Method for repairing micro-arc oxide film oil leakage at seal groove of cylinder body of actuator cylinder of airplane

A technology of micro-arc oxidation and sealing groove, which is applied to aircraft parts, ground devices, grinding machines, etc., can solve the problems of frequent oil leakage failures on the joint surface of the cylinder and the piston, and the aging of the micro-arc oxidation layer is particularly serious, and achieves a solution to the cylinder Oil leakage at the body seal groove, saving money, and great application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The method of repairing the oil leakage of the micro-arc oxidation film layer at the bottom of the sealing groove of the cylinder body of the aircraft actuator is carried out according to the following steps:

[0026] (1) Disassemble the cylinder body of the aircraft cylinder assembly that has oil leakage failure at the bottom of the seal groove of the cylinder cylinder body, and clean it with gasoline;

[0027] (2) Measure the surface roughness of the micro-arc oxidation film layer at the bottom of the cylinder sealing groove to be 2.83;

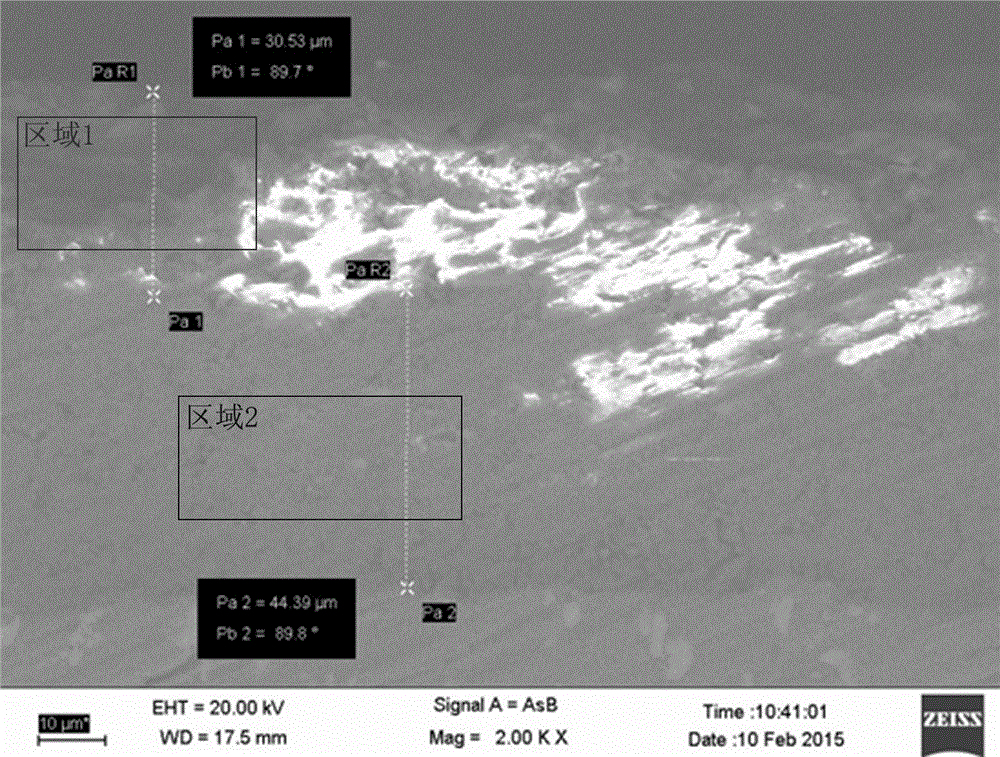

[0028] (3) Using an electron microscope to observe the microscopic cross-sectional morphology of the micro-arc oxidation film layer at the bottom of the sealing groove of the cylinder body, it is found that the micro-arc oxidation film layer produces a loose layer, and the cross-sectional morphology of the micro-arc oxidation film layer is as follows figure 1 As shown, the thickness of the oxide film is 74.92 μm, the thickness of the...

Embodiment 2

[0042] The method of repairing the oil leakage of the micro-arc oxidation film layer on the side of the sealing groove of the cylinder body of the aircraft actuator is carried out according to the following steps:

[0043] (1) Disassemble the cylinder body of the aircraft cylinder assembly that has oil leakage failure at the side of the seal groove of the cylinder cylinder body, and clean it with gasoline;

[0044] (2) Measure the surface roughness of the micro-arc oxidation film layer on the side of the sealing groove of the cylinder to be 2.47;

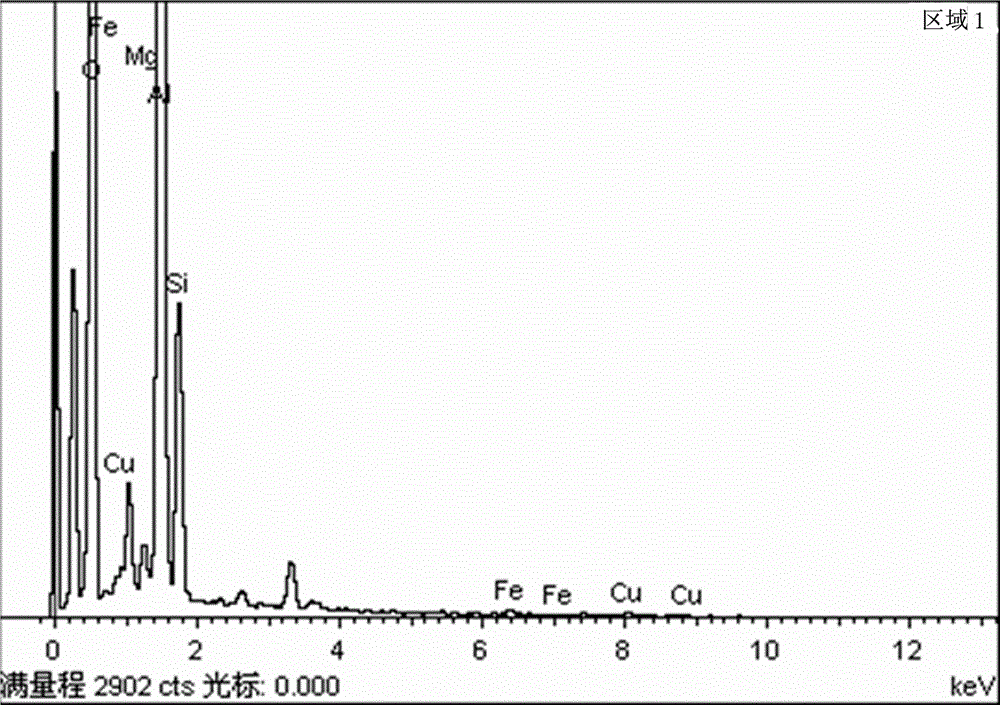

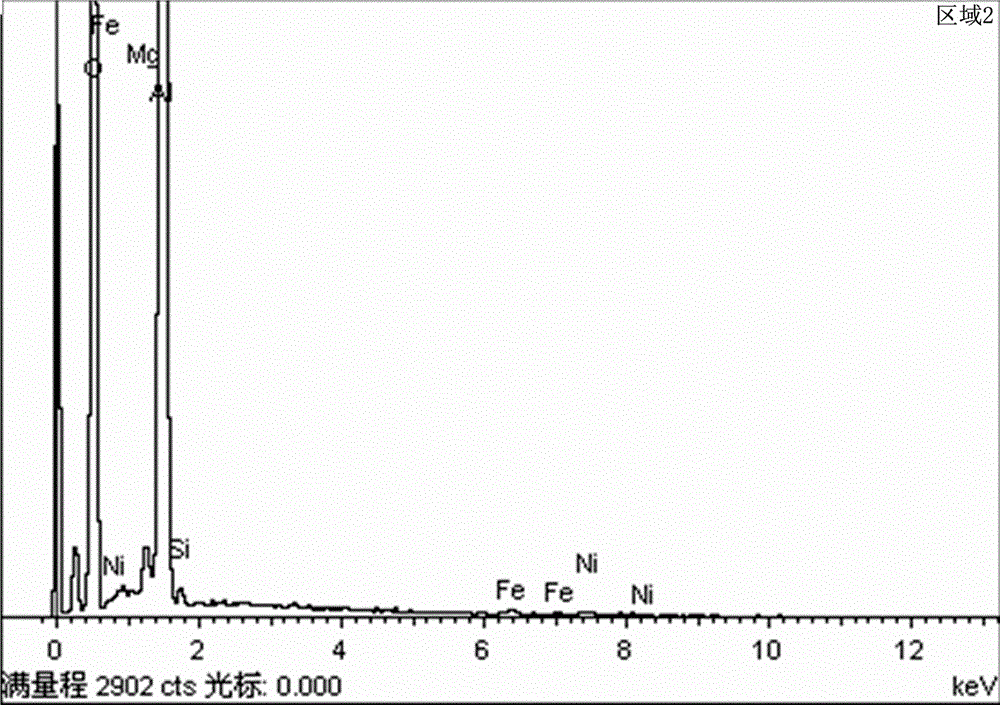

[0045] (3) Using an electron microscope and an energy spectrometer to measure whether a loose layer is produced on the micro-arc oxidation film layer on the side of the cylinder sealing groove, the result is a loose layer, in which the thickness of the oxide film is 75.34 μm, the thickness of the loose layer is 30.89 μm, and the thickness of the dense layer is 44.45 μm, the loose layer accounts for 41.00% of the total thickness; Tab...

Embodiment 3

[0059] The method of repairing the oil leakage of the micro-arc oxidation film layer on the side of the sealing groove of the cylinder body of the aircraft actuator is carried out according to the following steps:

[0060] (1) Disassemble the cylinder body of the aircraft cylinder assembly that has oil leakage failure at the side of the seal groove of the cylinder cylinder body, and clean it with gasoline;

[0061] (2) Measure the surface roughness of the micro-arc oxidation film layer on the side of the sealing groove of the cylinder to be 2.53;

[0062] (3) Using an electron microscope and an energy spectrometer to measure whether a loose layer is produced on the micro-arc oxidation film layer on the side of the cylinder sealing groove, the result is a loose layer, in which the thickness of the oxide film is 73.77 μm, the thickness of the loose layer is 28.89 μm, and the thickness of the dense layer is 44.88 μm, the loose layer accounts for 39.16% of the total thickness; Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com