Preparation method of plastic concrete with high water-binder ratio

A technology of plastic concrete and high water gel, which is applied in the field of plastic concrete preparation, can solve the problems of low plastic concrete water gel, high compressive strength, and low permeability coefficient, and achieve high compressive strength, good construction workability, and permeability The effect of coefficient reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

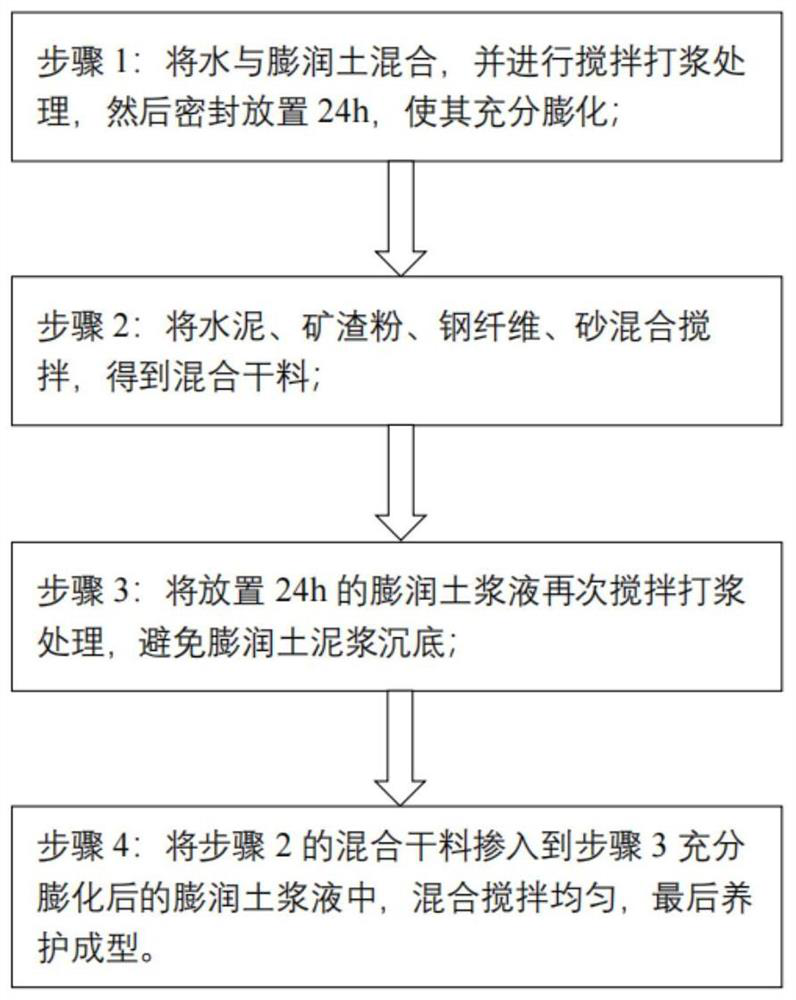

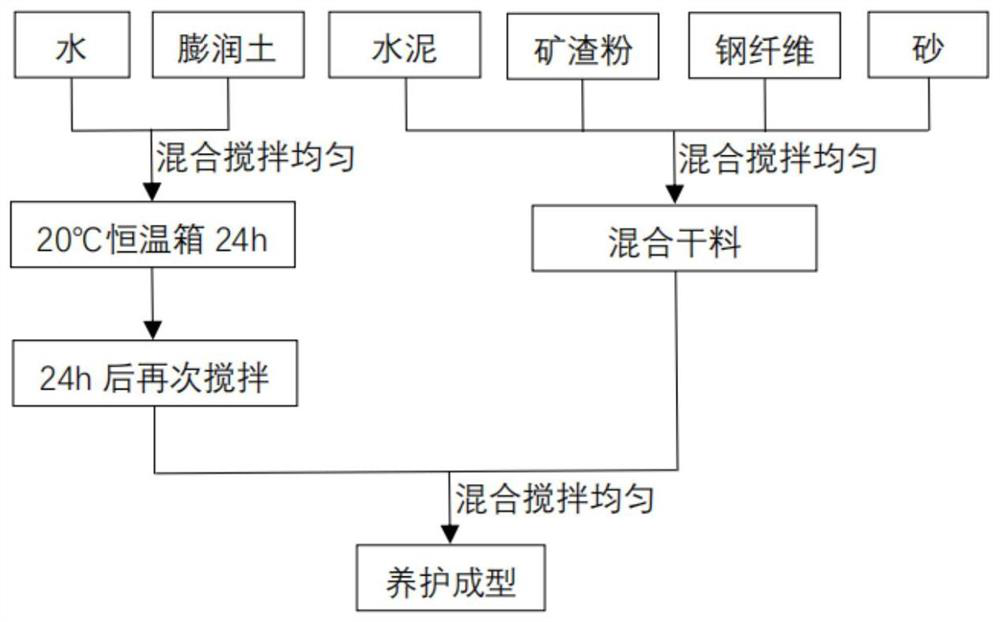

[0022] As shown in the figure, a method for preparing plastic concrete with a high water-binder ratio according to the present invention comprises the following steps:

[0023] Step 1: Mix water and bentonite, and stir evenly, then seal and place in a constant temperature box at a temperature of 20°C for 24 hours to make it fully expanded to obtain bentonite slurry, which is ready for use;

[0024] Wherein, the weight ratio of water and bentonite in the bentonite slurry is 22:4, usually, the weight part of water is 22, and the weight part of bentonite is 3-4;

[0025] The water used is deionized water with conductivity less than 0.1μs / cm;

[0026] The bentonite is at least one of calcium-based bentonite and sodium-based bentonite, and the particle size is 0.075-0.5mm;

[0027] Step 2: Dry mix cement, slag powder, steel fiber, and sand evenly to obtain a mixed dry material for use;

[0028] Wherein, the weight ratio of cement, slag powder, steel fiber and sand in the mixed dr...

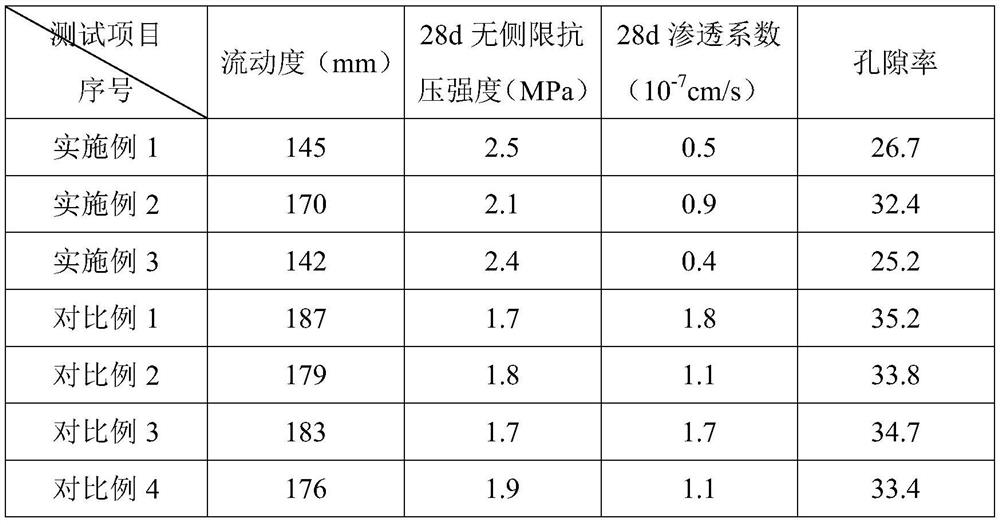

Embodiment 1

[0034] Embodiment 1: The present embodiment provides a kind of high water-binder ratio plastic concrete, comprises: the water of 22 parts by weight, the Inner Mongolia bentonite of 4 parts by weight, the cement of 2 parts by weight, the slag powder of 7 parts by weight, the slag powder of 1 part by weight Steel fiber, 64 parts by weight of sand, i.e. plastic concrete with a water-binder ratio of 1.7;

[0035] Specifically, 4 parts by weight of Inner Mongolia bentonite was poured into 22 parts by weight of water, and stirred for 120s, then sealed and placed in a thermostat at a temperature of 20°C for 24 hours, and the conductivity of the water used was deionized water of 0.098 μs / cm , Inner Mongolia bentonite is calcium-based bentonite with a particle size of 0.1 mm; after Inner Mongolia bentonite is expanded for 24 hours, mix 2 parts by weight of cement, 7 parts by weight of slag powder, 1 part by weight of steel fiber and 64 parts by weight of sand and stir for 60 seconds , ...

Embodiment 2

[0036] Embodiment 2: The present embodiment provides a kind of high water-binder ratio plastic concrete, comprises: the water of 22 parts by weight, the Inner Mongolia bentonite of 3 parts by weight, the cement of 1 part by weight, the slag powder of 7 parts by weight, the slag powder of 1 part by weight Steel fiber, 66 parts by weight of sand, i.e. plastic concrete with a water-binder ratio of 2.1;

[0037] Specifically, 3 parts by weight of Inner Mongolia bentonite was poured into 22 parts by weight of water, and stirred for 120s, then sealed and placed in a constant temperature box at a temperature of 20°C for 24 hours, and the conductivity of the water used was deionized water of 0.098 μs / cm , Inner Mongolia bentonite is calcium-based bentonite with a particle size of 0.1 mm; after Inner Mongolia bentonite is expanded for 24 hours, mix 1 weight part of cement, 7 weight parts of slag powder, 1 weight part of steel fiber and 66 weight parts of sand and stir for 60 seconds , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com