Chocolate sauce, stabilizer, double-layer chocolate fermented milk, formula and preparation method

A chocolate sauce and stabilizer technology, applied in dairy products, food preparation, milk preparations, etc., can solve the problems of upward migration of jam pigment, layering and turbidity of jam and fermented milk, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1, a kind of chocolate double-layer fermented milk and preparation method thereof

[0063] 1. Raw material formula:

[0064] Whole milk raw milk 76.995%, chocolate sauce 17%, sucrose 5.0%, modified starch 0.6%, gelatin 0.3%, pectin 0.1%, lactic acid bacteria starter (including Lactobacillus bulgaricus and Streptococcus thermophilus) 0.005%.

[0065] The performance indicators of each raw material meet the requirements of conventional quality standards in this field.

[0066] Two, produce the product of the present embodiment according to following process method:

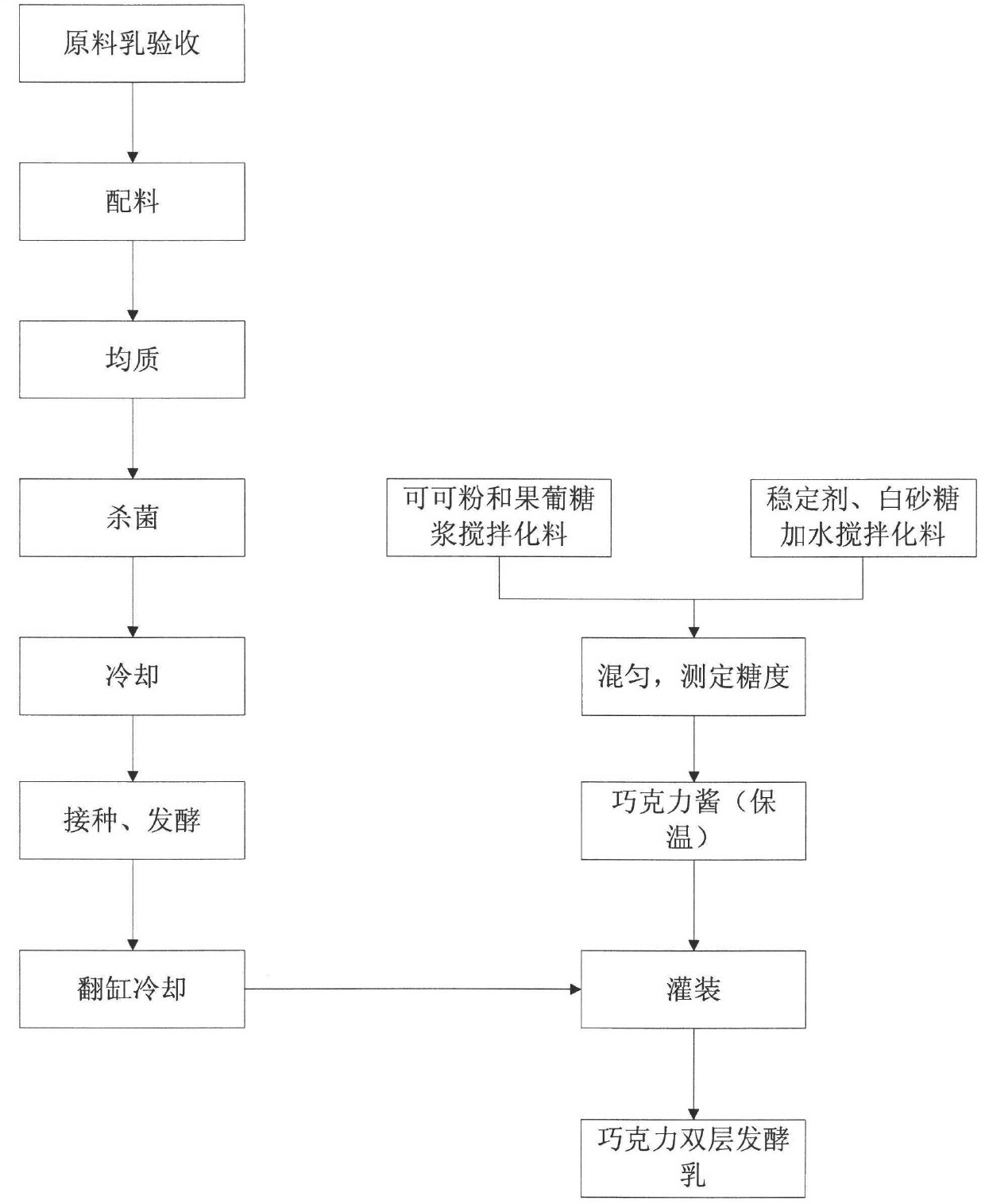

[0067] 1. Process flow:

[0068] Acceptance of raw milk→ingredients→homogenization→sterilization→cooling→inoculation, fermentation→turn over tank to cool→filling→refrigerate and ripen

[0069] 2. Process description:

[0070] 2.1 Acceptance of raw milk: fat ≥ 3.1%, protein ≥ 2.9%, 72% alcohol test negative, acidity 12°T ~ 18°T, impurity ≤ 2mg / kg, milk temperature ≤ 4°C, normal boiling; sensory,...

Embodiment 2

[0080] Embodiment 2, a kind of chocolate double-layer fermented milk and preparation method thereof

[0081] 1. Raw material formula:

[0082] Whole milk raw milk 70%, chocolate sauce 20%, sucrose 7.0%, modified starch 0.6%, gelatin 0.5%, agar 0.5%, sodium alginate 0.3%, pectin 0.1%, whey protein concentrate powder 0.5%, cream 0.49 %, lactic acid bacteria starter (including Lactococcus lactis subsp. lactis, Lactococcus lactis subsp. cremoris and Lactococcus lactis subsp. diacetyl) 0.01%.

[0083]The performance indicators of each raw material meet the requirements of conventional quality standards in this field.

[0084] Two, produce the product of the present embodiment according to following process method:

[0085] 1. Process flow:

[0086] Acceptance of raw milk→ingredients→homogenization→sterilization→cooling→inoculation, fermentation→turn over tank to cool→filling→refrigerate and ripen

[0087] 2. Process description:

[0088] 2.1 Acceptance of raw milk: fat ≥ 3.1%,...

Embodiment 3

[0098] Embodiment 3, a kind of chocolate double-layer fermented milk and preparation method thereof

[0099] 1. Raw material formula:

[0100] Whole milk raw milk 82%, chocolate sauce 15%, sucralose 0.01%, modified starch 0.3%, milk protein powder 2.488%, lactic acid bacteria starter (including Lactobacillus bulgaricus, Streptococcus thermophilus, Lactobacillus acidophilus, Bifidus longum bacillus, Lactobacillus fermentum and Lactobacillus helveticus) 0.002%, food flavor 0.2%.

[0101] The performance indicators of each raw material meet the requirements of conventional quality standards in this field.

[0102] Two, produce the product of the present embodiment according to following process method:

[0103] 1. Process flow:

[0104] Acceptance of raw milk→ingredients→homogenization→sterilization→cooling→inoculation, fermentation→turn over tank to cool→filling→refrigerate and ripen

[0105] 2. Process description:

[0106] 2.1 Acceptance of raw milk: fat ≥ 3.1%, protein ≥...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com