Inner core heating low-temperature cigarette based on unordered atomized sheet cigarette tobacco

A technology of low-temperature cigarettes and thin slices, which is applied in the fields of tobacco, cigars, smokers’ supplies, etc. It can solve the problems of cost reduction, smoke temperature, and cigarette paper affecting appearance quality and atomization effect, so as to improve heat dissipation effect and cool down Efficiency and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

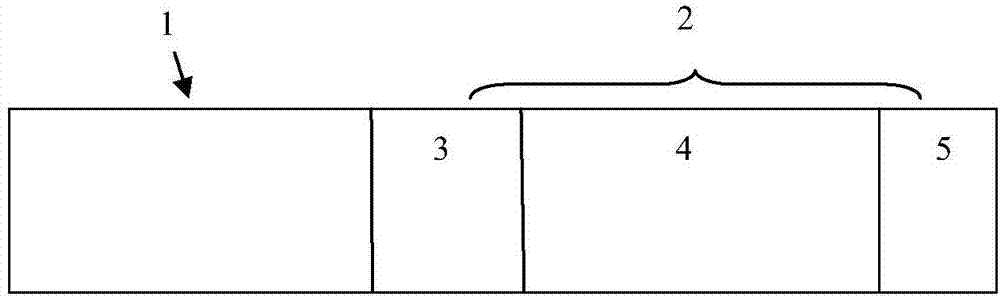

[0019] see figure 1 , a low-temperature cigarette with an electrically heated inner core based on disordered thin filaments, comprising an interconnected atomized tobacco segment 1 and a filter tip 2, wherein the atomized tobacco segment 1 is rolled by the disordered thin filaments according to the traditional cigarette method, atomized The cigarette paper of tobacco segment 1 is aluminum foil paper with a thickness of 0.04mm. The filter tip 2 is composed of a first hollow rod 3 , a membrane nozzle rod 4 and a second hollow rod 5 sequentially.

[0020] The total length of the cigarettes in this embodiment is 53 mm, and the diameter of the cigarettes is 7.7 mm. Wherein the length of the atomized tobacco section 1 is 20mm, the length of the first hollow rod 3 is 7mm, the hollow inner diameter is 5mm, the length of the film nozzle rod 4 is 20mm, the length of the second hollow rod 5 is 6mm, and the hollow inner diameter is 4mm. A suitable core heating device has a core needle l...

Embodiment 2

[0025] see figure 1 , a low-temperature cigarette with an electrically heated inner core based on disordered thin filaments, comprising sequentially connected atomized tobacco segment 1 and filter tip 2, wherein the atomized tobacco segment 1 is rolled by the disordered thin filament according to the traditional cigarette method, atomized The cigarette paper of tobacco segment 1 is aluminum foil paper with a thickness of 0.08mm. The filter tip 2 is composed of a first hollow rod 3 , a membrane nozzle rod 4 and a second hollow rod 5 sequentially.

[0026] The cigarette of this embodiment has a total length of 60 mm and a diameter of 6.5 mm. The length of the atomized tobacco section 1 is 22 mm, the length of the first hollow rod 3 is 10 mm, and the inner diameter is 3 mm. The film nozzle rod 4 has a length of 20 mm, the second hollow rod 5 has a length of 8 mm, and an inner diameter of 2 mm. The applicable core needle heating device has a core needle length of 23mm.

[0027...

Embodiment 3

[0031] see figure 1 , a low-temperature cigarette with an electrically heated inner core based on disordered thin filaments, comprising sequentially connected atomized tobacco segment 1 and filter tip 2, wherein the atomized tobacco segment 1 is rolled by the disordered thin filament according to the traditional cigarette method, atomized The cigarette paper of tobacco section 1 is aluminum foil paper with a thickness of 0.05 mm. The filter tip 2 is composed of a first hollow rod 3 , a membrane nozzle rod 4 and a second hollow rod 5 sequentially.

[0032] The total length of cigarettes in this embodiment is 48mm, and the diameter is 7.7mm. Wherein the atomized tobacco section 1 is 15mm, the first hollow rod 3 is 7mm, and the inner diameter is 5mm. The film nozzle rod 5 is 20mm, the second hollow rod 5 is 6mm, and the inner diameter is 4mm. The applicable core needle heating device has a core needle length of 16mm.

[0033] The atomized tobacco section 1 is composed of shre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com