Washing machine for conveniently separating granules of different granularities in solution

A washing machine, a convenient technology, applied in the field of washing machines, can solve the problems of increasing the number of washings, increasing the amount of detergent, washing, and poor separation effects, etc., to achieve the effect of avoiding leakage problems and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

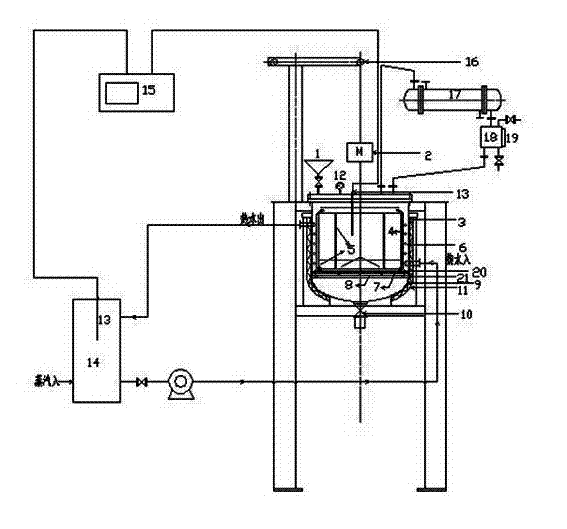

[0032] A washing machine is obtained, and the main part of the washing machine is mainly composed of a feeding port 1, a stirring device 2, a washing chamber 3, a filter bag 4, a supporting frame 5, a heating jacket 6, an insulating layer 11, a filter screen 7, a supporting partition The grid 8, the tiny particle collection chamber 9 and the discharge valve 10 are composed of several parts, wherein,

[0033] The washing chamber 3 and the microparticle collection chamber 9 are set up and down and connected by welding to form the kettle body; the lower part of the washing chamber is provided with a shelf ring 21 for placing the support grille 8, and the discharge valve 10 is arranged in the microparticle collection chamber of the kettle body The bottom of the bottom; the washing chamber 3 and the micro particle collection chamber 9 are separated by a 150-mesh stainless steel filter screen 7, and a support grille 8 is arranged under the filter screen 7, and the filter screen 7 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com