Device and method for preparing anhydrous aluminum fluoride

A water aluminum fluoride and aluminum fluoride technology, applied in aluminum fluoride, aluminum halide and other directions, can solve the problems of unstable quality and high energy consumption of dry aluminum fluoride, and achieve good fluidity, large specific gravity, and easy absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

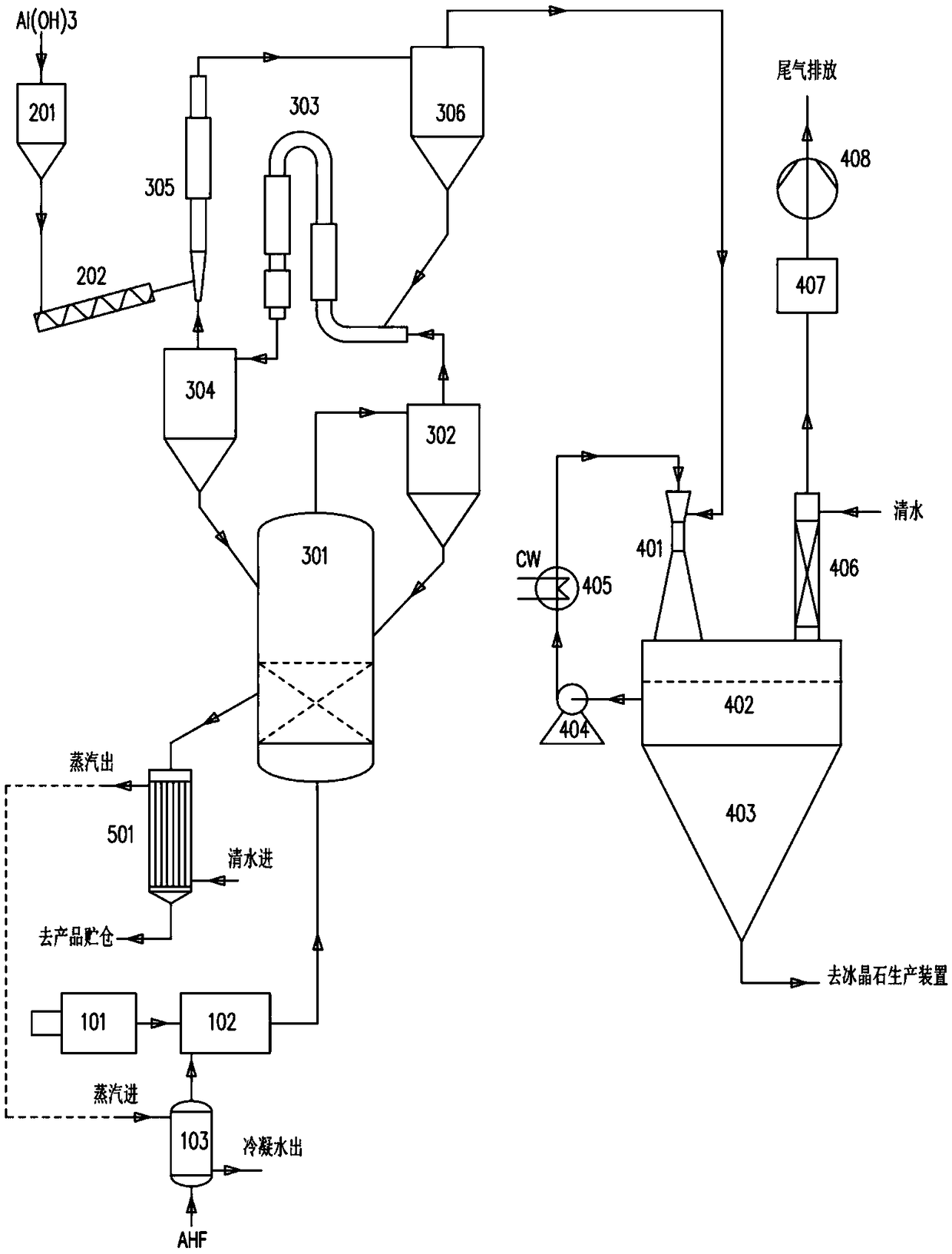

[0053] Such as figure 1 As shown, a device for preparing anhydrous aluminum fluoride includes: an air heater 101, a hydrogen fluoride vaporizer 103, a hydrogen fluoride mixer 102, a wet aluminum hydroxide metering bin 201, a wet aluminum hydroxide feed screw 202, a single layer Fluidized bed reactor 301, aluminum fluoride gas-solid separator 302, alumina reactor 303, alumina gas-solid separator 304, aluminum hydroxide dryer 305, aluminum hydroxide gas-solid separator 306, tail gas absorber 401 , absorption liquid circulation tank 402, absorption liquid settling tank 403, absorption liquid circulation pump 404, absorption liquid cooler 405, tail gas washing tower 406, gas-liquid separator 407, tail gas fan 408, aluminum fluoride static cooler 501 and these Pipes and valves that connect equipment together.

[0054] Air heater 101 is provided with 1 air inlet and 1 air outlet; Air inlet is connected with atmosphere, or is connected with atmosphere after passing through air clean...

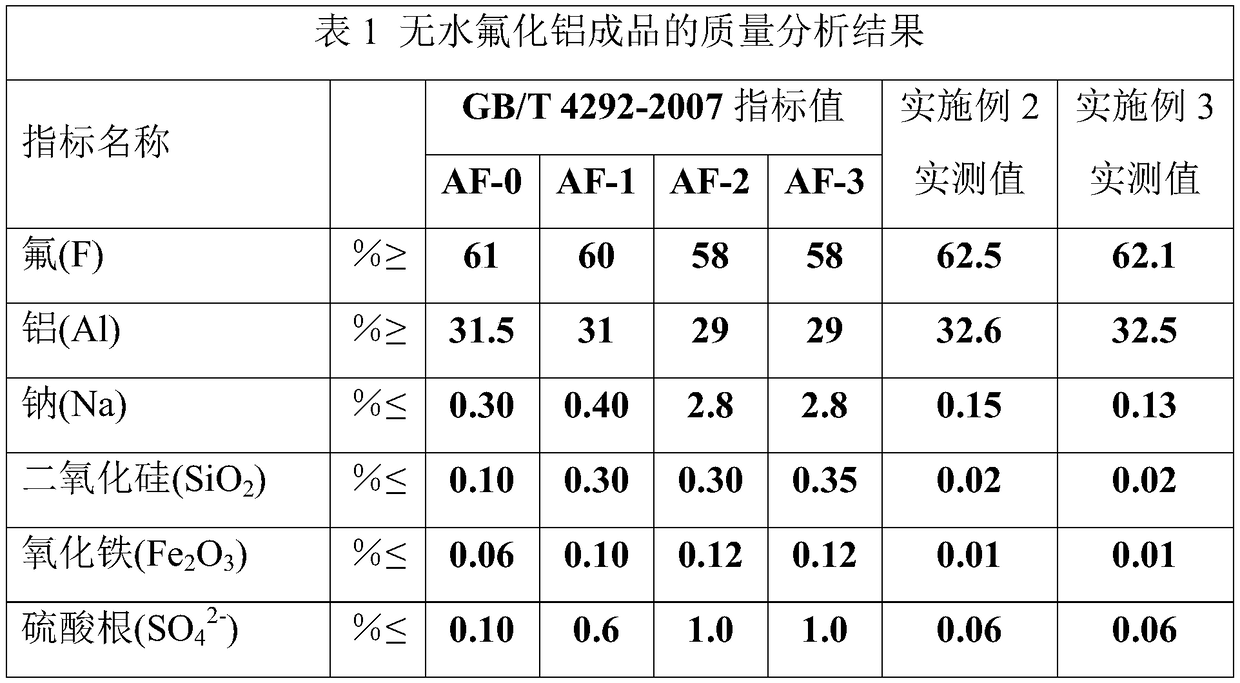

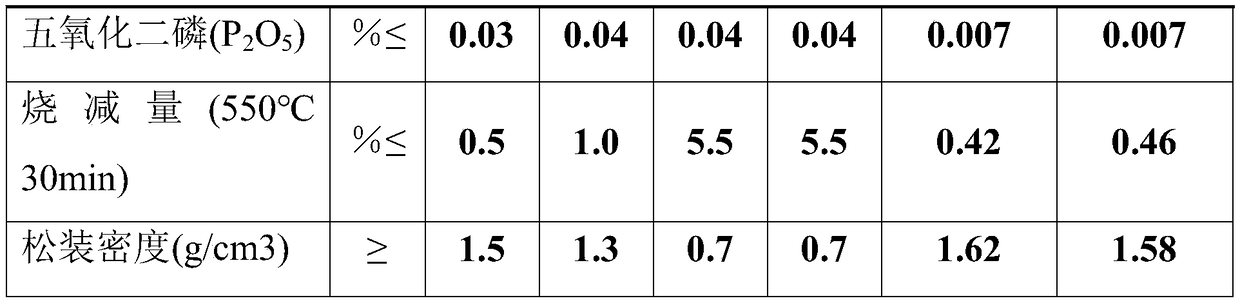

Embodiment 2

[0079] A method for preparing anhydrous aluminum fluoride, using the device of embodiment 1, comprising the following steps:

[0080] (1) The hot air heated to 450°C in the air heater 101 is sent into the system to raise the temperature of the entire system to above 400°C. 700kg of liquid hydrogen fluoride is put into the hydrogen fluoride vaporizer 103 and heated to convert it into gaseous AHF; hot air and gaseous AHF are mixed in the hydrogen fluoride mixer 102 and enter the bottom of the single-layer fluidized bed reactor 301.

[0081] (2) After about 1070kg of wet aluminum hydroxide (moisture content 7%) at room temperature is measured through wet aluminum hydroxide metering silo 201, enter aluminum hydroxide drier 305 by wet aluminum hydroxide feed screw 202, and come from aluminum oxide The medium-temperature airflow (temperature 420° C.) of the gas-solid separator 304 is fully mixed, and the surface water of the wet aluminum hydroxide is removed to become dry aluminum h...

Embodiment 3

[0087] A method for preparing anhydrous aluminum fluoride, using the device of embodiment 1, comprising the following steps:

[0088] (1) Firstly, the hot air heated to 450°C in the air heater 101 is sent into the system, so that the temperature of the whole system rises to above 400°C. 1400kg of liquid hydrogen fluoride is put into the hydrogen fluoride vaporizer 103 and heated to convert it into gaseous AHF; hot air and gaseous AHF are mixed in the hydrogen fluoride mixer 102 and enter the bottom of the single-layer fluidized bed reactor 301.

[0089] (2) After about 2140kg of wet aluminum hydroxide (moisture content 7%) at room temperature is measured through wet aluminum hydroxide metering silo 201, enter aluminum hydroxide drier 305 by wet aluminum hydroxide feed screw 202, and from aluminum oxide The medium-temperature airflow (temperature 420° C.) of the gas-solid separator 304 is fully mixed, and the surface water of the wet aluminum hydroxide is removed to become dry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com