Solder-resistant processing method of PCB and PCB

A processing method and PCB board technology, applied in the secondary processing of printed circuits, electrical components, printed circuit manufacturing, etc., can solve problems such as thin ink, and achieve the effect of solving the problem of thin ink on the edge of the line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

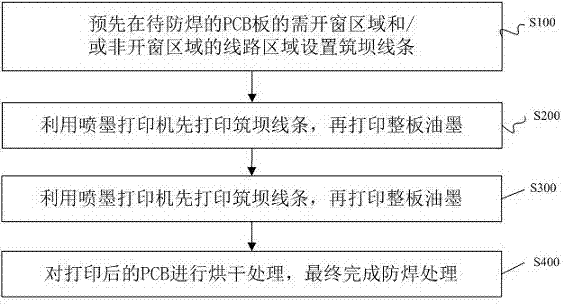

Method used

Image

Examples

Embodiment 1

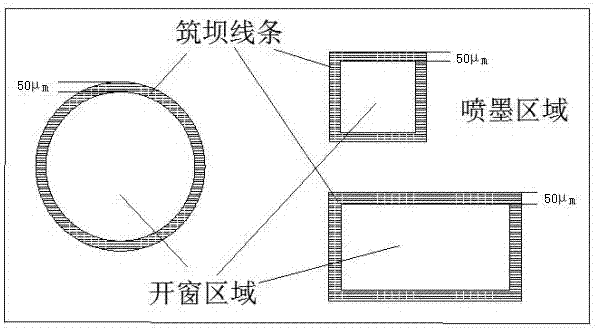

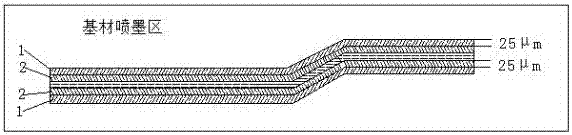

[0060] Step 1: CAM design: set damming lines with a line width of 50 μm in the area where the window needs to be opened and the line area in the non-opening area. The base material area where the window area intersects; the dam line in the line area located in the non-window area partially covers the copper surface of the line, and partly covers the base material area of the window area, and the line width of both parts is 25um;

[0061] Step 2: Pre-treatment of inkjet printing: pickling, super-roughening, and anti-rust treatment on the copper surface of the PCB board before solder masking. The amount is controlled at 0.8μm, and the copper surface antirust treatment time is 40s;

[0062] Step 3: Anti-seepage oil treatment before inkjet printing: soak the PCB board after inkjet printing pretreatment in the ink anti-seepage liquid for 40s, then put it into a horizontal cleaning line with a water washing spray pressure of 6psi for 60s, and finally Then dry the cleaned PCB boar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com