NMP (N-Methyl Pyrrolidone) wastewater low-temperature recycling system and method thereof

A recovery system and low-temperature technology, applied in the field of NMP waste water low-temperature recovery system, can solve problems such as high energy consumption and non-compliance with energy-saving and emission-reduction policies, and achieve the effects of improving production efficiency and relieving production pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

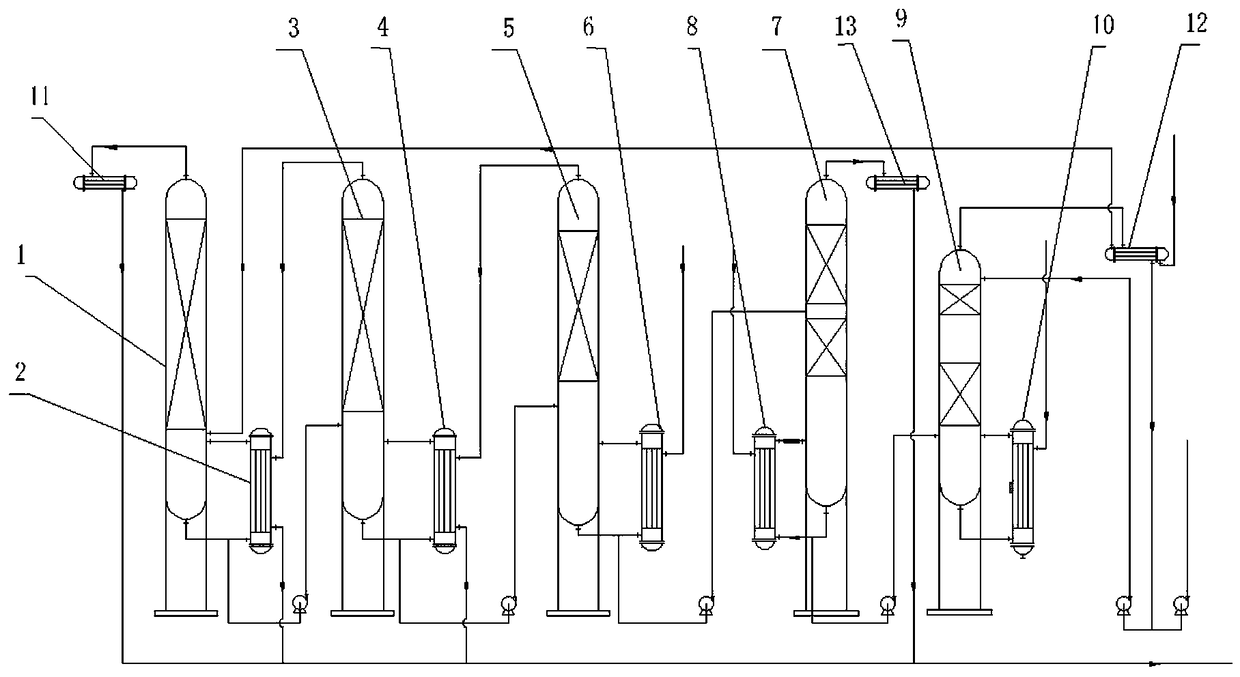

[0043] Such as figure 1As shown, a low-temperature recovery system for NMP waste water described in this embodiment includes a first-stage concentration tower 1, a second-stage concentration tower 3, a third-stage concentration tower 5, a vacuum rectification tower 7, and a refining tower 9 connected sequentially through pipelines; The liquid phase outlet of the first-stage concentration tower 1 is connected to the heat medium inlet of the first condenser 11; the liquid-phase outlet of each tower is connected to the liquid-phase feed port of the lower tower; the first-stage concentration tower The liquid-phase feed port of 1 is connected to the refrigerant outlet of the preheater 12 through the feed pipe; the first-stage concentration tower 1, the second-stage concentration tower 3, the third-stage concentration tower 5, the vacuum rectification tower 7 and the refining tower 9 Arranged in a straight line and connected to the reboilers respectively, they are the first-stage r...

Embodiment 2

[0063] A kind of NMP wastewater low-temperature recovery system described in this embodiment comprises a first-level concentration tower 1, a second-level concentration tower 3, a third-level concentration tower 5, a vacuum rectification tower 7 and a refining tower 9 connected sequentially through pipelines; The vapor phase outlet of the first stage concentration tower 1 is connected to the heat medium inlet of the first condenser 11; the liquid phase outlet of each tower is connected to the liquid phase feed port of the lower tower; the liquid phase of the first stage concentration tower 1 The phase feed port is connected to the refrigerant outlet of the preheater 12 through the feed pipe; the first-stage concentration tower 1, the second-stage concentration tower 3, the third-stage concentration tower 5, the vacuum rectification tower 7 and the refining tower 9 are arranged in a ring . A low-temperature recovery method for NMP wastewater is the same as in Example 1.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com