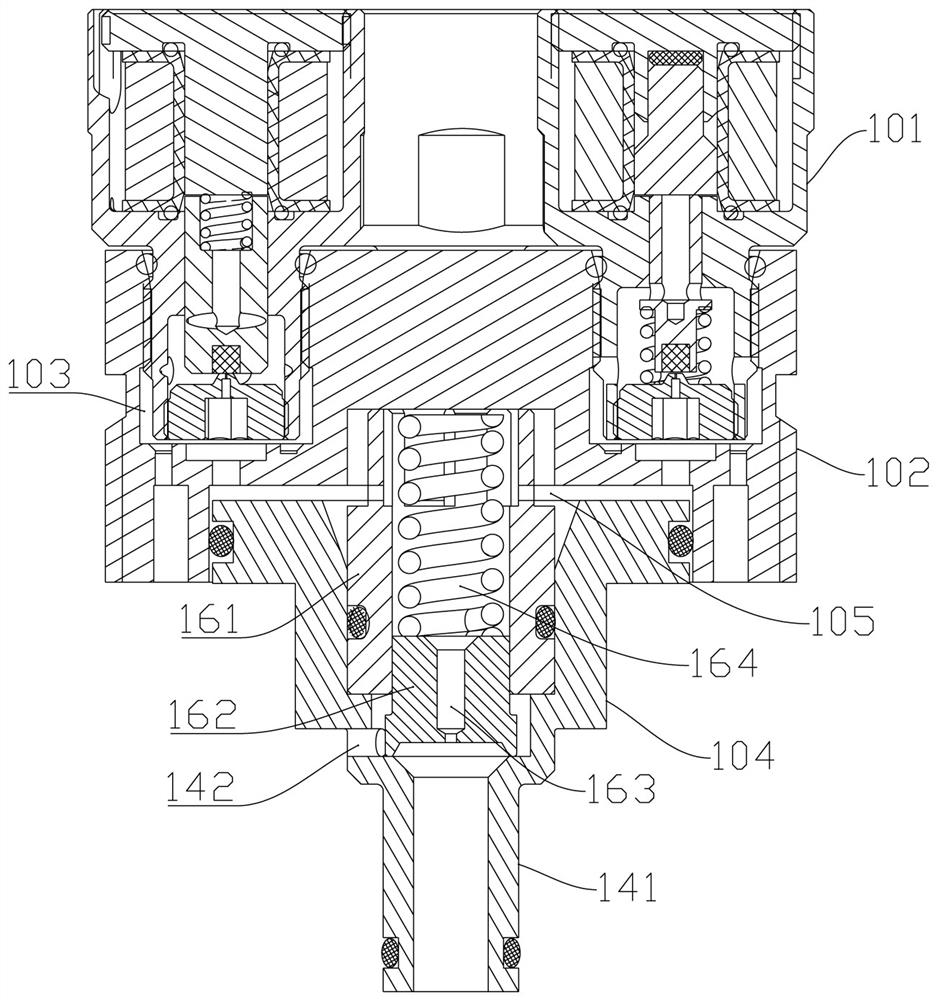

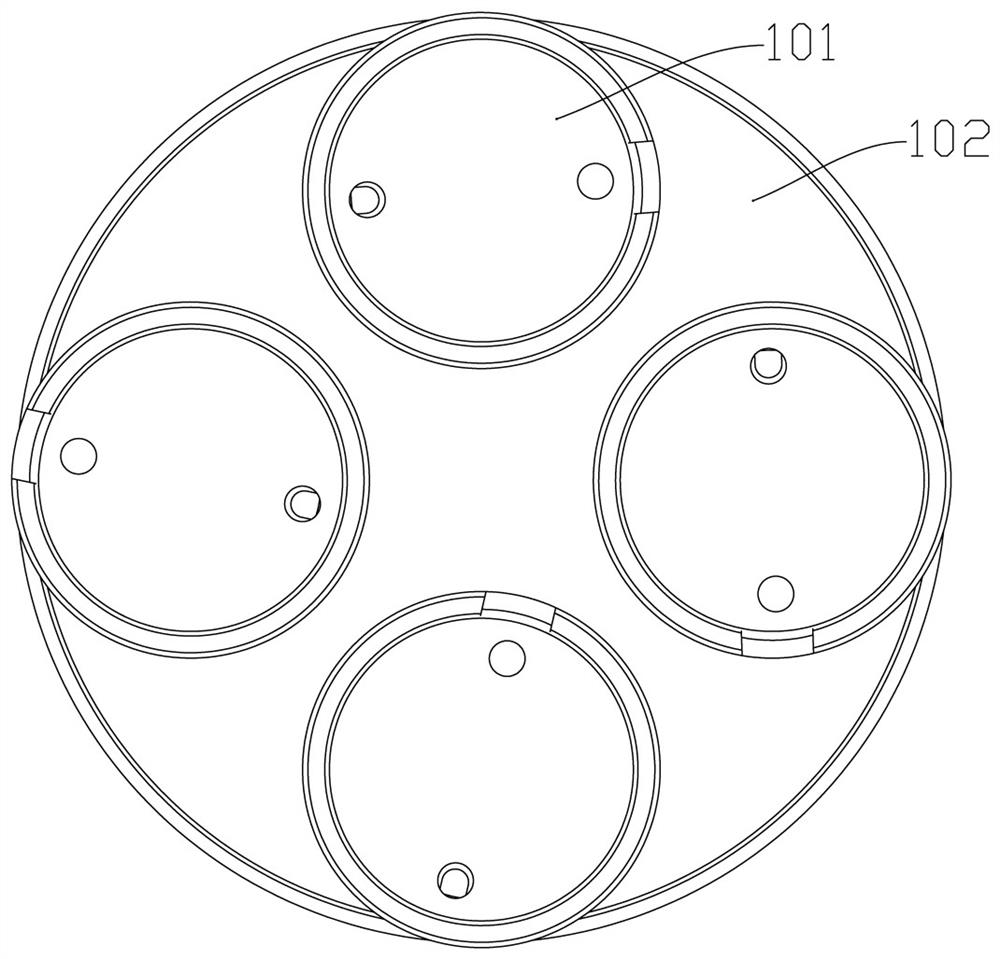

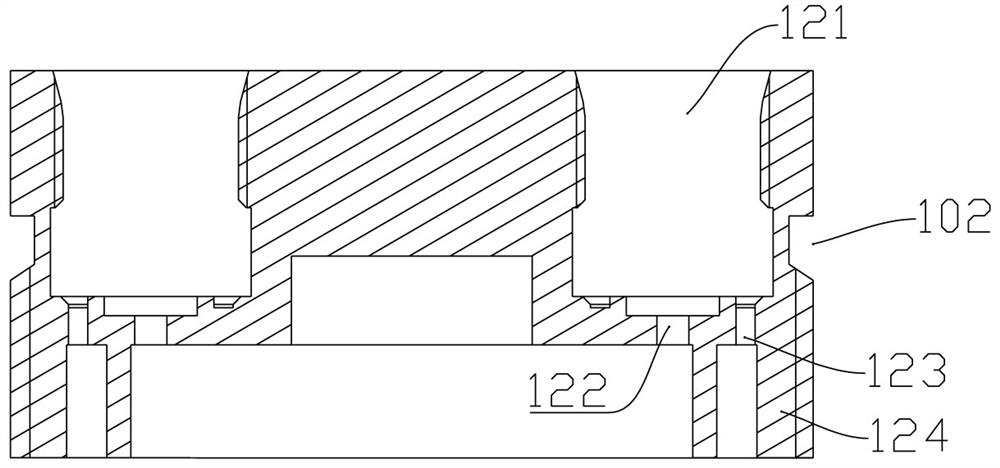

Flow control valve, vehicle suspension shock absorber assembly and vehicle suspension system

ActiveCN113251177ASimple structureReasonable designOperating means/releasing devices for valvesSpringsFlux controlControl valves

The invention relates to the technical field of valves, and discloses a flow control valve, a vehicle suspension shock absorber assembly and a vehicle suspension system. The flow control valve comprises a valve body assembly and multiple high-speed switch valves; the valve body assembly comprises a main valve body, multiple mounting parts are arranged on the main valve body, oil inlet holes and oil outlet holes which communicate with the interiors of the mounting parts are formed in the positions, located on the mounting parts, of the main valve body correspondingly, and the oil inlet holes communicate with the corresponding oil outlet holes to form multiple oil channels arranged in parallel; the high-speed switch valves are arranged in the mounting parts respectively and are in sealing fit with the mounting parts, and the on-off states of the oil channels are controlled by controlling opening and closing of the high-speed switch valves. The flow control valve has the characteristics of being large in flow adjusting range, high in response speed and high in flow control precision, and can be applied to different working conditions.

Owner:成都九鼎科技(集团)有限公司

A method of producing high-purity sodium sulfide

InactiveCN106395759AIncrease contact areaIncrease productionAlkali metal sulfides/polysulfidesFlue gasDiiron Trioxide

A method of producing high-purity sodium sulfide is disclosed. The method includes S100) a step of adding raw coal, mirabilite and a catalyst that is ferric oxide into a ball mill, and grinding, with the weight ratio of the mirabilite, the raw coal and the ferric oxide being 5:2:0.04, S200) a step of, after grinding, conveying into a stirrer, and stirring to fully mix the mixture, and S300) a step of, after stirring is finished, spraying the mixture into a calciner, maintaining a slightly-negative pressure atmosphere in the calciner, controlling the air excessive amount during calcination through a flue residual-oxygen detecting device, and maintaining the calcination temperature to be 1000-1100 DEG C through a material temperature monitoring device and a flue gas temperature monitoring device. The sodium sulfide produced by the method is high in purity and wide in application.

Owner:马艳玲

High-voltage power distribution room cooling and dehumidifying energy-saving device

InactiveCN104930663AReduce the temperatureReduce usage timeMechanical apparatusSpace heating and ventilation safety systemsHigh pressureOutdoor temperature

The invention discloses a high-voltage power distribution room cooling and dehumidifying energy-saving device which comprises an outdoor temperature sensor, an indoor temperature sensor, an outdoor humidity sensor, an indoor humidity sensor, an A / D converter, a single-chip microcomputer, a drive circuit, a key unit, a display unit, an axial flow fan, an air conditioner, a dehumidifier, an air outlet, an air inlet, an air input and output switching device and a dehumidifier air inlet switching device. By means of the device, the working time of the axial flow fan, the air conditioner and the dehumidifier can be overall arranged, and energy conservation and consumption reduction are achieved as mush as possible on the premise of ensuring that the indoor temperature and humidity of a high-voltage power distribution room are in a normal state.

Owner:王鹤

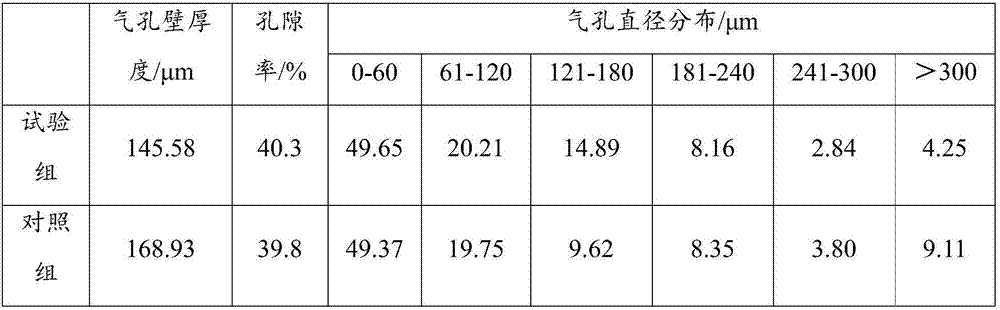

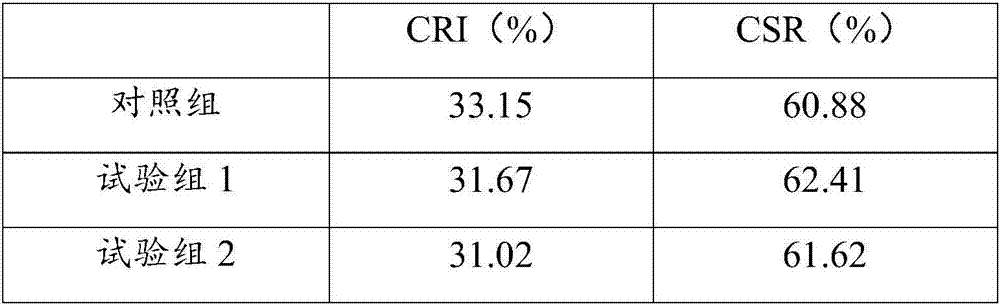

Coke modifier and preparation method and coke modifying method thereof

ActiveCN107142121ASlow down the lysis reactionReduce coke reactivityCoke ovensBlast furnace smeltingPolyacrylamide

The invention relates to the technical field of the coke modification in the blast furnace ironmaking and in particular to a coke modifier and a preparation method and a coke modifying method thereof. The provided coke modifier comprises boric oxide, silicate and polyacrylamide. The coke modifier is capable of slowing down the solution loss reaction of the coke, reducing the coke reactivity, and improving the post-reaction strength. The provided coke modifying method has the characteristics of simple process and convenient operation, is capable of reducing the coke reactivity, improving the post-reaction strength, and improving the permeability of a blast furnace. In addition, the pulverization of the coke is reduced, the effects of saving energy and reducing consumption can be realized, the load of a dedusting device is reduced, the service life of the device is prolonged, and the coke modifier can be extensively used for the blast furnace smelting industry.

Owner:河北金百祥科技有限公司

Stirring and heating type drum drying system

InactiveCN105783462AHeating evenlyConstant usageDrying machines with non-progressive movementsDrying solid materialsInsulation layerDrum drying

The invention discloses a stirring and heating type drum drying system. The stirring and heating type drum drying system comprises a material conveying device and at least one stirring and heating type drum drying machine arranged along the material conveying device. Each stirring and heating type drum drying machine comprises a drying drum, a scraping knife and a liquid material disc. The drying drum comprises an outer drum body. An inner drum body which is rotationally matched with the outer drum body and is coaxial with the outer drum body is arranged in the outer drum body. A heat insulation layer, an electrical heating layer and a thin wall heat conduction layer are sequentially arranged on the peripheral wall of the inner drum body from inside to outside. A medium cavity for storing a heat conduction medium is arranged between the outer drum body and the inner drum body. A stirring structure for stirring the heat conduction medium is evenly and annularly distributed on the peripheral wall of the thin wall heat conduction layer and comprises stirring teeth arranged on the peripheral wall of the thin wall heat conduction layer in an array manner. The bottom of the outer drum body is located in the liquid material disc. A knife edge of the scraping knife is tightly attached to the outer surface of the outer drum body. A material receiving plate communicating with the material conveying device is arranged below the scraping knife. The stirring and heating type drum drying system has the beneficial effects that heat conduction efficiency is high, and heating is uniform.

Owner:CHONGQING SUTEXIN ELECTRONICS CO LTD

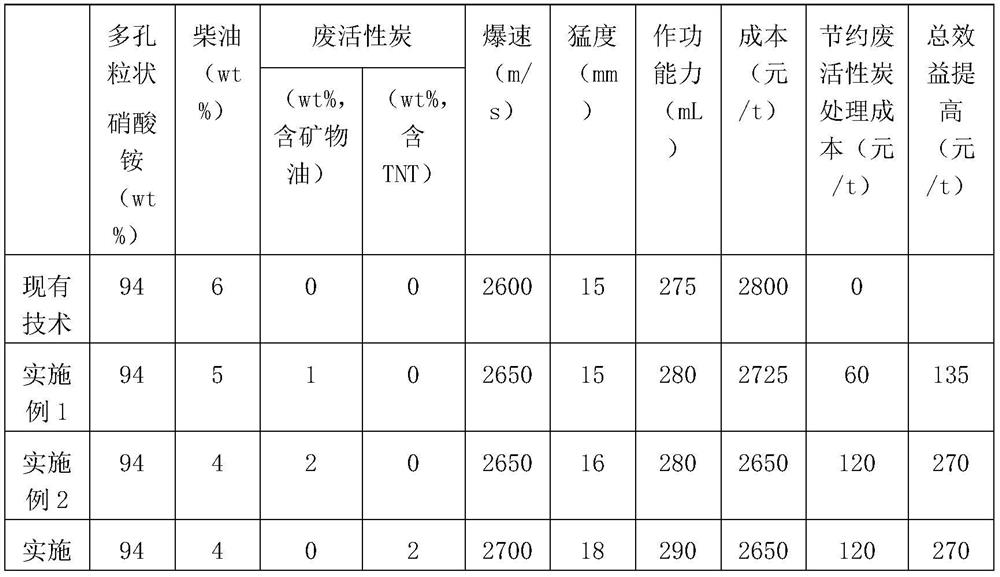

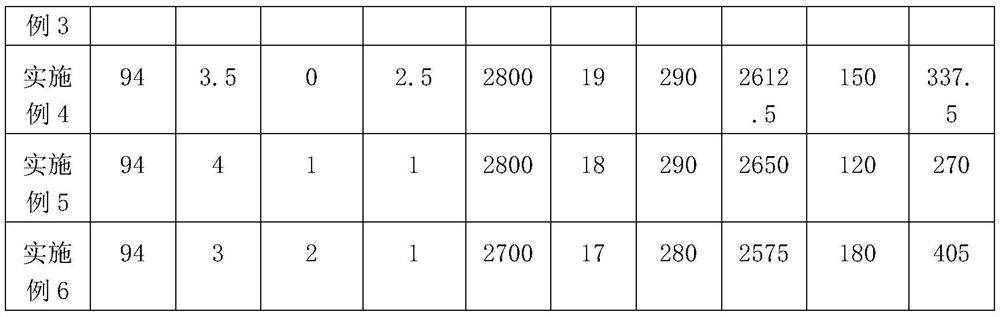

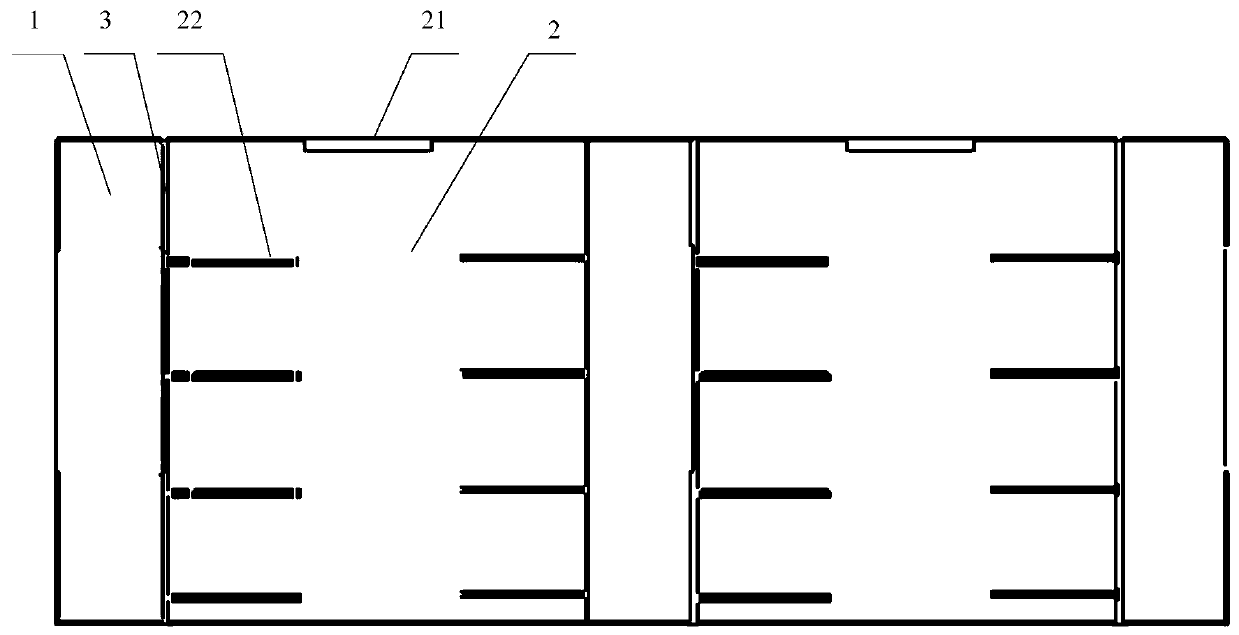

Porous granular ammonium nitrate fuel oil explosive and preparation method thereof

InactiveCN114230426AReduce usagePlay the effect of saving energy and reducing consumptionExplosive ingredient compoundingActivated carbonExplosive Agents

The invention discloses a porous granular ammonium nitrate fuel oil explosive, and also discloses a preparation method of the porous granular ammonium nitrate fuel oil explosive. The method has the advantages that 1, by adding the waste activated carbon adsorbed with mineral oil steam and TNT, the activated carbon and substances adsorbed by the activated carbon can be used as a reducing agent in the porous granular ammonium nitrate fuel oil explosive and can replace a part of diesel oil, the use amount of the diesel oil is reduced, and the effect of saving energy is achieved; 2, the waste activated carbon is used as a preparation raw material of the porous granular ammonium nitrate fuel oil explosive, so that the treatment problem of the waste activated carbon can be solved, the treatment cost of the waste activated carbon is reduced, and harm generated in the treatment process of the waste activated carbon is avoided; according to the invention, waste can be turned into wealth, and the production concept of long-term sustainable development is met; 3, the waste activated carbon is granular, so that the free-running property of the porous granular ammonium nitrate fuel oil explosive is not influenced after the waste activated carbon is added as a raw material, and on-site mixed loading is facilitated; and 4, the detonation velocity, brisance, work capability and other properties of the porous granular ammonium nitrate fuel oil explosive can be effectively improved.

Owner:内蒙古生力民爆股份有限公司

Machine room ventilation structure

PendingCN110769656ARealize heat dissipation and coolingAvoid lossCooling/ventilation/heating modificationsEngineeringMechanical engineering

The invention provides a machine room ventilation structure. The machine room ventilation structure comprises: a machine room; a server arranged in the machine room, wherein the machine room has a cool air supply structure; a heat channel used for connecting with the heat dissipation opening of the server; and a baffle structure used for separating the machine room from the heat channel, wherein athrough hole structure communicating with the machine room and the heat channel is formed in the baffle structure, the through hole structure is used for communicating with the heat dissipation opening of the server, and the inner wall of the through hole structure is attached to the outer wall of the server. According to the machine room ventilation structure, cool air only can pass through theserver, cools parts in the server, passes through the heat dissipation opening of the server and the through hole structure of the baffle structure and flows into the heat channel so as to effectivelyachieve heat dissipation and cooling of the server, avoid the loss caused by directly flowing the cool air into the heat channel, improve the utilization of the cool air, reduce the loss of the energy and have an effect on energy saving and consumption reduction.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com