Fat composition high in crystallization rate but gentle in SFC curve

A kind of oil composition and composition technology, applied in the direction of edible oil/fat, edible oil/fat phase, food science, etc., can solve the problems of oil leakage and hardening, achieve fast crystallization rate, solve oil leakage and good grease taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

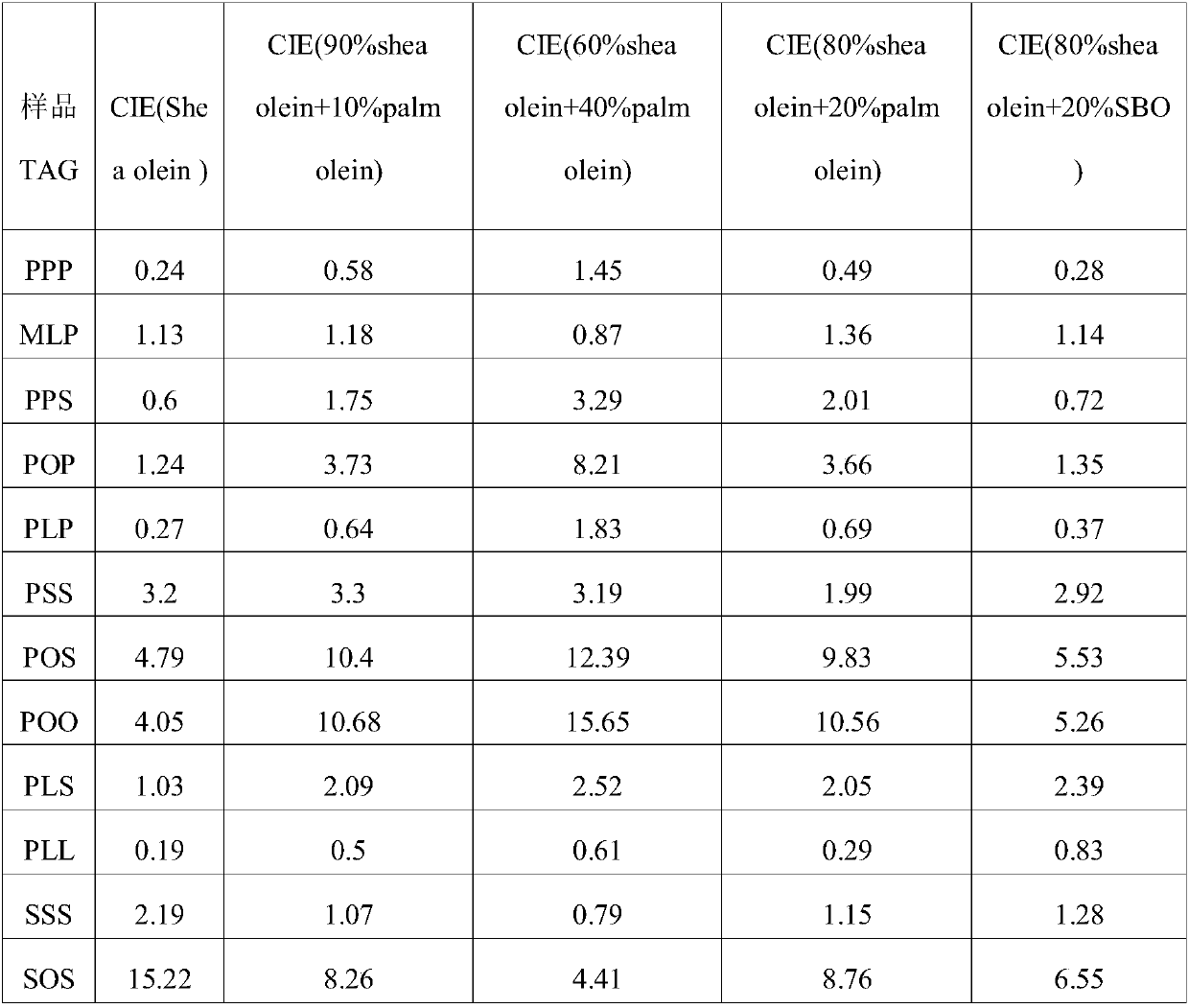

[0073] According to the formula shown in Table 1, mix the fat and oil according to the mass ratio (control the fat FFA% within 0.1wt%), first dehydrate under vacuum conditions at 105°C for 30min (control the moisture within 0.05wt%), then add the catalyst sodium methoxide, The dosage is 0.2-0.3% of the weight of the fat, and the reaction temperature is 105-110°C for 30-40 minutes, and the vacuum condition is 0.1bar minimum. Then a 10% concentration of citric acid solution was added to terminate the reaction, and the amount converted into citric acid was twice the amount of sodium methoxide. Then it is washed with water until it is neutral, dehydrated, decolorized, and refined for use.

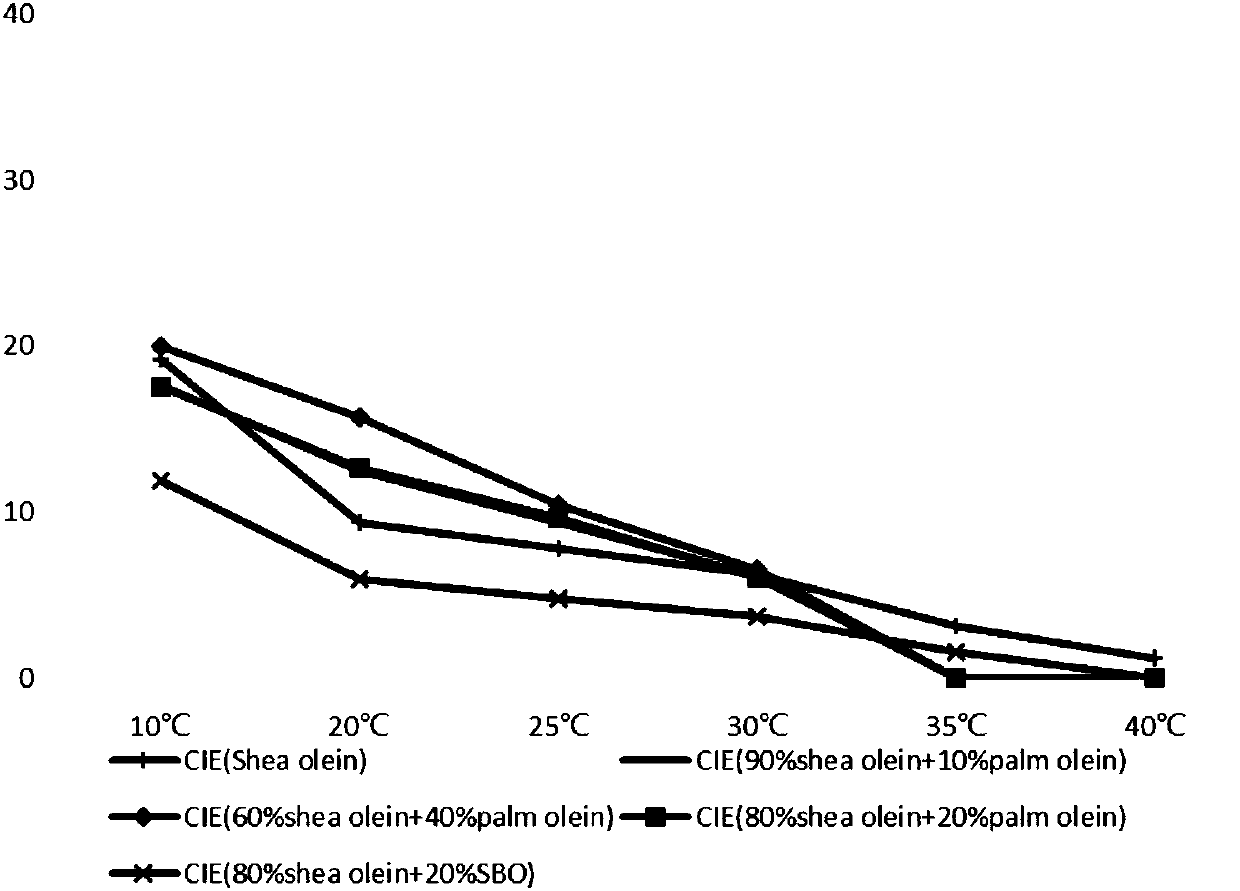

[0074] Refer to the AOCS cd 16b-93 method to detect the solid fat content of the prepared transesterified grease, namely SFC (solid fat content of plastic fat at a certain temperature). The specific detection method is as follows:

[0075] Take 1.5-2mL of the sample to be tested (if it is a non-liq...

Embodiment

[0088] The transesterification product prepared in the preparation example was stirred in a water bath of an ice-water mixture to crystallize and harden, and then the hardened fat was aged for 12 hours at a refrigerator temperature to prepare margarine for evaluation.

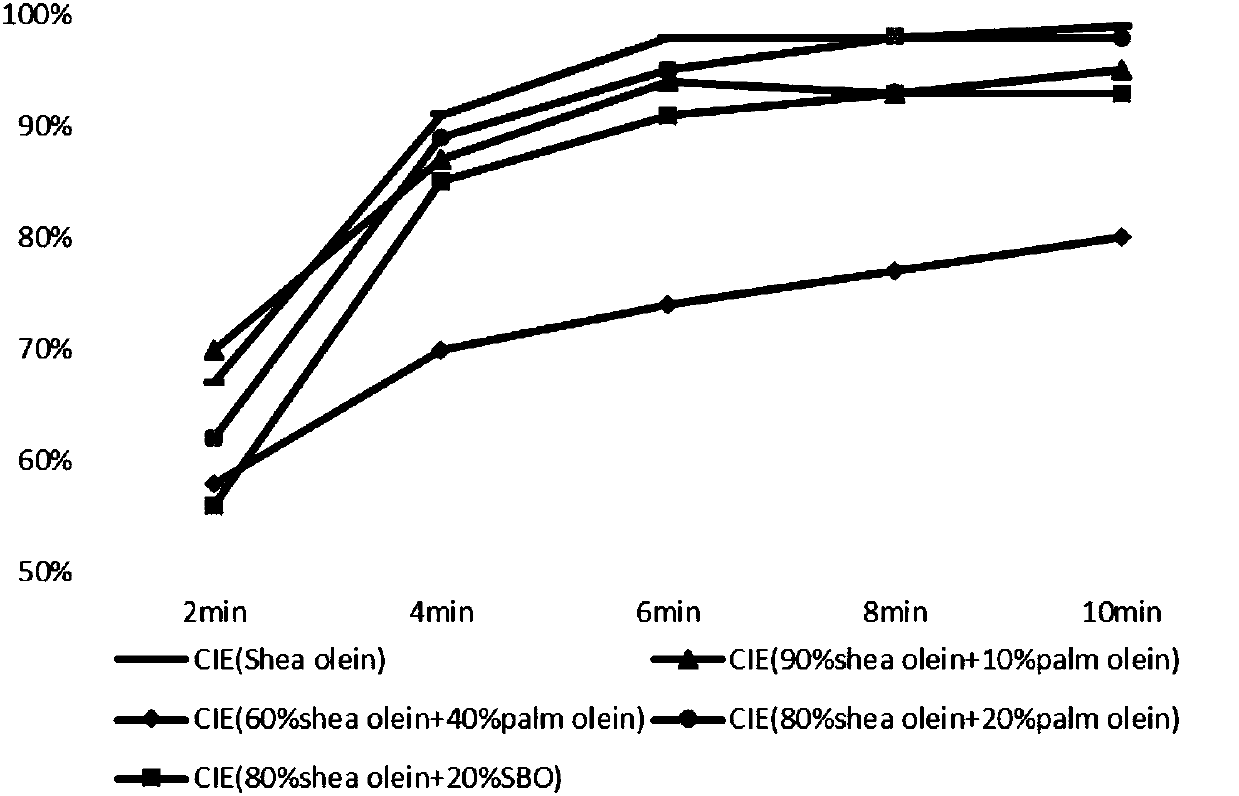

[0089] 1. Crystallization rate test:

[0090] Crystallization rate test method: Keep the grease sample at 60℃ for 30 minutes, and then test the solid fat content after 2min, 4min, 6min, 8min, and 10min in a water bath at 10℃, which is the amount of crystallization, and then divide it by 10 SFC value at ℃, get the crystallization rate.

[0091] The results are shown in Table 4 and figure 1 Shown.

[0092] Table 4: Crystallization rate data

[0093] sample 2min 4min 6min 8min 10min CIE(Shea olein)67%91%98%98%99% CIE (90% shea olein+10% palm olein)70%87%94%93%95% CIE (60% shea olein+40% palmolein)58%70%74%77%80% CIE (80% shea olein+20% palm olein)62%89%95%98%98% CIE (80% shea olein+20% SBO)56%85%91%93%93% CIE (5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com