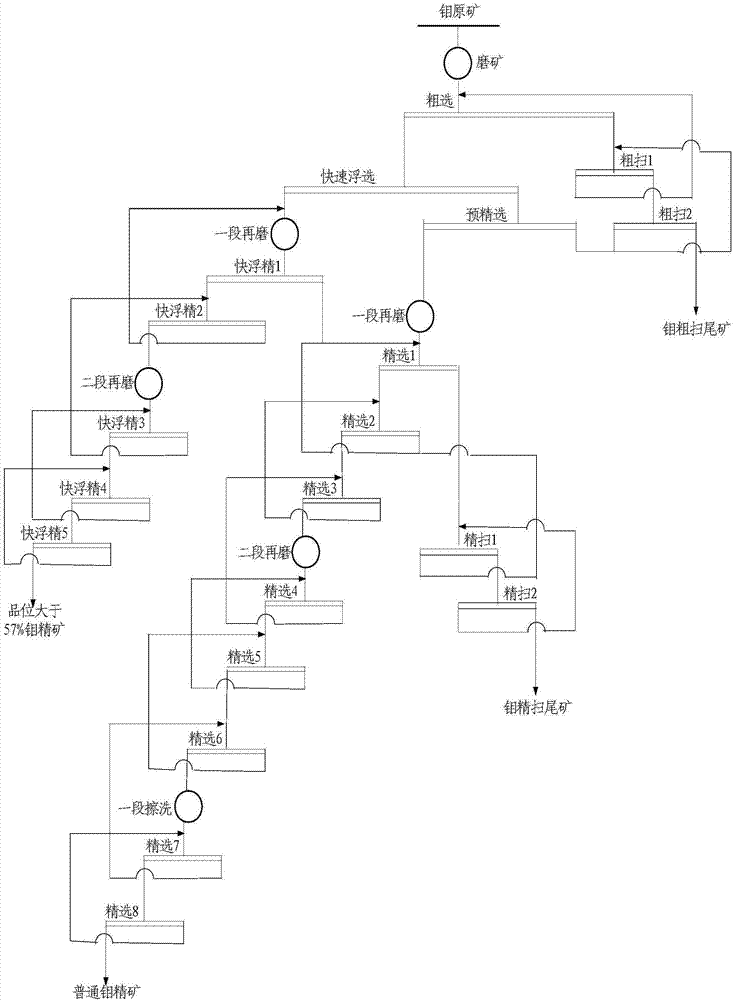

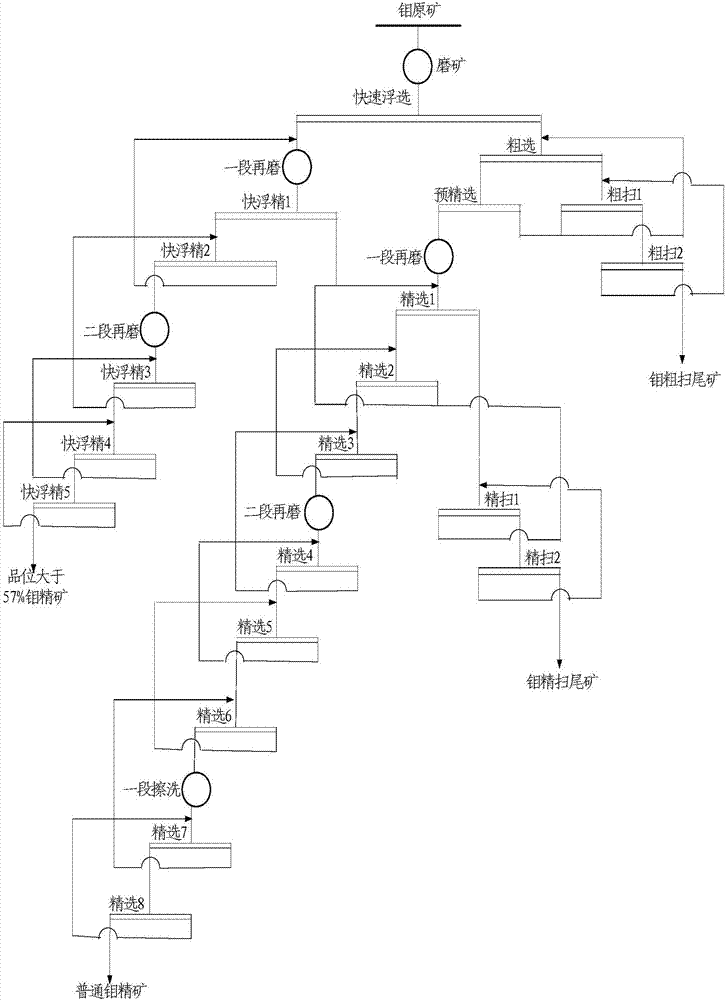

Process for step-by-step production of high-grade molybdenum concentrates and ordinary molybdenum concentrates

A molybdenum concentrate, high-grade technology, applied in the field of molybdenum concentrate production, can solve the problems of long selection process, low molybdenum grade of molybdenum concentrate, and high quality tail running, so as to enhance the collection capacity, reduce losses, and reduce the concentration of effect of selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The technique of the present embodiment comprises the following steps:

[0035] Step 1, adding water to grind molybdenum raw ore with a molybdenum grade of 0.115% to obtain a molybdenum slurry with a mass concentration of 30%, wherein the grinding fineness of the molybdenum raw ore is -0.074mm, accounting for 50wt%;

[0036] Step 2: Add main collector No. 0 diesel oil, auxiliary collector butylammonium black medicine and foaming agent terpineol oil to the molybdenum slurry obtained in step 1, and roughen for 10 minutes to obtain molybdenum rough tailings and molybdenum grade of 5% Molybdenum crude concentrate, the addition of No. 0 diesel oil, butyl ammonium black drug and terpineol oil is calculated according to the quality of molybdenum raw ore: No. 0 diesel oil 110g / t, butyl ammonium black drug 7g / t, terpineol oil 70g / t; Then the molybdenum coarse concentrate is subjected to rapid flotation for 35s to obtain the rapid flotation molybdenum tailings and the rapid flot...

Embodiment 2

[0043] The technique of the present embodiment comprises the following steps:

[0044] Step 1, adding water to grind the molybdenum raw ore with a molybdenum grade of 0.102% to obtain a molybdenum slurry with a mass concentration of 33%, wherein the grinding fineness of the molybdenum raw ore is -0.074mm, accounting for 65% by weight;

[0045] Step 2: Add main collector No. 0 diesel oil, auxiliary collector butyl ammonium black medicine and foaming agent terpineol oil to the molybdenum slurry obtained in step 1, and roughen for 8 minutes to obtain molybdenum coarse tailings and molybdenum grade of 3% Molybdenum crude concentrate, the addition of No. 0 diesel oil, butyl ammonium black drug and terpineol oil is calculated according to the quality of molybdenum raw ore: No. 0 diesel oil 90g / t, butyl ammonium black drug 5g / t, terpineol oil 55g / t, and then the molybdenum coarse concentrate is subjected to rapid flotation for 30s to obtain the rapid flotation molybdenum tailings an...

Embodiment 3

[0052] The technique of the present embodiment comprises the following steps:

[0053] Step 1. Grinding molybdenum raw ore with a molybdenum grade of 0.080% with water to obtain a molybdenum slurry with a mass concentration of 35%, wherein the grinding fineness of the molybdenum raw ore is -0.074mm, accounting for 60wt%;

[0054] Step 2. Add main collector No. 0 diesel oil, auxiliary collector butylammonium black medicine and loose foaming agent alcohol oil to the molybdenum slurry obtained in step 1. Roughly select molybdenum crude tailings and molybdenum grade of 2% molybdenum crude concentrate, the addition of No. 0 diesel oil, butyl ammonium black drug and terpineol oil is calculated according to the quality of molybdenum raw ore: No. 0 diesel oil 70g / t, butyl ammonium black drug 2g / t, terpineol oil 40g / t, and then the molybdenum coarse concentrate is subjected to rapid flotation for 15s to obtain the rapid flotation molybdenum tailings and the rapid flotation molybdenum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com