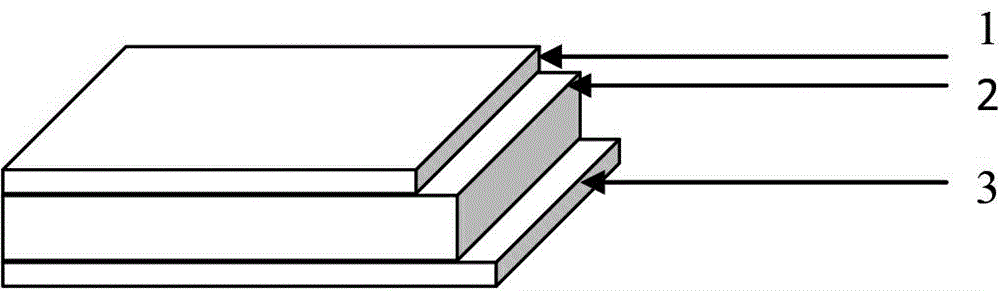

Ultrahigh-loose thickness noodle bowl paper and production process thereof

A technology of ultra-high-loose, noodle and bowl paper, applied in the field of noodle and bowl paper, can solve the problems of edge bursting, edge seepage, oil seepage, etc., achieve good edge seepage and oil seepage, reduce costs, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Prepare the ultra-high bulkiness face bowl paper of the present invention according to the following methods:

[0025] 1. Pulping process

[0026] Surface layer:

[0027] The ratio of surface layer pulp is: 35% NBKP (bleached softwood kraft pulp) + 65% LBKP (bleached broadleaf kraft pulp);

[0028] After the pulp board is disintegrated by a hydraulic machine according to a certain ratio, it is sent to the paper machine for papermaking through screening, beating, and pulping.

[0029] ② Core layer:

[0030] The ratio of core pulp is: 50% BCTMP (bleached chemical thermomechanical pulp) + 20% BKP (bleached broadleaf chemical pulp) + 30% broken paper;

[0031] After the pulp board is disintegrated by a hydraulic machine according to a certain ratio, it is sent to the paper machine for papermaking through screening, beating, and pulping.

[0032] ③ Bottom layer:

[0033] The ratio of bottom layer slurry is: 45%NBKP+55%LBKP;

[0034] After the pulp board is disintegra...

Embodiment 2

[0046] Prepare the ultra-high bulkiness face bowl paper of the present invention according to the following methods:

[0047] 1. Pulping process

[0048] Surface layer:

[0049] The ratio of surface layer pulp is: 42% NBKP (bleached softwood kraft pulp) + 58% LBKP (bleached broadleaf kraft pulp);

[0050] After the pulp board is disintegrated by a hydraulic machine according to a certain ratio, it is sent to the paper machine for papermaking through screening, beating, and pulping.

[0051] ② Core layer:

[0052] The pulp ratio of the core layer is: 45% BCTMP (bleached chemical thermomechanical pulp) + 23% BKP (bleached broadleaf chemical pulp) + 32% broken paper;

[0053] After the pulp board is disintegrated by a hydraulic machine according to a certain ratio, it is sent to the paper machine for papermaking through screening, beating, and pulping.

[0054] ③ Bottom layer:

[0055] The ratio of bottom layer slurry is: 50%NBKP+50%LBKP;

[0056] After the pulp board is ...

Embodiment 3

[0068] Prepare the ultra-high bulkiness face bowl paper of the present invention according to the following methods:

[0069] 1. Pulping process

[0070] Surface layer:

[0071] The ratio of surface layer pulp is: 50% NBKP (bleached softwood kraft pulp) + 50% LBKP (bleached broadleaf kraft pulp);

[0072] After the pulp board is disintegrated by a hydraulic machine according to a certain ratio, it is sent to the paper machine for papermaking through screening, beating, and pulping.

[0073] ② Core layer:

[0074] The pulp ratio of the core layer is: 50% BCTMP (bleached chemical thermomechanical pulp) + 20% BKP (bleached broadleaf chemical pulp) + 30% broken paper;

[0075] After the pulp board is disintegrated by a hydraulic machine according to a certain ratio, it is sent to the paper machine for papermaking through screening, beating, and pulping.

[0076] ③ Bottom layer:

[0077] The ratio of bottom layer slurry is: 35%NBKP+65%LBKP;

[0078] After the pulp board is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com