Low-temperature annealing process for reducing stress of glass-metal connection sealing structure

A technology of metal sealing and structural stress, which is applied to solar collectors using working fluids, components that conduct solar radiation and prevent heat radiation from flowing out, lighting and heating equipment, etc., and can solve the problem of glass breakage and accelerated Problems such as film aging attenuation, birefringent optical path difference, etc., to achieve the effect of improving safety reliability, increasing effective life, and reducing annealing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

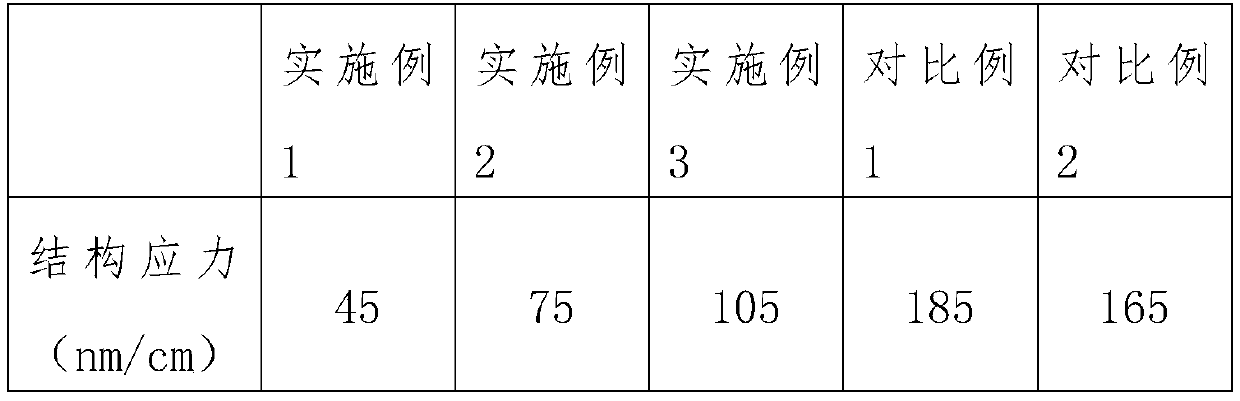

Examples

Embodiment 1

[0026] A low-temperature annealing process for reducing the stress of a glass-metal sealing structure, comprising the steps of:

[0027] Step 1: Put the sealed glass-metal sealing section into the annealing furnace, the inner diameter of the glass outer tube at the glass-metal sealing section is φ125, and the wall thickness is 3mm (the same below);

[0028] Step 2: Raise the temperature in the annealing furnace from room temperature to 200°C at a heating rate of 5°C / min, and keep at 200°C for 30 minutes;

[0029] Step 3: Raise the temperature in the annealing furnace from 200°C to 350°C at a heating rate of 3°C / min, and keep at 350°C for 40 minutes;

[0030] Step 4: Raise the temperature in the annealing furnace from 350°C to 450°C at a heating rate of 3°C / min, and keep at 350°C for 40 minutes;

[0031] Step 5: Raise the temperature in the annealing furnace from 450°C to 520°C at a heating rate of 3°C / min, and keep at 520°C for 70 minutes;

[0032] Step 6: Lower the temperat...

Embodiment 2

[0038] A low-temperature annealing process for reducing the stress of a glass-metal sealing structure, comprising the steps of:

[0039] Step 1: Put the sealed glass-metal sealing section into the annealing furnace;

[0040] Step 2: Raise the temperature in the annealing furnace from room temperature to 200°C at a heating rate of 7.5°C / min, and keep at 200°C for 20 minutes;

[0041] Step 3: Raise the temperature in the annealing furnace from 200°C to 350°C at a heating rate of 5°C / min, and keep at 350°C for 40 minutes;

[0042] Step 4: Raise the temperature in the annealing furnace from 350°C to 450°C at a heating rate of 5°C / min, and keep at 350°C for 40 minutes;

[0043] Step 5: Raise the temperature in the annealing furnace from 450°C to 520°C at a heating rate of 5°C / min, and keep at 520°C for 70 minutes;

[0044] Step 6: Lower the temperature in the annealing furnace from 520°C to 470°C at a cooling rate of 5°C / min, and keep at 350°C for 70 minutes;

[0045] Step 7: Lo...

Embodiment 3

[0050] A low-temperature annealing process for reducing the stress of a glass-metal sealing structure, comprising the steps of:

[0051] Step 1: Put the sealed glass-metal sealing section into the annealing furnace;

[0052]Step 2: Raise the temperature in the annealing furnace from room temperature to 200°C at a heating rate of 10°C / min, and keep at 200°C for 20 minutes;

[0053] Step 3: Raise the temperature in the annealing furnace from 200°C to 350°C at a heating rate of 8°C / min, and keep at 350°C for 40 minutes;

[0054] Step 4: Raise the temperature in the annealing furnace from 350°C to 450°C at a heating rate of 8°C / min, and keep at 350°C for 40 minutes;

[0055] Step 5: Raise the temperature in the annealing furnace from 450°C to 520°C at a heating rate of 6°C / min, and keep at 520°C for 70 minutes;

[0056] Step 6: Decrease the temperature in the annealing furnace from 520°C to 470°C at a cooling rate of 6°C / min, and keep it at 350°C for 70 minutes;

[0057] Step 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com