Throw-out collar of mechanical sealing device and mechanical sealing device

A technology of mechanical sealing device and ring body, which is applied in the field of shaft end sealing device and mechanical sealing device, which can solve the problems affecting the sealing performance of the floating sealing ring of the push ring, the limitation of the type of sealing ring, plastic deformation, etc., and achieve enhanced pressure resistance , reduce the pressure, reduce the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

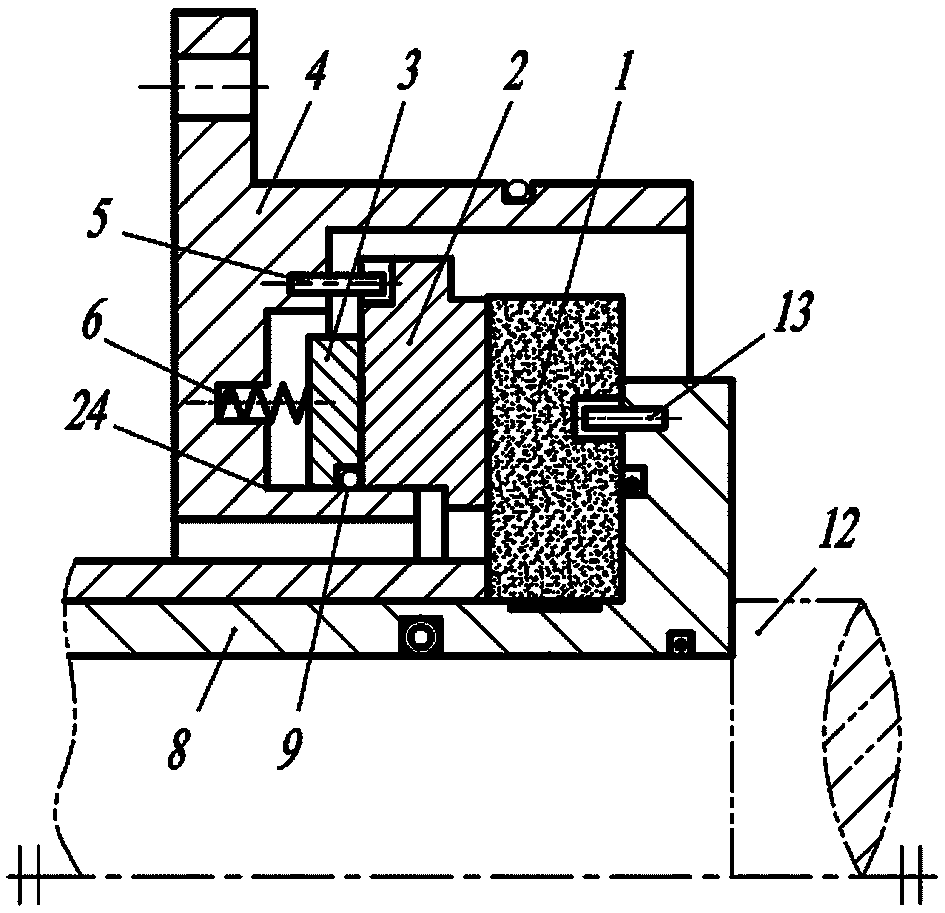

[0024] figure 1 with figure 2 What is shown is the basic structure of the traditional common mechanical seal device at present, as mentioned above.

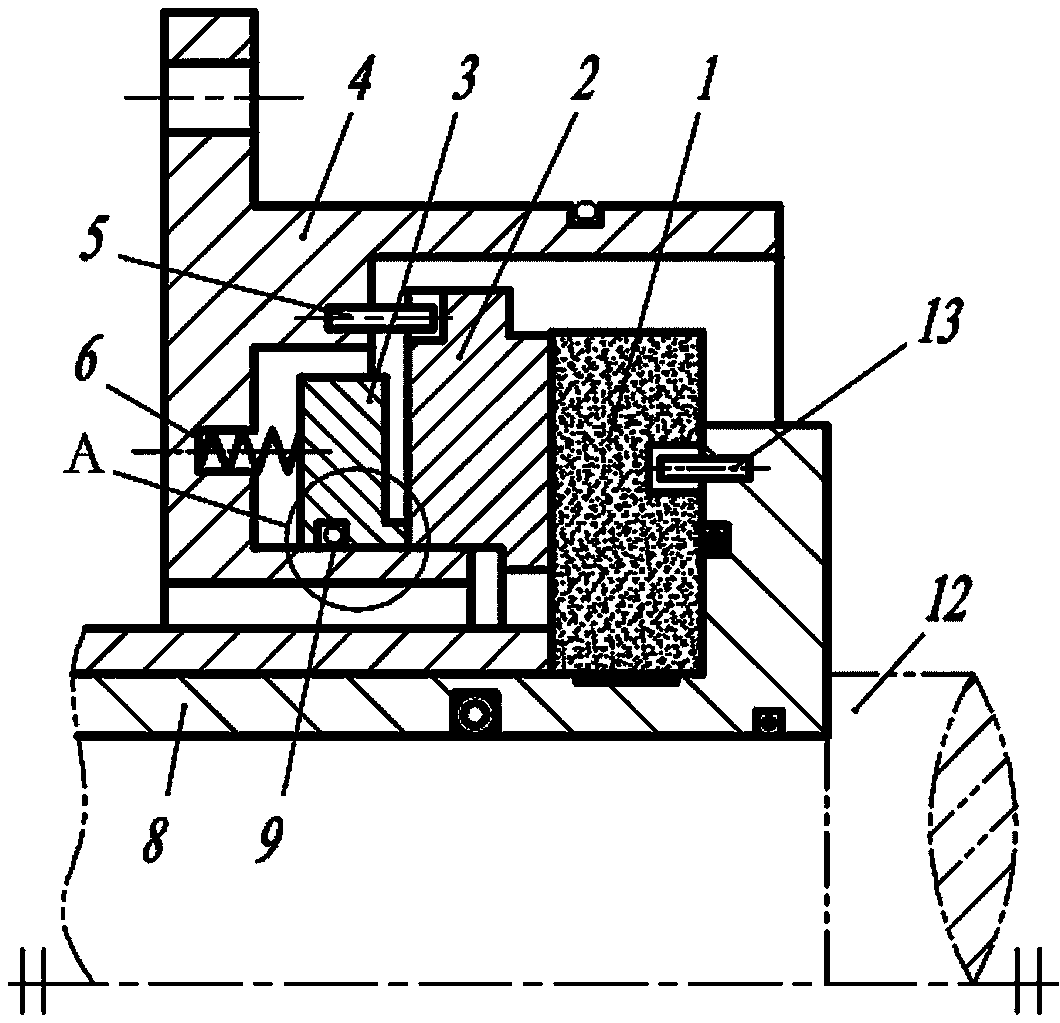

[0025] image 3 Shown is a mechanical seal device using the push ring with the above-mentioned structure of the present invention, including a moving ring 1 that is axially fixed and can rotate with the shaft 12, and the sealing surface at the end of the shaft is opposite to the moving ring 1 and can be axially floating. The non-rotating static ring 2 and the moving ring 1 are fixed on the shaft sleeve 8 through the transmission pin 13 with its inner hole surface and the non-sealed end surface, and the shaft sleeve 8 is fixed on the shaft 12. The static ring 2 is axially supported floatingly between the static ring seats 4 through the push ring 3 and elastic structures 6 such as springs arranged in contact with its non-sealed end surface, and is fixed by the anti-rotation pin 5 in the circumferential direction.

[0026] Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com