Flow control valve, vehicle suspension shock absorber assembly and vehicle suspension system

A flow control valve and vehicle suspension technology, applied in the field of vehicle suspension systems, can solve the problems of high energy consumption, slow response speed, and low control accuracy, and achieve the goals of improving comfort, short response time, and improving flow control accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

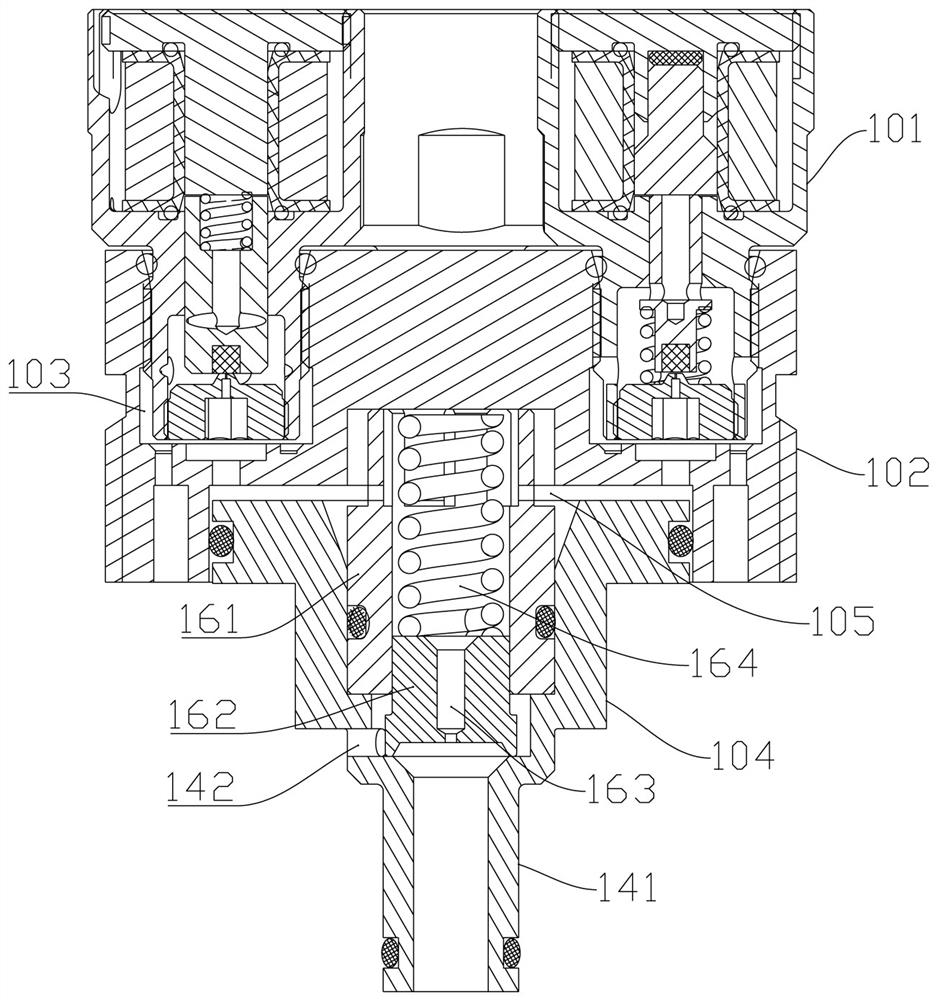

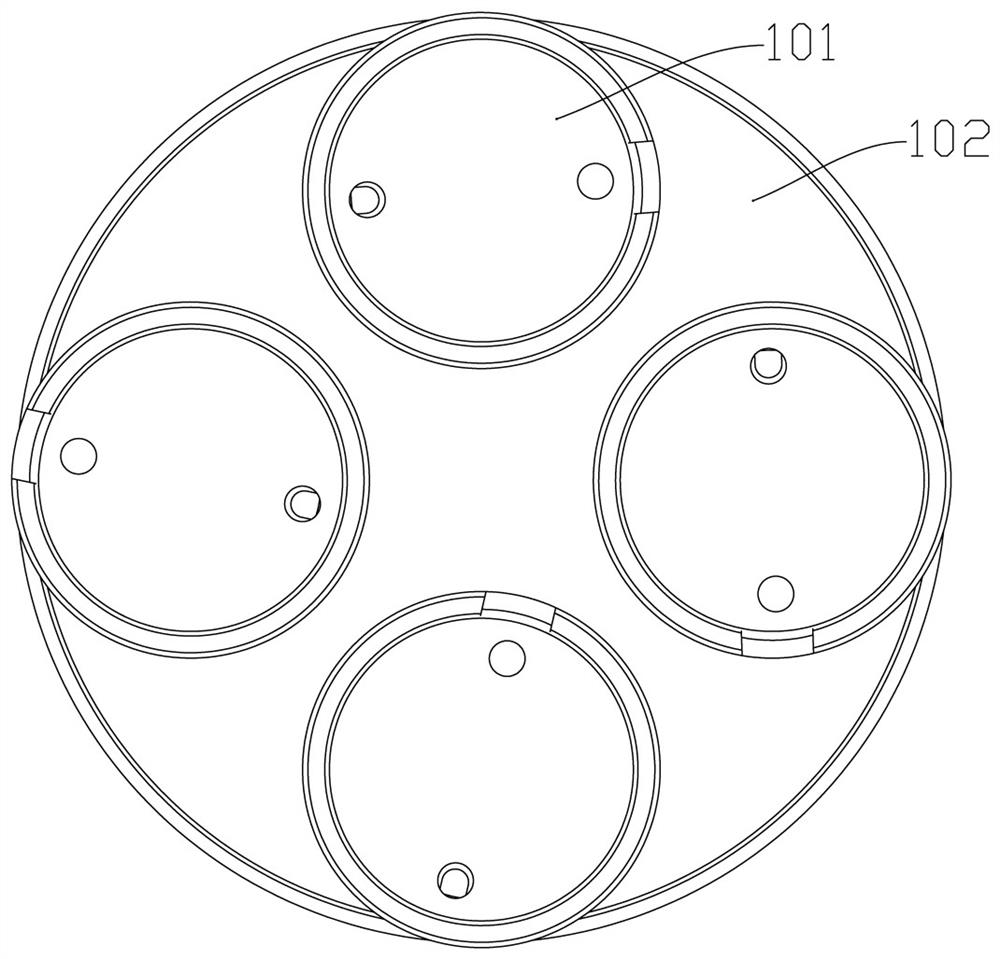

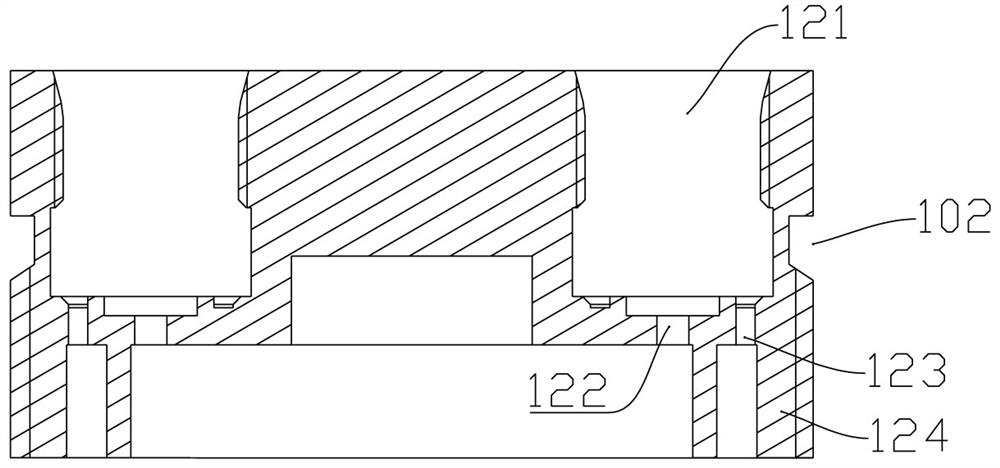

[0061] In this embodiment, a flow control valve is provided. The flow control valve adopts a plurality of high-speed on-off valves arranged in parallel to form an array structure. Through the on-off control of the high-speed on-off valve, a wide range of adjustment and control of the flow rate of the flow control valve can be realized. control; more importantly, through the integrated design of multiple high-speed on-off valves on one valve structure, the flow control of the flow control valve can be realized more simply, and the miniaturization of the overall structure of the flow control valve has been fully realized. While controlling the valve flow and controlling precision, the control valve has better performance.

[0062] refer to figure 1 and figure 2 , the flow control valve 100 in this embodiment includes:

[0063] Valve body assembly, the valve body assembly includes a main valve body 102, the main valve body 102 is provided with a plurality of installation parts...

Embodiment 2

[0080] This embodiment is a vehicle suspension shock absorber assembly, the vehicle suspension shock absorber assembly includes a shock absorber, the shock absorber is provided with a flow control valve, and the flow rate of the flow control valve is controlled to Adjust the damping force of the shock absorber. The flow control valve in Embodiment 1 is used to adjust and control the oil flow in a large range and with high precision through the flow control valve, so as to realize the adjustment and control of the damping force of the shock absorber; based on the flow control valve’s With the above performance, the shock absorber using the flow control valve has great progress and advantages compared with the prior art in terms of the adjustment range and control accuracy of the damping force. The following is a further description in conjunction with its specific structure:

[0081] refer to Figure 8 and Figure 9 , the shock absorber in this embodiment includes a cylinder...

Embodiment 3

[0092] This embodiment is a vehicle suspension system, which includes the vehicle suspension shock absorber assembly in the above embodiments, and the vehicle suspension shock absorber assembly is respectively arranged at positions corresponding to the front wheels and the rear wheels of the vehicle. Based on the performance of the vehicle suspension shock absorber assembly that adopts flow control control, the vehicle suspension system using the vehicle suspension shock absorber assembly has very good comprehensive performance and can well improve the comfort of the car and safety, it can meet the high-performance and high-quality requirements of the vehicle suspension system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com