Wet-mix plastering mortars prepared from stone chips and tailings sand

A technology for plastering mortar and tailings sand, applied in the field of wet-mix plastering mortar, can solve the problems of poor working performance of wet-mixed plastering mortar, unsatisfactory particle gradation of stone chips, and not being reasonably utilized, etc. Guaranteed continuity of use, low price, and the effect of solving bleeding problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The wet-mixed plastering mortar prepared with stone chips and tailings sand consists of the following components: 180kg cement, 70kg fly ash, 70kg mineral powder, 220kg water, 1150kg stone chips, 350kg tailings sand, and 5kg mortar admixture. Wherein, the mortar additive is a thickening agent, and the thickening agent is composed of the following components: 2kg sulfonic acid air-entraining agent, 30kg naphthalene water reducer, 6kg sodium gluconate, 0.5kg polypropylene short fiber, 8kg latex powder, 40kg sodium bentonite. Take by weighing 5kg from the prepared thickening agent for the preparation of plastering mortar. The particle size of the stone chips is not greater than 4.75mm, and the weight fraction of stone powder in the stone chips is 2-3%; the gradation range of the stone chips is: 4.75mm: 10-20; 2.36mm: 25-50; 1.18 mm: 40~50; 0.6mm: 60~90; 0.3mm: 80~95; 0.15mm: 90~100; the fineness modulus is 3.1~4.0. The particle size of the tailings sand is not greater th...

Embodiment 2

[0020] The difference from Example 1 is that the wet-mixed plastering mortar prepared with stone chips and tailings sand consists of the following components: 200kg cement, 80kg fly ash, 50kg mineral powder, 230kg water, 1250kg stone chips, 200kg tailings sand , 10kg mortar admixture. Wherein, the mortar additive is a thickening agent, and the thickening agent is composed of the following components: 3kg sulfonic acid air-entraining agent, 40kg naphthalene water reducer, 2kg sodium gluconate, 1.5kg polypropylene short fiber, 10kg latex powder, 20kg sodium bentonite. Take by weighing 10kg from the prepared thickening agent for the preparation of plastering mortar.

Embodiment 3

[0022] The difference from Example 1 is that the wet-mixed plastering mortar prepared with stone chips and tailings sand consists of the following components: 220kg cement, 60kg fly ash, 60kg mineral powder, 250kg water, 1000kg stone chips, 280kg tailings sand , 15kg mortar admixture. Wherein, the mortar additive is a thickening agent, and the thickening agent is composed of the following components: 4kg sulfonic acid air-entraining agent, 20kg naphthalene water reducer, 4kg sodium gluconate, 2kg polypropylene short fiber, 5kg Latex powder, 30kg sodium bentonite. Take by weighing 15kg from the prepared thickening agent for the preparation of plastering mortar.

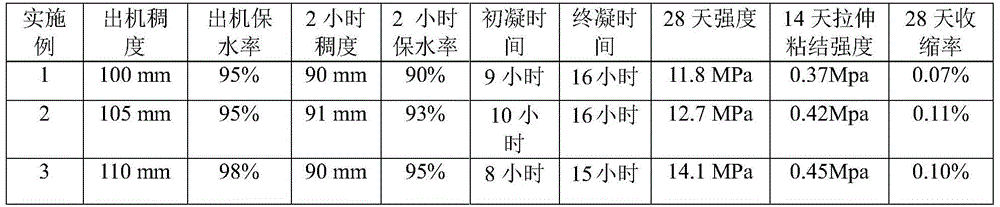

[0023] Table 1 Performance index of wet-mixed plastering mortar prepared in three examples

[0024]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com