A kind of cotton-like full-dull warp-knitted fabric and its production method

A production method and full extinction technology, applied in the field of textile fabrics, can solve problems such as unfavorable application, impact, and unstable output, and achieve stable dimensions, moderate elasticity, and solve the effects of not being able to produce at high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

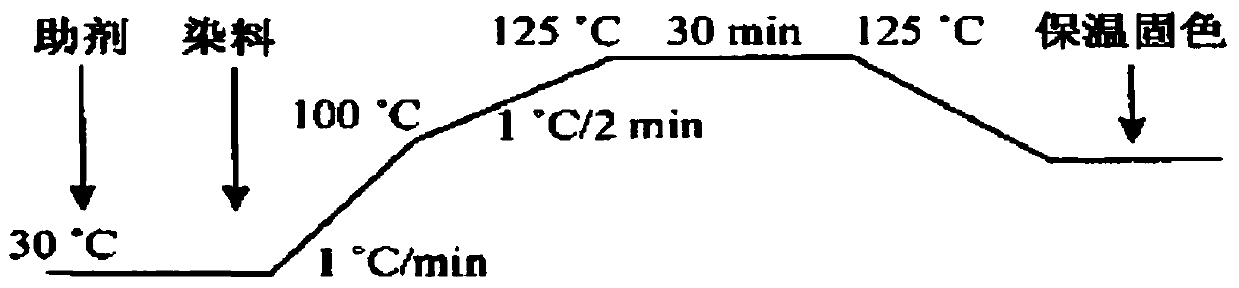

Method used

Image

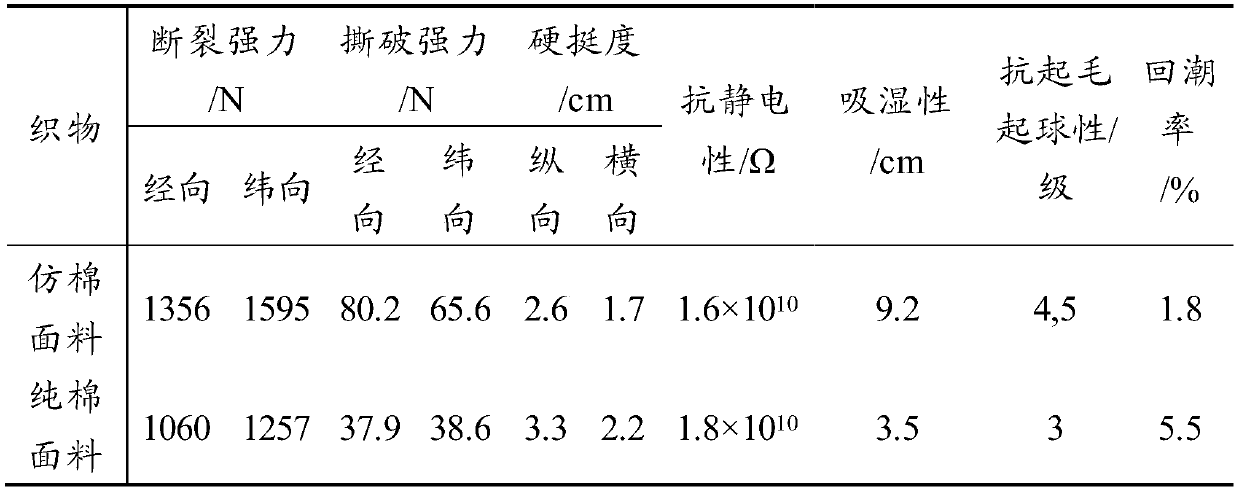

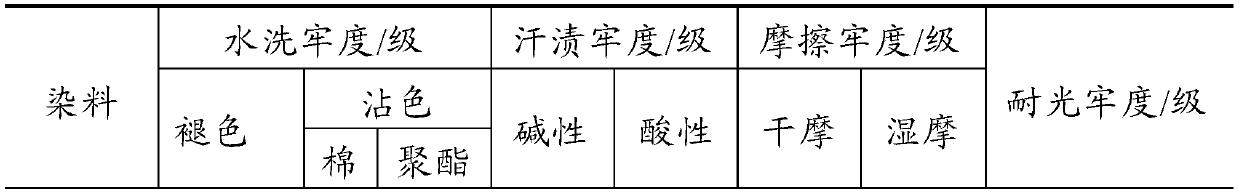

Examples

Embodiment 1

[0053] 1. Preparation process of full-dull polyester imitation cotton filament

[0054] The selected raw material is (6.7tex POY+6.7tex FDY) / 36F polyester composite yarn (provided by Jiangsu Shenghong Chemical Fiber Co., Ltd.). , to obtain full matting cotton-like polyester filaments. Tested by conventional methods, the breaking strength of the full-dull cotton-like polyester filament is 4.95cN / dtex, the breaking elongation is 15.75%, and the boiling water shrinkage is 23%.

[0055] 2. The weaving process of cotton-like full-dull flannel gray cloth

[0056] (1) Warping

[0057] Warping machine: Karl Mayer warping machine;

[0058] Machine speed is 500m / min;

[0059] The number of pan heads is 5;

[0060] Yarn length is 10000cm;

[0061] The number of head lines is 520.

[0062] (2) Machine weaving

[0063] Warp knitting machine type: Tricot warp knitting machine HKS4;

[0064] Machine speed: 900r / min;

[0065] Machine number: E28;

[0066] Width: 160cm.

[0067] 3....

Embodiment 2

[0102] 1. Preparation process of full-dull polyester imitation cotton filament

[0103] The selected raw material is (22.2dtex POY+29.9tex FDY) / 72F polyester composite yarn (provided by Jiangsu Shenghong Chemical Fiber Co., Ltd.). , to obtain full matting cotton-like polyester filaments. Tested by conventional methods, the breaking strength of the full-dull cotton-like polyester filament is 3.72cN / dtex, the breaking elongation is 13.15%, and the boiling water shrinkage is 19%.

[0104] 2. The weaving process of cotton-like full-dull flannel gray cloth

[0105] (1) Warping

[0106] Warping machine: Karl Mayer warping machine;

[0107] Machine speed is 500m / min;

[0108] The number of pan heads is 5;

[0109] Yarn length is 10000cm;

[0110] The number of head lines is 520.

[0111] (2) Machine weaving

[0112] Warp knitting machine type: Tricot warp knitting machine HKS4;

[0113] Machine speed: 900r / min;

[0114] Machine number: E28;

[0115] Width: 160cm.

[0116]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com