A kind of LC30 light-weight high-strength pumping ceramsite concrete and its preparation method

A ceramsite concrete, high-strength technology, applied in the field of building materials to achieve the effects of low apparent density, improved workability, and inhibition of floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

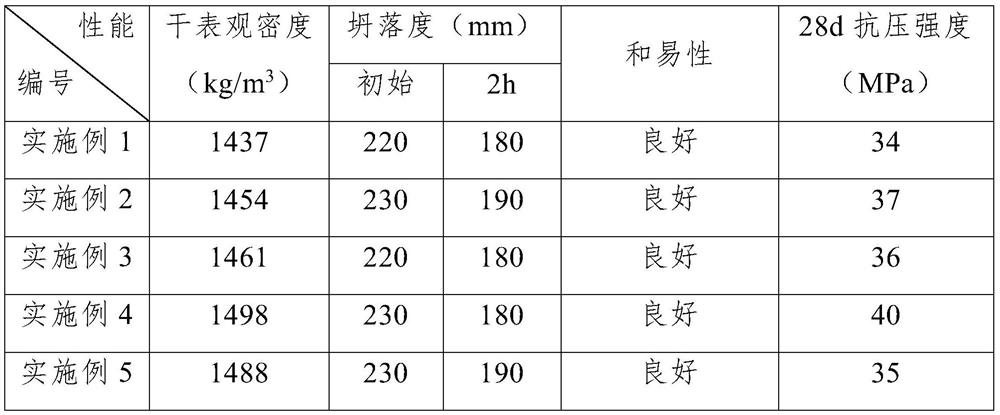

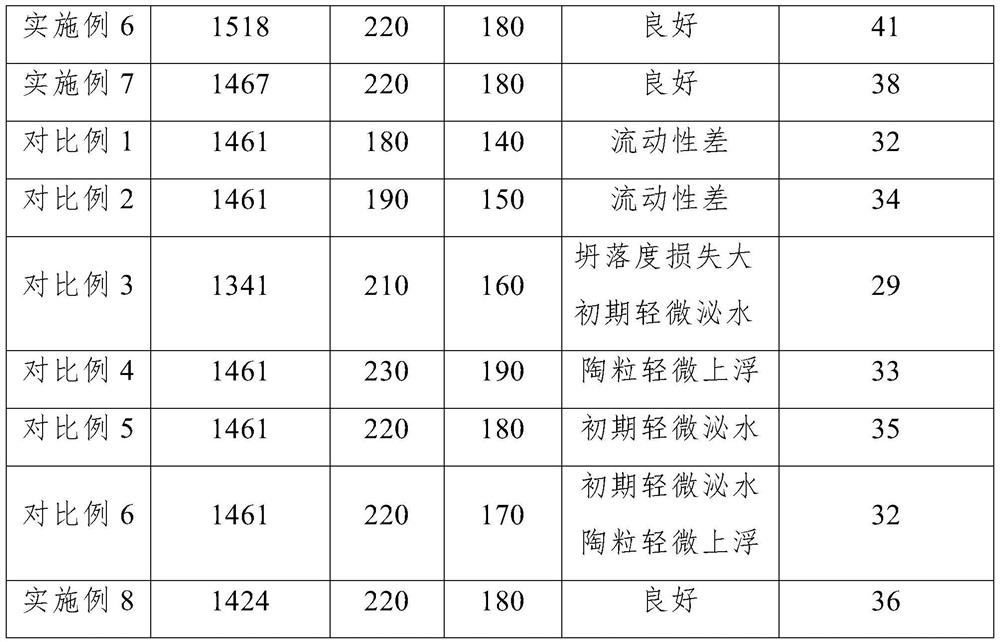

Examples

Embodiment 1

[0029] The ceramsite concrete of the present embodiment is composed of the following components in parts by mass: 340 parts of cement, 130 parts of fly ash, 302 parts of ceramsite, 340 parts of ceramic sand, 90 parts of natural medium sand, and 95 parts of machine-made sand medium sand, 70 parts of natural fine sand, 8.4 parts of water reducing agent, 188 parts of mixing water, 22 parts of additional water, 0.096 parts of water-soluble organic tackifier;

[0030] The ceramsite is a 5mm-20mm continuous gradation of crushed stone type shale ceramsite, and the bulk density of the ceramsite is 560kg / m 3 , the 2h water absorption rate is 9.5%, the cylinder compressive strength is 3.0MPa, the ceramsite has a dense structure and uniform pore distribution; the material of the ceramic sand is the same as that of the ceramsite, and the ceramic sand is medium sand, and the bulk density is 750kg / m2 3 .

[0031] The preparation method of the ceramsite concrete of the present embodiment co...

Embodiment 2

[0035] The ceramsite concrete of the present embodiment is composed of the following components in parts by mass: 350 parts of cement, 126 parts of fly ash, 280 parts of ceramsite, 355 parts of ceramic sand, 98 parts of natural medium sand, 97 parts of machine-made sand medium sand, 77 parts of natural fine sand, 8.8 parts of water reducing agent, 190 parts of mixing water, 22 parts of additional water, 0.103 parts of water-soluble organic tackifier;

[0036] The ceramsite is a 5mm-20mm continuous gradation of crushed stone type shale ceramsite, and the bulk density of the ceramsite is 600kg / m 3 , the 2h water absorption rate is 8.9%, the cylinder compressive strength is 3.3MPa, the ceramsite has a dense structure and uniform pore distribution; the material of the ceramsite is the same as that of the ceramsite, and the ceramsite is medium sand with a bulk density of 820kg / m2 3 .

[0037] The preparation method of the ceramsite concrete of the present embodiment comprises the ...

Embodiment 3

[0041] The ceramsite concrete of the present embodiment is composed of the following components in parts by mass: 345 parts of cement, 123 parts of fly ash, 315 parts of ceramsite, 350 parts of ceramic sand, 93 parts of natural medium sand, 93 parts of machine-made sand medium, 72 parts of natural fine sand, 8.2 parts of water reducing agent, 185 parts of mixing water, 23 parts of additional water, and 0.097 parts of water-soluble organic tackifier;

[0042] The ceramsite is a 5mm-20mm continuous gradation of crushed stone shale ceramsite, and the bulk density of the ceramsite is 610kg / m 3 , the 2h water absorption rate is 9.0%, the cylinder compressive strength is 3.3MPa, the ceramsite has a dense structure and uniform pore distribution; the material of the ceramic sand is the same as that of the ceramsite, and the ceramic sand is medium sand, and the bulk density is 810kg / m2 3 .

[0043] The preparation method of the ceramsite concrete of the present embodiment comprises th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com