Energy-saving hot air premixed type fierce-fire stove

A premixed, hot air technology, applied in the field of fierce fire stoves, can solve the problems of loss, environmental pollution, inability to save energy and reduce consumption, and achieve the effect of full combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

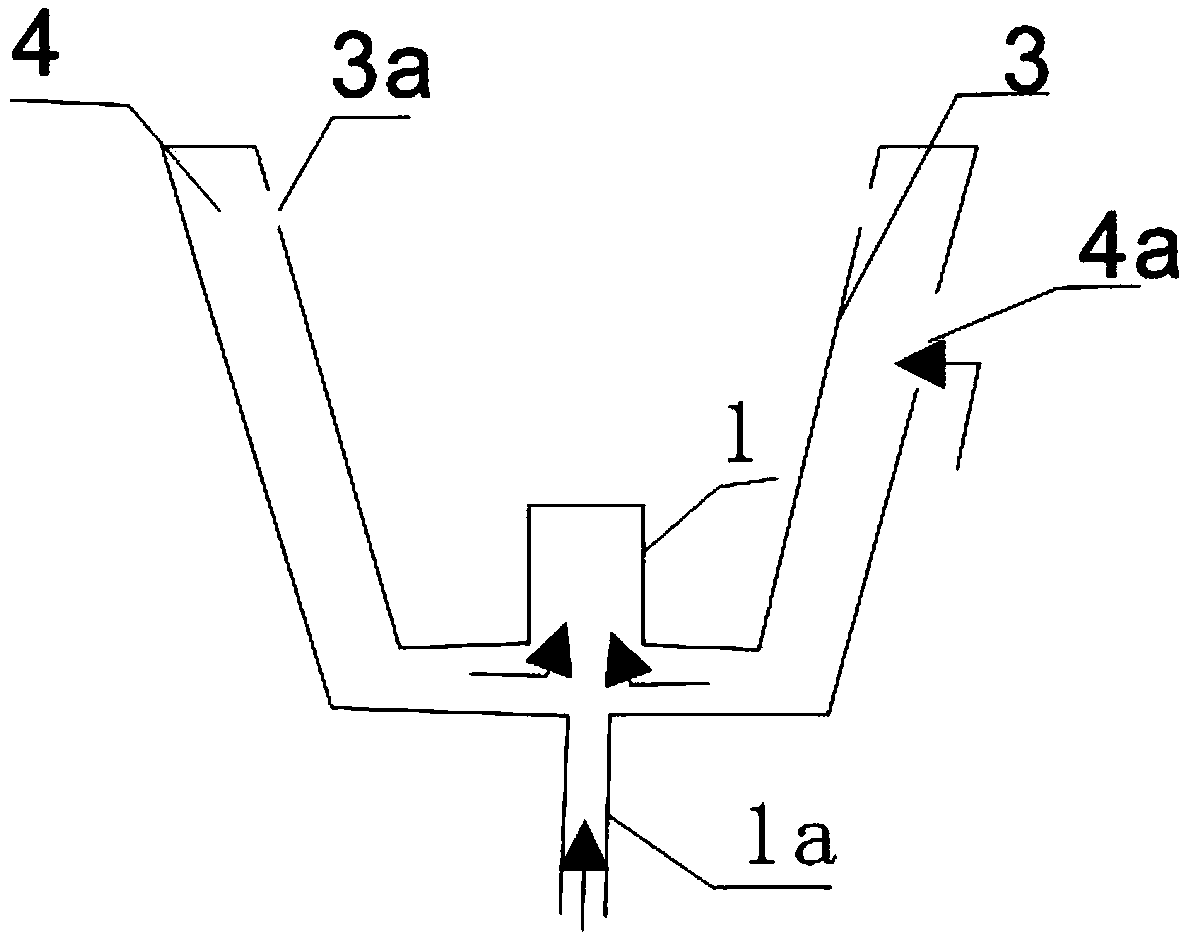

[0029] Such as figure 1 As shown: the energy-saving hot air premixed high-fire stove is composed of a stove body, a stove core 1, and a blower.

[0030] The cooker body includes an inner casing 3 with a stove mouth at the upper end thereof, and the inner casing 3 may be conical, cylindrical, or square and other shapes. Conical shapes are shown in the figure. A sealed hot air interlayer 4 is arranged outside the inner casing 3, that is, an interlayer is arranged outside the side wall and the bottom plate of the inner casing 3, and the interlayers of the side wall and the bottom plate communicate. The upper part of the side wall of the sealed hot air interlayer 4 is provided with an air inlet 4a communicating with the air inlet device. The air inlet device is a blower, and the air outlet pipe of the blower is connected with the air inlet 4a (the blower is not shown in the figure).

[0031] The stove core 1 is installed in the center of the bottom plate of the inner casing. S...

Embodiment 2

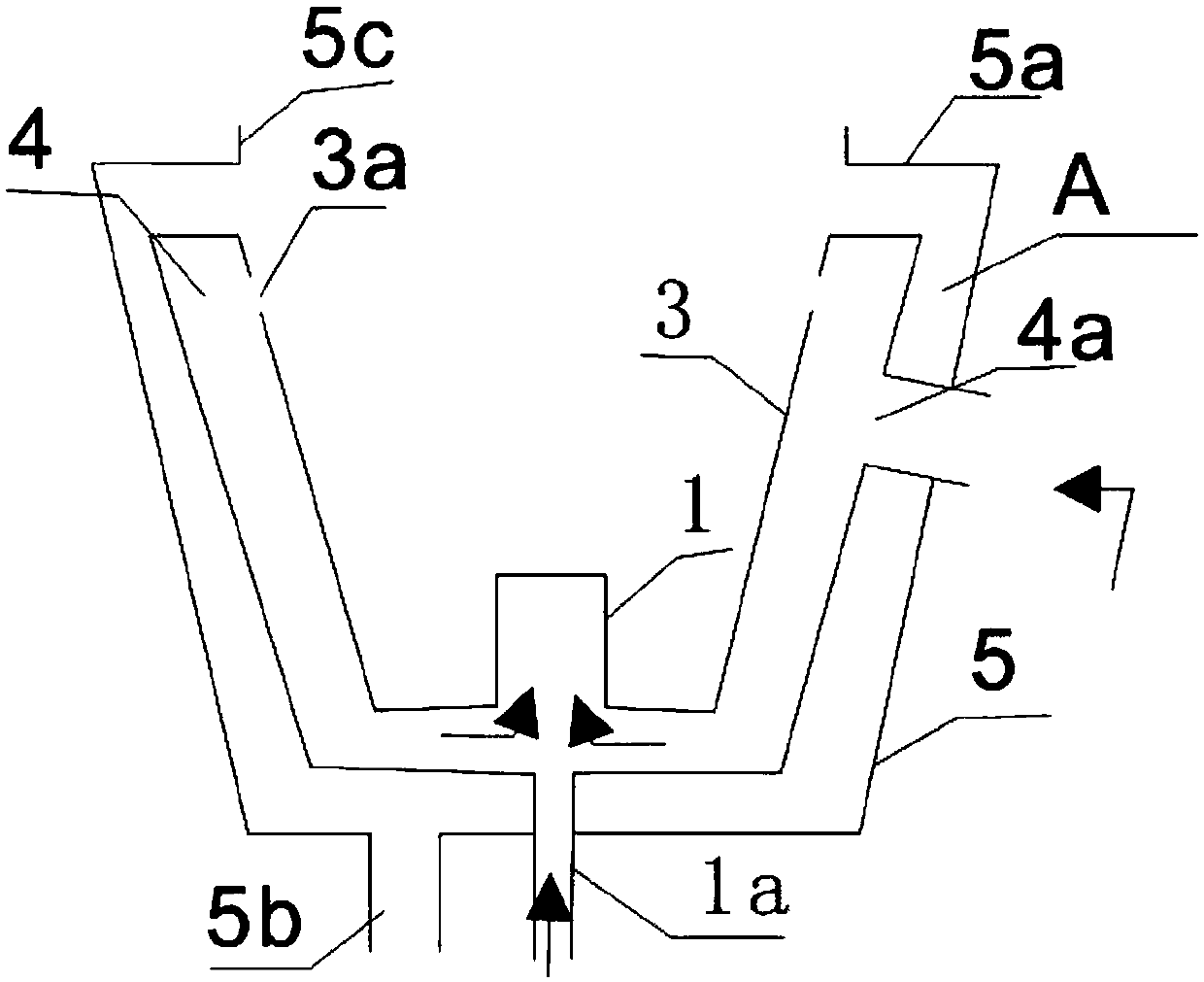

[0033] Such as figure 2 As shown, the other is the same as the embodiment 1, the difference is that the upper part of the inner wall of the inner casing 3 is circumferentially distributed with secondary combustion air gathering small holes 3a.

[0034] The cooker body also includes an outer shell 5 with an upper end open, there is a gap between the outer shell 5 and the outer wall of the sealed hot air interlayer 4, and the outer wall of the outer shell 5 and the sealed hot air interlayer 4 forms a secondary combustion exhaust chamber A, and the outer wall of the outer shell 5 The inner flange 5a is arranged on the upper port and extends to the stove mouth of the inner casing 3. The inner flange 5a is located above the top of the inner casing 3, and there is a gap with the top of the inner casing 3. Gas enters the secondary combustion exhaust chamber A from the gap between the inner flange 5a and the top end of the inner casing 3 . The bottom surface of the outer casing 5 is...

Embodiment 3

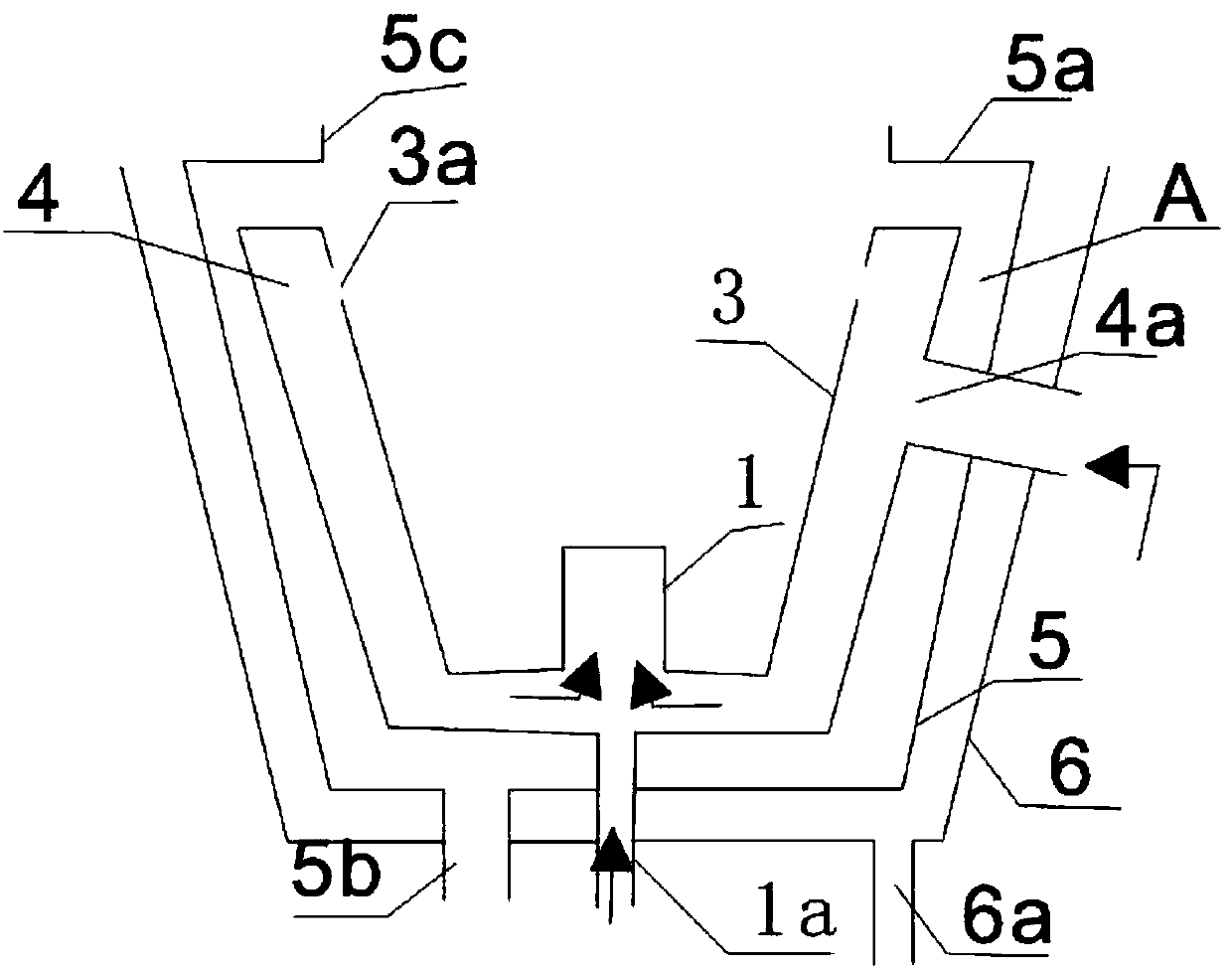

[0036] Such as image 3 As shown, the others are the same as in Embodiment 2, the difference is that the cooker body also includes an air blower air intake shell 6 located outside the shell with an upper end open, there is a gap between the air blower air intake shell 6 and the outer shell 5, and the air blower air intake shell 6 Flange is not set on the upper port, it only needs to be made as high as the outer casing 5. The gas inlet pipe 1a and the exhaust pipe 5b extend outside the blower air inlet shell 6, and the air inlet 4a extends outside the blower air inlet shell 6 to be connected with the air outlet pipe of the blower.

[0037] An air outlet 6a is provided on the bottom plate of the air blower air inlet shell 6 to be connected with the air inlet of the air blower. The mouth of the inner flange 5a of the outer casing 5 is provided with an upward lip ring 5c for placing a pot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com