Lightweight high-strength waterproof concrete and preparation method thereof

A waterproof concrete and high-strength technology, applied in the field of concrete, can solve the problems of the requirements for waterproofness of lightweight concrete materials, the need to increase the strength, and the bulk density, and achieve the effects of excellent flow performance, increased compactness, and inhibition of cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The present invention also provides a preparation method for lightweight high-strength waterproof concrete described in the above technical solution, comprising the following steps:

[0051] Take raw materials according to parts by weight;

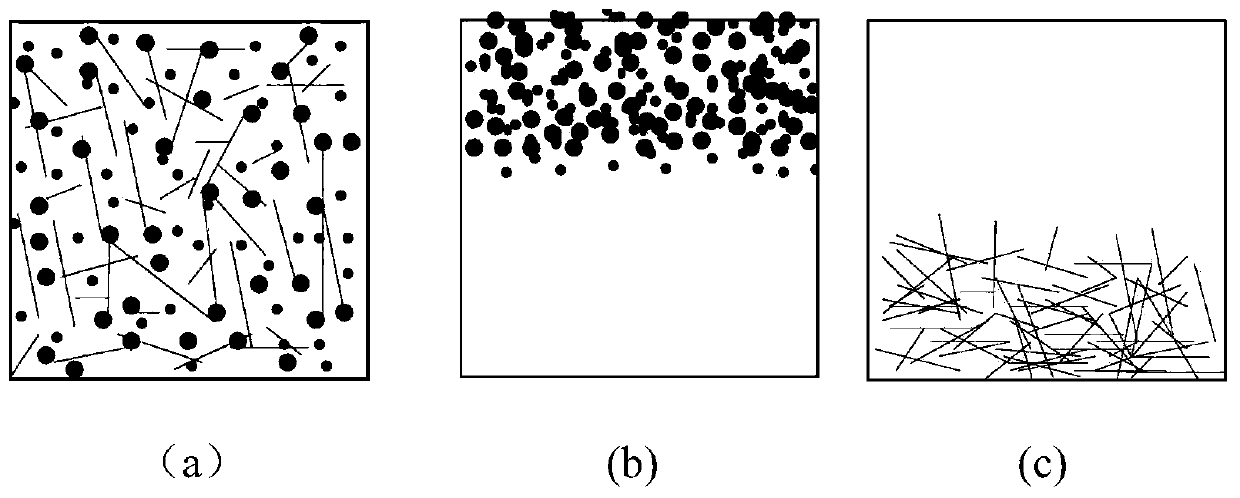

[0052] mixing Portland cement, silica fume, mineral powder, fly ash, glass microspheres and iron tailings sand to obtain the first mixture;

[0053] Mixing the first mixture, sealing fly ash ceramsite and steel fiber to obtain a second mixture;

[0054] The permanent condensate RMO is mixed with water to obtain the third mixture;

[0055] Mix the third mixture with the water reducer and add it into the second mixture in three equal parts, and stir evenly to obtain a test piece;

[0056] The test block is cured to obtain the lightweight high-strength waterproof concrete.

[0057] In the present invention, the mixing is preferably mechanically stirred for more than 200s.

[0058] In the present invention, the curing is preferably ...

Embodiment 1

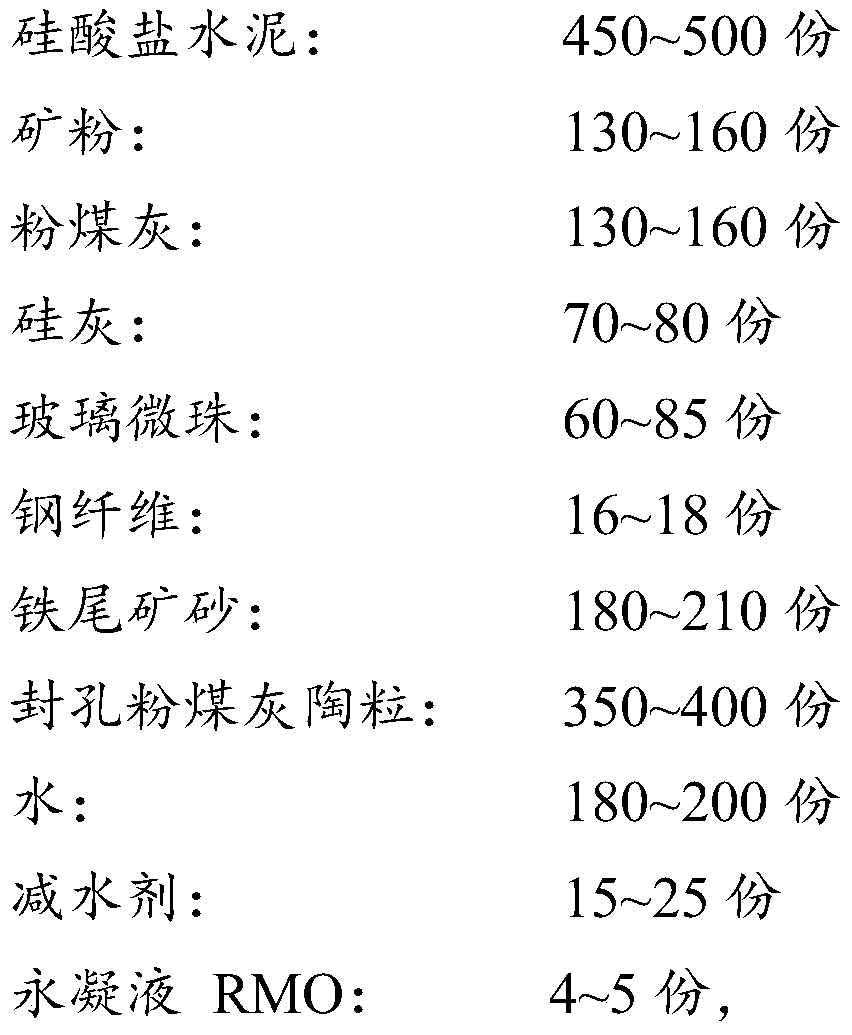

[0073] The embodiment of the present invention proposes a kind of lightweight waterproof concrete (sand rate is 34%, water cement ratio 0.2), comprises following components by weight:

[0074] Cementitious material: 400 parts of Portland cement; 72 parts of silica fume; 158 parts of fly ash; 158 parts of mineral powder; 61 parts of glass beads;

[0075] Fine aggregate: 181.9 parts of 0-5mm iron tailings;

[0076] Coarse aggregate: 7 parts of 3-5mm fly ash ceramsite; 75 parts of 5-8mm fly ash ceramsite; 272 parts of 8-15mm fly ash ceramsite;

[0077] 17.1 parts of steel fiber; 4.5 parts of CRETO RMO; 165.3 parts of water; 21.2 parts of water reducing agent.

Embodiment 2

[0079] Cementitious materials: 450 parts of Portland cement; 72 parts of silica fume; 158 parts of fly ash; 158 parts of mineral powder; 61 parts of glass beads;

[0080] Fine aggregate: 181.9 parts of 0-5mm iron tailings;

[0081] Coarse aggregate: 7 parts of 3-5mm fly ash ceramsite; 75 parts of 5-8mm fly ash ceramsite; 272 parts of 8-15mm fly ash ceramsite;

[0082] 17.1 parts of steel fiber; 4.5 parts of CRETO RMO; 175.3 parts of water; 22.5 parts of water reducer;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com