Patents

Literature

123results about How to "Suppression of floating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lightweight aggregate concrete for heat preservation of structures

ActiveCN103951350ACompact structureHigh strengthSolid waste managementApparent densityExpanded clay aggregate

The invention relates to lightweight aggregate concrete for heat preservation of structures, and belongs to the technical field of building materials for civilian use. The lightweight aggregate concrete for heat preservation of structures comprises the following raw materials in parts by mass: 360-460 parts of cement-based cementing material, 410-460 parts of ceramsite, 110-120 parts of modified vitrified micro balls, 15-20 parts of concrete modifier, 260-290 parts of water and 3.6-4.6 parts of water reducing agent. The lightweight aggregate concrete for heat preservation of structures with the heat conductivity coefficient of 0.25-0.4W / (m.K) and the dry apparent density of 900-1200kg / m<3> is obtained by using the modified vitrified micro balls and the ceramsite as aggregates under the synergistic effect of the components according to a reasonable component proportion, and after the lightweight aggregate concrete is cured for 28 days, the compressive strength of the lightweight aggregate concrete is 8-15MPa. The lightweight aggregate concrete for heat preservation of structures has good heat preservation performance and relatively high strength. Compared with the strength of a full lightweight concrete material prepared from ceramsite perlite, the strength of the lightweight aggregate concrete is obviously improved; compared with the heat conductivity coefficient of a full lightweight concrete material prepared from ceramsite pottery sand, the heat conductivity coefficient of the lightweight aggregate concrete is obviously reduced; and the lightweight aggregate concrete can be used as a lightweight aggregate concrete material for heat preservation of structures.

Owner:CENT SOUTH UNIV

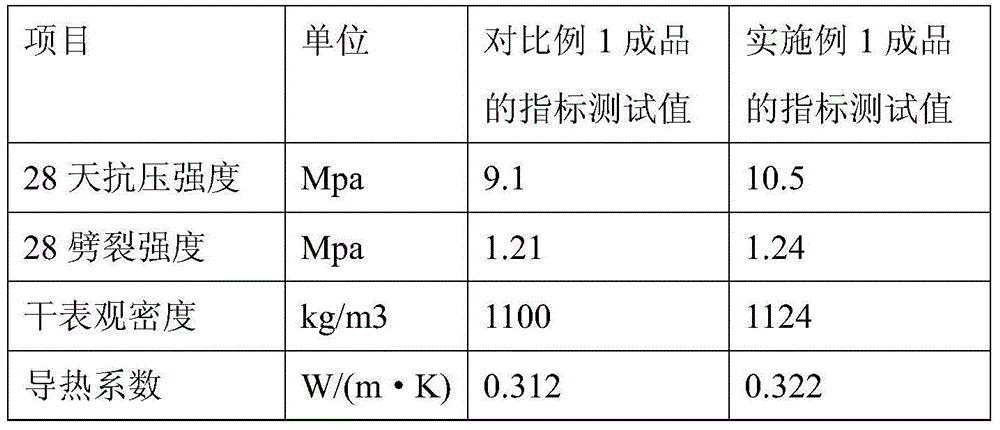

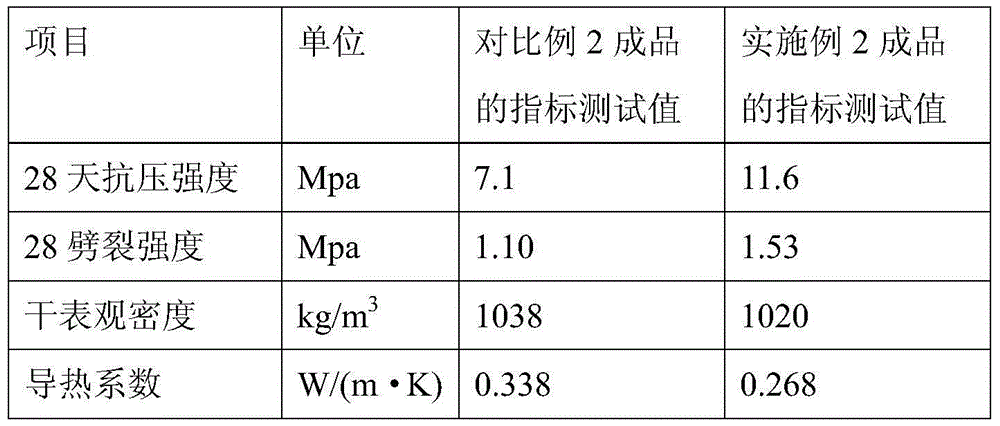

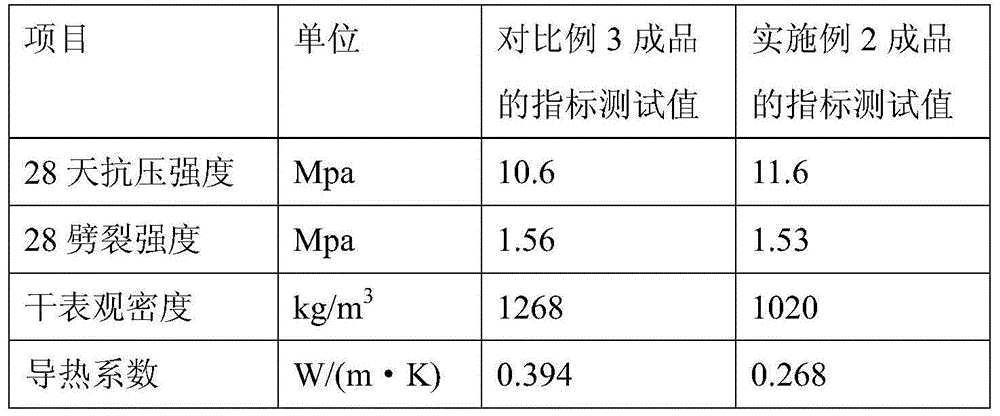

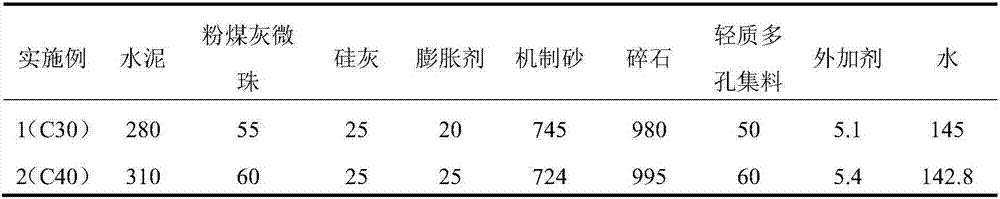

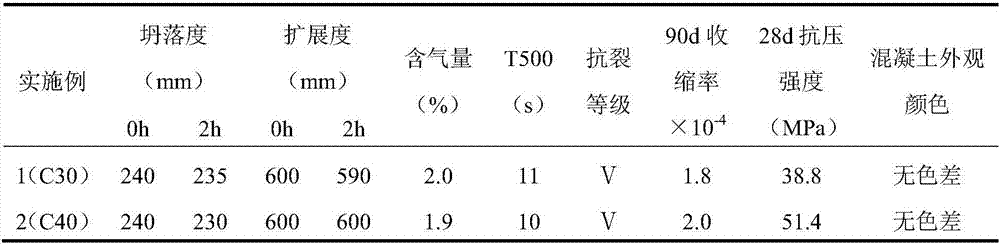

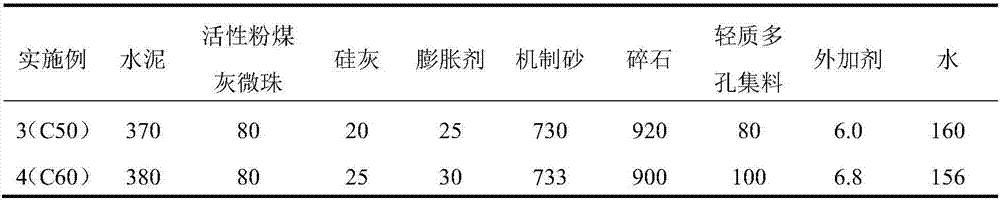

Bridge self-compaction anti-crack bare concrete prepared by utilizing high fine powder content machine-made sand

The invention discloses a bridge self-compaction anti-crack bare concrete prepared by utilizing high fine powder content machine-made sand. The bridge self-compaction anti-crack bare concrete is prepared from cement, activated fly ash microbeads, silica fume, an expanding agent, machine-made sand, gravel, a light-weight porous aggregate, a high-performance additive and water. The bridge self-compaction anti-crack bare concrete provided by the invention adopts the high fine powder content machine-made sand to replace common natural river sand, utilizes the activated fly ash microbeads and the silica fume for adjusting the viscosity and the fluidity of the concrete so as to improve the homogeneity of a concrete slurry, and further additive is used for reducing the gas content of the concrete, so that a working performance and a fluidity keeping performance of the concrete are improved; meanwhile, the expanding agent and the light-weight porous aggregate are combined, so that the volume stability and an anti-early-age cracking behavior of the bare concrete can be effectively improved. The self-compaction anti-crack bare concrete obtained through the invention has wide adaptability on different fine powder content machine-made sand, excellent working performance, mechanical property, volume stability performance and anti-cracking ability, uniform appearance and color, and better mirror surface effect.

Owner:WUHAN UNIV OF TECH +2

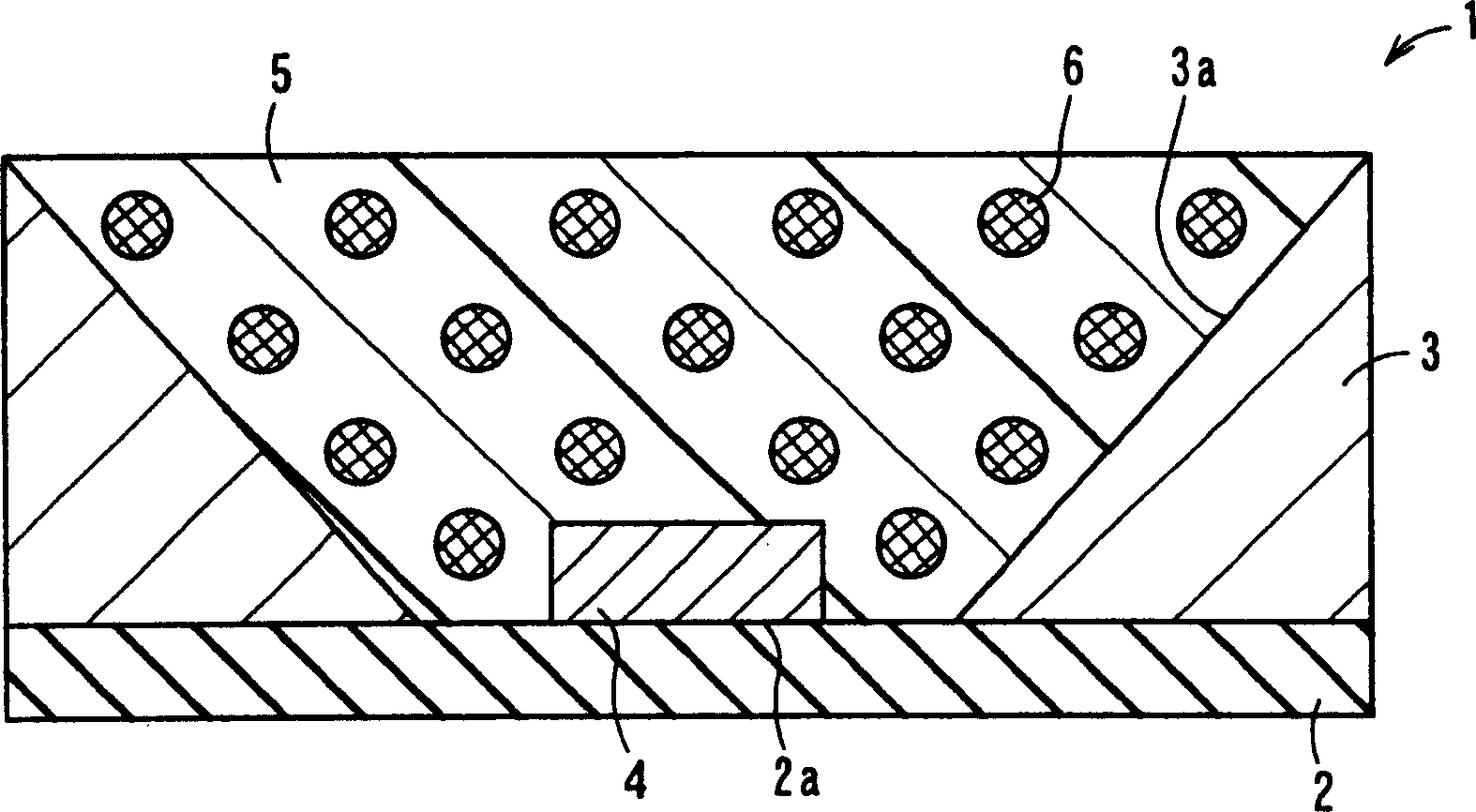

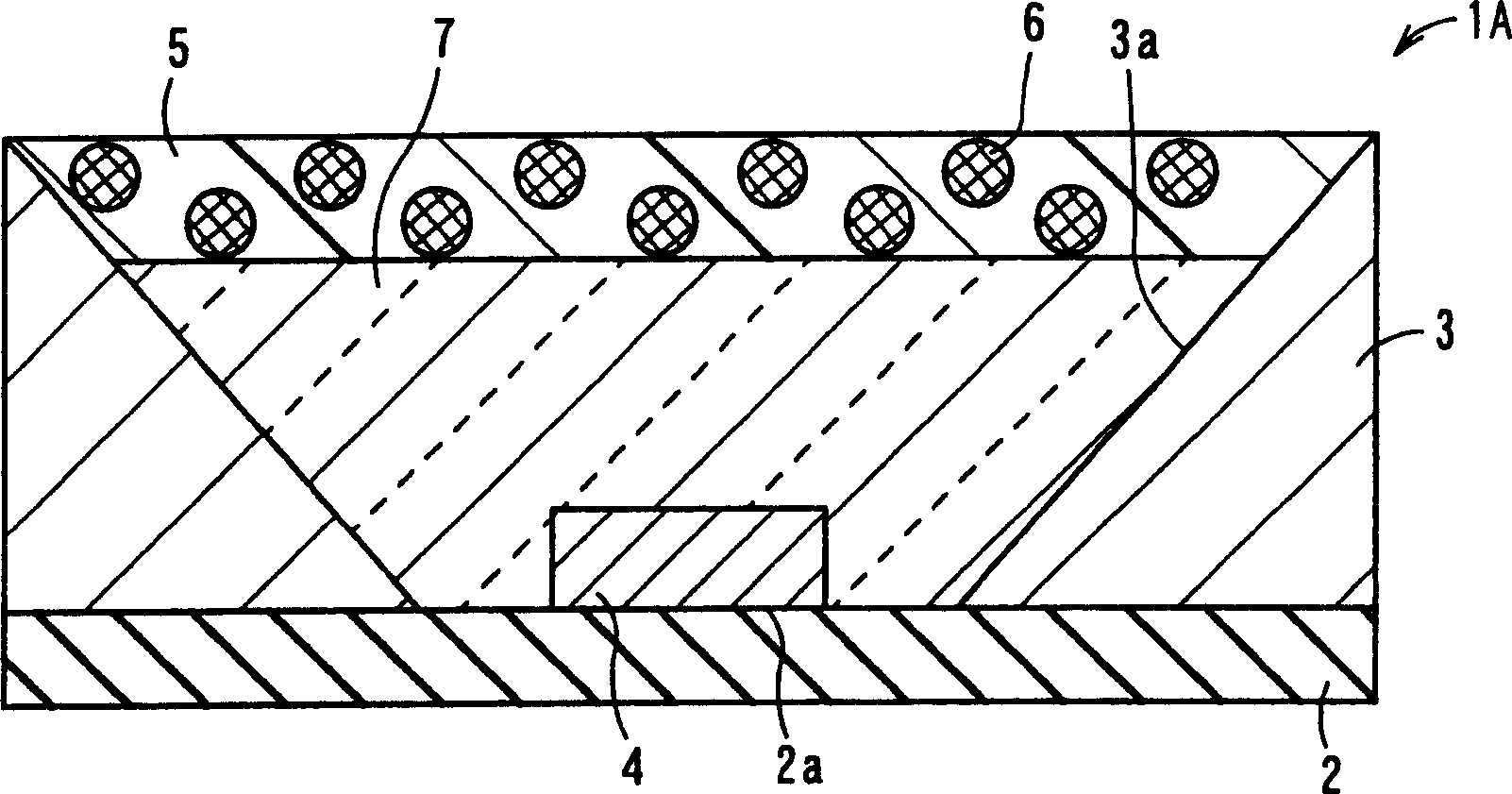

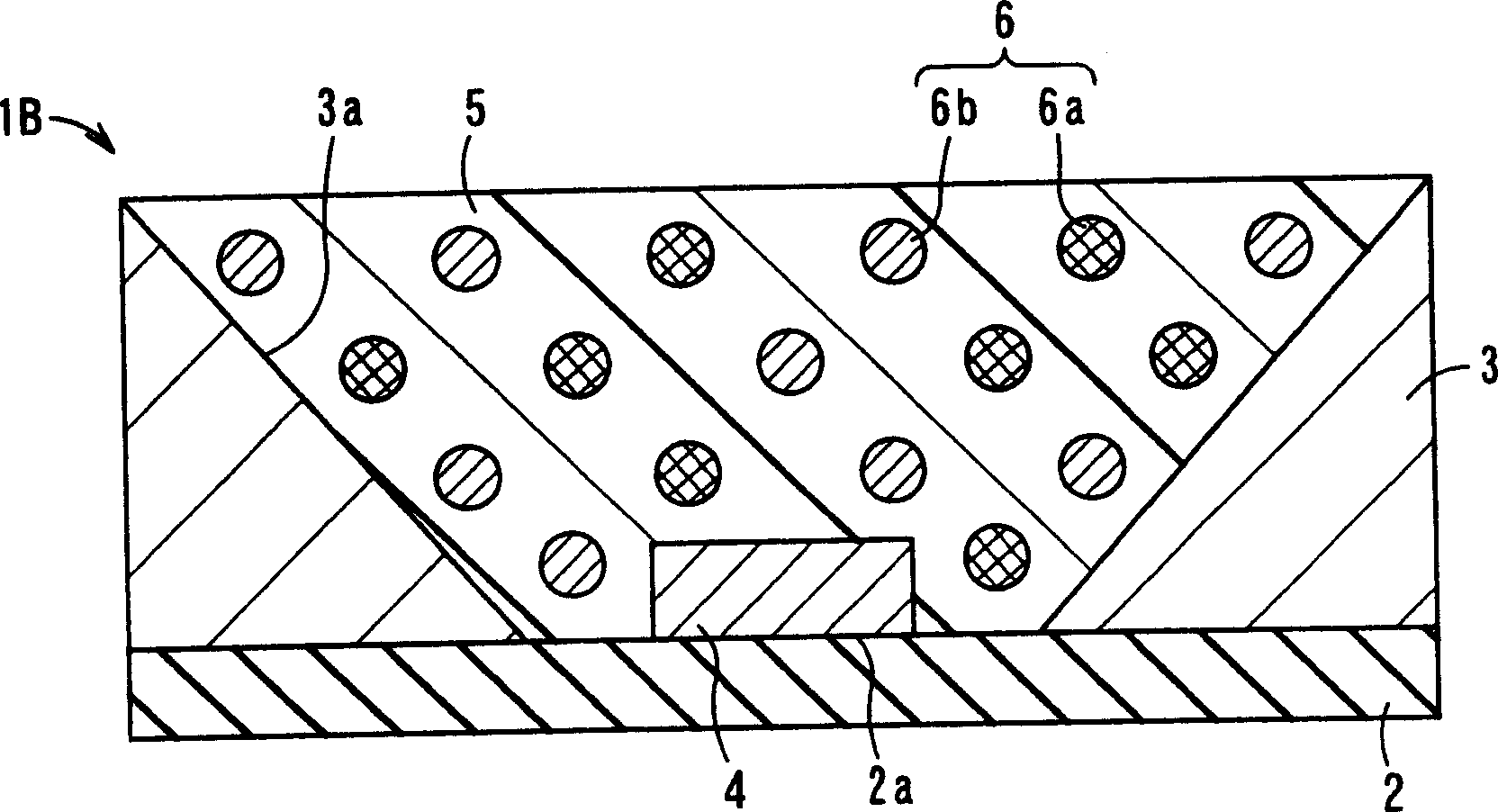

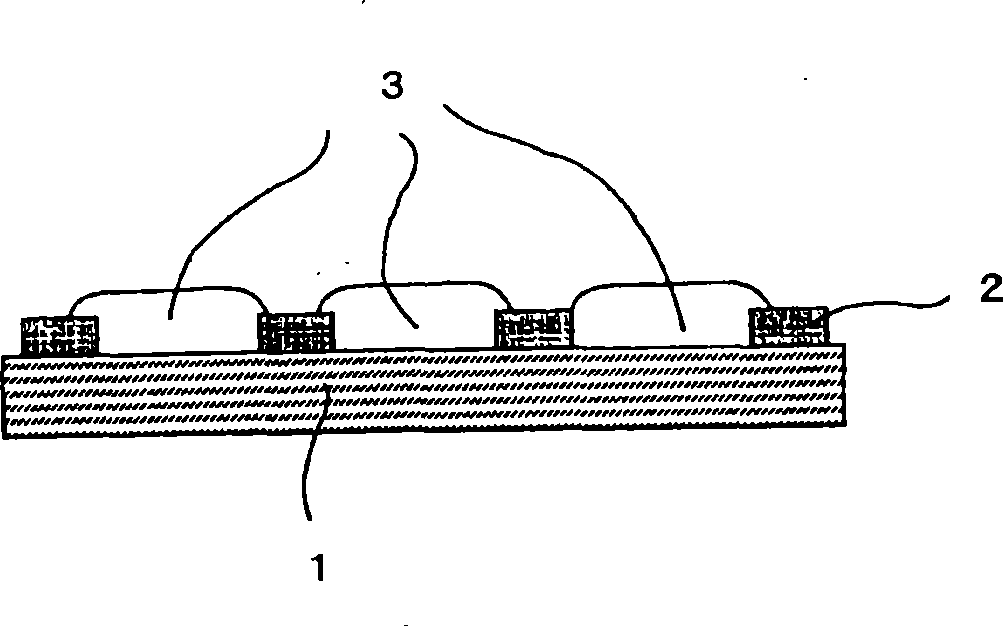

Light-emitting apparatus and illuminating apparatus

InactiveCN1674317AIncrease the intensity of radiant lightReduced light extraction efficiencyOther plywood/veneer working apparatusMechanical surface treatmentPhosphorLight emitting device

There is provided a light-emitting apparatus with favorable radiation light intensity, which is excellent in light extraction efficiency, color temperature and color rendering property. The light-emitting apparatus includes a light-emitting element, a base body having, on its top surface, a placement portion for emplacing thereon the light-emitting element, a frame body attached to the top surface of the base body so as to surround the placement portion, a light transmitting member disposed inside the frame body so as to cover the light-emitting element, and phosphors contained in the light transmitting member, which performs wavelength conversion on the light emitted from the light-emitting element. The light transmitting member has a pre-cured viscosity ranging from 0.4 to 50 Pa.s.

Owner:KYOCERA CORP

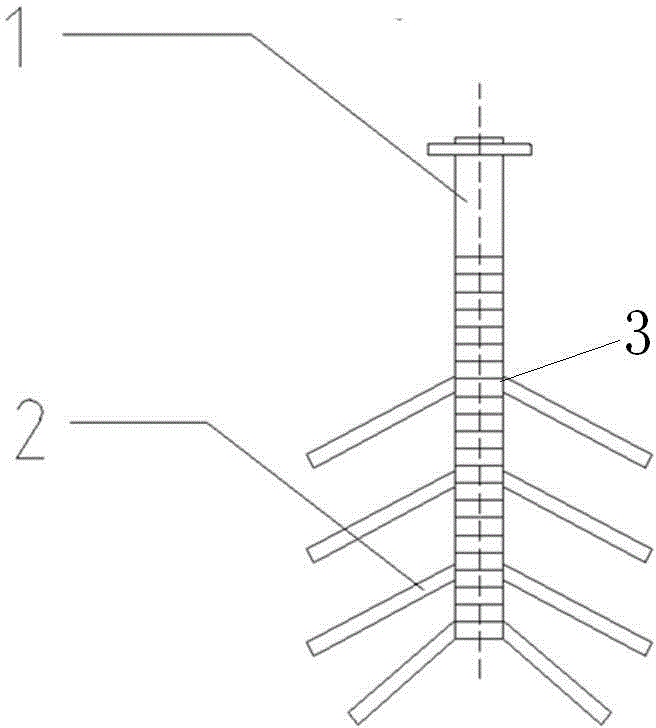

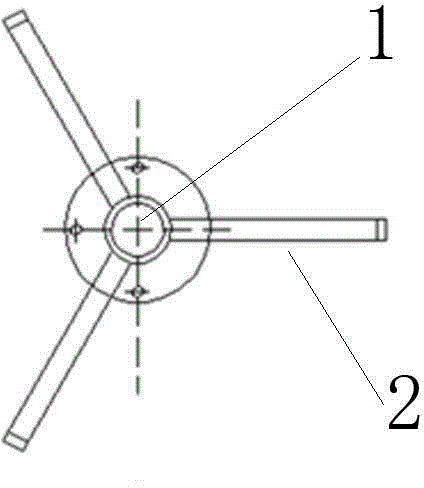

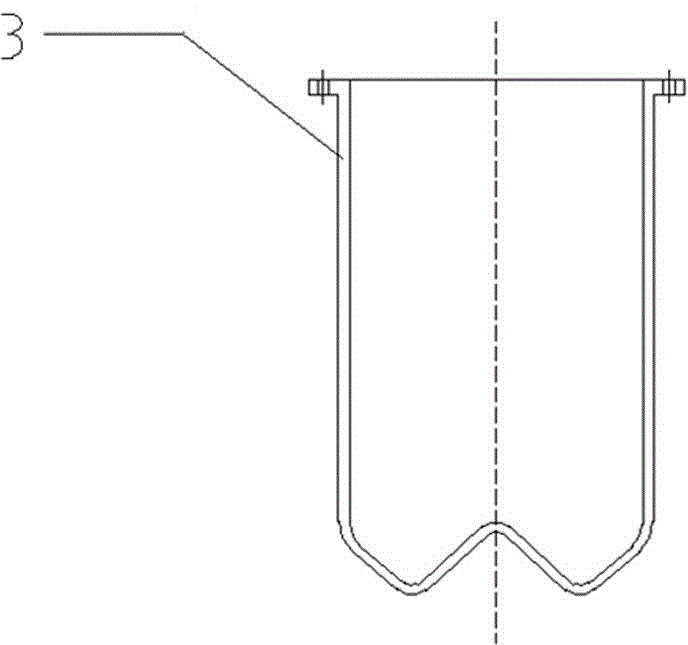

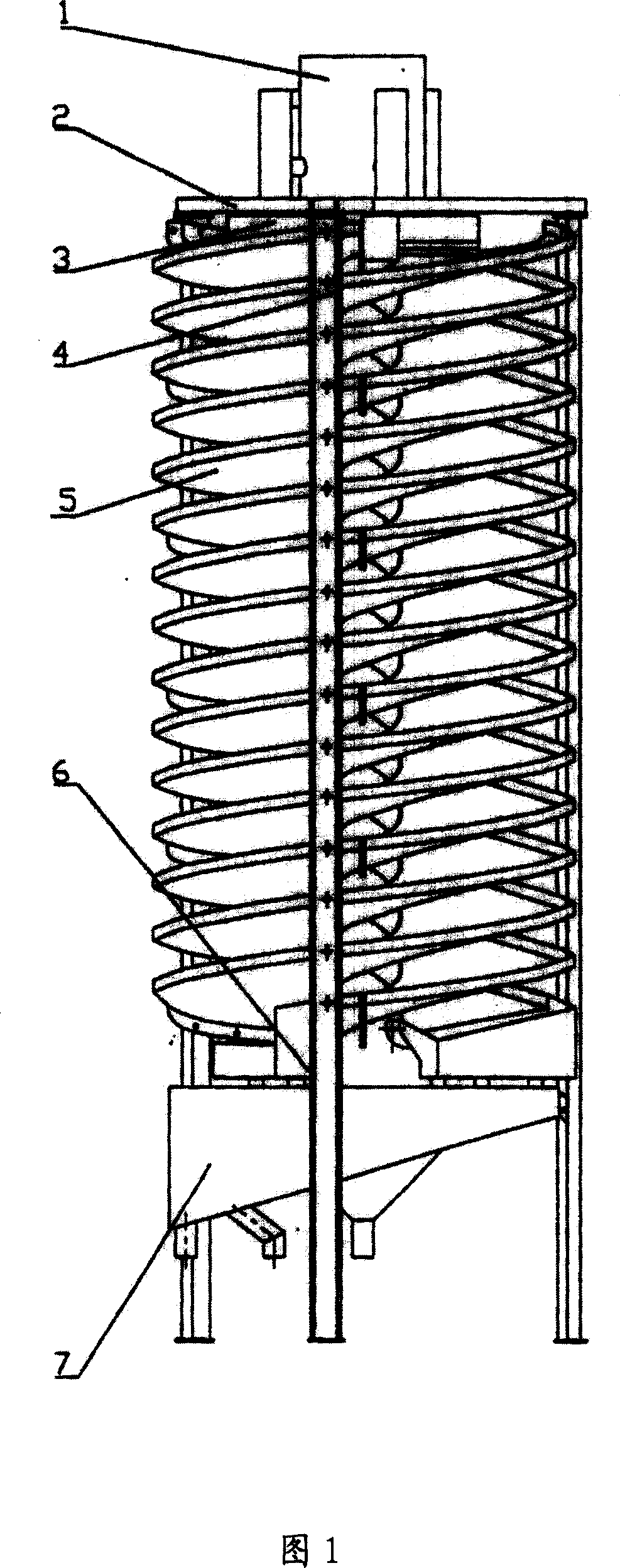

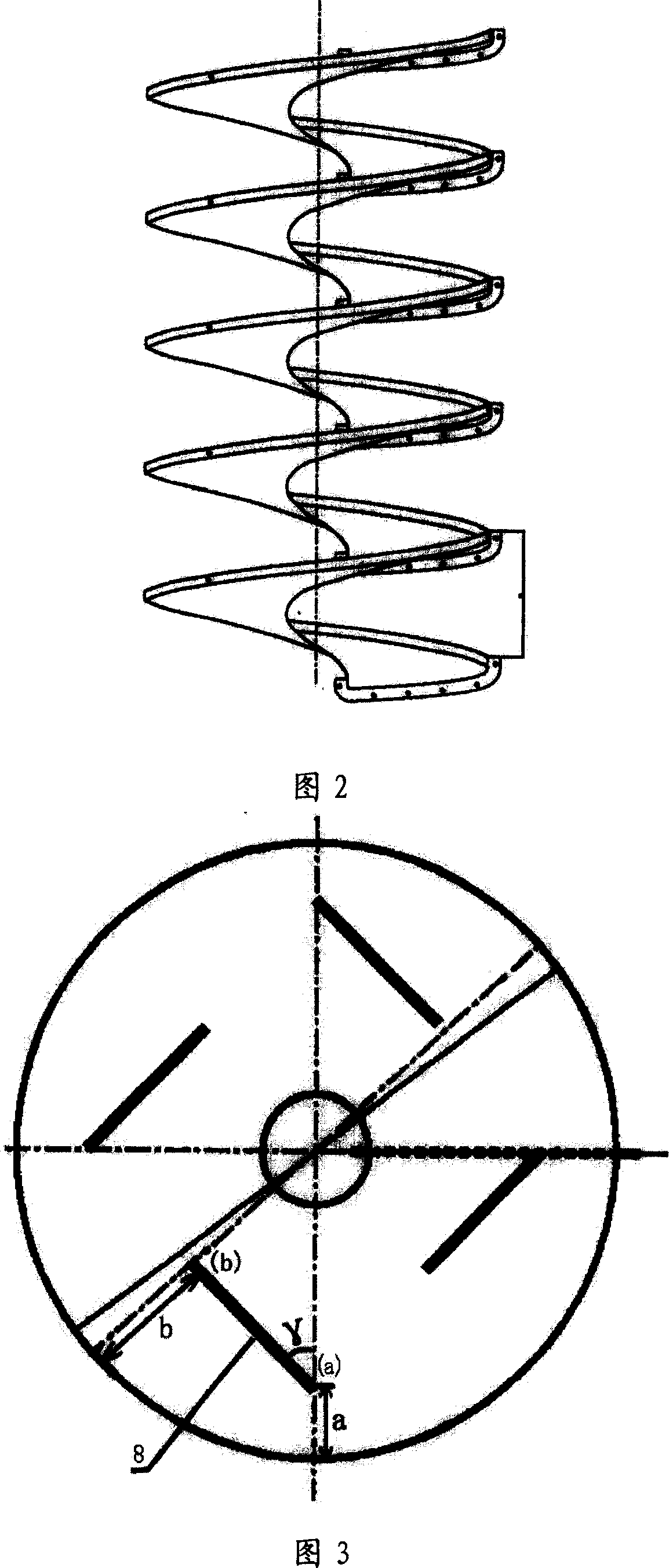

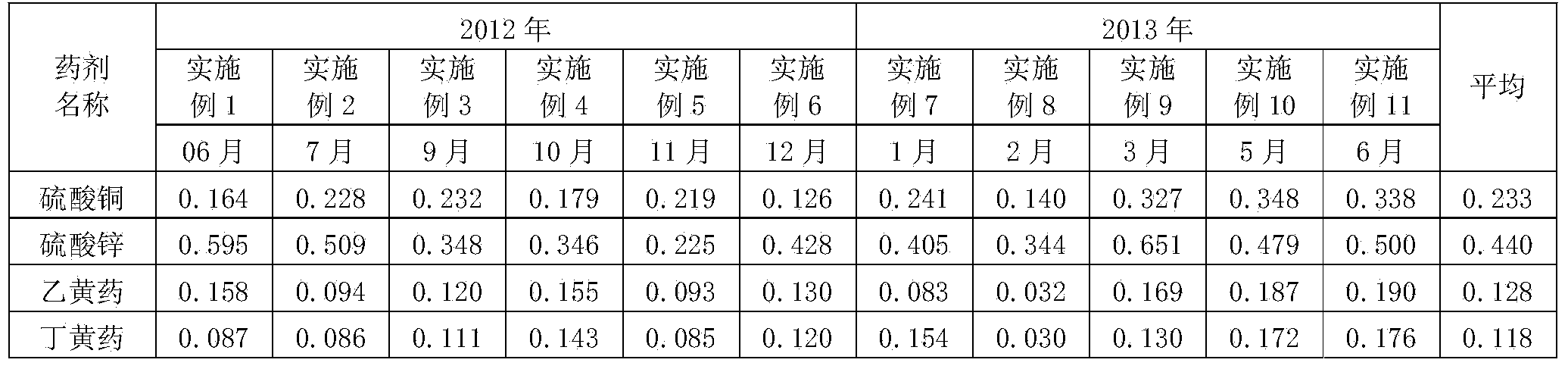

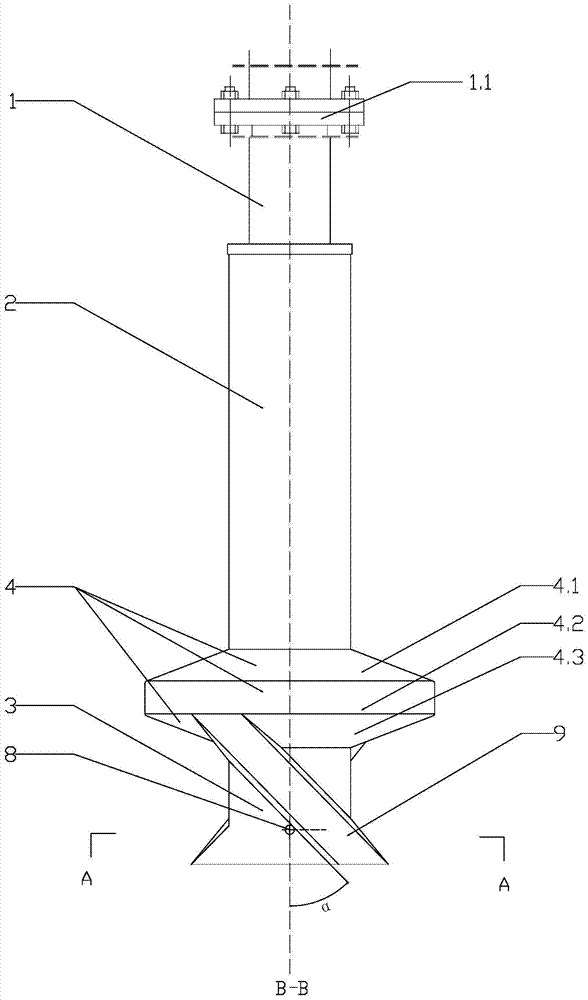

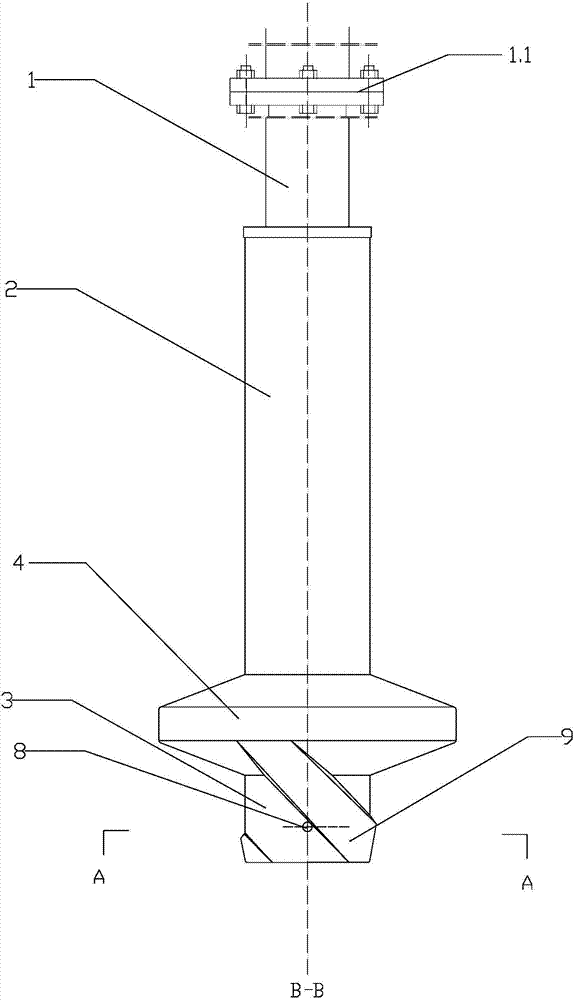

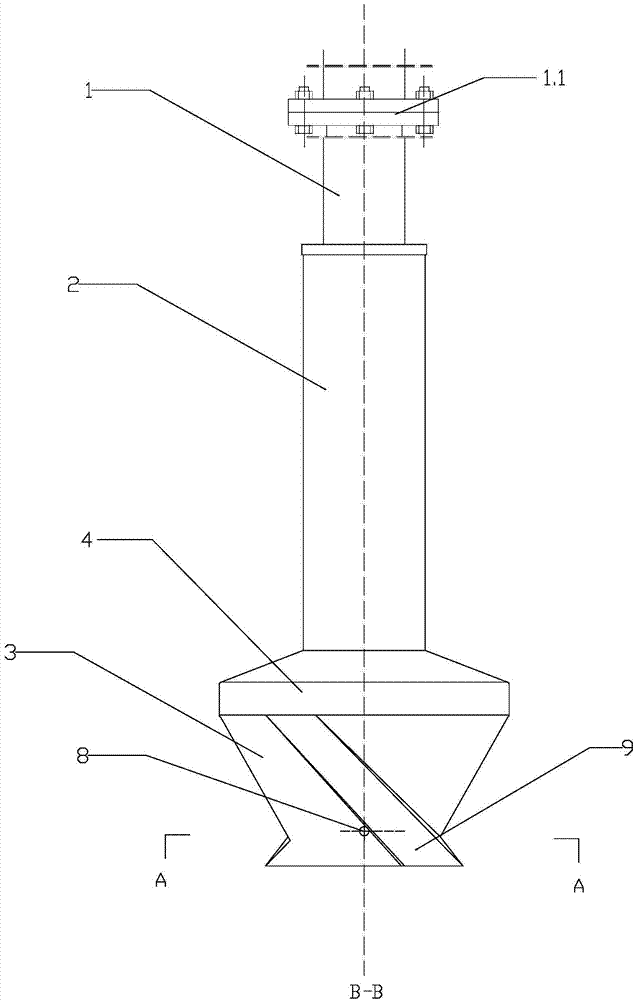

Tackifying and foaming stirring device for preparing foamed aluminum

ActiveCN104607079ASuppression of floatingStir wellRotary stirring mixersMixer accessoriesPolymer scienceAluminum can

The invention discloses a tackifying and foaming stirring device for preparing foamed aluminum, relates to a stirring device, and solves the problem that the high-quality foamed aluminum cannot be prepared by adopting the existing forming device. The tackifying and foaming stirring device for preparing the foamed aluminum comprises a cylindrical stirring furnace body, wherein a heating device is fixed outside the furnace body, a stirring paddle is arranged inside the furnace body, and the stirring paddle is installed on a furnace cover; the stirring paddle is in a four-layer folded-blade paddle form, four layers of paddle blades are arranged on a central shaft of the stirring paddle, each layer is provided with three paddle blades, the paddle blades at each layer are arranged to stagger each other for 120 degrees, a dip angle of the paddle blades at the lowermost layer is smaller than that of the paddle blades at the upper three layers, and the upper part of the central shaft is fixed on the furnace cover through a fixing disc and the central shaft driven by a motor to rotate. The tackifying and foaming stirring device is simple in structure, ingenious in design, capable of uniformly and rapidly stirring metal liquid by virtue of the four-layer paddle blades and good in foaming effect.

Owner:广东磐龙交通环境设施工程有限公司

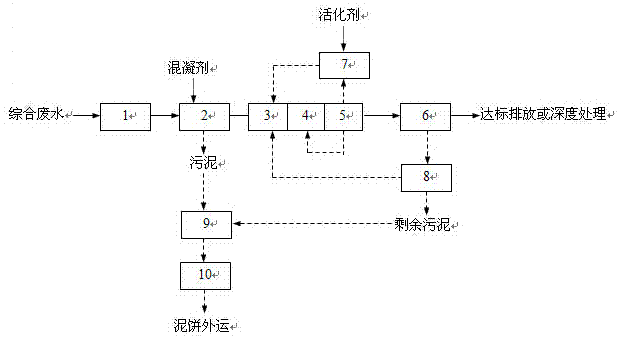

Hypoxia-aerobic comprehensive treatment method for tannery waste water

ActiveCN104710087AReduce processing loadImprove settlement performanceWaste water treatment from animal processingMultistage water/sewage treatmentChemistryTreatment effect

The invention provides a hypoxia-aerobic comprehensive treatment method for tannery waste water. The hypoxia-aerobic comprehensive treatment method for the tannery waste water comprises the following steps: (1), performing classification pretreatment on waste water in a tannery production process, and fully mixing the pretreated water; (2), performing coagulating precipitation treatment on mixed waste water; (3), importing precipitated supernate into a hypoxia-aerobic pool to generate nitrification and denitrification reactions; (4), imputing the waste water treated in the hypoxia-aerobic pool into a secondary precipitation tank to perform a precipitation treatment, directly discharging precipitated supernate or performing an advanced treatment according to standard requests, enabling the precipitated sludge to backflow to the hypoxia-aerobic pool; and (5), conveying the sludge in a coagulating precipitation pool and the residual sludge in the secondary precipitation tank to a sludge concentration pool, dewatering by utilizing a sludge dewatering machine to form filter cakes, and conveying the filter cakes outside. According to the hypoxia-aerobic comprehensive treatment method for the tannery waste water, the quality and the quantity of water entering a subsequent treatment unit can be fully balanced, the treatment load of a biochemical system is effectively reduced, the settling property of the sludge is improved, the nitrification and denitrification efficiencies of the system are quickly improved, the sludge loss is prevented, the treatment effect is stabilized, and the quality of supernate effluent is ensured.

Owner:SHANDONG ACAD OF ENVIRONMENTAL SCI CO LTD

Comprehensive recovery method for tungsten accompanying fluorite resources

The invention discloses a comprehensive recovery method for tungsten accompanying fluorite resources. The method comprises the steps that tungsten accompanying fluorite ore is broken and ground and then is subjected to magnetic separation deferrization and flotation desulfuration; the desulfured tailings are subjected to flotation separation I through a combined inhibitor composed of sodium silicate, bake glue and gallotannic acid and a collecting agent fatty acid to obtain tungsten and fluorite bulk concentrate; the bulk concentrate is subjected to flotation separation II through an inhibitor amino phosphonate after being subjected to acid decalcification treatment, the foam product is fluorite concentrate, and the tailings product is tungsten concentrate. By means of the method, the comprehensive recovery rate of tungsten and fluorite resources is greatly improved, the flow is short, the medicament is simple, operation is convenient, the labor intensity is low, energy consumption is low, environmental protection and high efficiency are achieved, and the ore dressing cost is greatly reduced.

Owner:CENT SOUTH UNIV

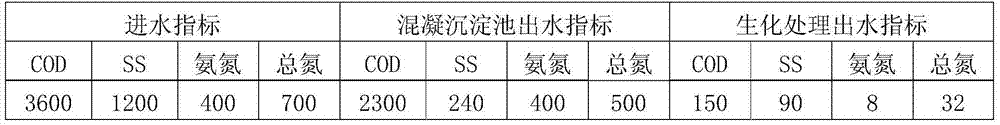

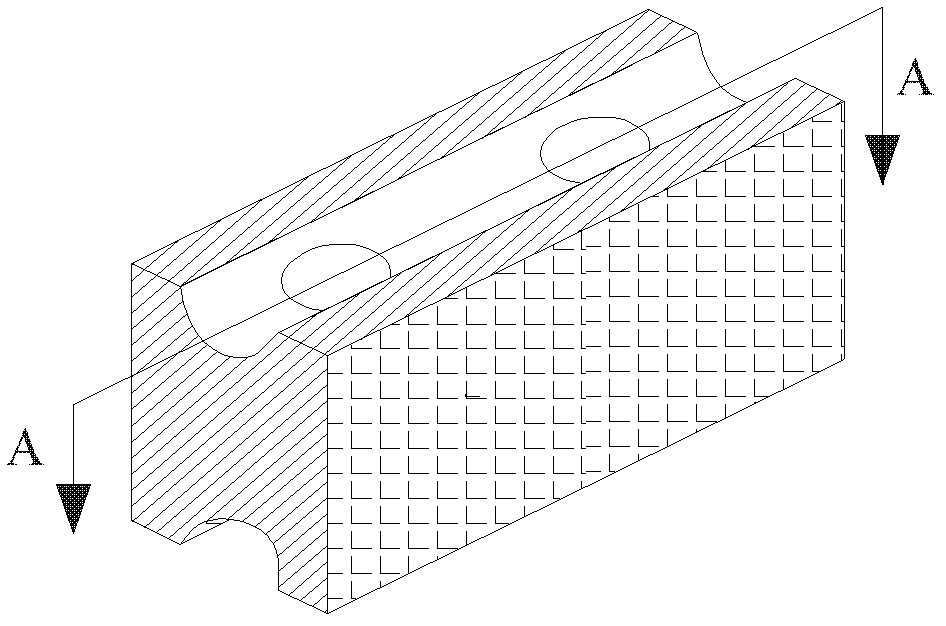

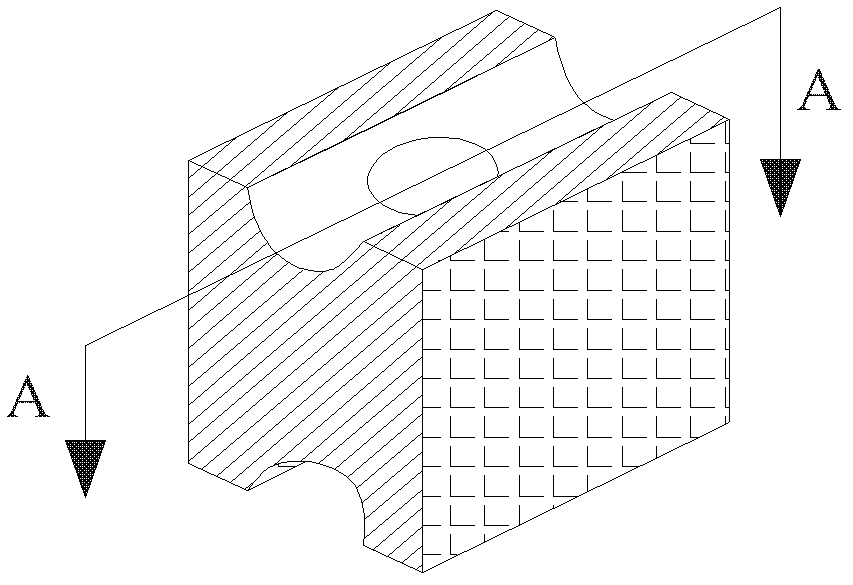

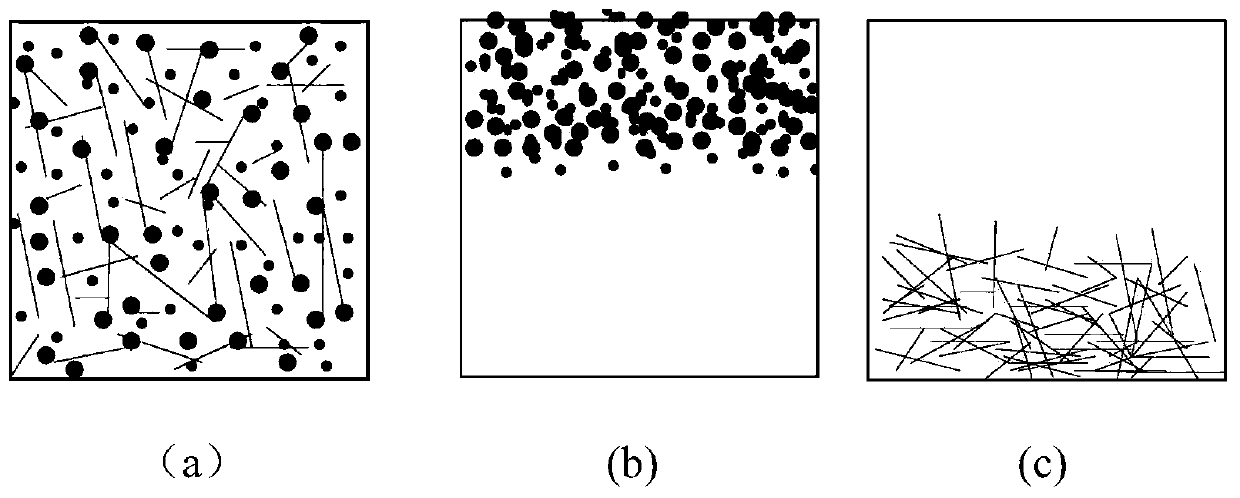

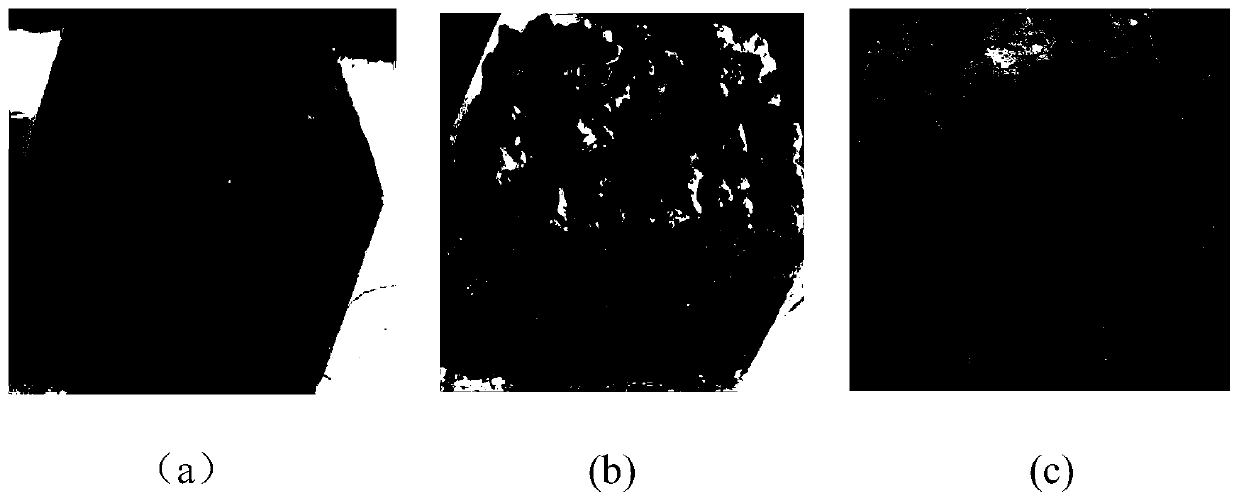

Full-lightweight ceramsite concrete and preparation method thereof

The invention relates to full-lightweight ceramsite concrete and a preparation method thereof. The full-lightweight ceramsite concrete is prepared from, by weight, 278-339 parts of cement, 318-344 parts of ceramsite, 334-382 parts of pottery sand, 50-55 parts of coal ash, 35-42 parts of silica fume, 0.001-3 parts of triisopropanolamine, 0.5-3 parts of a water reducing agent and 0.001-3 parts of athickening agent. The method includes steps: subjecting ceramsite and pottery sand to surface pretreatment through alkyl alkoxy silane, prewetting ceramsite and pottery sand to achieve a saturated surface dry state, then sequentially feeding lightweight aggregates, cement, silica fume and coal ash into a forced mixer, and well mixing to obtain the full-lightweight ceramsite concrete. The full-lightweight ceramsite concrete prepared according to the method has advantages of light weight, high peaceability and effectiveness in inhibition of ceramsite floating and has a promising application prospect in the field of energy-saving construction engineering.

Owner:CHINA THREE GORGES UNIV

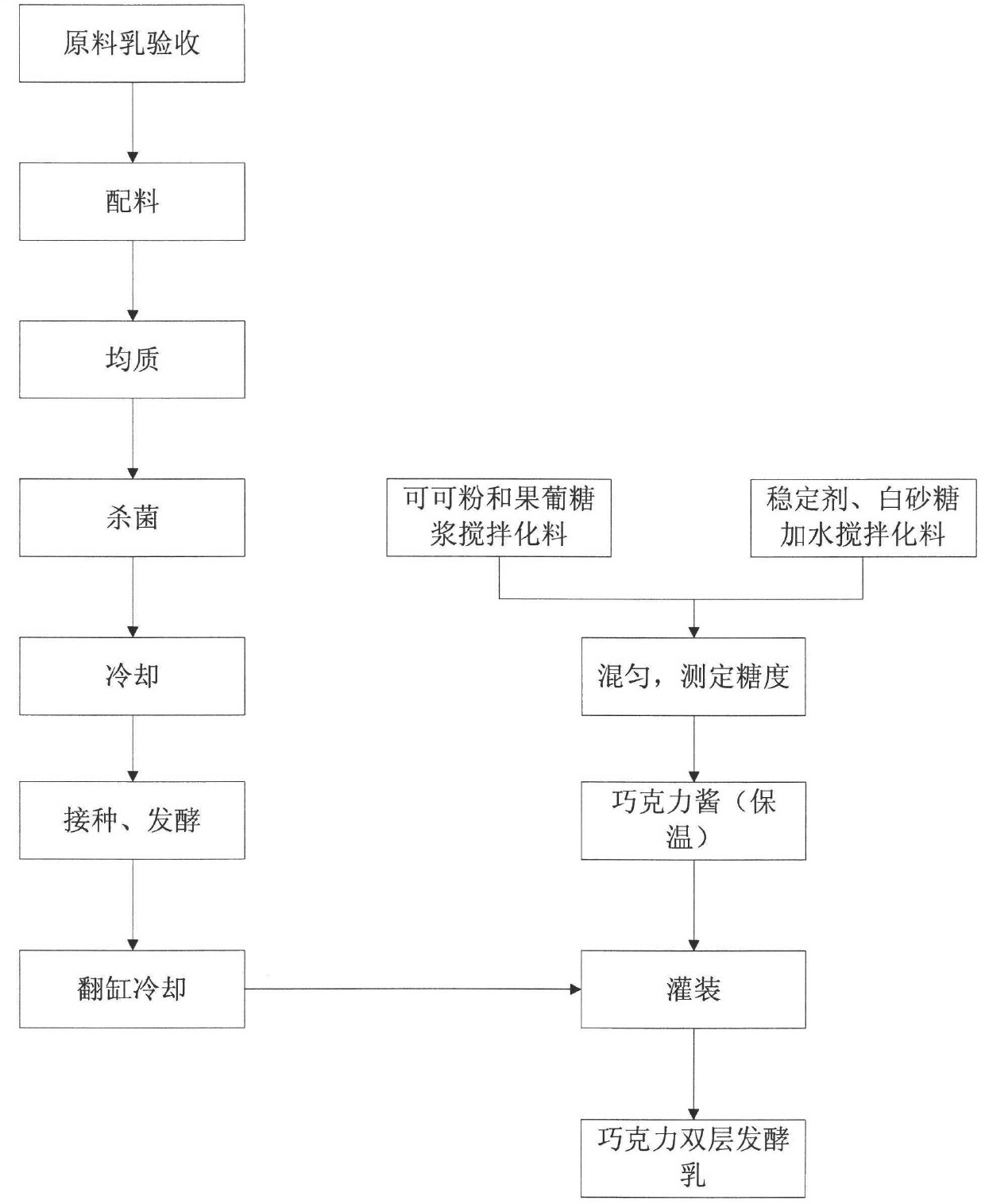

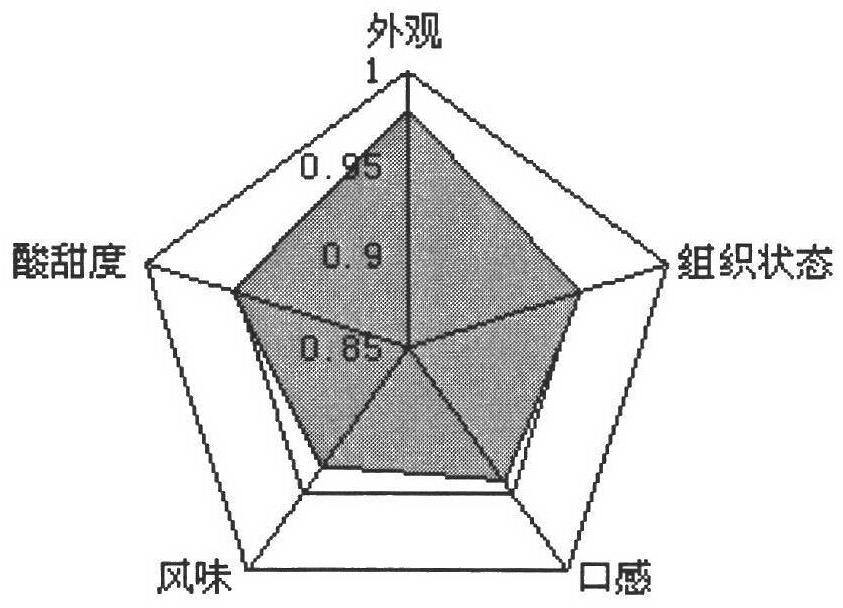

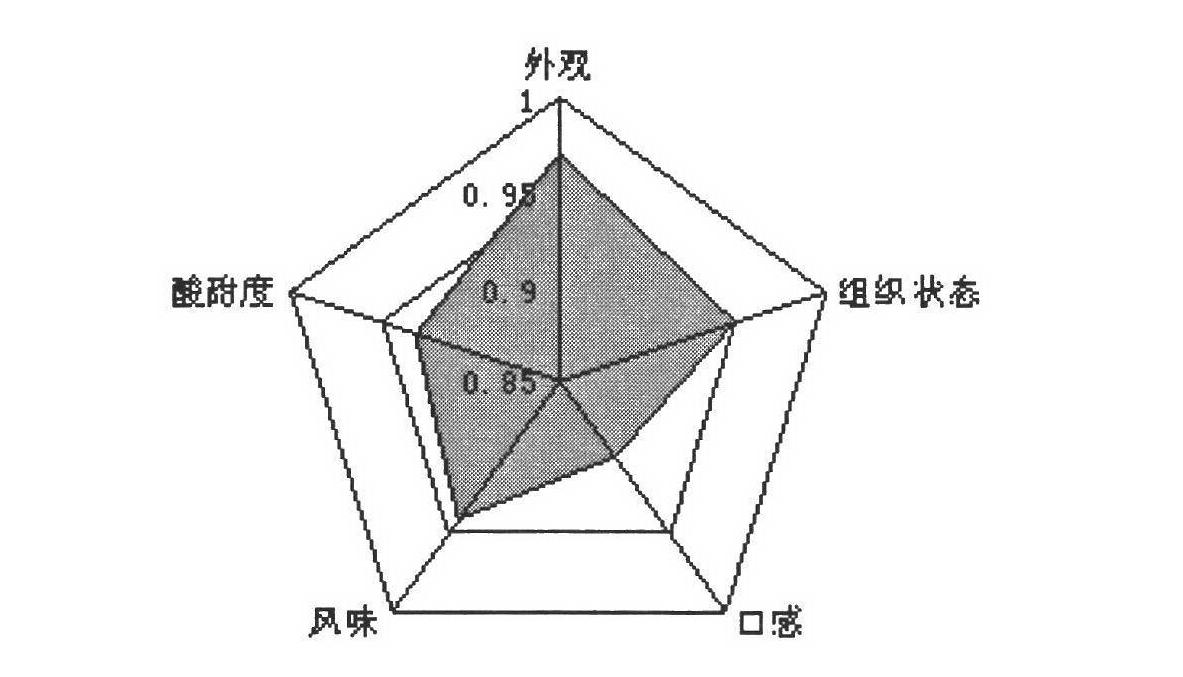

Chocolate sauce, stabilizer, double-layer chocolate fermented milk, formula and preparation method

ActiveCN102630863AImprove gel performanceIncrease elasticityMilk preparationCocoaCocoa PowdersFlavor

The invention discloses a chocolate sauce stabilizer which contains carrageenan, sodium carboxymethylcellulose, sodium citrate, potassium chloride and glucose. A formula of chocolate sauce contains fructose corn syrup, cocoa powder, sugar, the stabilizer and deionized water. A preparation method for the chocolate sauce comprises the following step of: mixing glycine liquor and cocoa syrup uniformly to obtain the chocolate sauce. A formula of double-layer chocolate fermented milk contains fermented milk and the chocolate sauce. A preparation method for the double-layer chocolate fermented milkcomprises the following steps of: (1) covering the chocolate sauce of more than or equal to 65 DEG C on the lower layer of a container, and cooling the temperature to be below 45 DEG C; and (2) adding the fermented milk into the container in the step (1) to cover the chocolate sauce. According to the chocolate sauce and the double-layer chocolate fermented milk obtained by the preparation methods, the double-layer chocolate fermented milk is clear in layering of the chocolate sauce and the fermented milk and has the advantages of stable structure, smooth mouthfeel and thick flavor.

Owner:BRIGHT DAIRY & FOOD

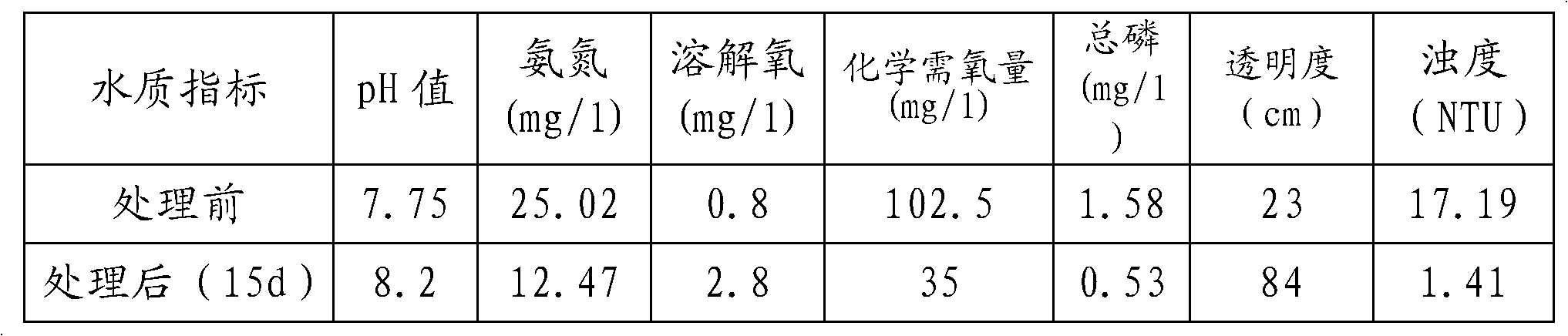

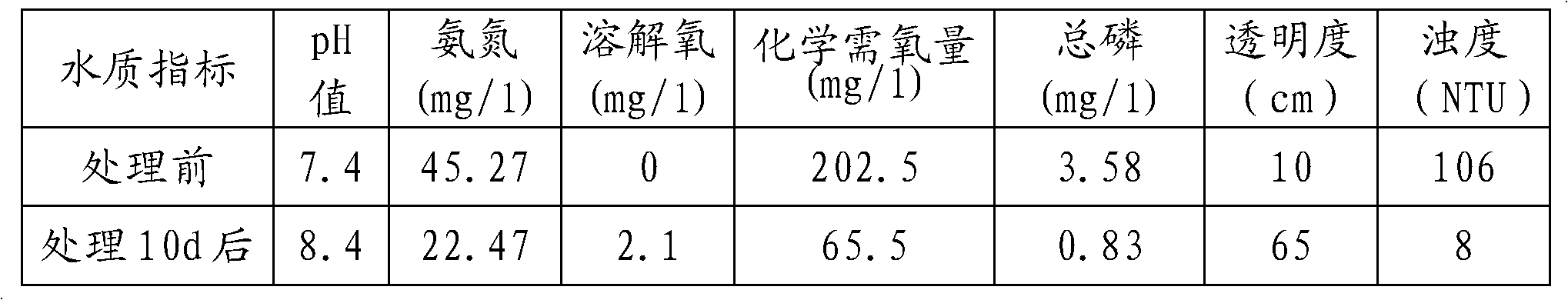

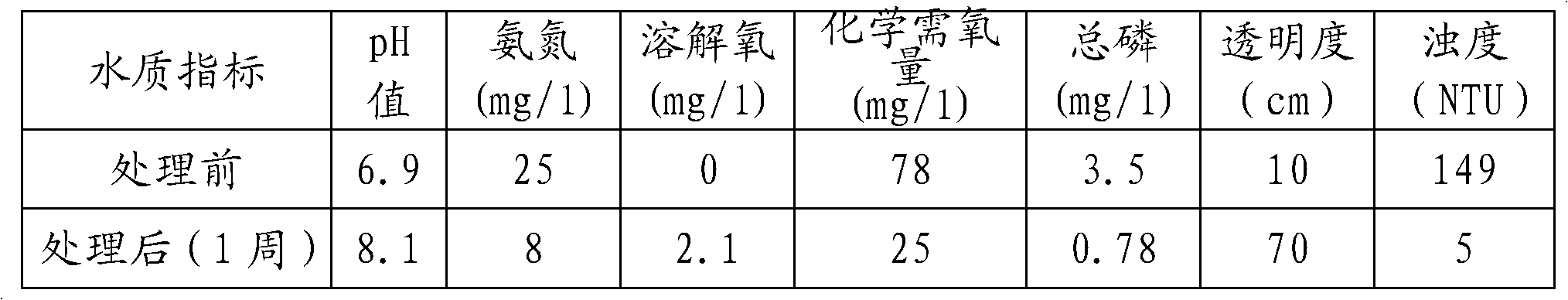

Method for treating water quality of black-odor river channel

InactiveCN102583881AEfficient removalSuppression of floatingMultistage water/sewage treatmentOxygenFlood control

A method for treating water quality of a black-odor river channel comprises the following steps, (1) determining river-water oxygen-dissolving amount X mg / L; (2) placing a bottom material scavenging agent mg / L in the river channel; (3) spraying a photosynthetic bacterium environment scavenging agent in the river channel; and (4) placing polyaluminium chloride and microbial flocculant in the river channel. The bottom material scavenging agent is a mixture of calcium peroxide and oxalic acid. The method for treating the water quality of the black-odor river channel is simple, can effectively restrain upward floating of bottom mud of the river channel, eliminates odor, effectively removes COD, NH3-N and total phosphorus in the river and greatly improves transparency of the river water. Besides, flood control and navigation of the river channel are not influenced, emergency preparation time is little, and chemicals take effect in 1-2 days after applied.

Owner:GUANGDONG ZHONGDA ENVIRONMENTAL PROTECTION TECH INVESTMENT

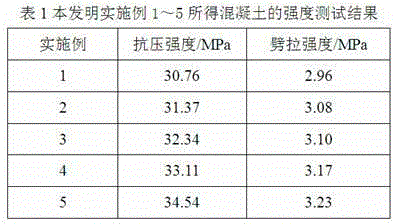

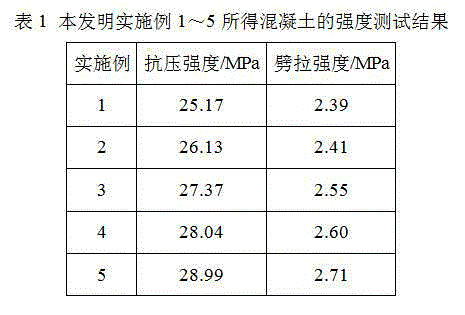

Waste sintered brick recycled C30 concrete and preparation method thereof

ActiveCN104529333AImprove uniformityImprove quality and tightnessSolid waste managementCompressive resistanceBrick

The invention relates to waste sintered brick recycled C30 concrete and a preparation method thereof. The waste sintered brick recycled C30 concrete is prepared from cement, a waste sintered brick recycled coarse aggregate, a fine aggregate, water and a water reducing agent at a weight ratio of 1 to (1.679-1.737) to (0.653-0.817) to (0.367-0.397) to (0.006-0.01). The C30 concrete prepared by the method disclosed by the invention is qualified and stable in strength, high in compressive strength and split and tensile strength, good in working performances such as workability, fluidity and water retention property, simple and environmentally friendly in preparation process and easy to implement.

Owner:ZHENGZHOU UNIV

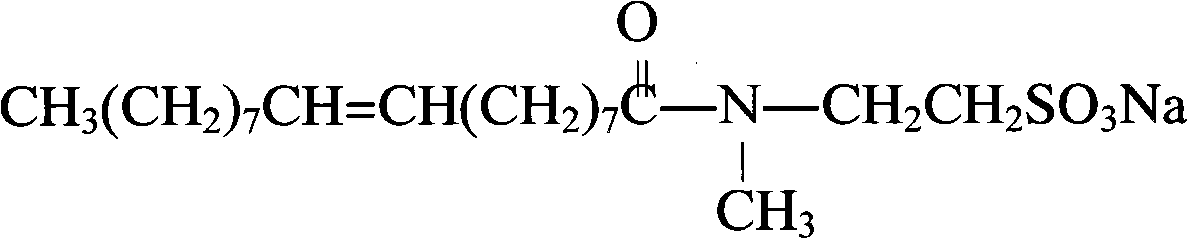

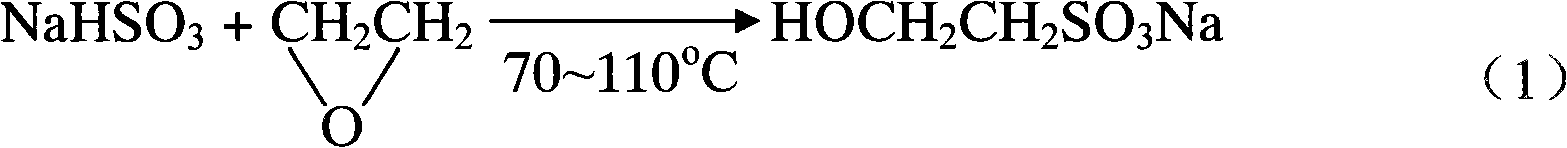

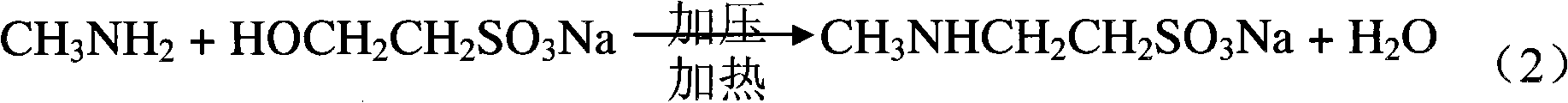

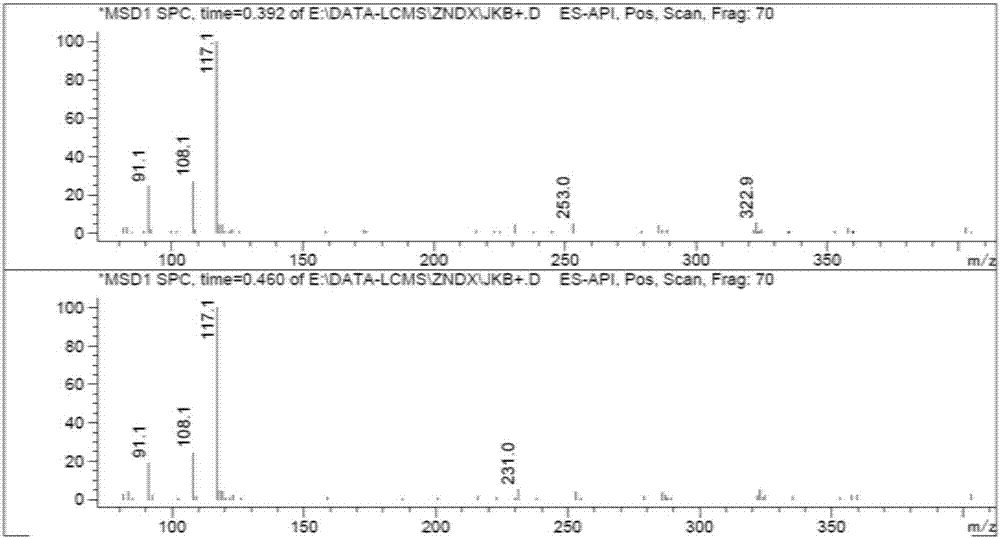

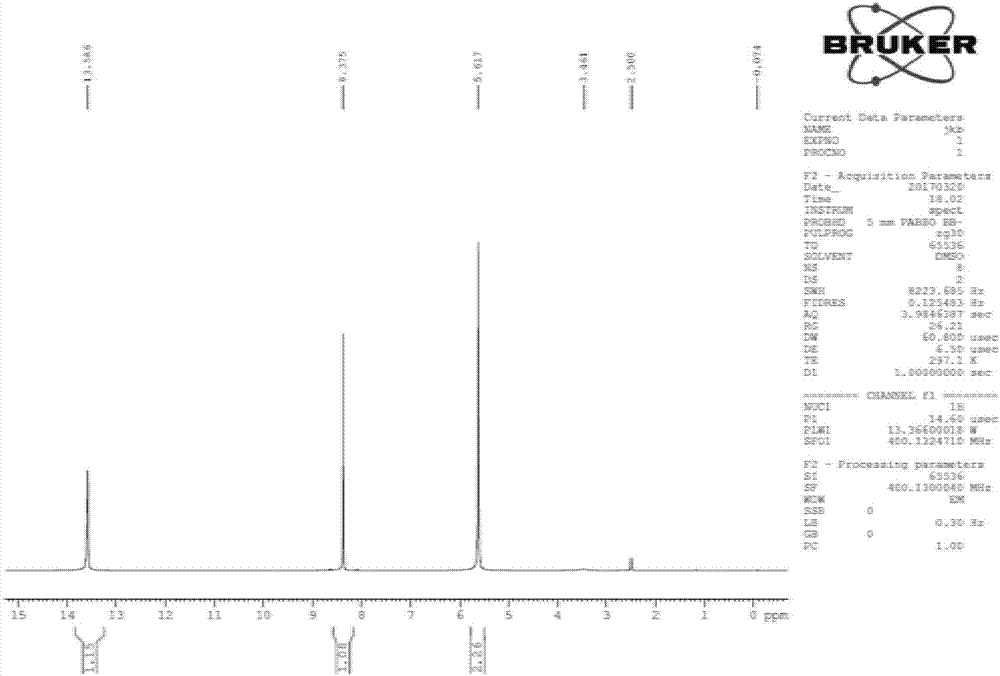

Novel mica inhibitor and preparation method and use method thereof

ActiveCN101850305ASuppression of floatingReduce loss rateSulfonic acids salts preparationFlotationSulfonateLoss rate

The invention discloses a novel mica inhibitor and a preparation method and a use method thereof. The mica inhibitor is N-methyl-9-heptadecenoic amidoethyl sodium sulfonate. The use method is as follows: (1) mica inhibitor N-methyl fatty amido acetate is prepared into aqueous solution with 5 to 10 percent of weight concentration; (2) mica ore is crushed or ground into 0.1mm to 2mm; (3) each ton of ore is added with 100g to 500g of mica inhibitor and 100g to 800g of carboxylic acid collector and uniformly mixed for 5 to 10 minutes, and deferrization operation is carried out before mica floatation. In the deferrization operation before mica floatation, the mica inhibitor is added to inhibit mica from floating up, so that the loss rate of mica is reduced. The mica recovery efficiency is increased. The mica inhibitor solves the problem that the loss rate of mica is high in the deferrization operation of floatation before mica floatation operation, the ferric mineral adsorbed on the surface of mica can be separated from the surface of mica, and during the floatation of ferric mineral, less mica is mechanically entrapped to float up.

Owner:XINJIANG RES INST OF NON FERROUS METALS

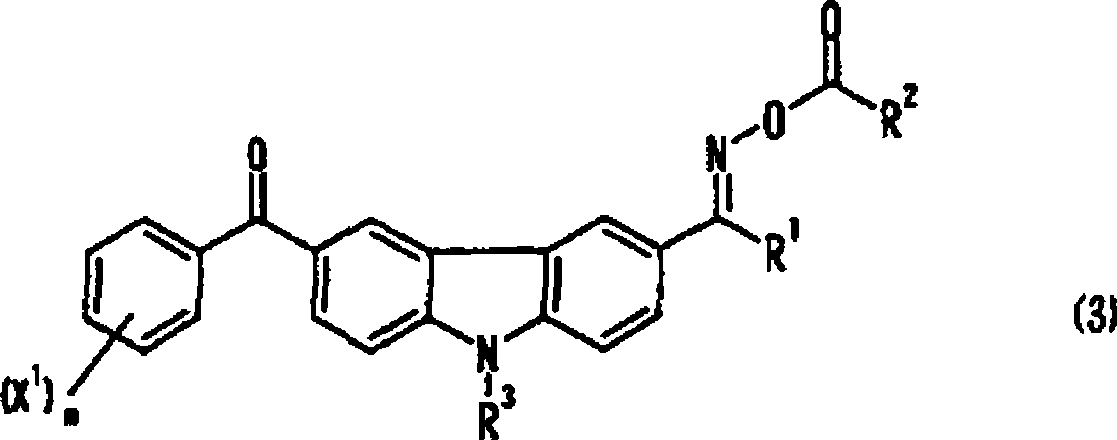

Mineral separation process for improving brown iron ore grade

The invention relates to a method for selecting limonite, which comprises that a, using ball grinder, screw grading machine and high-frequency vibration screen to grind mineral, b, reselecting, roughly selecting, fine selecting, and secondary selecting, c, reversely floating selecting to obtain high-level limonite. The invention utilizes reselection and reverse floating selection, with low cost to be used in the mineral selection industry whose yield is 100000t. And the invention adds a high-frequency vibration screen into traditional ball grinder and screw grading machine to improve the grading efficiency as 30% and adds secondary fine selection to reduce the mud content under 5%, and improve 2-3 degrees of the levels of mineral. And the invention removes mud before reverse floating selection to reduce agent consumption.

Owner:李东明

Lead zinc ore flotation depressing agent composition and lead zinc ore flotation method

The invention provides a lead zinc ore flotation depressing agent composition and a lead zinc ore flotation method. The problem that the grade of zinc in lead concentrate is high is solved, the zinc recovery rate is improved, meanwhile, the consumption of flotation reagents needed in the method is low, and cost is greatly saved. In addition, the depressing agent composition restraining zinc floating is good in zinc retraining effect, nontoxic, free of time limiting performance and wide in raw material source.

Owner:HUNAN SHUI KOU SHAN NONFERROUS METALS GRP

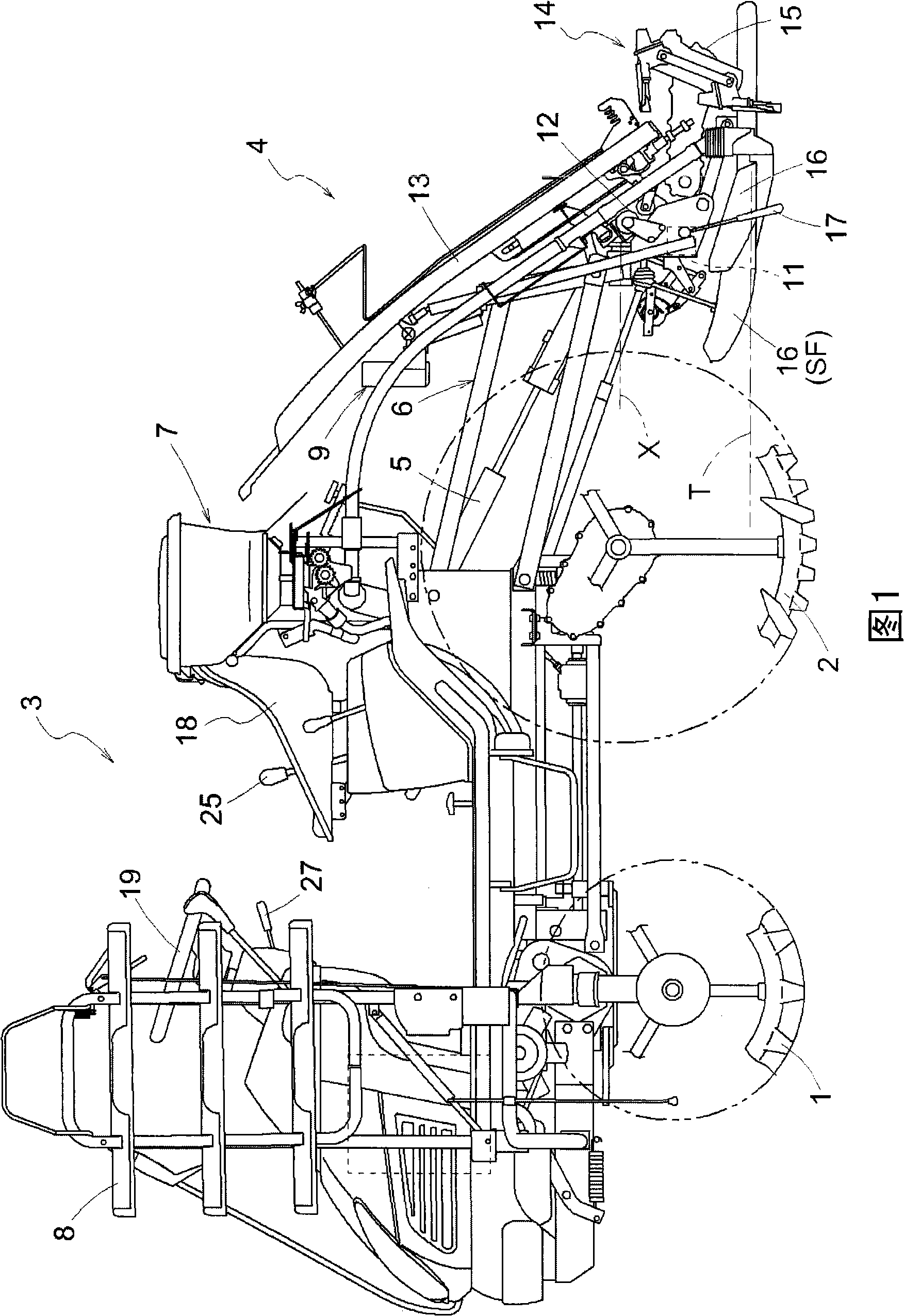

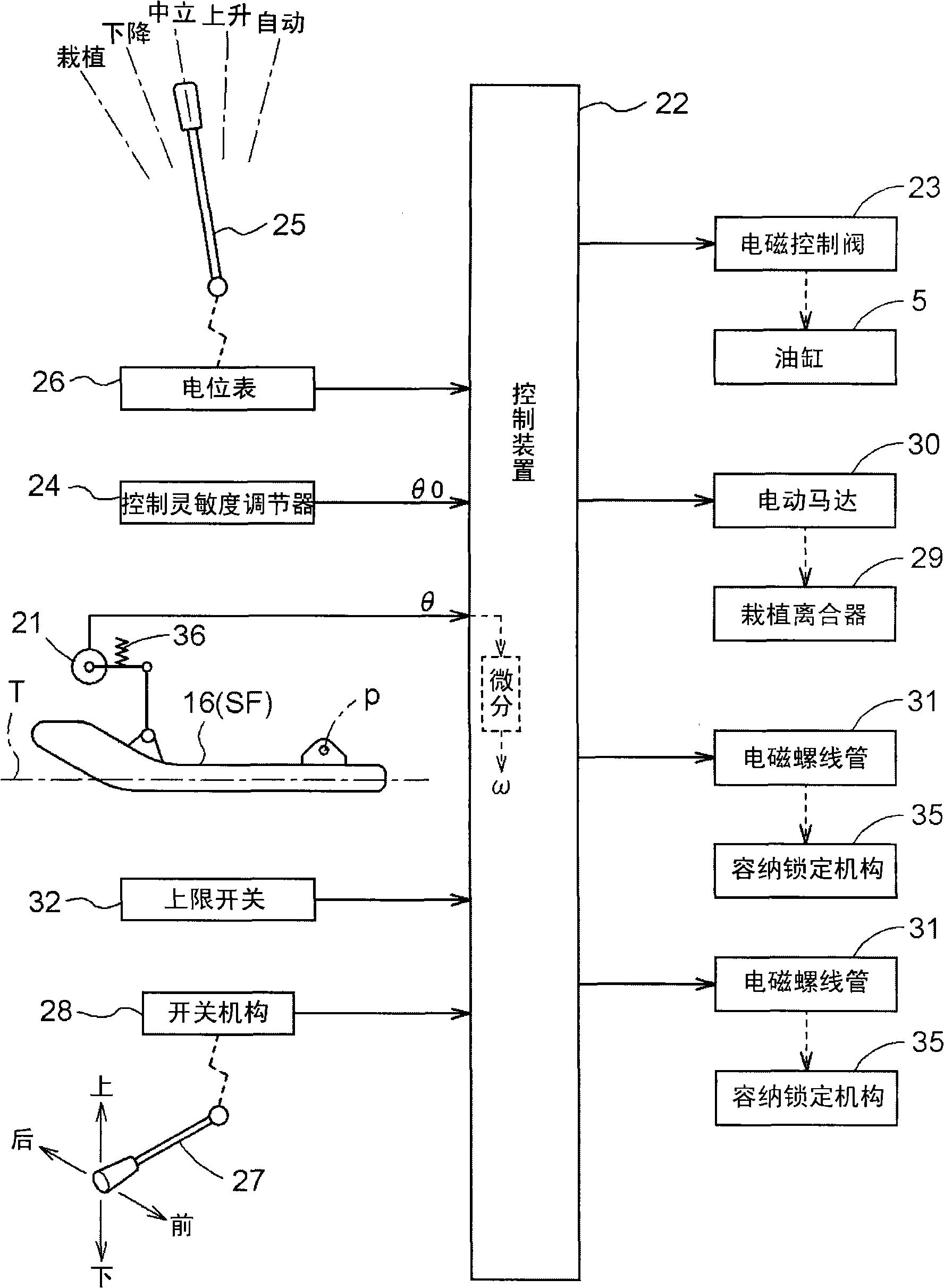

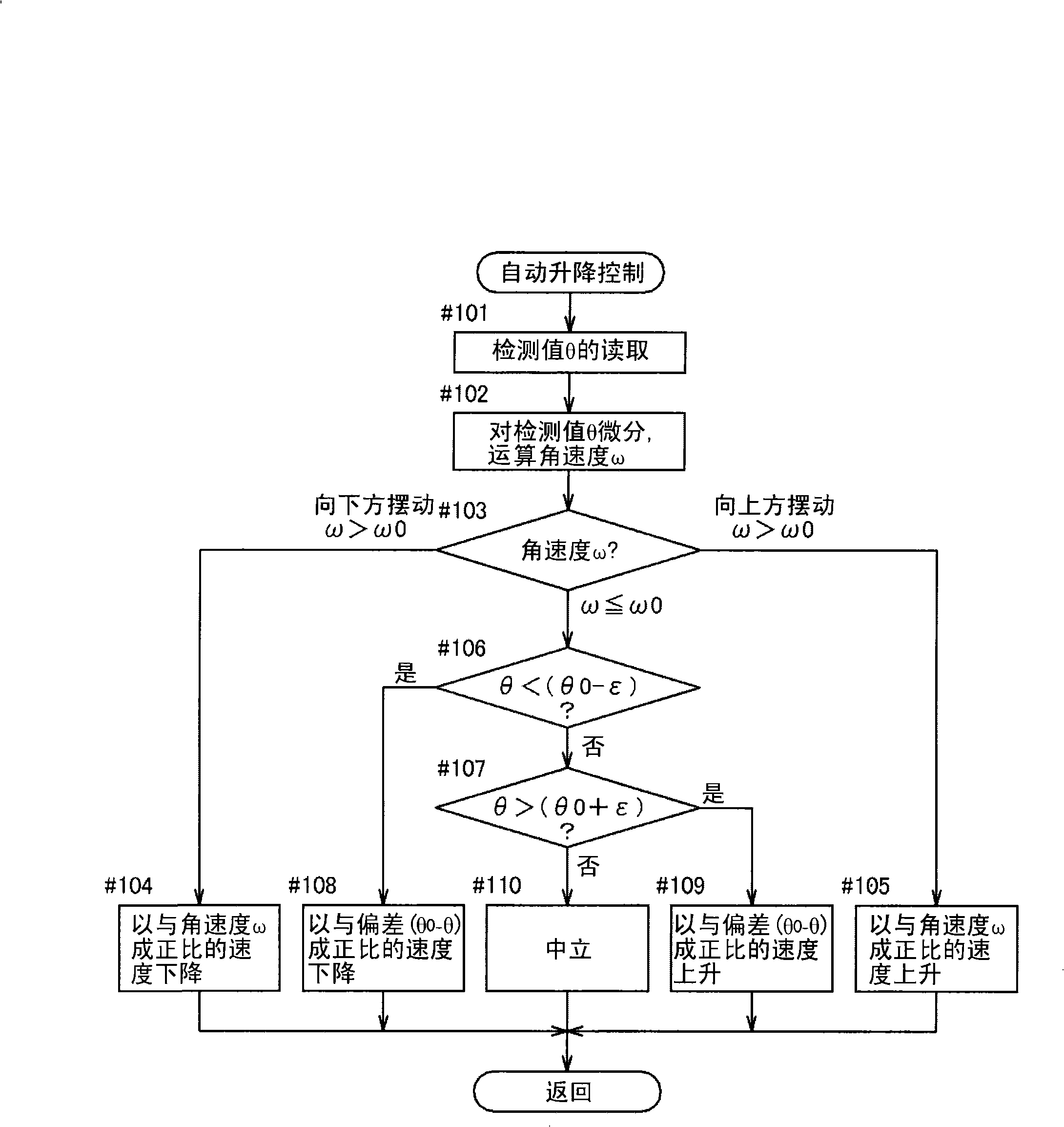

Lifting controller for agricultural working machine

ActiveCN101261522ASuppression of floatingInhibit deteriorationAgricultural machinesControl using feedbackDifferential coefficientAgricultural work

The invention provides an elevating control apparatus for an agricultural working machine which include an elevating drive mechanism. The elevating drive mechanism can be connected with a working apparatus of a drive machine body by elevating freely, control action based on detected high information to ground, maintain high of the working apparatus to ground with a given high, and process elevating action suitably even if high of the working apparatus changing rapidly. A detection value (thet) of a high detection apparatus come from the detection working apparatus to ground and a variable speed (omege) obtained by processing differential coefficient to the detection value, are used as a high information to ground for controlling action of the elevating drive mechanism (5).

Owner:KUBOTA LTD

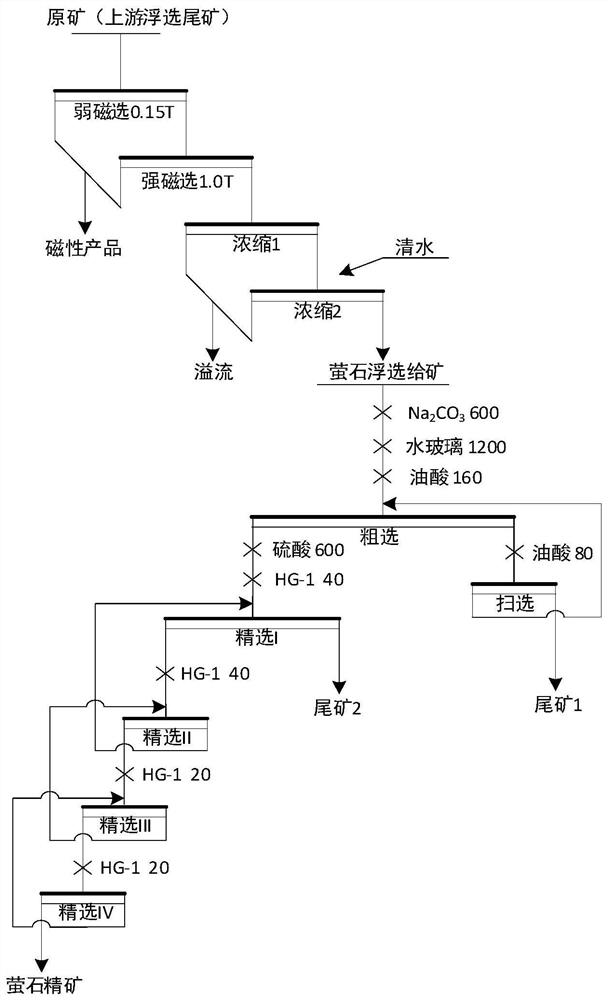

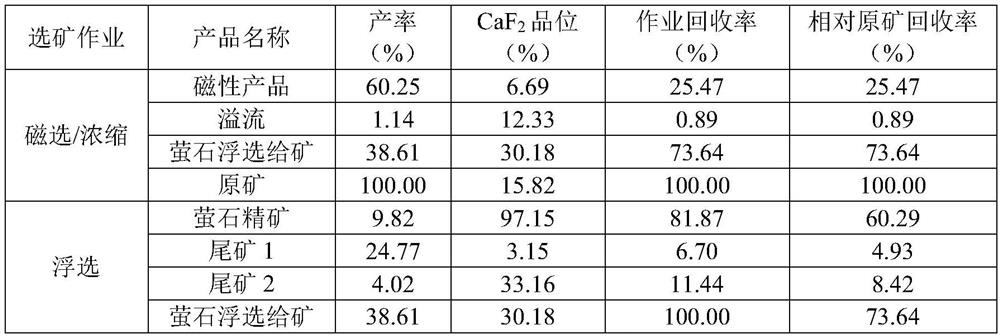

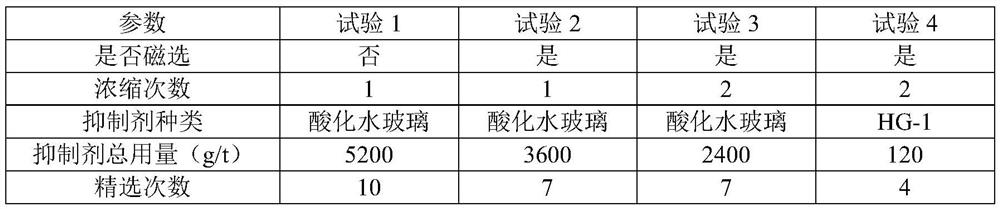

Beneficiation process for recovering fluorite from tailings

ActiveCN111644270AAchieve pre-enrichmentAchieve removalFlotationMagnetic separationCalciteSodium silicate

The invention discloses a beneficiation process for recovering fluorite from tailings, which comprises the following steps: carrying out weak magnetic-strong magnetic operation on raw ore to obtain anon-magnetic product; concentrating the non-magnetic product by using a first concentration box to obtain a first concentrated underflow, adding clear water to dilute the first concentrated underflow,and further concentrating the mixture in a second concentration box to obtain a second concentrated underflow; performing fluorite roughing and scavenging on the second concentrated underflow to obtain rough concentrate, performing concentration I, concentration II, concentration III and concentration IV on the rough concentrate, wherein the concentrate of the concentration IV is final concentrate. Waste is thrown through magnetic separation, so that pre-enrichment of fluorite is achieved, and the flotation operation handling capacity is reduced; through two-stage concentration operation, slime and ore pulp agents are removed, and equipment and agent investment is reduced; an efficient organic inhibitor is adopted for deeply inhibiting floating of calcite and quartz, the dosage of the efficient organic inhibitor is far smaller than that of conventional acidified sodium silicate, the number of concentration operation sections is reduced, and finally high-quality fluorite concentrate with the CaF2 grade larger than 97% is obtained.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

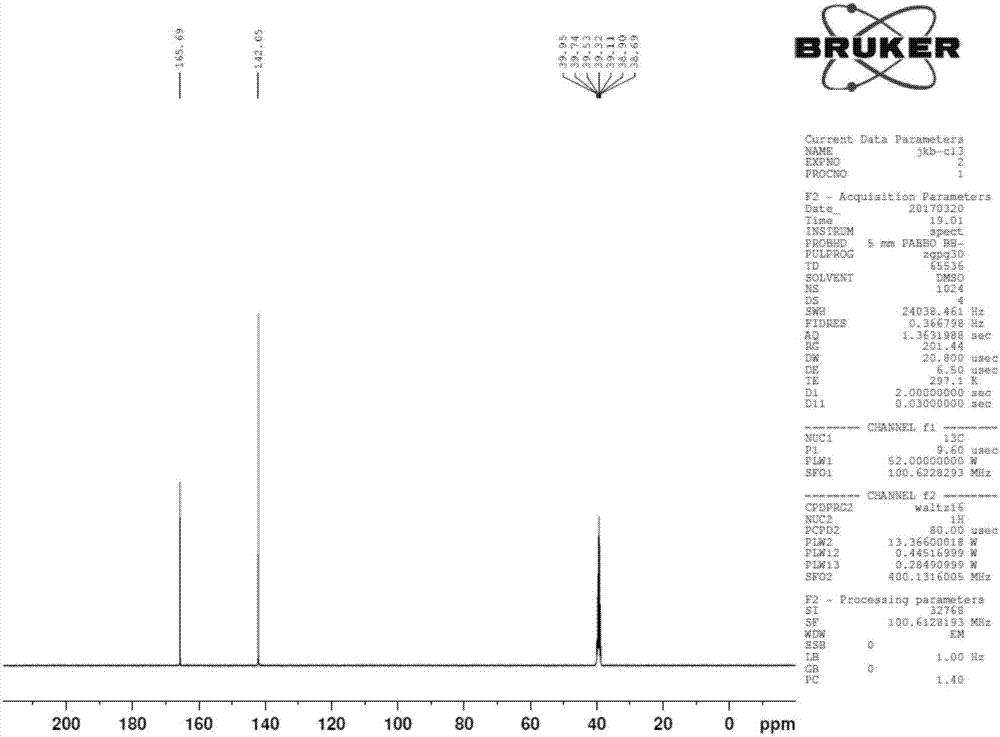

Application of aminotriazolethione compound serving as metal sulfide mineral surface modification agent

ActiveCN107029893ASpecial molecular structureSuppression of floatingFlotationBismuth sulfideChemical compound

The invention discloses application of an aminotriazolethione compound serving as a metal sulfide mineral surface modification agent. The aminotriazolethione compound comprises a hydrophilic modification perssad and an aminotriazolethione perssad at the same time. The aminotriazolethione compound mainly serves as the non-molybdenum sulfide mineral surface modification agent for flotation separation of the molybdenum sulfide mineral and the non-molybdenum sulfide mineral, the hydrophilia of the surfaces of the sulfide minerals with the natural hydrophobicity can be enhanced, especially, the hydrophilia of the surfaces of copper pyrites, chalcocite, galena, blende, brasses, the bismuth sulfide mineral and other non-molybdenum sulfide minerals can be effectively improved, and efficient flotation separation of the molybdenum sulfide mineral and the non-molybdenum sulfide mineral is achieved.

Owner:CENT SOUTH UNIV

Hematite anti-floatation depressor

InactiveCN104437889ASuppression of floatingReduce energy consumptionFlotationIron industryPotassium permanganate

The invention relates to a hematite anti-floatation depressor. The hematite anti-floatation depressor is prepared by waste residues produced during bear making, potassium permanganate, sodium hydroxide and water according to the weight proportion of 1:5-20%:4-20%:80-120%. The hematite anti-floatation depressor is easy to prepare, good in floatation effect and low in usage, the defects of maize starch as the depressor are overcome, selectivity of the depressor is improved, iron recovery rate is increased, usage of the depressor is reduced, the requirements of the dressing process are met, sufficiency of iron ore resources for the iron and steel industry in China is ensured, and immoderate reliance and consumption on grains are reduced.

Owner:ANSTEEL GRP MINING CO LTD

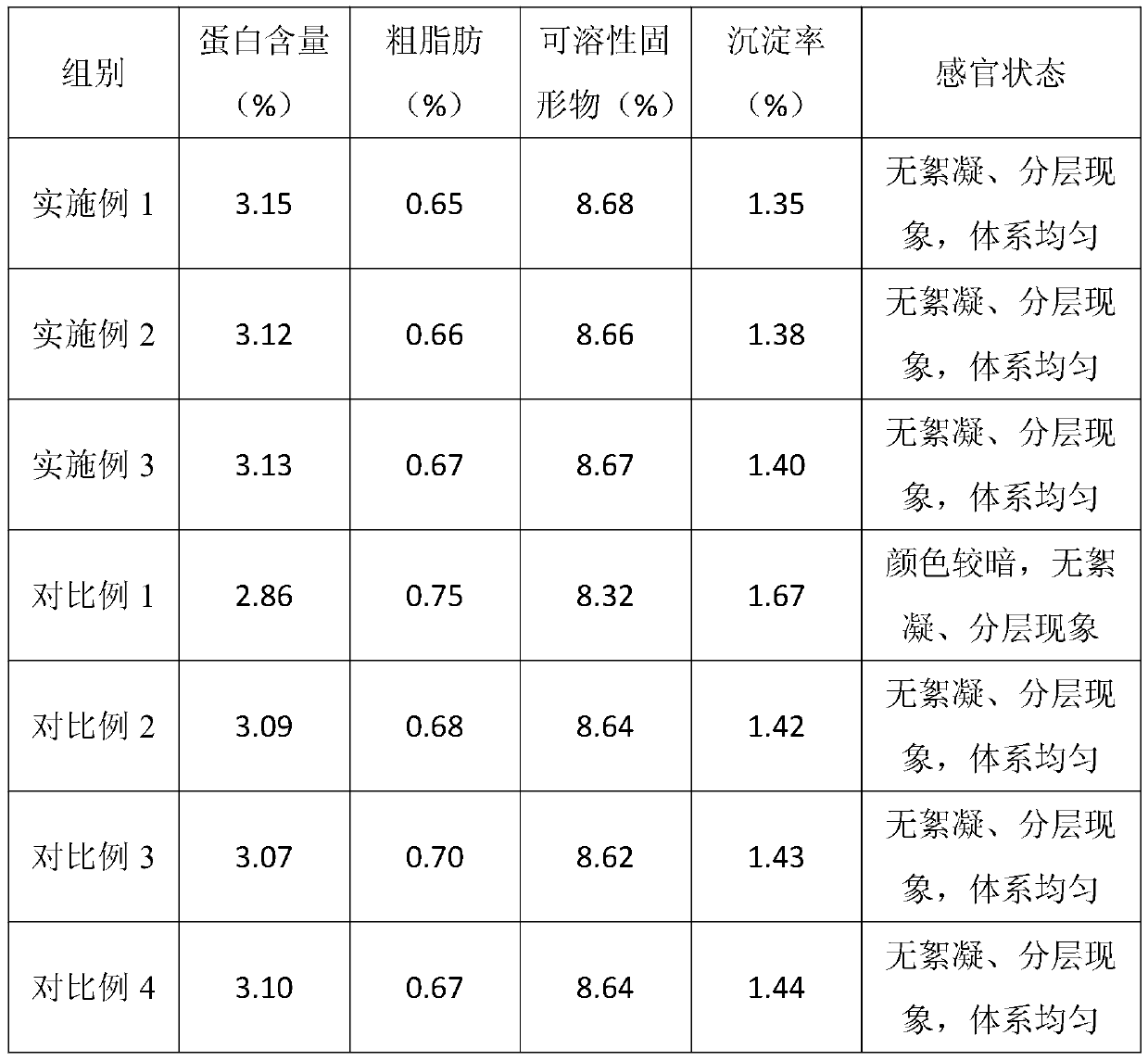

Macadamia nut drink and preparation method thereof

The invention provides a macadamia nut drink, which belongs to the technical field of drink preparation. The macadamia nut drink comprises the following materials: macadamia nut, xylitol, sorbitan, sucrose, citric acid, lactic acid, an emulsifier, a stabilizer, fungal protease, papain, aminopeptidase, and lactic acid bacteria; and the weight ratio of papain, aminopeptidase and lactic acid bacteriais: (0.1-0.2): (0.008-0.02): (0.2-0.3). The macadamia nut drink is obtained by the steps of pressing, pulping, enzymatic hydrolysis, debittering, blending, homogenization, fermentation, sterilizationand the like. The macadamia nut drink improves the nutrient content and stability of macadamia nut drink by using a reinforcing system composed of papain, aminopeptidase and lactic acid bacteria.

Owner:SOUTH ASIAN TROPICAL AGRI SCI RES INST OF GUANGXI

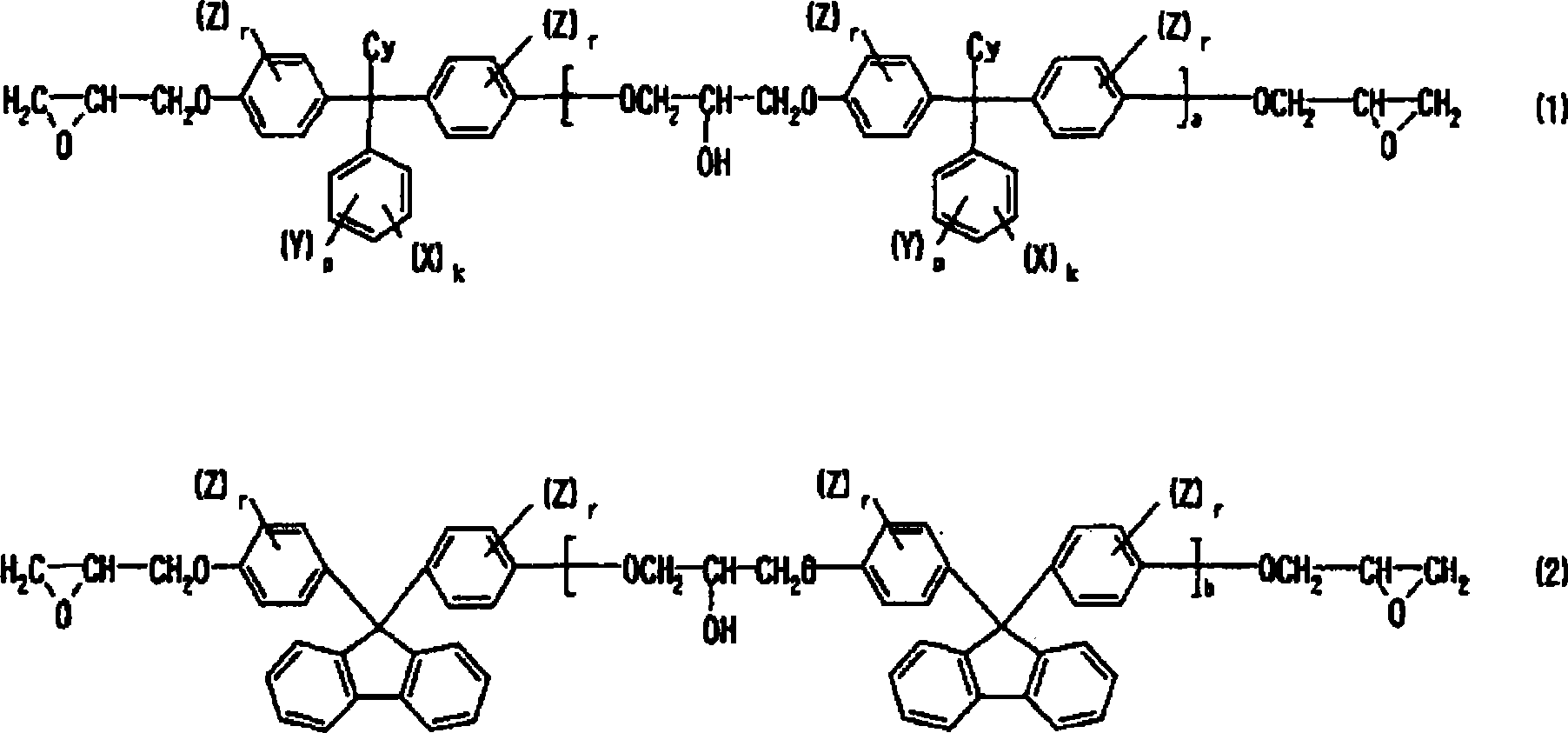

Color resist composition and a color filter using the same

InactiveCN101546122ASuppression of floatingOptical filtersPhotosensitive materials for photomechanical apparatusResistOrganic solvent

The present invention provides a color resist composition and a color filter using the same. The color resist composition contains (A) coloring matter, (B) alkali developable resin composition, (C) photopolymerization initiator and (D) organic solvent, the (D) organic solvent contains PGMAC and dialkylacylamide selected from DMAC or DEAC as necessary components, thereby restraining deflection caused by upwards float or removal of the color resist at time of color resist development with alkali developing liquid. Furthermore, surface roughness concentration of a light shading layer or the coloring layer may be reduced by using the color resist composition, and developing unevenness of the color filter may be prevented.

Owner:ADEKA CORP

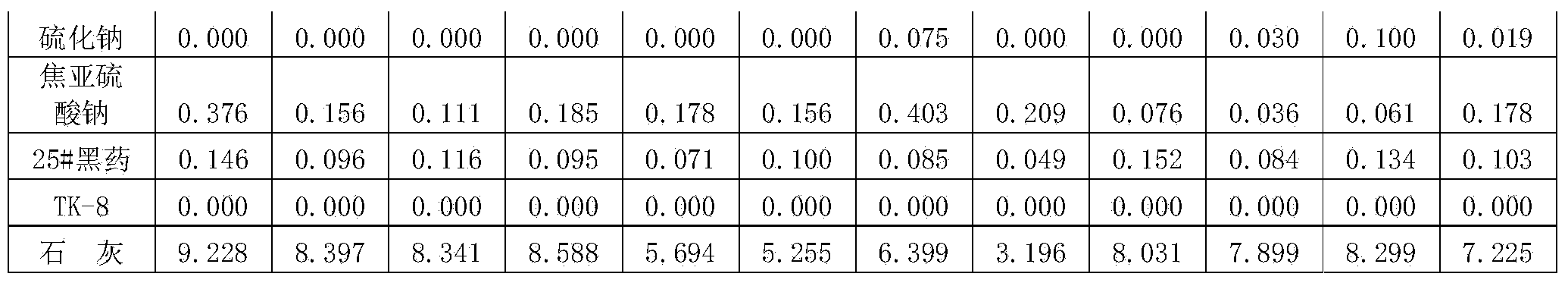

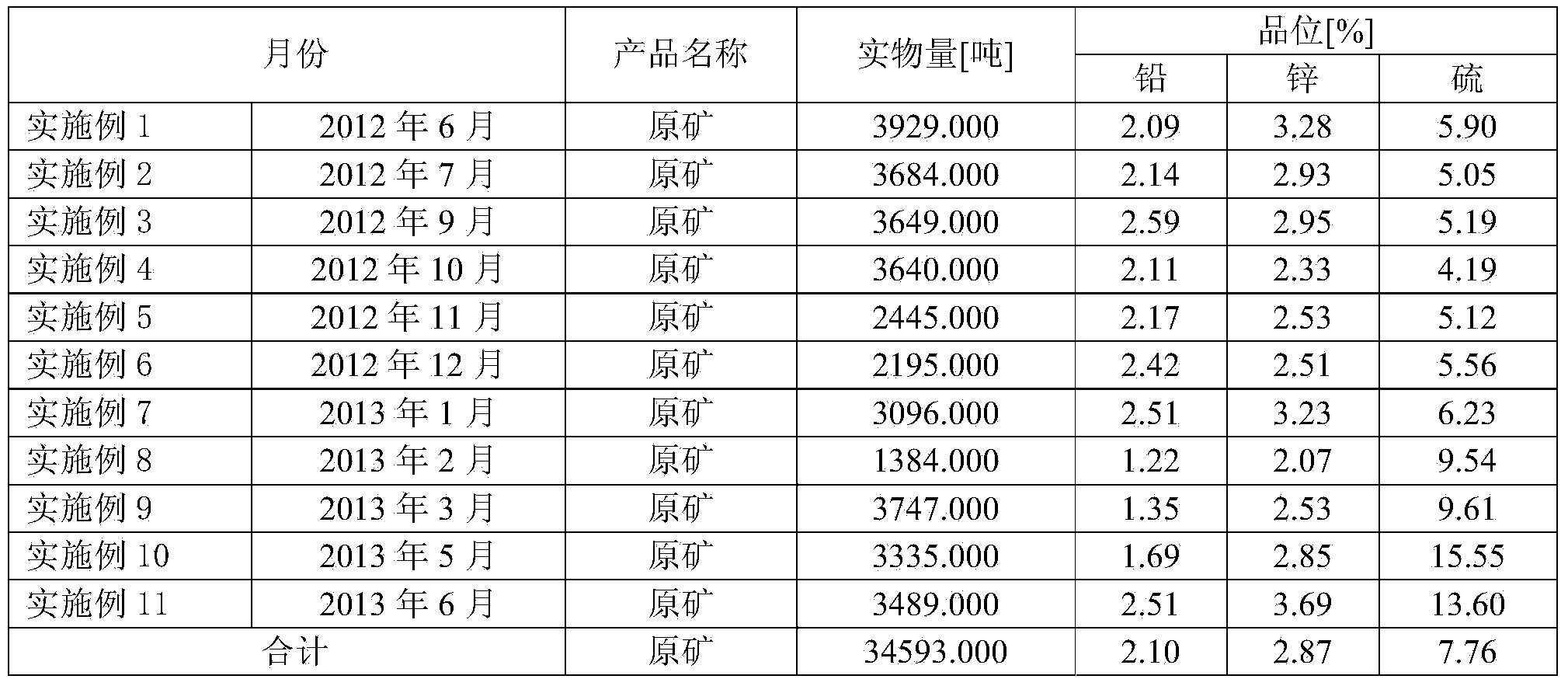

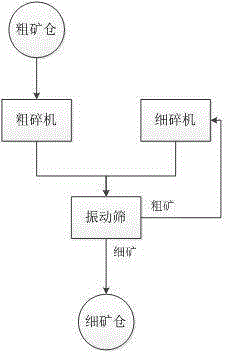

Production technology for lead and zinc floatation mineral powder

InactiveCN105289851AEnhanced water claritySuppression of floatingFlotationOre concentrateSodium sulfites

The invention discloses a production technology for lead and zinc floatation mineral powder. The technology sequentially comprises the steps of a, ore crushing, b, ore grinding, c, ore dissolving pulp preparing, d, dosing and stirring, e, lead floatation, f, zinc floatation, g, water removing and h, milltailing treatment. Added drugs comprise inhibitors, collecting agents, activating agents and foaming agents. The inhibitors are made of one or several of zinc sulfate, lime, sodium sulphide and sodium sulfite, so that the hydrophilic property of the zinc ore is enhanced, and upward floating of the zinc ore is inhibited; the problem that the grade of zinc in the lead concentrates is high is solved, and the zinc recycling rate is improved; meanwhile, used flotation reagents are small in consumption, and the cost is saved; the whole production technology is environment-friendly; and the production technology is good in floatation effect, non-poisonous, free of time bound, wide in raw material resource and capable of being widely applied and popularized.

Owner:HANGZHOU XINLEI MINING GRP CO LTD

Waste sintered brick recycled C25 concrete and preparation method thereof

ActiveCN104556905ARealize recyclingIncrease profitSolid waste managementBrickUltimate tensile strength

The invention relates to waste sintered brick recycled C25 concrete and a preparation method thereof. The C25 concrete is prepared from cement, waste sintered brick recycled coarse aggregate, fine aggregate and water at a mass ratio of 1: (1.76-1.96): (1.15-1.23): (0.42-0.46). The prepared concrete has qualified and stable strength as well as good working performance such as workability, fluidity, water-retaining property and the like, the preparation process is simple and environment-friendly, and construction is easier.

Owner:ZHENGZHOU UNIV

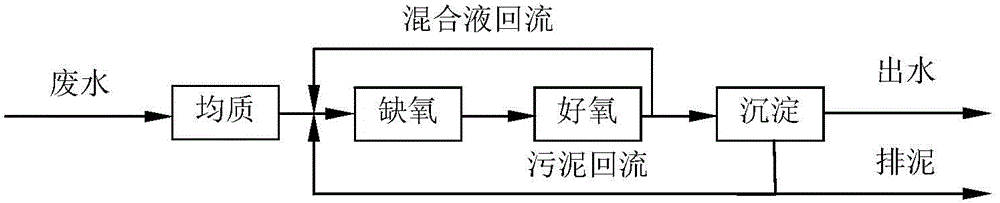

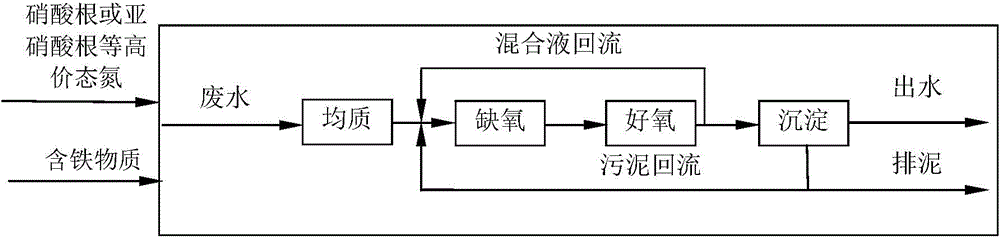

Method for rapidly starting denitrification-nitrification biochemical treatment system

ActiveCN104445612AStart fastImprove water compliance rateTreatment with aerobic and anaerobic processesSludgeDenitrifying bacteria

The invention relates to a method for rapidly starting a denitrification-nitrification biochemical treatment system, the denitrification-nitrification biochemical treatment system comprises the following components: a homogenizing unit, an anoxic unit, an aerobic unit and a deposition unit; the anoxic unit and the aerobic unit are collectively referred to as a biochemistry unit. The method is characterized in that an oxidizability substance required by denitrification is added in the homogenizing unit or the anoxic unit for domestication of denitrifying bacteria in advance, an iron compound is added at the homogenizing unit or the anoxic unit or the aerobic unit or an outlet of the aerobic unit for improving the sludge settlement performance of the deposition unit, and inhibition of iron ion in the iron compound (except iron hydroxide) on the denitrification and nitrification reactions can be eliminated by adding alkalescence substance. The method guarantees rapid starting of the denitrification-nitrification biochemical treatment system, when the denitrification-nitrification biochemical treatment system is started by using same seed sludge and a water inlet program. The method provided by the invention can complete starting by at least three weeks in advance, and the effluent standard-reaching rate at a starting period is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

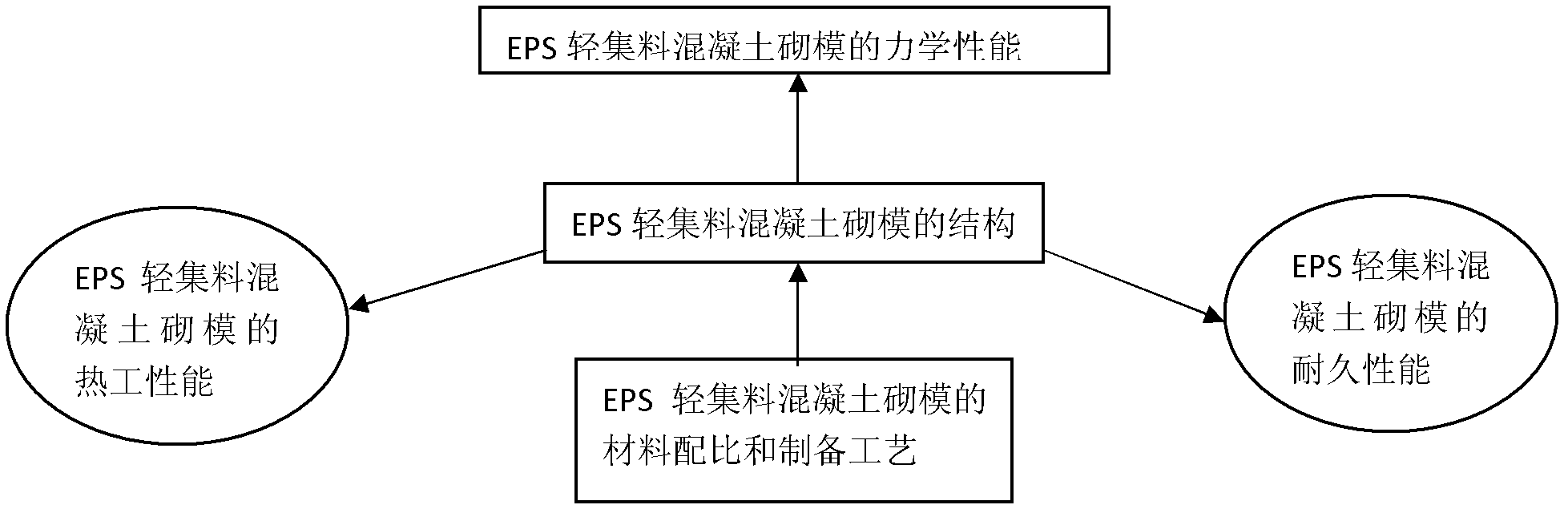

EPS (Expandable Polystyrene) light aggregate concrete thermal insulation hollow block and construction method thereof

InactiveCN102674759ASimple construction methodQuality improvementClimate change adaptationHeat proofingSilica fumeThermal insulation

The invention provides an EPS (Expandable Polystyrene) light aggregate concrete thermal insulation hollow block and a construction method thereof, belonging to the technical of a concrete building material. The hollow block is prepared by using waste EPS (Expandable Polystyrene) particles as aggregates in concrete, the cement as a cementing material and adding pulverized fuel ash, silica fume, polymer emulsion and water. The EPS light aggregate concrete thermal insulation hollow block solves the problems of weight and thermal insulation property when a brick-concrete structure is used as a wall; and due to the recycling of lots of pulverized fuel ash and EPS, the environmental stress is eased, and the EPS light aggregate concrete thermal insulation hollow block has very effect on the elimination of environmental pollution. The hollow block provided by the invention has the characteristics of light weight, excellent thermal insulation property, simple construction method and green environmental protection.

Owner:CHINA ELECTRIC POWER RES INST +1

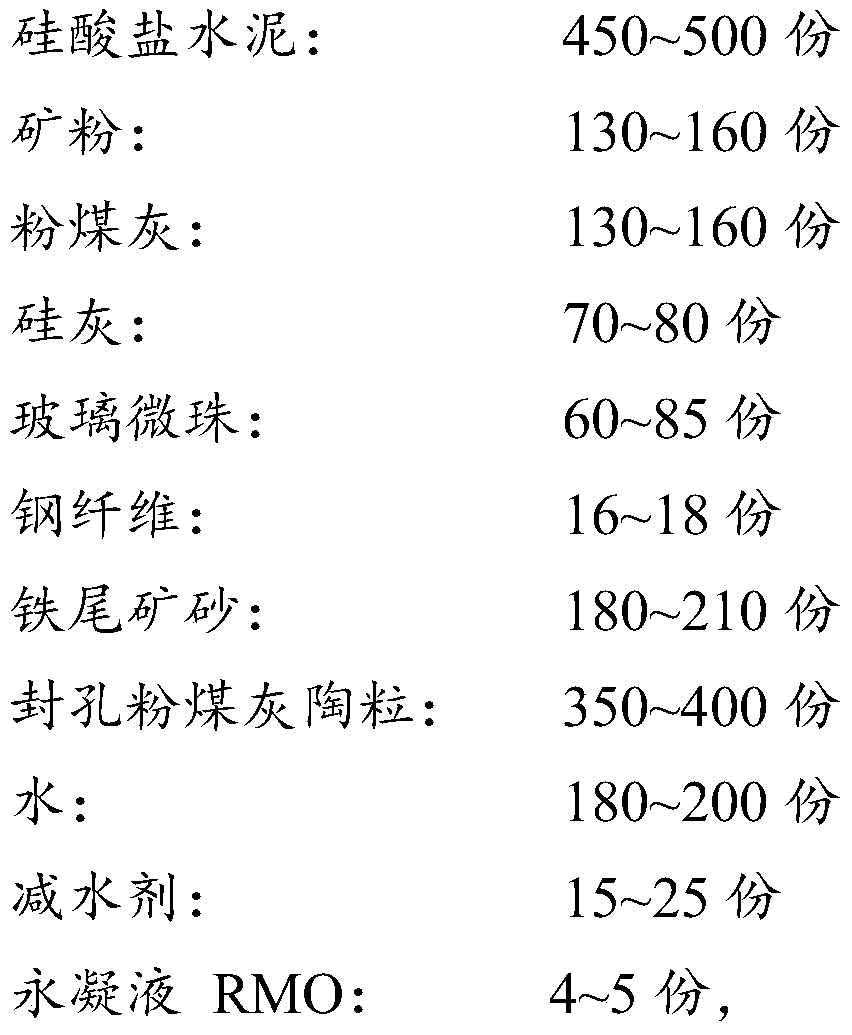

Lightweight high-strength waterproof concrete and preparation method thereof

The invention provides lightweight high-strength waterproof concrete and a preparation method thereof, and belongs to the field of concrete. The lightweight high-strength waterproof concrete comprisesthe following components in parts by mass: 450 to 500 parts of Portland cement, 130 to 160 parts of mineral powder, 130 to 160 parts of fly ash, 70 to 80 parts of silica fume, 60 to 85 parts of glassmicro-beads, 16 to 18 parts of steel fibers, 180 to 210 parts of iron tailing sand, 350 to 400 parts of pore-sealing fly ash ceramsite, 180 to 200 parts of water, 15 to 25 parts of a water reducing agent and 4 to 5 parts of a permanent solidification liquid RMO. The pore-sealing fly ash ceramsite is prepared by a method comprising the following steps: immersing fly ash ceramsite into a mixed solution of RMO and water, pre-wetting, draining off water after 1 hour, and then carrying out coating treatment by using a mixture of Portland cement and iron tailing sand powder, so as to obtain the pore-sealing fly ash ceramsite. The concrete disclosed by the invention has the properties of light weight, high strength and water resistance.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

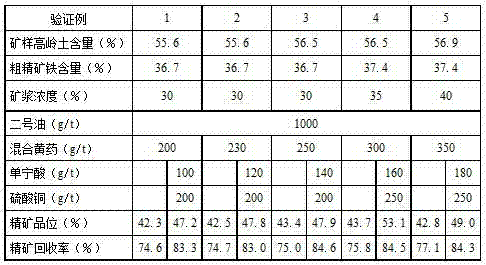

Combined agent for pyrite flotation

InactiveCN102357427AStrong collection performanceThe equipment is less corrosiveFlotationOre concentratePyrite

The invention discloses a combined agent for pyrite flotation. The combined agent comprises No.2 oil serving as a foaming agent, and a collecting agent formed by mixing ethyl xanthate and butyl xanthate; and under the conditions that the mass content of iron is 36.7 to 37.4 percent and the mass content of kaolin impurity is 55.6 to 57.3 percent in pyrite, based on 30 to 40 mass percent pyrite pulp, the combined agent contains 1,000 g / t of No.2 oil, 200 to 400 g / t of ethyl xanthate and butyl xanthate mixed in a ratio of 1:1, 100 to 200 g / t of tannic acid, and 200 to 350 g / t of copper sulfate. According to the combined agent for flotation of the pyrite using kaolin as a main impurity, the ore concentrate grade of the pyrite is greatly improved, and the yield of the pyrite is also greatly improved; and meanwhile, the combined agent has the advantages of low equipment corrosion, low adverse effect on the human body and the environment and relatively low cost, and further improves the comprehensive benefit.

Owner:CHONGQING UNIV

Emulsion stabilizer and milk drink containing the same

ActiveCN1761398ASuppression of floatingImprove emulsion stabilityMilk preparationMilk preservationEmulsionAnimal protein

A milk drink excellent in emulsion stability is obtained by incorporating a vegetable protein (preferably a vegetable protein and a sucrose / fatty acid ester and / or polyglycerol / fatty acid ester) into a milk drink. The vegetable protein preferably is soybean protein. The sucrose / fatty acid ester preferably is one having an HLB of 10 or higher. The polyglycerol / fatty acid ester preferably is one having a cloud point as measured under given conditions of 80 DEG C or higher. An animal protein may be used in combination therewith. In this case, the animal protein preferably is a protein derived from cow's milk.

Owner:MITSUBISHI RAYON CO LTD

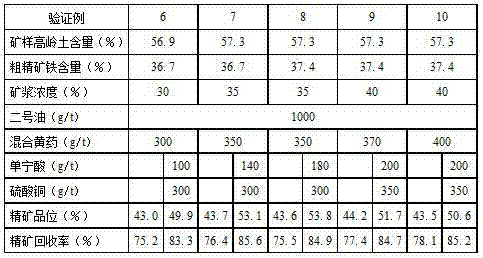

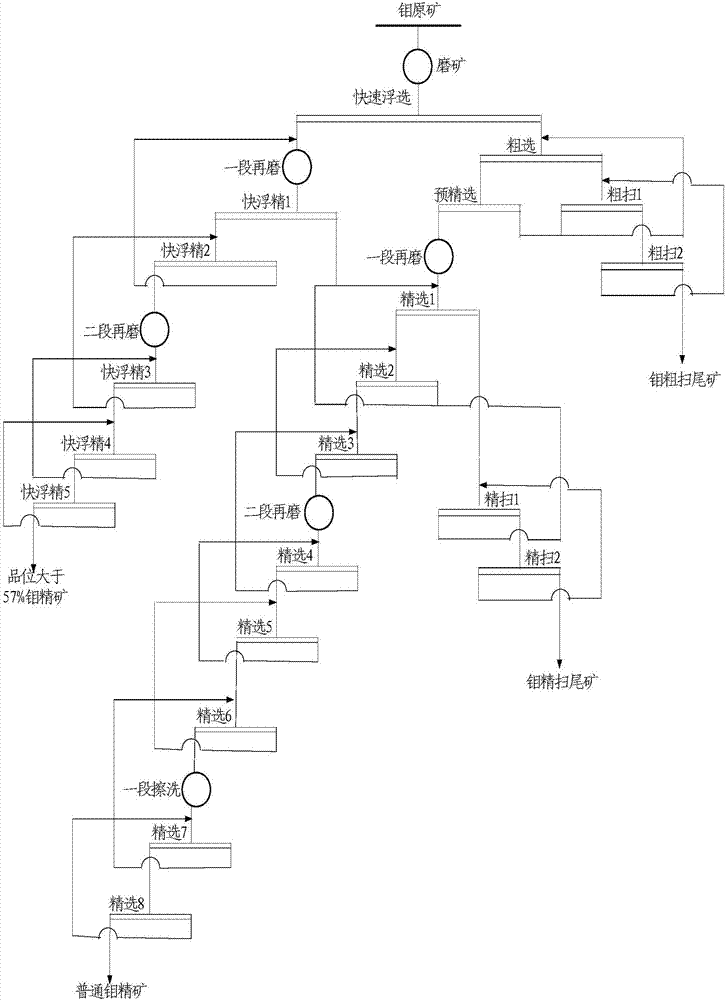

Process for step-by-step production of high-grade molybdenum concentrates and ordinary molybdenum concentrates

ActiveCN107309074AIncrease floatability differenceFewer picksFlotationWet separationTotal recoveryPre selection

The invention discloses a process for step-by-step production of high-grade molybdenum concentrates and ordinary molybdenum concentrates. The process comprises the following steps that 1, molybdenum crude ore is added with water and ground, and molybdenum ore pulp is obtained; 2, the molybdenum ore pulp is subjected to roughing, molybdenum rough concentrates and molybdenum rough tailings are obtained, the molybdenum rough concentrates or the molybdenum ore pulp is subjected to fast flotation, and fast flotation molybdenum rough concentrates and fast flotation molybdenum tailings are obtained; 3, the fast flotation molybdenum rough concentrates are subjected to two-stage regrinding and selection for five times, and the high-grade molybdenum concentrates where the grade of molybdenum is larger than 57% are obtained; 4, the fast flotation molybdenum tailings obtained through the molybdenum ore pulp are subjected to roughing, and molybdenum rough concentrates and molybdenum rough tailings are obtained; and 5, the fast flotation molybdenum tailings obtained through the molybdenum rough concentrates or the molybdenum rough concentrates in the step 4 are subjected to pre-selection at first and then subjected to two-stage regrinding, selection for eight times and scrubbing for one time, and molybdenum fine tailings and the ordinary molybdenum concentrates where the grade of molybdenum is 52%-55% are obtained. According to the process for step-by-step production of the high-grade molybdenum concentrates and the ordinary molybdenum concentrates, a differential flotation technology is utilized, the molybdenum concentrates of different grades are obtained, the number of selection is shortened, and the total recovery rate of the molybdenum concentrates is increased.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Synchronous grouting slurry for shield construction of water-rich stratum and preparation method thereof

The invention relates to synchronous grouting slurry for shield construction of a water-rich stratum and a preparation method thereof. The synchronous grouting slurry comprises a component A, a component B and a component C, wherein the raw materials of the component A comprise silicate 42.5-grade cement, II-grade fly ash, river sand and sodium bentonite, the raw materials of the component B comprise hydroxyethyl methyl cellulose and tap water, the raw material of the component C comprises nano silicon dioxide, the tap water, the ratio of the blending amount of the component B to the blending amount of the component A is 3: 5, and the ratio of the blending amount of the component C to the blending amount of the component A is 1: 2; the synchronous grouting slurry is high in early-stage shear strength, good in groutability, stable, high in stone rate, low in bleeding rate and good in dilution resistance, certain shear resistance is provided after the synchronous grouting slurry is injected, then duct pieces are inhibited from floating upwards, the effect of stabilizing the duct pieces can be achieved, and the problems of cracking and water seepage of the duct pieces are solved.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP +1

High-performance spray gun for molten iron injection pretreatment

The invention discloses a high-performance spray gun for molten iron injection pretreatment. The high-performance spray gun comprises a connection segment, a gun body segment and an injection segment, which are sequentially communicated, wherein a swirling diffuser is arranged between the gun body segment and the injection segment and comprises an upper cone, a cylinder and a lower reversed cone, which are sequentially communicated; 2-4 nozzles are uniformly formed between a main pipe of the spray gun and a seal head in the circumferential direction of the spray gun and positioned in the side wall of the injection segment; swirling pieces obliquely arranged on the outer wall from the top end of the lower reversed cone to the bottom end surface of the injection segment and positioned above the nozzles. By strengthening three key kinetic parameters of molten iron injection pretreatment, the spray gun significantly improves the kinetic conditions of molten iron injection pretreatment and achieves the comprehensive purposes of improving the sulfur removal efficiency of injection pretreatment and the utilization rate of desulfurizer reaction, shortening the injection time and increasing the production capacity of desulfurization equipment.

Owner:武汉钢铁有限公司

Emulsion stabilizer and milk beverage

ActiveCN1905811ASuppression of floatingImprove emulsion stabilityMilk preparationTransportation and packagingEmulsionSorbitan

A coffee beverage that even when the amount of roasted coffee beans is large or when use is made of deeply roasted coffee beans, inhibits the floating of milk components and is free from any aggregation despite long-term storage. Use is made of an emulsion stabilizer composed of a sorbitan fatty acid ester and a diglycerol fatty acid ester wherein the content of monoesters is >= 50 wt.%. As the sorbitan fatty acid ester, preferred use is made of one of >= 4 HLB. In particular, this emulsion stabilizer is effective in a milk coffee wherein the content of coffee extract is in the range of 5 to 10 wt.% in terms of raw beans.

Owner:MITSUBISHI RAYON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com