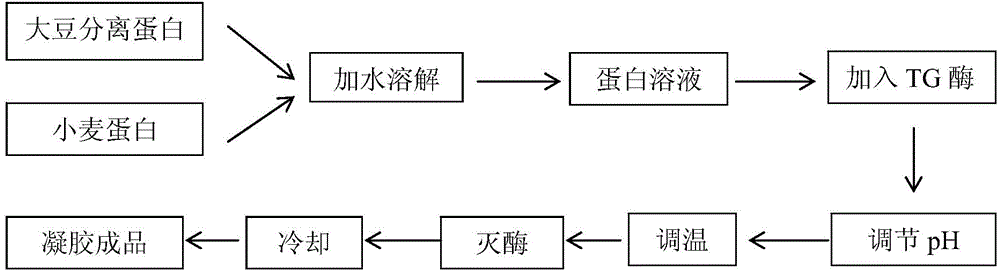

TG enzyme modification high-intensity mixed gel and preparing method thereof

A hybrid gel and high-strength technology, which is applied in plant protein processing and other fields, can solve the problems of poor solubility of wheat protein gel, low strength of soybean protein gel, and weak protein gel properties, and achieve low cost and high quality. Uniform structure, good gel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Accurately and quantitatively weigh soybean protein isolate, wheat protein and TG enzyme, dissolve the mixed powder of soybean protein isolate and wheat protein with distilled water. Stir with a stirrer at 300r / min for 2 hours to obtain a solution, add 30U / g (ratio of enzyme activity equivalent to substrate protein) TG enzyme to the solution and stir evenly, adjust the pH of the mixture to 7.5 with NaOH solution, and put it in a vibrating In a constant temperature water bath, keep warm in a 40°C aqueous solution for 2 hours, then sterilize it in a 95°C constant temperature water bath for 50 minutes, then immediately cool it in an ice bath, take it out and store it at 4°C overnight to obtain a mixed gel.

[0029] After testing, the gel strength of the mixed gel prepared in this embodiment is 90g, the water holding rate is 71.93%, and the soluble protein content is 6.98mg / ml.

Embodiment 2

[0031] Accurately and quantitatively weigh soybean protein isolate, wheat protein, and TG enzyme, dissolve the mixed powder of soybean protein isolate and wheat protein in distilled water, add 13g / 100mL of soybean protein isolate and 1g / 100mL of wheat protein in distilled water, stir with magnetic force Stir at 300r / min for 2 hours to obtain a solution, add 30U / g (ratio of enzyme activity equivalent to substrate protein) TG enzyme to the solution and stir evenly, adjust the pH of the mixture to 7.5 with NaOH solution, and put it in a constant temperature shaker In a water bath, keep warm in an aqueous solution at 40°C for 3 hours, then sterilize in a constant temperature water bath at 95°C for 50 minutes, then immediately cool it in an ice bath, take it out and store it at 4°C overnight to obtain a mixed gel.

[0032] After testing, the gel strength of the mixed gel prepared in this example is 116g, the water holding rate is 84.67%, and the soluble protein content is 8.74mg / ml....

Embodiment 3

[0034] Accurately and quantitatively weigh soybean protein isolate, wheat protein, and TG enzyme, dissolve the mixed powder of soybean protein isolate and wheat protein in distilled water, add 10g / 100mL of soybean protein isolate in distilled water, and 1g / 100mL of wheat protein, stir with magnetic force Stir at 300r / min for 2 hours to obtain a solution, add 30U / g (ratio of enzyme activity equivalent to substrate protein) TG enzyme to the solution and stir evenly, adjust the pH of the mixture to 7.0 with NaOH solution, and put it in a constant temperature shaker In a water bath, keep warm in a 40°C aqueous solution for 2 hours, then sterilize in a constant temperature water bath at 80°C for 50 minutes, then immediately cool it down in an ice bath, take it out and store it at 4°C overnight to obtain a mixed gel.

[0035] After testing, the gel strength of the mixed gel prepared in this embodiment is 80g, the water holding rate is 76.47%, and the soluble protein content is 7.46mg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| gel strength | aaaaa | aaaaa |

| gel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com